ASTM B737-10(2015)

(Specification)Standard Specification for Hot-Rolled and/or Cold-Finished Hafnium Rod and Wire

Standard Specification for Hot-Rolled and/or Cold-Finished Hafnium Rod and Wire

ABSTRACT

This specification covers hot-, cold-, or both hot- and cold-rolled hafnium rods and wires in either one of two grades. All grades should be in the recrystallization annealed condition unless specified otherwise. The materials should be made from ingots produced by vacuum melting in an electron beam or consumable arc furnaces, or both, of a type conventionally used for reactive metals. Samples for chemical composition tests should be taken from the top, middle, and bottom of the ingots. The requirements for mechanical properties do not apply to wires. Corrosion tests shall be done in water. All rods should be furnished in mechanically descaled and pickled, centerless ground and pickled, or centerless ground, pickled, and oxidized surface finish, while wires should be furnished in either conditioned and pickled or conditioned, pickled, and oxidized surface finish.

SIGNIFICANCE AND USE

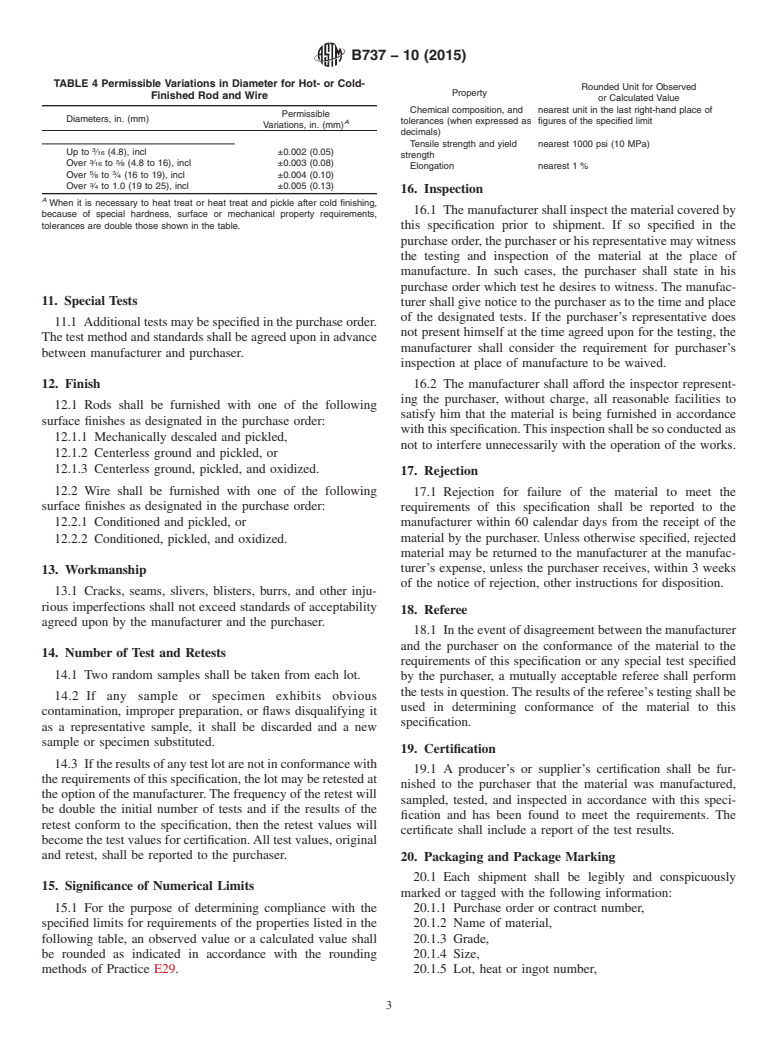

15.1 For the purpose of determining compliance with the specified limits for requirements of the properties listed in the following table, an observed value or a calculated value shall be rounded as indicated in accordance with the rounding methods of Practice E29.

Property

Rounded Unit for Observed

or Calculated Value

Chemical composition, and tolerances (when expressed as decimals)

nearest unit in the last right-hand place of figures of the specified limit

Tensile strength and yield strength

nearest 1000 psi (10 MPa)

Elongation

nearest 1 %

SCOPE

1.1 This specification covers hot- or cold-worked hafnium rod and wire.

1.2 This specification contains two material grades, one specifically for nuclear applications (Grade R1) and one for commercial alloying applications (Grade R3).

