ASTM B352/B352M-02(2006)

(Specification)Standard Specification for Zirconium and Zirconium Alloy Sheet, Strip, and Plate for Nuclear Application

Standard Specification for Zirconium and Zirconium Alloy Sheet, Strip, and Plate for Nuclear Application

ABSTRACT

This specification covers hot- and cold-rolled zirconium and zirconium alloy sheet, strip, and plate. One unalloyed and three alloys for use in nuclear applications are described. Materials covered by this specification shall be produced by multiple vacuum melting in arc furnaces, electron beam melting, or other melting processes. The material shall conform to the required chemical composition for tin, iron, chromium, nickel, niobium, and oxygen. The alloy shall also conform to the specified maximum impurity values for aluminum, boron, cadmium, calcium, carbon, chromium, cobalt, copper, hafnium, hydrogen, iron, magnesium, manganese, molybdenum, nickel, niobium, nitrogen, phosphorus, silicon, tin, tungsten, titanium, and uranium. The material shall conform to the prescribed mechanical properties such as tensile strength, yield strength, and elongation. Two samples chosen at random shall be corrosion tested. Sheet, strip, or plate shall conform to the permissible variations in the dimensions prescribed. The material shall also undergo tests which shall include ultrasonic inspection and other special tests.

SCOPE

1.1 This specification covers hot- and cold-rolled zirconium and zirconium alloy sheet, strip, and plate.

1.2 One unalloyed and three alloys for use in nuclear applications are described.

1.3 The products covered in this specification include the following forms and sizes:

1.3.1 Sheet, 24 in. (600 mm) or more in width; under 0.187 in. (4.8 mm) in thickness,

1.3.2 Strip, less than 24 in. (600 mm) in width; under 0.187 in. (4.8 mm) in thickness, and

1.3.3 Plateover 10 in. (250 mm) in width; 0.187 in. (4.8 mm) and over in thickness.

Note 1—Material over 0.187 in. (4.8 mm) in thickness and less than 10 in. (250 mm) wide is covered as bar in Specification B 351.

1.4 Unless a single unit is used, for example corrosion mass gain in mg/dm2, the values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore each system must be used independently of the other. SI values cannot be mixed with inch-pound values.

1.5 The following precautionary caveat pertains only to the test method portions of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B352/B352M – 02 (Reapproved 2006)

Standard Specification for

Zirconium and Zirconium Alloy Sheet, Strip, and Plate for

Nuclear Application

This standard is issued under the fixed designation B352/B352M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B350/B350M Specification for Zirconium and Zirconium

Alloy Ingots for Nuclear Application

1.1 This specification covers hot- and cold-rolled zirconium

B351/B351M Specification for Hot-Rolled and Cold-

and zirconium alloy sheet, strip, and plate.

Finished Zirconium and Zirconium Alloy Bars, Rod, and

1.2 One unalloyed and three alloys for use in nuclear

Wire for Nuclear Application

applications are described.

E8 Test Methods for Tension Testing of Metallic Materials

1.3 The products covered in this specification include the

E21 Test Methods for Elevated Temperature Tension Tests

following forms and sizes:

of Metallic Materials

1.3.1 Sheet, 24 in. [600 mm] or more in width; under 0.187

E29 Practice for Using Significant Digits in Test Data to

in. [4.8 mm) in thickness,

Determine Conformance with Specifications

1.3.2 Strip, less than 24 in. [600 mm] in width; under 0.187

E114 Practice for Ultrasonic Pulse-Echo Straight-Beam Ex-

in. [4.8 mm] in thickness, and

amination by the Contact Method

1.3.3 Plate, over 10 in. [250 mm] in width; 0.187 in. [4.8

E214 Practice for Immersed Ultrasonic Testing by the

mm] and over in thickness.

Reflection Method Using Pulsed Longitudinal Waves

NOTE 1—Materialover0.187in.[4.8mm]inthicknessandlessthan10

G2/G2M Test Method for Corrosion Testing of Products of

in. [250 mm] wide is covered as bar in Specification B351/B351M.

