ASTM D6816-11

(Practice)Standard Practice for Determining Low-Temperature Performance Grade (PG) of Asphalt Binders

Standard Practice for Determining Low-Temperature Performance Grade (PG) of Asphalt Binders

SIGNIFICANCE AND USE

Estimated critical cracking temperature, as determined by this practice, is a criterion for specifying the low-temperature properties of asphalt binder in accordance with Specification D6373.

This practice is designed to identify the temperature region where the induced thermal stress in a typical HMA subjected to rapid cooling (1°C/h) exceeds the fracture stress of the HMA.

For evaluating an asphalt binder for conformance to Specification D6373, the test temperature for the BBR and DTT data is selected from Table 1 of Specification D6373 according to the grade of asphalt binder.

Note 3—Other rates of elongation and test temperatures may be used to test asphalt binders for research purposes.

SCOPE

1.1 This practice covers the calculation of low-temperature properties of asphalt binders using data from the bending beam rheometer (see Test Method D6648) (BBR) and the direct tension tester (see Test Method D6723) (DTT). It can be used on data from unaged material or from material aged using Test Method D2872 (RTFOT), Practice D6521 (PAV), or Test Method D2872 (RTFOT) and Practice D6521 (PAV). It can be used on data generated within the temperature range from +6°C to -36°C. This practice generates data suitable for use in binder specifications such as Specification D6373.

1.2 This practice is only valid for data on materials that fall within the scope of suitability for both Test Method D6648 and Test Method D6723.

1.3 This practice can be used to determine the following:

1.3.1 Critical cracking temperature of an asphalt binder, and

1.3.2 Whether or not the failure stress exceeds the thermal stress in a binder at a given temperature.

1.4 This practice determines the critical cracking temperature for a typical asphalt binder based on the determination of the temperature where the asphalt binder's strength equals its thermal stress as calculated by this practice. The temperature so determined is intended to yield a low temperature PG Grade of the sample being tested. The low temperature PG grade is intended for use in purchase specifications and is not intended to be a performance prediction of the HMA (Hot Mix Asphalt) in which the asphalt binder is used.

1.5 The development of this standard was based on SI units. In cases where units have been omitted, SI units are implied.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—The algorithms contained in this standard require implementation by a person trained in the subject of numerical methods and viscoelasticity. However, due to the complexity of the calculations they must, of necessity, be performed on a computer. Software to perform the calculation may be written, purchased as a spreadsheet, or as a stand-alone program.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6816 − 11

Standard Practice for

Determining Low-Temperature Performance Grade (PG) of

1

Asphalt Binders

This standard is issued under the fixed designation D6816; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

NOTE 1—The algorithms contained in this standard require implemen-

1. Scope

tation by a person trained in the subject of numerical methods and

1.1 This practice covers the calculation of low-temperature

viscoelasticity. However, due to the complexity of the calculations they

propertiesofasphaltbindersusingdatafromthebendingbeam must, of necessity, be performed on a computer. Software to perform the

calculationmaybewritten,purchasedasaspreadsheet,orasastand-alone

rheometer (see Test Method D6648) (BBR) and the direct

2

program.

tension tester (see Test Method D6723) (DTT). It can be used

on data from unaged material or from material aged usingTest

2. Referenced Documents

Method D2872 (RTFOT), Practice D6521 (PAV), or Test

3

2.1 ASTM Standards:

Method D2872 (RTFOT) and Practice D6521 (PAV). It can be

C670Practice for Preparing Precision and Bias Statements

used on data generated within the temperature range from

for Test Methods for Construction Materials

+6°C to -36°C. This practice generates data suitable for use in

D8Terminology Relating to Materials for Roads and Pave-

binder specifications such as Specification D6373.

ments

1.2 This practice is only valid for data on materials that fall

D2872Test Method for Effect of Heat andAir on a Moving

withinthescopeofsuitabilityforbothTestMethodD6648and

Film of Asphalt (Rolling Thin-Film Oven Test)

Test Method D6723.

D6373 Specification for Performance Graded Asphalt

Binder

1.3 This practice can be used to determine the following:

D6521Practice for Accelerated Aging of Asphalt Binder

1.3.1 Criticalcrackingtemperatureofanasphaltbinder,and

Using a Pressurized Aging Vessel (PAV)

1.3.2 Whether or not the failure stress exceeds the thermal

D6648Test Method for Determining the Flexural Creep

stress in a binder at a given temperature.

