ASTM F1488-00

(Specification)Standard Specification for Coextruded Composite Pipe

Standard Specification for Coextruded Composite Pipe

SCOPE

1.1 This specification covers coextruded composite pipe, produced by a coextrusion die system, in which the concentric layers are formed and combined before exiting the die.

1.1.1 Materials listed in the material section are permitted to be used in any layer of the coextruded composite pipe. When coextruded composite pipe is produced with three layers, the middle layer is permitted to be solid or thermally foamed.

1.1.2 The function of this specification is to provide standardization of product, to produce technical data, and to serve as a purchasing guide.

1.2 Compounds that do not meet the requirements of the material section are excluded.

1.3 The coextruded composite pipe is permitted to be perforated in accordance with any specified standard or by agreement between the purchaser and the supplier.

1.4 The coextruded composite pipe is permitted to be belled for joining by solvent cementing or belled for joining by an elastomeric seal (gaskets), in accordance with any specified standard or by agreement between the purchaser and the supplier.

1.5 Recommendations for storage, joining, installation, and rationale are listed in Appendixes X1, X2, X3, and X4, respectively.

1.6 When installed underground, coextruded composite pipe shall be installed in accordance with Practice D2321.

1.7 The values stated in inch-pound units are to be regarded as the standard. A companion standard written in SI units is under development.

1.8 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Note 1-Related specifications are as follows: D2661, D2665, D2729, D2750, D2751, D2949, D3034, F512, F628, F758, F789, and F891.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: F 1488 – 00 An American National Standard

Standard Specification for

Coextruded Composite Pipe

This standard is issued under the fixed designation F 1488; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This specification covers coextruded composite pipe, 2.1 The following standards contain provisions which,

produced by a coextrusion die system, in which the concentric though referenced in this specification, constitute provisions of

layers are formed and combined before exiting the die. this specification. All standards are subject to revision and

1.1.1 Materials listed in the material section are permitted to parties using this specification shall reference the most recent

be used in any layer of the coextruded composite pipe. When edition of the standards listed as follows.

coextruded composite pipe is produced with three layers, the 2.2 ASTM Standards:

middle layer is permitted to be solid or thermally foamed. D 618 Practice for Conditioning Plastics and Electrical

1.1.2 The function of this specification is to provide stan- Insulatings Material for Testing

dardization of product, to produce technical data, and to serve D 696 Test Method for Coefficient of Linear Thermal Ex-

as a purchasing guide. pansion of Plastics Between −30C and 30C

1.2 Compounds that do not meet the requirements of the D 883 Terminology Relating to Plastics

material section are excluded. D 1600 Terminology for Abbreviated Terms Relating to

1.3 The coextruded composite pipe is permitted to be Plastics

perforated in accordance with any specified standard or by D 1898 Practice for Sampling of Plastics

agreement between the purchaser and the supplier. D 1972 Practice for Generic Marking of Plastic Products

1.4 The coextruded composite pipe is permitted to be belled D 2122 Test Method for Determining Dimensions of Ther-

for joining by solvent cementing or belled for joining by an moplastic Pipe and Fittings

elastomeric seal (gaskets), in accordance with any specified D 2235 Specification for Solvent Cement for Acrylonitrile-

standard or by agreement between the purchaser and the Butadiene-Styrene (ABS) Plastic Pipe and Fittings

supplier. D 2321 Practice for Underground Installation of Flexible

1.5 Recommendations for storage, joining, installation, and Thermoplastic Pipe for Sewers and Other Gravity-Flow

rationale are listed in Appendixes X1, X2, X3, and X4, Applications

respectively. D 2412 Test Method for Determination of External Loading

1.6 The values stated in inch-pound units are to be regarded Characteristics of Plastic Pipe by Parallel-Plate Loading

as the standard. A companion standard written in SI units is D 2444 Test Method for Impact Resistance of Thermoplas-

under development. tic Pipe and Fittings by Means of a Tup (Falling Weight)

1.7 The text of this specification references notes, footnotes, D 2564 Specification for Solvent Cements for Poly(Vinyl

and appendixes which provide explanatory material. These Chloride) (PVC) Plastic Piping Systems

notes and footnotes (excluding those in tables and figures) shall D 2661 Specification for Acrylonitrile-Butadiene-Styrene

not be considered as requirements of this specification. (ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe

1.8 This standard does not purport to address all of the and Fittings

safety concerns, if any, associated with its use. It is the D 2665 Specification for Poly(Vinyl Chloride) (PVC) Plas-

responsibility of the user of this standard to establish appro- tic Drain, Waste, and Vent Pipe and Fittings

priate safety and health practices and determine the applica- D 2729 Specification for Poly(Vinyl Chloride) (PVC)

bility of regulatory limitations prior to use. Sewer Pipe and Fittings

D 2750 Specification for Acrylonitrile-Butadiene-Styrene

NOTE 1—Related specifications are as follows: D 2661, D 2665,

(ABS) Plastic Utilities Conduit and Fittings

D 2729, D 2750, D 2751, D 2949, D 3034, F 512, F 628, F 758, F 789,

D 2751 Specification for Acrylonitrile-Butadiene-Styrene

and F 891.