Zirconium, Hafnium, and Their Alloys in Water at 680°F

1.4 Unless a single unit is used, for example corrosion mass

[360°C] or in Steam at 750°F [400°C]

gain in mg/dm , the values stated in either inch-pound or SI

3. Terminology

units are to be regarded separately as standard. The values

stated in each system are not exact equivalents; therefore each

3.1 Definitions of Terms Specific to This Standard:

system must be used independently of the other. SI values

3.1.1 annealed, n—denotes material that exhibits a recrys-

cannot be mixed with inch-pound values.

tallized grain structure.

1.5 The following precautionary caveat pertains only to the

3.2 Lot Definitions:

test method portions of this specification. This standard does

3.2.1 castings, n—alotshallconsistofallcastingsproduced

not purport to address all of the safety concerns, if any,

from the same pour.

associated with its use. It is the responsibility of the user of this

3.2.2 ingot, n—no definition required.

standard to establish appropriate safety and health practices

3.2.3 rounds, flats, tubes, and wrought powder metallurgical

and determine the applicability of regulatory limitations prior

products (single definition, common to nuclear and non-

to use.

nuclear standards), n—a lot shall consist of a material of the

same size, shape, condition, and finish produced from the same

2. Referenced Documents

ingot or powder blend by the same reduction schedule and the

2.1 ASTM Standards:

same heat treatment parameters. Unless otherwise agreed

between manufacturer and purchaser, a lot shall be limited to

the product of an 8 h period for final continuous anneal, or to

This specification is under the jurisdiction of ASTM Committee B10 on

a single furnace load for final batch anneal.

Reactive and Refractory Metals and Alloys and is the direct responsibility of

Subcommittee B10.02 on Zirconium and Hafnium. 3.2.4 sponge, n—a lot shall consist of a single blend

Current edition approved Sept. 15, 2006. Published October 2006. Originally

produced at one time.

approved in 1960. Last previous edition approved in 2002 as B352/B352M – 02.

DOI: 10.1520/B0352_B0352M-02R06.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Withdrawn. The last approved version of this historical standard is referenced

the ASTM website. on www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B352/B352M – 02 (2006)

3.2.5 weld fittings, n—definition is to be mutually agreed 4.2 In addition to the data specified in 4.1, the following

upon between manufacturer and the purchaser. options and points of agreement between the manufacturer and

the purchaser should be specified on the purchase order as

4. Ordering Information

required:

4.1 Purchase orders for material under this specification

4.2.1 Temperatureanddirectionofmechanicaltesting(see8

should include the following information as required to ad-

and Table 2),

equately describe the desired material:

4.2.2 Workmanship standards (Section 13),

4.1.1 Quantity (weight or number of pieces),

4.2.3 Special tests (Section 12),

4.1.2 Name of material,

4.2.4 Inspection (Section 17), and

4.1.3 Condition (Section 6),

4.2.5 Corrosion visual standards (Section 9).

4.1.4 Finish (Section 14),

4.2.6 Oxygen limits (see footnote A, Table 1).

4.1.5 Form (Sheet, strip, plate,)

4.1.6 Edge (Section 15),

5. Materials and Manufacture

4.1.7 Dimensions (size, thickness, width and length),

4.1.8 Grade designation (Table 1), and

5.1 Materials covered by this specification shall be pro-

4.1.9 ASTM designation and year of issue.

duced by multiple vacuum melting in arc furnaces, electron

beam melting, or other melting processes conventionally used

NOTE 2—Atypical ordering description is as follows: _ 5000 lb reactor

for reactive metals; all processes to be done in furnaces usually

grade zirconium alloy, cold-rolled, vacuum annealed strip, 4.750 by 0.065

by 72 in., ASTM Specification B352/B352M - 01, Grade R60804. used for reactive metals.

TABLE 1 Chemical Requirements

Composition, Weight %

Element UNS R60001 UNS R60802 UNS R60804 UNS R60901

Tin . . . 1.20–1.70 1.20–1.70 . . .

Iron . . . 0.07–0.20 0.18–0.24 . . .

Chromium . . . 0.05–0.15 0.07–0.13 . . .

