ASTM G202-12

(Test Method)Standard Test Method for Using Atmospheric Pressure Rotating Cage

Standard Test Method for Using Atmospheric Pressure Rotating Cage

SIGNIFICANCE AND USE

3.1 The rotating cage (RC) test system is relatively inexpensive and uses simple flat specimens that allow replicates to be run with each setup. (1-11).3

3.2 The RC method can be used to evaluate either corrosion inhibitors, or materials, or both. Guide G184 describes the procedure to use rotating cage to evaluate corrosion inhibitors.

3.3 In this test method, a general procedure is presented to obtain reproducible results using RC to simulate the effects of different types of coupon materials, inhibitor concentrations, oil, gas and brine compositions, temperature, and flow. Oil field fluids may often contain sand; however, this test method does not cover erosive effects that occur when sand is present.

SCOPE

1.1 This test method covers a generally accepted procedure to conduct the rotating cage (RC) experiment under atmospheric pressure.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: G202 − 12

Standard Test Method for

1

Using Atmospheric Pressure Rotating Cage

This standard is issued under the fixed designation G202; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Significance and Use

1.1 This test method covers a generally accepted procedure 3.1 The rotating cage (RC) test system is relatively inex-

to conduct the rotating cage (RC) experiment under atmo- pensive and uses simple flat specimens that allow replicates to

3

spheric pressure. be run with each setup. (1-11).

1.2 The values stated in SI units are to be regarded as the 3.2 TheRCmethodcanbeusedtoevaluateeithercorrosion

standard. The values given in parentheses are for information inhibitors, or materials, or both. Guide G184 describes the

only. procedure to use rotating cage to evaluate corrosion inhibitors.

1.3 This standard does not purport to address all of the

3.3 In this test method, a general procedure is presented to

safety concerns, if any, associated with its use. It is the

obtain reproducible results using RC to simulate the effects of

responsibility of the user of this standard to establish appro-

different types of coupon materials, inhibitor concentrations,

priate safety and health practices and determine the applica-

oil,gasandbrinecompositions,temperature,andflow.Oilfield

bility of regulatory limitations prior to use.

fluids may often contain sand; however, this test method does

not cover erosive effects that occur when sand is present.

2. Referenced Documents

4. Apparatus

2

2.1 ASTM Standards:

4.1 Fig. 1 shows the schematic diagram of the RC system.

D1141 Practice for the Preparation of Substitute Ocean

The vessel is manufactured from acrylic. At the bottom of the

Water

container, a PTFE base is snugly fitted. At the center of the

D1193 Specification for Reagent Water

base, a hole is drilled, into which the lower end of the rotating

D1293 Test Methods for pH of Water

shaft is placed. This arrangement stabilizes the rotating shaft

E691 Practice for Conducting an Interlaboratory Study to

and the coupons. The length of the rotating shaft between the

Determine the Precision of a Test Method

top and bottom covers is 40 cm (15.7 in.). The rotating cage is

G1 Practice for Preparing, Cleaning, and Evaluating Corro-

attached to the shaft in such a way that the top of the cage is

sion Test Specimens

30 cm (11.8 in.) from the bottom cover.