Stiffness of Asphalt Binder Using the Bending Beam

1.4 This practice determines the critical cracking tempera-

Rheometer (BBR)

ture for a typical asphalt binder based on the determination of

D6723Test Method for Determining the Fracture Properties

the temperature where the asphalt binder’s strength equals its

of Asphalt Binder in Direct Tension (DT)

thermalstressascalculatedbythispractice.Thetemperatureso

determinedisintendedtoyieldalowtemperaturePGGradeof

3. Terminology

the sample being tested. The low temperature PG grade is

3.1 Definitions—Fordefinitionsofgeneraltermsusedinthis

intended for use in purchase specifications and is not intended

standard, refer to Terminology D8.

to be a performance prediction of the HMA(Hot MixAsphalt)

3.2 Definitions of Terms Specific to This Standard:

in which the asphalt binder is used.

3.2.1 Arrhenius parameter, a ,n—this is the constant coef-

1

1.5 ThedevelopmentofthisstandardwasbasedonSIunits.

ficient in the Arrhenius model for shift factors: ln(a)=

T

In cases where units have been omitted, SI units are implied.

a ·((1/T) − (1/T )).

1 ref

1.6 This standard may involve hazardous materials,

3.2.2 coeffıcient of linear thermal expansion, α,n—the

operations, and equipment. This standard does not purport to

fractional change in size in one dimension associated with a

address all of the safety concerns, if any, associated with its

temperature increase of 1°C.

use. It is the responsibility of the user of this standard to

establish appropriate safety and health practices and deter-

2

The sole source of supply of the software package TSAR known to the

mine the applicability of regulatory limitations prior to use.

committee at this time is Abatech, Incorporated. If you are aware of alternative

suppliers, please provide this information to ASTM International Headquarters.

1

This practice is under the jurisdiction of ASTM Committee D04 on Road and Your comments will receive careful consideration at a meeting of the responsible

1

Paving Materials and is the direct responsibility of Subcommittee D04.44 on technical committee , which you may attend.

3

Rheological Tests. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved July 1, 2011. Published August 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2002. Last previous edition approved in 2002 as D6816– 02 which was Standards volume information, refer to the standard’s Document Summary page on

withdrawn 2007 and reinstated in July 2011. DOI: 10.1520/D6

...

This document is not anASTM standard and is intended only to provide the user of anASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:D6816–02 Designation:D6816–11

Standard Practice for

Determining Low-Temperature Performance Grade (PG) of

1

Asphalt Binders

This standard is issued under the fixed designation D6816; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