Nickel . . . 0.03–0.08 . . . . . .

Niobium (columbium) . . . . . . . . . 2.40–2.80

AA A

Oxygen 0.09–0.15

Iron + chromium + nickel . . . 0.18–0.38 . . . . . .

Iron + chromium . . . . . . 0.28–0.37 . . .

Maximum Impurities, Weight %

Aluminum 0.0075 0.0075 0.0075 0.0075

Boron 0.00005 0.00005 0.00005 0.00005

Cadmium 0.00005 0.00005 0.00005 0.00005

Calcium . 0.0030 0.0030 .

Carbon 0.027 0.027 0.027 0.027

Chromium 0.020 . . . . . . 0.020

Cobalt 0.0020 0.0020 0.0020 0.0020

Copper 0.0050 0.0050 0.0050 0.0050

Hafnium 0.010 0.010 0.010 0.010

Hydrogen 0.0025 0.0025 0.0025 0.0025

Iron 0.150 . . . . . . 0.150

Magnesium 0.0020 0.0020 0.0020 0.0020

Manganese 0.0050 0.0050 0.0050 0.0050

Molybdenum 0.0050 0.0050 0.0050 0.0050

Nickel 0.0070 . . . 0.0070 0.0070

Niobium . 0.0100 0.0100 .

Nitrogen 0.0080 0.0080 0.0080 0.0080

Phosphorus . . . . . . . . . 0.0020

Silicon 0.0120 0.0120 0.0120 0.0120

Tin 0.0050 . . . . . . 0.010

Tungsten 0.010 0.010 0.010 0.010

Titanium 0.0050 0.0050 0.0050 0.0050

Uranium 0.00035 0.00035 0.00035 0.00035

A

When so specified in the purchase order, oxygen shall be determined and reported. Maximum, minimum, or both, permissible values should be specified in the

purchase order.

B352/B352M – 02 (2006)