G16 Guide for Applying Statistics to Analysis of Corrosion

Data

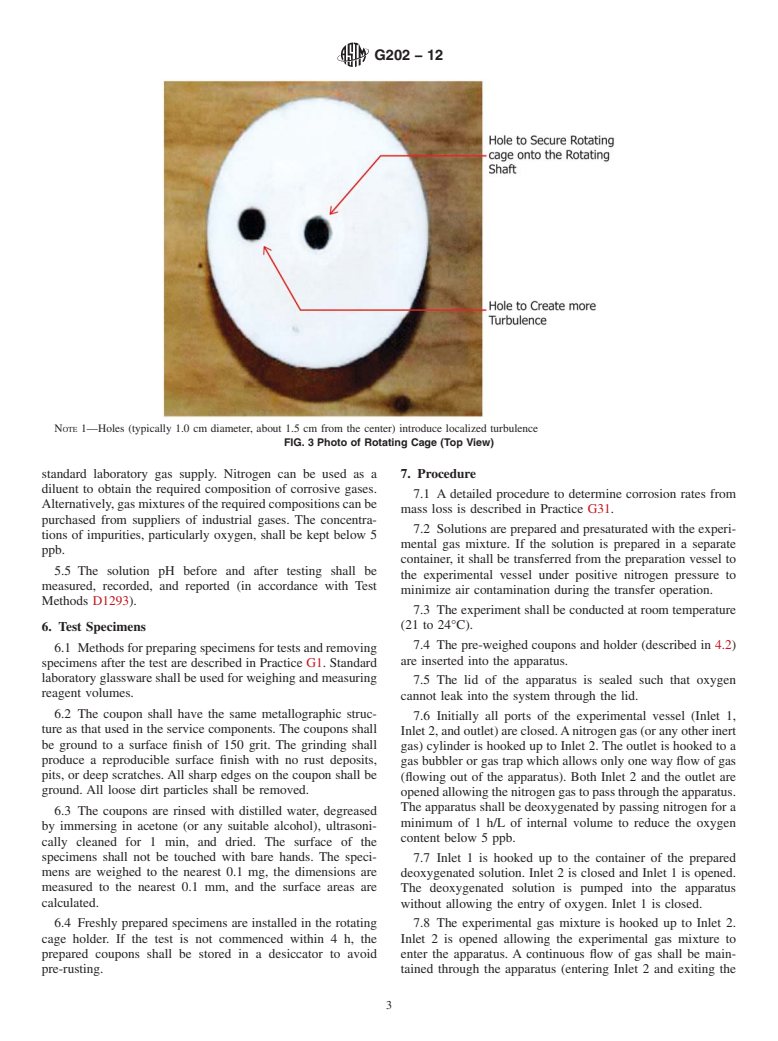

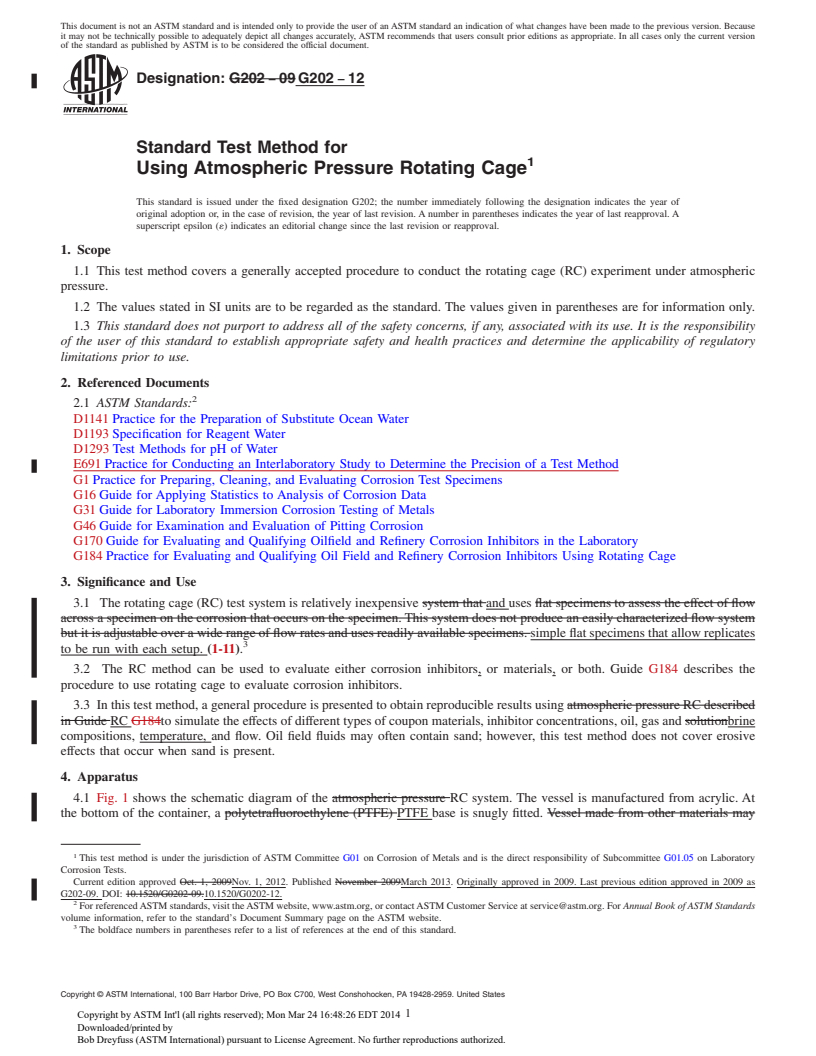

4.2 Eight coupons (each of length 75 mm, width 19 mm,

2

G31 Guide for Laboratory Immersion Corrosion Testing of

thickness 3 mm, and surface area 34.14 cm )) are supported

Metals

betweentwoPTFEdisks(of80-mmdiameter)mounted75mm

G46 Guide for Examination and Evaluation of Pitting Cor-

apartonthestirringrod(Fig.2).Holes(diameter10mm)about

rosion

15 mm away from the center are drilled in the top and bottom

G170 Guide for Evaluating and Qualifying Oilfield and

PTFEplatesofthecagetoincreasetheturbulenceontheinside

Refinery Corrosion Inhibitors in the Laboratory

surface of the coupon (Fig. 3). This experimental setup can be

G184 Practice for Evaluating and Qualifying Oil Field and

used at rotation speeds up to 1000 rpm.

Refinery Corrosion Inhibitors Using Rotating Cage

4.3 Flow patterns inside the RC depend on the rotation

speed, the volume of the container, and the nature of the fluids

used. The flow patterns are described in Guide G170.

1

This test method is under the jurisdiction of ASTM Committee G01 on

Corrosion of Metals and is the direct responsibility of Subcommittee G01.05 on

4.4 Volume of solution to the surface area of the specimen

Laboratory Corrosion Tests.

has some effect on the corrosion rate. The minimum solution

Current edition approved Nov. 1, 2012. Published March 2013. Originally

3 2

volume(cm )tometalsurfacearea(cm )isnotlessthan14cm

approved in 2009. Last previous edition approved in 2009 as G202-09. DOI:

3 2

10.1520/G0202-12. (cm /cm ) (10).

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3

Standards volume information, refer to the standard’s Document Summary page on The boldface numbers in parentheses refer to a list of references at the end of

the ASTM website. this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

G202 − 12

FIG. 1 Schematic Diagram of Rotating Cage

all reagents conform to the specifications of the Committee on

Analytical Reagents of the