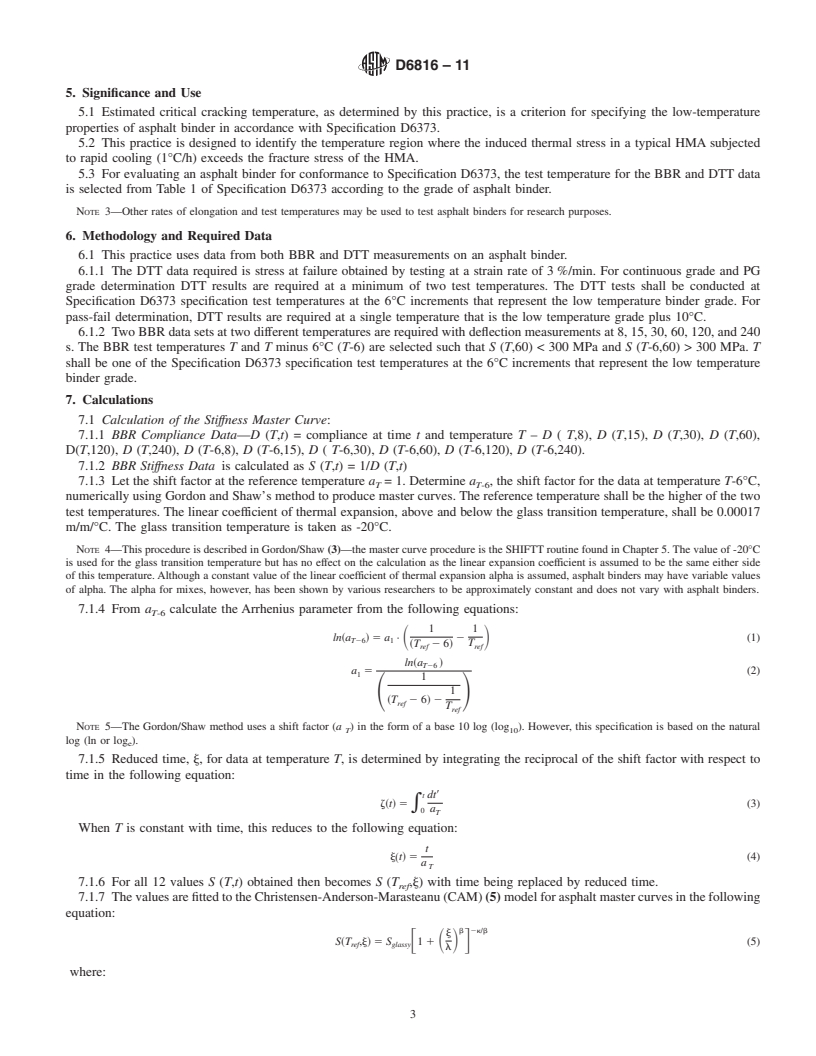

1. Scope

1.1 This practice covers the calculation of low-temperature properties of asphalt binders using data from the bending beam

rheometer (see Test Method D6648) (BBR) and the direct tension tester (see Test Method D6723) (DTT). It can be used on data

from unaged material or from material aged using Test Method D2872 (RTFOT), Practice D6521 (PAV), or Test Method D2872

(RTFOT) and Practice D6521 (PAV). It can be used on data generated within the temperature range from +6°C to -36°C. This

practice generates data suitable for use in binder specifications such as Specification D6373.

1.2 ThispracticeisonlyvalidfordataonmaterialsthatfallwithinthescopeofsuitabilityforbothTestMethodD6648andTest

Method D6723.

1.3 This practice can be used to determine the following:

1.3.1 Critical cracking temperature of an asphalt binder, and

1.3.2 Whether or not the failure stress exceeds the thermal stress in a binder at a given temperature.

1.4 This practice determines the critical cracking temperature for a typical asphalt binder based on the determination of the

temperature where the asphalt binder’s strength equals its thermal stress as calculated by this practice. The temperature so

determinedisintendedtoyieldalowtemperaturePGGradeofthesamplebeingtested.ThelowtemperaturePGgradeisintended

for use in purchase specifications and is not intended to be a performance prediction of the HMA(Hot MixAsphalt) in which the

asphalt binder is used.

1.5 The development of this standard was based on SI units. In cases where units have been omitted, SI units are implied.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all

of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate

safety and health practices and determine the applicability of regulatory limitations prior to use.

NOTE 1—Thealgorithmscontainedinthisstandardrequireimplementationbyapersontrainedinthesubjectofnumericalmethodsandviscoelasticity.

However, due to the complexity of the calculations they must, of necessity, be performed on a computer. Software to perform the calculation may be

2

written, purchased as a spreadsheet, or as a stand-alone program.

2. Referenced Documents

3

2.1 ASTM Standards:

C670 Practice for Preparing Precision and Bias Statements for Test Methods for Construction Materials

D8 Terminology Relating to Materials for Roads and Pavements

D2872 Test Method for Effect of Heat and Air on a Moving Film of Asphalt (Rolling Thin-Film Oven Test)

D6373 Specification for Performance Graded Asphalt Binder

D6521 Practice for Accelerated Aging of Asphalt Binder Using a Pressurized Aging Vessel (PAV)

D6648 TestMethodforDeterminingtheFlexuralCreepStiffnessofAsphaltBinderUsingtheBendingBeamRheometer(BBR)

D6723 Test Method for Determining the Fracture Properties of Asphalt Binder in Direct Tension (DT)

1

This practice is under the jurisdiction ofASTM Committee D04 on Road and Paving Materials and is the direct responsibility of Subcommittee D04.44 on Rheological

Tests.

Current edition approved July 10, 2002. Published September 2002. DOI: 10.1520/D6816-02.

CurrenteditionapprovedJuly1,2011.PublishedAugust2011.Lastpreviouseditionpublished2002asD6816–02whichwaswithdrawn2007andreinstatedinJuly2011.

DOI: 10.1520/D6816-11.

2

The sole source of supply of the software packageTSAR known to the committee at this time isAbatech, Incorporated. If you are aware of alternative suppliers, please

provide this information toASTM International Headquarters.Your comments will receive careful consideration at a meeting of the responsible technical committee , which

you may attend.

3

ForreferencedASTMstandards,visittheASTMwebsite,www.astm.org,orcontactASTMCustomerServiceatservice@astm.org.For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

----

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.