A

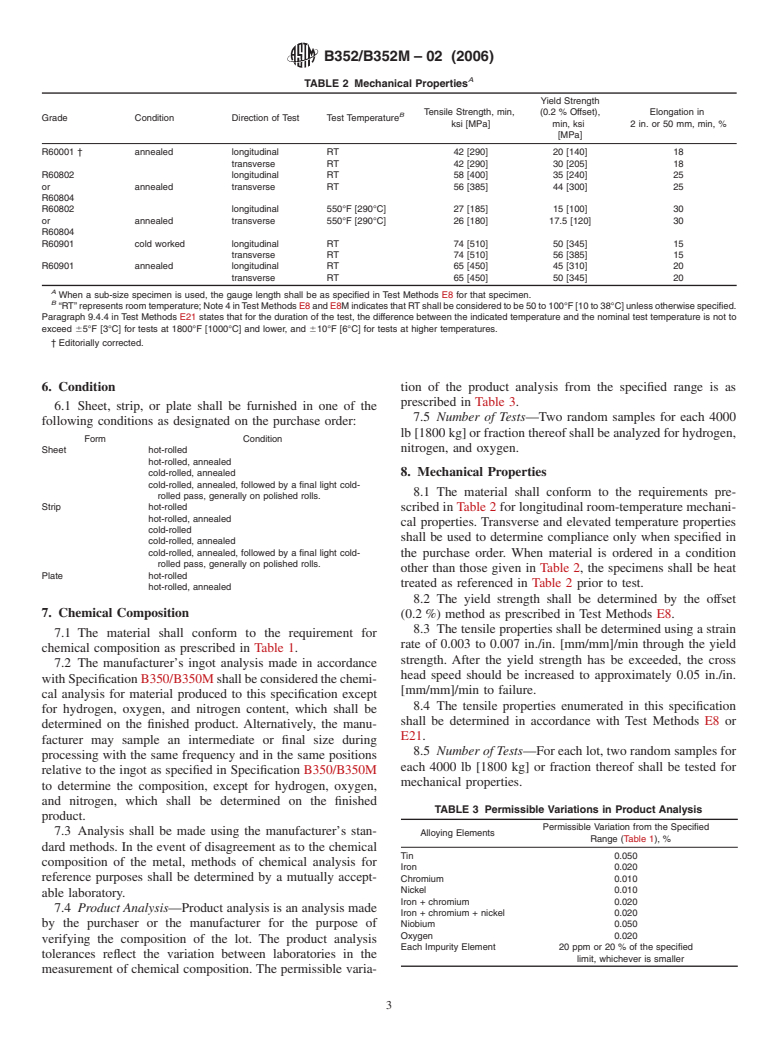

TABLE 2 Mechanical Properties

Yield Strength

Tensile Strength, min, (0.2 % Offset), Elongation in

B

Grade Condition Direction of Test Test Temperature

ksi [MPa] min, ksi 2 in. or 50 mm, min, %

[MPa]

R60001 † annealed longitudinal RT 42 [290] 20 [140] 18

transverse RT 42 [290] 30 [205] 18

R60802 longitudinal RT 58 [400] 35 [240] 25

or annealed transverse RT 56 [385] 44 [300] 25

R60804

R60802 longitudinal 550°F [290°C] 27 [185] 15 [100] 30

or annealed transverse 550°F [290°C] 26 [180] 17.5 [120] 30

R60804

R60901 cold worked longitudinal RT 74 [510] 50 [345] 15

transverse RT 74 [510] 56 [385] 15

R60901 annealed longitudinal RT 65 [450] 45 [310] 20

transverse RT 65 [450] 50 [345] 20

A

When a sub-size specimen is used, the gauge length shall be as specified in Test Methods E8 for that specimen.

B

“RT” represents room temperature; Note 4 in Test Methods E8 and E8M indicates that RT shall be considered to be 50 to 100°F [10 to 38°C] unless otherwise specified.

Paragraph 9.4.4 in Test Methods E21 states that for the duration of the test, the difference between the indicated temperature and the nominal test temperature is not to

exceed 65°F [3°C] for tests at 1800°F [1000°C] and lower, and 610°F [6°C] for tests at higher temperatures.

† Editorially corrected.

6. Condition tion of the product analysis from the specified range is as

prescribed in Table 3.

6.1 Sheet, strip, or plate shall be furnished in one of the

7.5 Number of Tests—Two random samples for each 4000

following conditions as designated on the purchase order:

lb [1800 kg] or fraction thereof shall be analyzed for hydrogen,

Form Condition

nitrogen, and oxygen.

Sheet hot-rolled

hot-rolled, annealed

cold-rolled, annealed 8. Mechanical Properties

cold-rolled, annealed, followed by a final light cold-

8.1 The material shall conform to the requirements pre-

rolled pass, generally on polished rolls.

Strip hot-rolled scribed in Table 2 for longitudinal room-temperature mechani-

hot-rolled, annealed

cal properties. Transverse and elevated temperature properties

cold-rolled

shall be used to determine compliance only when specified in

cold-rolled, annealed

cold-rolled, annealed, followed by a final light cold-

the purchase order. When material is ordered in a condition

rolled pass, generally on polished rolls.

other than those given in Table 2, the specimens shall be heat

Plate hot-rolled

treated as referenced in Table 2 prior to test.

hot-rolled, annealed

8.2 The yield strength shall be determined by the offset

7. Chemical Composition (0.2 %) method as prescribed in Test Methods E8.

8.3 The tensile properties shall be determined using a strain

7.1 The material shall conform to the requirement for

rate of 0.003 to 0.007 in./in. [mm/mm]/min through the yield

chemical composition as prescribed in Table 1.

strength. After the yield strength has be exceeded, the cross

7.2 The manufacturer’s ingot analysis made in accordance

head speed should be increased to approximately 0.05 in./in.

withSpecificationB350/B350Mshallbeconsideredthechemi-

[mm/mm]/min to failure.

cal analysis for material produced to this specification except

8.4 The tensile properties enumerated in this specification

for hydrogen, oxygen, and nitrogen content, which shall be

shall be determined in accordance with Test Methods E8 or

determined on the finished product. Alternatively, the manu-

E21.

facturer may sample an intermediate or final size during

8.5 Number of Tests—For each lot, two random samples for

processing with the same frequency and in the same positions

each 4000 lb [1800 kg] or fraction thereof shall be tested for

relative to the ingot as specified in Specification B350/B350M

mechanical properties.

to determine the composition, except for hydrogen, oxygen,

and nitrogen, which shall be determined on the finished

TABLE 3 Permissible Variations in Product Analysis

product.