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: G202 − 09 G202 − 12

Standard Test Method for

1

Using Atmospheric Pressure Rotating Cage

This standard is issued under the fixed designation G202; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers a generally accepted procedure to conduct the rotating cage (RC) experiment under atmospheric

pressure.

1.2 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

D1141 Practice for the Preparation of Substitute Ocean Water

D1193 Specification for Reagent Water

D1293 Test Methods for pH of Water

E691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

G1 Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens

G16 Guide for Applying Statistics to Analysis of Corrosion Data

G31 Guide for Laboratory Immersion Corrosion Testing of Metals

G46 Guide for Examination and Evaluation of Pitting Corrosion

G170 Guide for Evaluating and Qualifying Oilfield and Refinery Corrosion Inhibitors in the Laboratory

G184 Practice for Evaluating and Qualifying Oil Field and Refinery Corrosion Inhibitors Using Rotating Cage

3. Significance and Use

3.1 The rotating cage (RC) test system is relatively inexpensive system that and uses flat specimens to assess the effect of flow

across a specimen on the corrosion that occurs on the specimen. This system does not produce an easily characterized flow system

but it is adjustable over a wide range of flow rates and uses readily available specimens. simple flat specimens that allow replicates

3

to be run with each setup. (1-11).

3.2 The RC method can be used to evaluate either corrosion inhibitors, or materials, or both. Guide G184 describes the

procedure to use rotating cage to evaluate corrosion inhibitors.

3.3 In this test method, a general procedure is presented to obtain reproducible results using atmospheric pressure RC described

in Guide RC G184to simulate the effects of different types of coupon materials, inhibitor concentrations, oil, gas and solutionbrine

compositions, temperature, and flow. Oil field fluids may often contain sand; however, this test method does not cover erosive

effects that occur when sand is present.

