ASTM D5821-95

(Test Method)Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate

Standard Test Method for Determining the Percentage of Fractured Particles in Coarse Aggregate

SCOPE

1.1 This test method covers the determination of the percentage, by mass or by count, of a coarse aggregate sample that consists of fractured particles meeting specified requirements.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are provided for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or

withdrawn. Contact ASTM International (www.astm.org) for the latest information.

Designation: D 5821 – 95

AMERICAN SOCIETY FOR TESTING AND MATERIALS

100 Barr Harbor Dr., West Conshohocken, PA 19428

Reprinted from the Annual Book of ASTM Standards. Copyright ASTM

Standard Test Method for

Determining the Percentage of Fractured Particles in Coarse

1

Aggregate

This standard is issued under the fixed designation D 5821; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of the per-

centage, by mass or by count, of a coarse aggregate sample that

consists of fractured particles meeting specified requirements.

1.2 The values stated in SI units are to be regarded as the

standard. The values in parentheses are provided for informa-

tion only.

1.3 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 136 Test Method for Sieve Analysis of Fine and Coarse

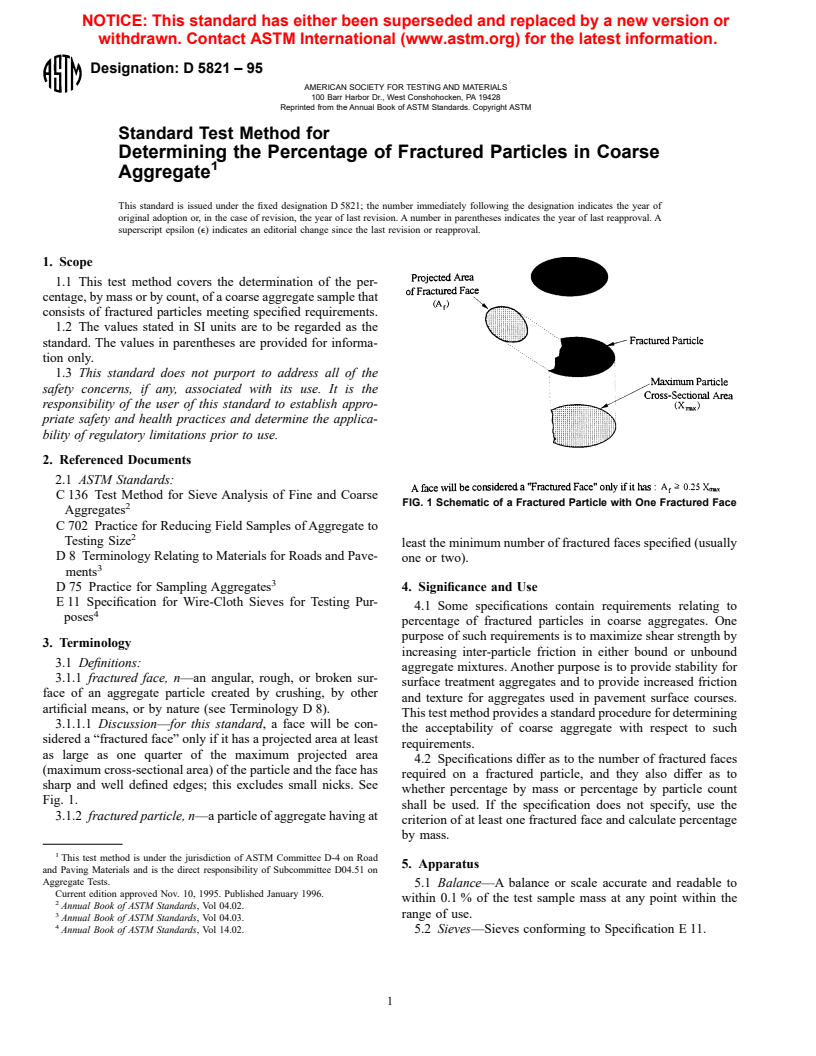

FIG. 1 Schematic of a Fractured Particle with One Fractured Face

2

Aggregates

C 702 Practice for Reducing Field Samples of Aggregate to

2

Testing Size

least the minimum number of fractured faces specified (usually

D 8 Terminology Relating to Materials for Roads and Pave-

one or two).

3

ments

3

4. Significance and Use

D 75 Practice for Sampling Aggregates

E 11 Specification for Wire-Cloth Sieves for Testing Pur-

4.1 Some specifications contain requirements relating to

4

poses

percentage of fractured particles in coarse aggregates. One

purpose of such requirements is to maximize shear strength by

3. Terminology

increasing inter-particle friction in either bound or unbound

3.1 Definitions:

aggregate mixtures. Another purpose is to provide stability for

3.1.1 fractured face, n—an angular, rough, or broken sur-

surface treatment aggregates and to provide increased friction

face of an aggregate particle created by crushing, by other

and texture for aggregates used in pavement surface courses.

artificial means, or by nature (see Terminology D 8).

This test method provides a standard procedure for determining

3.1.1.1 Discussion—for this standard, a face will be con-

the acceptability of coarse aggregate with respect to such

sidered a “fractured face” only if it has a projected area at least

requirements.

as large as one quarter of the maximum projected area

4.2 Specifications differ as to the number of fractured faces

(maximum cross-sectional area) of the particle and the face has

required on a fractured particle, and they also differ as to

sharp and well defined edges; this excludes small nicks. See

whether percentage by mass or percentage by particle count

Fig. 1.

shall be used. If the specification does not specify, use the

3.1.2 fractured particle, n—a particle of aggregate having at

criterion of at least one fractured face and calculate percentage

by mass.

1

This test method is under the jurisdiction of ASTM Committee D-4 on Road

5. Apparatus

and Paving Materials and is the direct responsibility of Subcommittee D04.51 on

Aggregate Tests.

5.1 Balance—A balance or scale accurate and readable to

Current edition approved Nov. 10, 1995. Published January 1996.

within 0.1 % of the test sample mass at any point within the

2

Annual Book of ASTM Standards, Vol 04.02.

3

range of use.

Annual Book of ASTM Standards, Vol 04.03.

4

Annual Book of ASTM Standards, Vol 14.02. 5.2 Sieves—Sieves conforming to Specification E 11.

1

---------------------- Page: 1 ----------------------

D 5821

5.3 Splitter—A sample splitter suitable for dividing field has the required number of fractured faces, (2) particles not

samples into test portion sizes in accordance with Practice meeting the specified criteria, and (3) questionable or border-

C 702. line particles. If the required number of fractured faces is not

5.4 Spatula—A spatula or similar tool to aid in sorting given in the applicable specifications, the determination will be

aggregate particles. made on the basis of a minimum of one fractured face.

8.4 Determine the mass or count of particles in the fractured

6. Sampling

particle category, the mass or count of the questionable

6.1 Sample the aggregate in accordance with Practice D 75. particles, and the mass or count of the particles not meeting the

specified fracture criteria. Use mass to calculate percent

7. Sample Preparation

fractured particles unless percentage by particle count is

specified.

7.1 Dry the sample sufficiently to obtain a clean sepa

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.