(ABS) Sewer Pipe and Fittings

D 2855 Practice for Making Solvent-Cemented Joints with

Poly(Vinyl Chloride) (PVC) Pipe and Fittings

This specification is under the jurisdiction of ASTM Committee F-17 on Plastic

Piping and is the direct responsibility of Subcommittee F17.11 on Composite.

Annual Book of ASTM Standards, Vol 08.01.

Current edition approved May 10, 2000. Published August 10, 2000.Originally

Discontinued; see 1997 Annual Book of ASTM Standards, Vol 08.01.

published as F 1488 – 94. Last previous edition F 1488 – 98.

Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1488

D 2949 Specification for 3.25-in. Outside Diameter Poly- Fed. Std. No. 123 Marking for Shipments (Civil Agencies)

(Vinyl Chloride) (PVC) Plastic Drain, Waste, and Vent 2.5 Military Standard:

Pipe and Fittings

MIL-STD-129 Marking for Shipment and Storage

D 3034 Specification for Type PSM Poly(Vinyl Chloride)

2.6 Uniform Classification Committee Standard:

(PVC) Sewer Pipe and Fittings

Uniform Freight Classification

D 3139 Specification for Joints for Plastic Pressure Pipes

2.7 National Motor Freight Traffıc Association Standard:

Using Flexible Elastomeric Seals 10

National Motor Freight Classification

D 3212 Specification for Joints for Drain and Sewer Plastic

Pipes Using Flexible Elastomeric Seals

3. Terminology

D 3965 Specification for Rigid Acrylonitrile-Butadiene-

3.1 Definitions—Definitions are in accordance with Termi-

Styrene (ABS) Compounds for Pipe and Fittings

nologies D 883 and F 412. Abbreviations are in accordance

D 4000 Classification System for Specifying Plastic Mate-

with Terminology D 1600. Plastic materials are classified in

rials

accordance with Classification System D 4000. Generic mark-

D 4396 Specification for Rigid Poly(Vinyl Chloride) (PVC)

ing is in accordance with Practice D 1972.

and Related Plastic Compounds for Nonpressure Piping

3.1.1 coextrusion—a process whereby two or more heated

Products

or unheated plastic material streams forced through one or

D 5033 Guide for the Development of Standards Relating to

more shaping orifice(s) become one continuously formed

the Proper Use of Recycled Plastics

piece.

F 402 Practice for Safe Handling of Solvent Cements,

3.1.2 compound—a mixture of a polymer with other ingre-

Primers, and Cleaners Used for Joining Thermoplastic Pipe

dients, such as fillers, stabilizers, catalysts, processing aids,

and Fittings

lubricants, modifiers, pigments, or curing agents.

F 412 Terminology Relating to Plastic Piping Systems

3.1.3 dimension ratio—the average specified diameter of a

F 477 Specification for Elastomeric Seals (Gaskets) for

pipe divided by the minimum specified wall thickness.

Joining Plastic Pipe

3.1.4 out-of-roundness—the allowed difference between the

F 493 Specification for Solvent Cements for Chlorinated

maximum measured diameter and the minimum measured

Poly(Vinyl Chloride) (CPVC) Plastic Pipe and Fittings

diameter (stated as an absolute deviation).

F 512 Specification for Smooth-Wall Poly(Vinyl Chloride)

3.1.5 thermally foamed plastic—a cellular plastic produced

(PVC) Conduit and Fittings for Underground Installation

by applyiong heat to effect gaseous decomposition or volatil-

F 545 Specification for PVC and ABS Injected Solvent

ization of a constituent. (1985)

Cemented Plastic Pipe Joints

3.1.6 virgin plastic, adj—material in the form of pellets,

F 628 Specification for Acrylonitrile-Butadiene-Styrene

granules, powder, floc, or liquid that has not been subjected to

(ABS) Schedule 40 Plastic Drain, Waste, and Vent Pipe

use or processing other than that required for its initial

With a Cellular Core

manufacture. (1985, D 883)

F 656 Specification for Primers for Use in Solvent Cement

3.2 Definitions of Terms Specific to This Standard:

Joints of Poly(Vinyl Chloride) (PVC) Plastic Pipe and

3.2.1 coextruded composite pipe—pipe consisting of two or

Fittings

more concentric layers of the same or different material bonded

F 758 Specification for Smooth-Wall Poly(Vinyl Chloride)

together in processing by any combination of temperature,

(PVC) Plastic Underdrain Systems for Highway, Airport,

pressure, grafting, crosslinking, or adhesion with a specific

and Similar Drainage

purpose to serve as pipe.