1.3 The products covered include the following:

1.3.1 Rod 3/8 to 1 in. (9.5 to 25 mm) in diameter.

1.3.2 Wire less than 3/8 in. (9.5 mm) in diameter.

1.4 Unless a single unit is used, for example, corrosion mass gain in mg/dm2, the values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. SI values cannot be mixed with inch-pound values.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B737 −10 (Reapproved 2015)

Standard Specification for

1

Hot-Rolled and/or Cold-Finished Hafnium Rod and Wire

This standard is issued under the fixed designation B737; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 3.1.1 rounds, flats, tubes, and wrought powder metallurgical

products (single definition, common to nuclear and non-

1.1 This specification covers hot- or cold-worked hafnium

nuclear standards) , n—a lot shall consist of a material of the

rod and wire.

samesize,shape,condition,andfinishproducedfromthesame

1.2 This specification contains two material grades, one

ingot or powder blend by the same reduction schedule and the

specifically for nuclear applications (Grade R1) and one for

same heat treatment parameters. Unless otherwise agreed

commercial alloying applications (Grade R3).

between manufacturer and purchaser, a lot shall be limited to

the product of an 8 h period for final continuous anneal, or to

1.3 The products covered include the following:

3

1.3.1 Rod ⁄8 to 1 in. (9.5 to 25 mm) in diameter. a single furnace load for final batch anneal.

3

1.3.2 Wire less than ⁄8 in. (9.5 mm) in diameter.

4. Ordering Information

1.4 Unlessasingleunitisused,forexample,corrosionmass

2

gain in mg/dm , the values stated in either inch-pound or SI

4.1 Purchase orders for material under this specification

units are to be regarded separately as standard. The values

shall include the following information as required to ad-

stated in each system are not exact equivalents; therefore, each equately describe the desired material:

system must be used independently of the other. SI values

4.1.1 Quantity (weight or number of pieces),

cannot be mixed with inch-pound values.

4.1.2 Name of material,

1.5 This standard does not purport to address all of the 4.1.3 Form (rod, wire),

safety concerns, if any, associated with its use. It is the

4.1.4 Finish (Section 12),

responsibility of the user of this standard to establish appro-

4.1.5 Applicable dimensions (diameter and length),

priate safety and health practices and determine the applica-

4.1.6 Grade (Table 1),

bility of regulatory limitations prior to use.

4.1.7 ASTM designation and year of issue,

4.1.8 Zirconium analysis requirements (Table 1), and

2. Referenced Documents

4.1.9 Workmanship standards (Section 13).

2

2.1 ASTM Standards:

NOTE 1—A typical ordering description is as follows: 500 lb hafnium

E8Test Methods for Tension Testing of Metallic Materials

rod,annealed;mechanicallydescaledandpickled;0.375in.diameterby6

E21TestMethodsforElevatedTemperatureTensionTestsof

in. minimum random lengths; Grade R1;ASTM Specification B737-01.

Metallic Materials

4.2 In addition to the data specified in 4.1, the following

E29Practice for Using Significant Digits in Test Data to

optionsandpointsofagreementbetweenthemanufacturerand

Determine Conformance with Specifications

the purchaser shall be specified on the purchase order if

E2626Guide for Spectrometric Analysis of Reactive and

required:

