ASTM B447-07

(Specification)Standard Specification for Welded Copper Tube

Standard Specification for Welded Copper Tube

ABSTRACT

This specification establishes the requirements for welded copper tube with a longitudinal seam free of filler metal produced from sheet or strip of one of the Copper UNS Nos. C10100, C10200, C10300, C10800, C11000, C12000, C12200, and C14200. Copper C11000 welded tube shall not be used in applications where hydrogen embrittlement during heating is a concern. Tempers of the welded tube types are as follows: as-welded: WM50, WM02, or WM04, welded and annealed: W060 and W050, welded and cold drawn: WH00, WH02, and WH04, and fully finished: O60, O50, H55, H58, and H80. The product shall be manufactured by forming the material into a tubular shape on a suitable forming mill and welding shall be accomplished by any process that produces forge or fusion welds. The external flash of forge welded tube shall be removed by scarfing and the internal flash shall be treated by IFI (to remain in the as-welded condition), IFR (scarfing) or IFD (rolling or drawing) technique. The material shall conform to the chemical composition requirements prescribed for copper, phosphorus, and arsenic, as determined by chemical analysis. The welded tubes shall meet the requirements specified for grain size, electrical mass resistivity, mechanical properties such as tensile strength and Rockwell hardness, dimensions, and mass. Performance requirements includes microscopical examination, hydrogen embrittlement susceptibility test, and expansion test. Requirements for tensile, electromagnetic (eddy-current), hydrostatic, and pneumatic tests are detailed.

SCOPE

1.1 This specification establishes the requirements for welded copper tube with a longitudinal seam free of filler metal produced from sheet or strip of the following coppers:Copper UNS Nos.Type of CopperC10100Oxygen-free electronicC10200Oxygen-freeC10300Oxygen-free, extra low phosphorusC10800Oxygen-free, low phosphorusC11000Electrolytic tough pitchC12000Phosphorus deoxidized, low residual phosphorusC12200Phosphorus deoxidized, high residual phosphorusC14200Phosphorus deoxidized, arsenical

1.2 Unless otherwise specified in the contract or purchase order, product furnished of any listed copper, with the exception of copper C11000, shall be considered acceptable.

1.2.1 Copper C11000 welded tube shall not be used in applications where hydrogen embrittlement during heating is a concern.

1.3 Values stated in inch-pound units are the standard except for grain size which is given in SI units. Values given in parentheses are for information only.

1.4 The following hazard caveat pertains only to Section 13 of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B447 – 07

Standard Specification for

1

Welded Copper Tube

This standard is issued under the fixed designation B447; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope* B153 Test Method for Expansion (Pin Test) of Copper and

Copper-Alloy Pipe and Tubing

1.1 This specification establishes the requirements for

B170 Specification for Oxygen-Free Electrolytic Copper—

weldedcoppertubewithalongitudinalseamfreeoffillermetal

Refinery Shapes

produced from sheet or strip of the following coppers:

B193 Test Method for Resistivity of Electrical Conductor

Copper UNS Nos. Type of Copper

Materials

C10100 Oxygen-free electronic

B577 Test Methods for Detection of Cuprous Oxide (Hy-

C10200 Oxygen-free

drogen Embrittlement Susceptibility) in Copper

C10300 Oxygen-free, extra low phosphorus

B601 Classification for Temper Designations for Copper

C10800 Oxygen-free, low phosphorus

C11000 Electrolytic tough pitch

and Copper Alloys—Wrought and Cast

C12000 Phosphorus deoxidized, low residual phosphorus

B846 Terminology for Copper and Copper Alloys

C12200 Phosphorus deoxidized, high residual phosphorus

E3 Guide for Preparation of Metallographic Specimens

C14200 Phosphorus deoxidized, arsenical

E8 Test Methods for Tension Testing of Metallic Materials

1.2 Unless otherwise specified in the contract or purchase

E29 Practice for Using Significant Digits in Test Data to

order, product furnished of any listed copper, with the excep-

Determine Conformance with Specifications

tion of copper C11000, shall be considered acceptable.

E53 TestMethodforDeterminationofCopperinUnalloyed

1.2.1 Copper C11000 welded tube shall not be used in

Copper by Gravimetry

applications where hydrogen embrittlement during heating is a

E62 Test Methods for Chemical Analysis of Copper and

concern.