F 789 Specification for Type PS-46 and Type PS-115 Poly- 3.2.2 IPS-DR-PS Series—coextruded pipe produced to an

(Vinyl Chloride) (PVC) Plastic Gravity Flow Sewer Pipe

iron pipe outside diameter (OD) with a dimension ratio (DR)

and Fittings and pipe stiffness (PS).

F 891 Specification for Coextruded Poly(Vinyl Chloride) 3.2.3 IPS Schedule 40 Series—coextruded composite pipe

(PVC) Plastic Pipe with a Cellular Core produced to an iron pipe outside diameter (OD) with a

F 913 Specification for Thermoplastic Elastomeric Seals Schedule 40 wall thickness.

3.2.4 lot—all pipe produced of one size and from one

(Gaskets) for Joining Plastic Pipe

extrusion line, during one designated 24-h period.

2.3 ANSI Standards:

3.2.5 qualification test—an evaluation, generally nonrepeti-

ANSI Z 34.1 American National Standard for Certification-

tive, conducted on an existing, altered, or new product to

Third-Party Certification Program

determine acceptability.

ANSI Z 34.2 American National Standard for Certification-

Self-Certification by Producer or Supplier

2.4 Federal Standard:

Available from Standardization Documents Order Desk, Bldg. 4 Section D, 700

Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Available from the Uniform Classification Committee, Suite 1106, 222 South

Annual Book of ASTM Standards, Vol 08.02. Riverside Plaza, Chicago, IL 60606.

6 10

Annual Book of ASTM Standards, Vol 08.03. Available from the National Motor Freight Traffic Association, Inc., National

Available from American National Standards Institute, 11 W. 42nd St., 13th Motor Freight Classification, American Tracking Association, Inc. Traffic Dept.,

Floor, New York, NY 10036. 1616 P St., NW, Washington, DC 20036.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

F 1488

3.2.6 rework composite pipe material—a blend of the dif- virgin plastic material conforming to the requirements of

ferent materials used in the different layers of the coextruded Specification D 4396 and shall meet all of the requirements for

composite pipe. Cell Class 2-2-4-2-4.

3.2.7 Sewer and Drain DR-PS Series—coextruded compos- 6.4.1 The color and form of the material shall be by

ite pipe produced to a sewer and drain outside diameter (OD) agreement between the purchaser and the supplier in accor-

with a dimension ratio (DR) and pipe stiffness (PS). dance with Specification D 4396.

6.4.2 Individual cell class values are permitted to be greater

4. Classification

than those listed.

4.1 Coextruded composite pipe produced in compliance 6.5 Rework Material—A blend of clean rework material

with this specification in different dimension ratios (DR) and

generated from the manufacturer’s own pipe production may

pipe stiffness (PS) is used for different applications. be used by the same manufacturer, provided the pipe produced

4.1.1 IPS Schedule 40 Series—Coextruded composite pipe

meets all of the requirements of this specification.

is used for above or below ground installation for communi- 6.5.1 Rework material is excluded from standard definitions

cation conduit, electrical conduit, drain, waste, and vent pipe,

of recycled materials in accordance with Guide D 5033.

and plastic underdrain systems for highway, airport, and 6.5.2 Rework material generated from composite pipe shall

similar drainage, where a Schedule 40 IPS is required.

not be used in the outer layer.

4.1.2 IPS-DR-PS Series—Coextruded composite pipe is 6.5.3 Rework material generated from composite pipe with

used for above or below ground installation for communication

a thermally foamed layer shall not be used in the inner or outer

conduit, electrical conduit, and drain, waste, and vent pipe. layer.