Permissible Variation from the Specified

7.3 Analysis shall be made using the manufacturer’s stan- Alloying Elements

Range (Table 1), %

dard methods. In the event of disagreement as to the chemical

Tin 0.050

composition of the metal, methods of chemical analysis for

Iron 0.020

reference purposes shall be determined by a mutually accept-

Chromium 0.010

Nickel 0.010

able laboratory.

Iron + chromium 0.020

7.4 Product Analysis—Product analysis is an analysis made

Iron + chromium + nickel 0.020

by the purchaser or the manufacturer for the purpose of Niobium 0.050

Oxygen 0.020

verifying the composition of the lot. The product analysis

Each Impurity Element 20 ppm or 20 % of the specified

tolerances reflect the variation between laboratories in the

limit, whichever is smaller

measurement of chemical composition. The permissible varia-

B352/B352M – 02 (2006)

TABLE 5 Permissible Variations in Length of Hot- and Cold-

9. Corrosion Properties

Rolled Zirconium Sheet

9.1 Twosampleschosenatrandomfromeach4000lb[1800

Permissible Variations in Length, in.

kg] or fraction thereof shall be corrosion tested in steam at Specified Length, ft [m]

[mm]

750°F [399°C], 1500 psi [10.3 MPa] for 72 h or 336 h at the Up to 10 [3] + ⁄2 [+13], –0

Over 10 to 20 [3 to 6] +1 [+25], –0

option of the manufacturer in accordance with Test Method

G2/G2M.

9.2 Acceptance Criterion:

TABLE 6 Permissible Variations in Thickness of Hot-Rolled

9.2.1 Grades R60802 and R60804—All coupons thus tested

Zirconium Strip

shall exhibit a continuous, black, lustrous oxide film and be

Variation from Specified Thickness for

free of white or brown corrosion product in excess of standards

Widths Given, Over and Under, in. [mm]

Specified Width, in. [mm]

previously agreed upon between manufacturer and purchaser.

0.187–0.1180 0.1197–0.0830

Coupons shall exhibit a weight gain or not more than 22

[4.8–3.0], incl. [3.0–2.1], incl

2 2

mg/dm in a 72-h test or 38 mg/dm in a 336-h test.

To 3 ⁄2 [90] 0.006 [0.15] 0.005 [0.13]

9.2.2 Grade R60901—All coupons shall exhibit a continu- Over 3 ⁄2 –12 [90–300] 0.007 [0.18] 0.006 [0.15]

Over 12–18 [300–460] 0.008 [0.20] 0.008 [0.20]

ous, uniform, dark gray oxide film. Coupons shall exhibit a

Over 18–24 [460–610] 0.010 [0.25] 0.010 [0.25]

weight gain of not more than 35 mg/dm in a 72-h test or 60

mg/dm in a 336-h test.

10. Permissible Variations in Dimensions 12.1.3 Any defect reflections greater than the indication

from the reference standard should be rejected.

10.1 Sheet, strip, or plate shall conform to the permissible

12.2 Additionaltestsmaybespecifiedinthepurchaseorder.

variations in dimensions prescribed in the applicable Tables

The test method and standards shall be agreed upon in advance

4-12, incl.

between manufacturer and purchaser.

11. Significance of Numerical Limits

13. Workmanship and Appearance

11.1 For the purpose of determining compliance with the

13.1 Sheet, strip, or plate shall be free of cracks, seams,

specified limits for requirements of the properties listed in the

slivers, blisters, and other injurious imperfections in accor-

following table, an observed value or a calculated value shall

dance with standards of acceptability agreed upon between the

be rounded as indicated in accordance with the rounding

manufacturer and the purchase

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.