Refractory Metals

4.2.1 Mechanical test temperature (see 8.1),

3. Terminology

4.2.2 Mechanical test requirements for Grade R3 (Section

8),

3.1 Definitions:

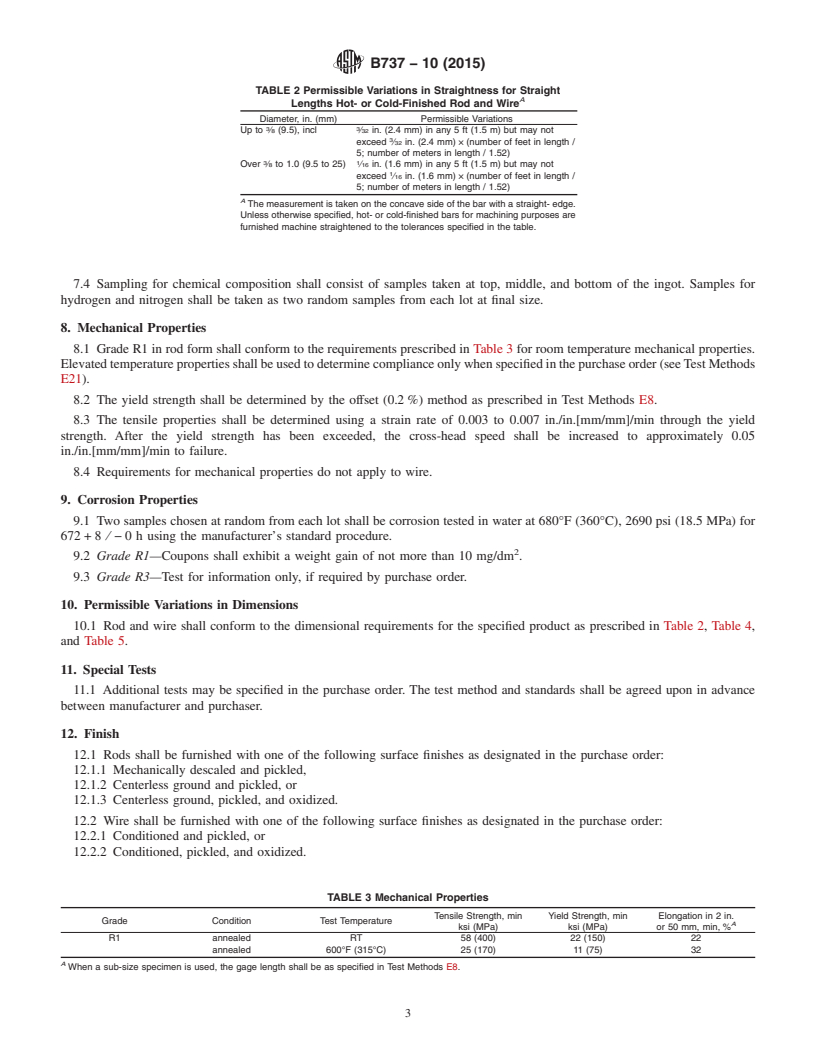

4.2.3 Straightness (Table 2),

4.2.4 Special tests (Section 11),

1

This specification is under the jurisdiction of ASTM Committee B10 on

4.2.5 Inspection (Section 16),

Reactive and Refractory Metals and Alloys and is the direct responsibility of

Subcommittee B10.02 on Zirconium and Hafnium.

4.2.6 Hafnium isotopic composition and its analysis, (Table

Current edition approved May 1, 2015. Published May 2015. Originally

1),

approved in 1984. Last previous edition approved in 2010 as B737–10. DOI:

4.2.7 Metallurgical condition (Section 6),

10.1520/B0737-10R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

4.2.8 Corrosion test Grade 3 (9.3),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.2.9 Rejected material return (Section 17), and

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. 4.2.10 Certification requirements (Section 19).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B737−10 (2015)

TABLE 1 Chemical Requirements — Maximum Impurity Level

7. Chemical Composition

Composition, Weight %

7.1 The material shall conform to the requirements for

Alloying

Nuclear Grade

chemical composition as prescribed in Table 1.

Grade

Element

Grade R1 Grade R3

7.2 The manufacturer’s ingot analysis shall be considered

Aluminum

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B737 − 10 B737 − 10 (Reapproved 2015)

Standard Specification for

1

Hot-Rolled and/or Cold-Finished Hafnium Rod and Wire

This standard is issued under the fixed designation B737; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers hot- or cold-worked hafnium rod and wire.

1.2 This specification contains two material grades, one specifically for nuclear applications (Grade R1) and one for commercial

alloying applications (Grade R3).

1.3 The products covered include the following:

3

1.3.1 Rod ⁄8 to 1 in. (9.5 to 25 mm) in diameter.

3

1.3.2 Wire less than ⁄8 in. (9.5 mm) in diameter.

2

1.4 Unless a single unit is used, for example, corrosion mass gain in mg/dm , the values stated in either inch-pound or SI units

are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must

be used independently of the other. SI values cannot be mixed with inch-pound values.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2

2.1 ASTM Standards:

E8 Test Methods for Tension Testing of Metallic Materials

E21 Test Methods for Elevated Temperature Tension Tests of Metallic Materials

E29 Practice for Using Significant Digits in Test Data to Determine Conformance with Specifications

E2626 Guide for Spectrometric Analysis of Reactive and Refractory Metals

3. Terminology

3.1 Definitions:

3.1.1 rounds, flats, tubes, and wrought powder metallurgical products (single definition, common to nuclear and non-nuclear

standards) , n—a lot shall consist of a material of the same size, shape, condition, and finish produced from the same ingot or

powder blend by the same reduction schedule and the same heat treatment parameters. Unless otherwise agreed between

manufacturer and purchaser, a lot shall be limited to the product of an 8 h period for final continuous anneal, or to a single furnace

load for final batch anneal.

4. Ordering Information

4.1 Purchase orders for material under this specification shall include the following information as required to adequately

describe the desired material:

4.1.1 Quantity (weight or number of pieces),

4.1.2 Name of material,

4.1.3 Form (rod, wire),

4.1.4 Finish (Section 12),

4.1.5 Applicable dimensions (diameter and length),

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.02 on Zirconium and Hafnium.

Current edition approved May 1, 2010May 1, 2015. Published May 2010May 2015. Originally approved in 1984. Last previous edition approved in 20052010 as

B737 – 05.B737 – 10. DOI: 10.1520/B0737-10.10.1520/B0737-10R15.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B737 − 10 (2015)

4.1.6 Grade (Table 1),

4.1.7 ASTM designation and year of issue,

4.1.8 Zirconium analysis requirements (Table 1), and

4.1.9 Workmanship standards (Section 13).

NOTE 1—A typical ordering description is as follows: 500 lb hafnium rod, annealed; mechanically descaled and pickled; 0.375 in. diameter by 6 in.

minimum random lengths; Grade R1; ASTM Specification B737 - 01.

4.2 In addition to the data specified in 4.1, the following options and points of agreement between the manufacturer and the

purchaser shall be specified on the purchase order if required:

4.2.1 Mechanical test temperature (see 8.1),

4.2.2 Mechanical test requirements for Grade R3 (Section 8),

4.2.3 Straightness (Table 2),

4.2.4 Special tests (Section 11),

4.2.5 Inspection (Section 16),

4.2.6 Hafnium isotopic composition and its analysis, (Table 1),

4.2.7 Metallurgical condition (Section 6),

4.2.8 Corrosion test Grade 3 (9.3),

4.2.9 Rejected mate

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.