4.1.3 Sewer and Drain DR-PS Series—Coextruded com-

7. Performance Requirements

posite pipe is used for gravity flow sewer and drain pipe, and

plastic underdrain systems for highway, airport, and similar

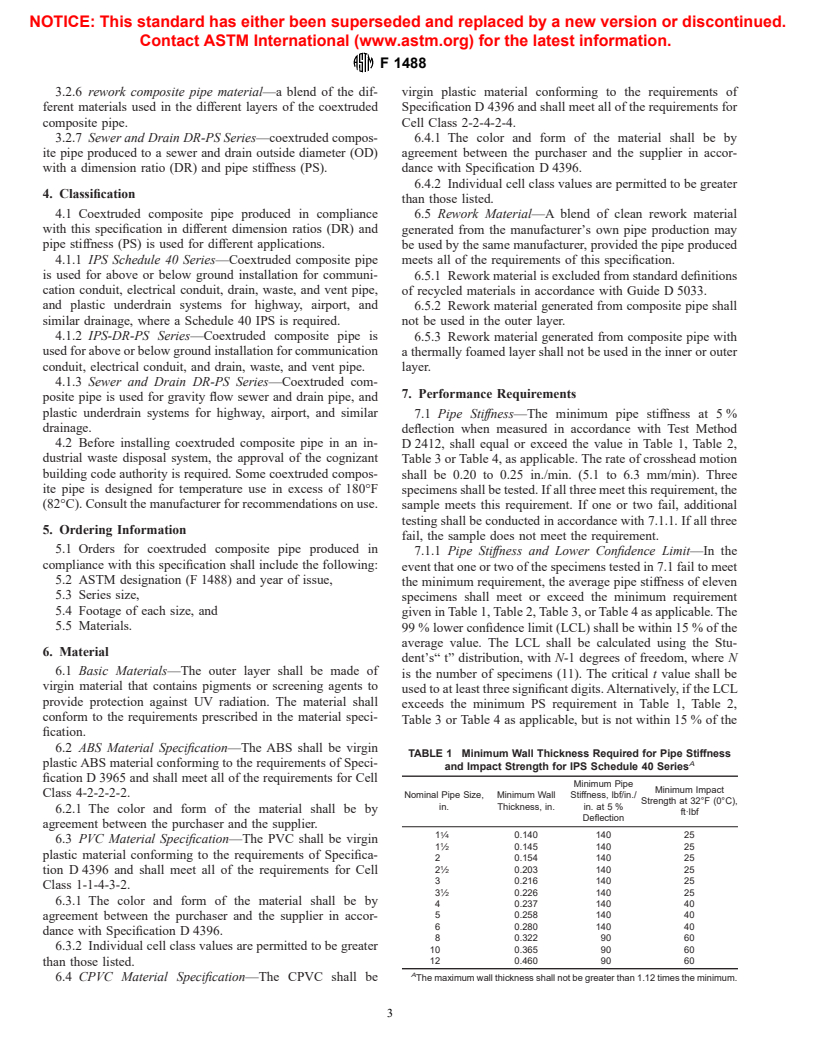

7.1 Pipe Stiffness—The minimum pipe stiffness at 5 %

drainage.

deflection when measured in accordance with Test Method

4.2 Before installing coextruded composite pipe in an in-

D 2412, shall equal or exceed the value in Table 1, Table 2,

dustrial waste disposal system, the approval of the cognizant

Table 3 or Table 4, as applicable. The rate of crosshead motion

building code authority is required. Some coextruded compos-

shall be 0.20 to 0.25 in./min. (5.1 to 6.3 mm/min). Three

ite pipe is designed for temperature use in excess of 180°F

specimens shall be tested. If all three meet this requirement, the

(82°C). Consult the manufacturer for recommendations on use. sample meets this requirement. If one or two fail, additional

testing shall be conducted in accordance with 7.1.1. If all three

5. Ordering Information

fail, the sample does not meet the requirement.

5.1 Orders for coextruded composite pipe produced in

7.1.1 Pipe Stiffness and Lower Confidence Limit—In the

compliance with this specification shall include the following:

event that one or two of the specimens tested in 7.1 fail to meet

5.2 ASTM designation (F 1488) and year of issue,

the minimum requirement, the average pipe stiffness of eleven

5.3 Series size,

specimens shall meet or exceed the minimum requirement

5.4 Footage of each size, and

given in Table 1, Table 2, Table 3, or Table 4 as applicable. The

5.5 Materials.

99 % lower confidence limit (LCL) shall be within 15 % of the

average value. The LCL shall be calculated using the Stu-

6. Material

dent’s“ t” distribution, with N-1 degrees of freedom, where N

6.1 Basic Materials—The outer layer shall be made of

is the number of specimens (11). The critical t value shall be

virgin material that contains pigments or screening agents to

used to at least three significant digits. Alternatively, if the LCL

provide protection against UV radiation. The material shall

exceeds the minimum PS requirement in T

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.