4. Apparatus

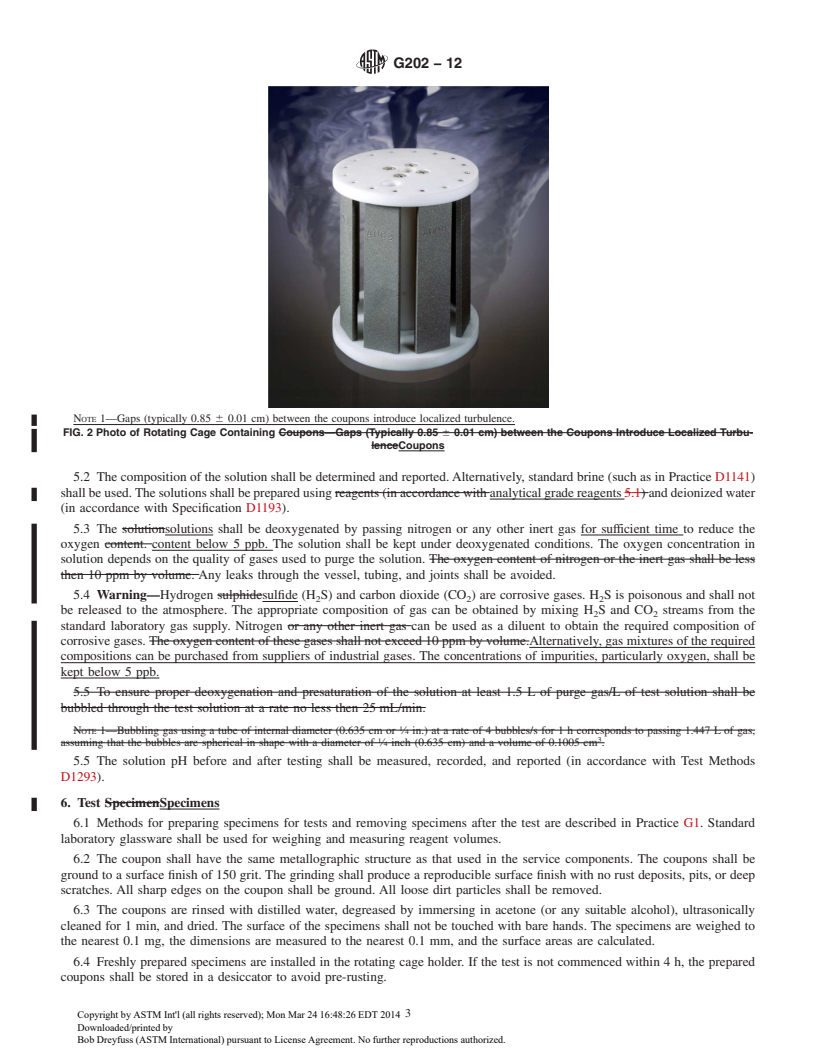

4.1 Fig. 1 shows the schematic diagram of the atmospheric pressure RC system. The vessel is manufactured from acrylic. At

the bottom of the container, a polytetrafluoroethylene (PTFE) PTFE base is snugly fitted. Vessel made from other materials may

1

This test method is under the jurisdiction of ASTM Committee G01 on Corrosion of Metals and is the direct responsibility of Subcommittee G01.05 on Laboratory

Corrosion Tests.

Current edition approved Oct. 1, 2009Nov. 1, 2012. Published November 2009March 2013. Originally approved in 2009. Last previous edition approved in 2009 as

G202-09. DOI: 10.1520/G0202-09.10.1520/G0202-12.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

The boldface numbers in parentheses refer to a list of references at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

Copyright by ASTM Int'l (all rights reserved); Mon Mar 24 16:48:26 EDT 2014

Downloaded/printed by

Bob Dreyfuss (ASTM International) pursuant to License Agreement. No further reproductions authorized.

---------------------- Page: 1 ----------------------

G202 − 12

FIG. 1 Schematic Diagram of Rotating Cage

be used provided it is first ascertained that they are compatible with the solutions and gases to be used in the test. At the center

of the base, a hole is drilled, into which the lower end of the rotating shaft is placed. This arrangement stabilizes the rotating shaft

and the coupons. The length of the rotating sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.