Copper Alloys (Photometric Methods)

1.3 Valuesstatedininch-poundunitsarethestandardexcept

E112 Test Methods for Determining Average Grain Size

for grain size, which is given in SI units. Values given in

E243 Practice for Electromagnetic (Eddy-Current) Exami-

parentheses are for information only.

nation of Copper and Copper-Alloy Tubes

1.4 The following hazard caveat pertains only to Section 13

E255 Practice for Sampling Copper and Copper Alloys for

ofthisspecification: This standard does not purport to address

the Determination of Chemical Composition

all of the safety concerns, if any, associated with its use. It is

E527 Practice for Numbering Metals and Alloys in the

the responsibility of the user of this standard to establish

Unified Numbering System (UNS)

appropriate safety and health practices and determine the

applicability of regulatory limitations prior to use.

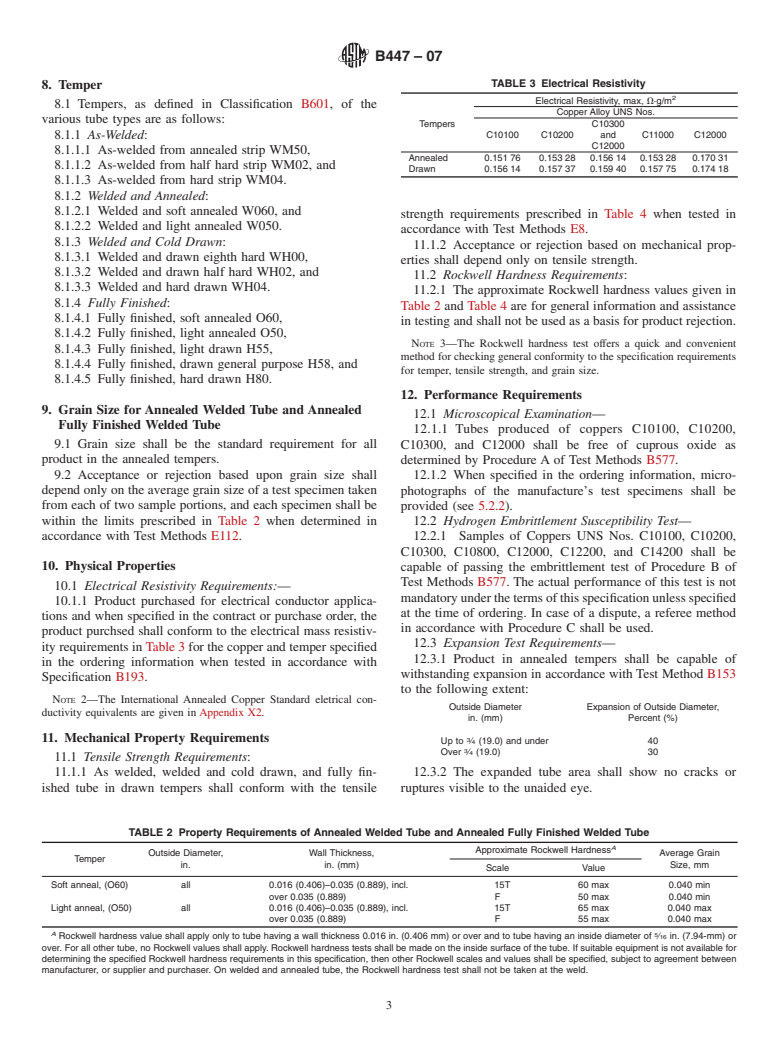

3. Terminology

3.1 Definitions:

2. Referenced Documents

3.1.1 For definitions of terms related to copper and copper

2

2.1 ASTM Standards:

alloys refer to Terminology B846.

3.2 Definitions of Terms Specific to This Standard:

1

ThisspecificationisunderthejurisdictionofASTMCommitteeB05onCopper

3.2.1 lengths, mill, n—straight lengths, including ends that

and CopperAlloys and is the direct responsibility of Subcommittee B05.04 on Pipe

are conveniently manufactured in the mills.

and Tube.

3.2.1.1 Discussion—Full-length pieces are usually 10, 12,

Current edition approved April 1, 2007. Published April 2007. Originally

or 20 ft and subject to established length tolerances.

approved in 1967. Last previous edition approved in 2002 as B447–02. DOI:

10.1520/B0447-07.

3.2.2 lengths, stock, n—straightlengthsthataremillcutand

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

stored in advance of orders.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

3.2.2.1 Discussion—Stocklengthsareusually6to20ftand

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. subject to established tolerances.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B447 – 07

4. Classification 6.1.2 In the event heat identification or traceability is

required, the purchaser shall specify the details desired.

4.1 The following types of welded tube are manufactured

under this specification:

NOTE 1—Due to the discontinuous nature of the processing of castings

4.1.1 As-Welded—Aconditioncreatedasaresultofforming into wrought products, it is not always practical to identify a specific

casti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.