ASTM D7147-05

(Specification)Standard Specification for Testing and Establishing Allowable Loads of Joist Hangers

Standard Specification for Testing and Establishing Allowable Loads of Joist Hangers

ABSTRACT

This specification covers a procedure for evaluating metal devices used for wood-to-wood, wood-to-concrete, wood-to-concrete masonry, and wood-to-steel joist, beam, and girder connections. It describes test methods for evaluating the capacities of joist hangers subject to vertical and torsional loading. Also, this specification provides a method of assigning allowable loads to joist hangers based on measured strength and deformation characteristics. Test specimens consisting of a length of joist supported by joist hangers attached to two headers are subjected to a vertical load by a suitable testing machine, while the vertical load and corresponding deflection of the joist are measured and recorded to provide load-slip data.

SCOPE

1.1 This specification covers a procedure for evaluating metal devices used for wood-to-wood, wood-to-concrete, wood-to-concrete masonry, and wood-to-steel connections. This method is intended for use with devices used to connect joists, beams, and girders together. These devices are commonly described as joist hangers.

1.2 This specification describes test methods for evaluating the capacities of joist hangers subject to vertical and torsional loading.

1.3 This specification provides a method of assigning allowable loads to joist hangers based on measured strength and deformation characteristics. Information obtained by the provisions of this specification is applicable to design when using the Allowable Stress Design method.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D7147 – 05

Standard Specification for

Testing and Establishing Allowable Loads of Joist Hangers

This standard is issued under the fixed designation D7147; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Wood-Based Materials

D3737 Practice for Establishing Allowable Properties for

1.1 This specification covers a procedure for evaluating

Structural Glued Laminated Timber (Glulam)

metal devices used for wood-to-wood, wood-to-concrete,

D4442 Test Methods for Direct Moisture Content Measure-

wood-to-concrete masonry, and wood-to-steel connections.

ment of Wood and Wood-Base Materials

This method is intended for use with devices used to connect

D4444 Test Method for Laboratory Standardization and

joists, beams, and girders together. These devices are com-

Calibration of Hand-Held Moisture Meters

monly described as joist hangers.

D5055 Specification for Establishing and Monitoring Struc-

1.2 This specification describes test methods for evaluating

tural Capacities of Prefabricated Wood I-Joists

the capacities of joist hangers subject to vertical and torsional

D5456 SpecificationforEvaluationofStructuralComposite

loading.

Lumber Products

1.3 Thisspecificationprovidesamethodofassigningallow-

E4 Practices for Force Verification of Testing Machines

able loads to joist hangers based on measured strength and

E8 Test Methods for Tension Testing of Metallic Materials

deformation characteristics. Information obtained by the pro-

E575 Practice for Reporting Data from Structural Tests of

visions of this specification is applicable to design when using

Building Constructions, Elements, Connections, and As-

the Allowable Stress Design method.

semblies

1.4 This standard does not purport to address all of the

F606 Test Methods for Determining the Mechanical Prop-

safety concerns, if any, associated with its use. It is the

erties of Externally and Internally Threaded Fasteners,

responsibility of the user of this standard to establish appro-

Washers, Direct Tension Indicators, and Rivets

priate safety and health practices and determine the applica-

F1470 Practice for Fastener Sampling for Specified Me-

bility of regulatory limitations prior to use.

chanical Properties and Performance Inspection

2. Referenced Documents F1575 Test Method for Determining Bending Yield Mo-

ment of Nails

2.1 ASTM Standards:

2.2 Other Standards:

C31/C31M Practice for Making and Curing Concrete Test

ANSI/AF&PANDS-2001 National Design Specificationfor

Specimens in the Field

Wood Construction

C39/C39M Test Method for Compressive Strength of Cy-

ANSI/ASME B18.2.1 Square and Hex Bolts and Screws

lindrical Concrete Specimens

(Inch Series), 1996

C90 Specification for Loadbearing Concrete Masonry Units

Specification and Commentary for the Design of Cold-

C270 Specification for Mortar for Unit Masonry

Formed Steel Structural Members, 1996

C1314 Test Method for Compressive Strength of Masonry

Specification for Structural Steel Buildings, 1989

Prisms

D9 Terminology Relating to Wood and Wood-Based Prod-

3. Terminology

ucts

3.1 The following section defines terms used in this speci-

D245 Practice for Establishing Structural Grades and Re-

fication. See Terminology D9 for other terminology.

lated Allowable Properties for Visually Graded Lumber

3.2 Definitions:

D2395 Test Methods for Specific Gravity of Wood and

1 3

This specification is under the jurisdiction ofASTM Committee D07 on Wood Available from American Forest and Paper Association (AF&PA), 1111 19th

and is the direct responsibility of Subcommittee D07.05 on Wood Assemblies. St., NW, Suite 800, Washington, DC 20036.

Current edition approved April 1, 2005. Published April 2005. DOI: 10.1520/ Available from American Society of Mechanical Engineers (ASME), ASME

D7147-05. International Headquarters, Three Park Ave., New York, NY 10016-5990.

2 5

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American Iron and Steel Institute (AISI), 1101 17th St., NW,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Suite 1300, Washington, DC 20036.

Standards volume information, refer to the standard’s Document Summary page on Available from American Institute of Steel Construction (AISC), One E.

the ASTM website. Wacker Dr., Suite 3100, Chicago, IL 60601-2001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D7147 – 05

3.2.1 header—amembersupportingajoisthanger.Aheader

may also be referred to as a “supporting” member.

3.2.2 joist—a bending member supported by a joist hanger.

A joist may also be referred to as a “supported” member.

3.2.3 joist hanger—a metal device, usually cold-formed

from light-gage steel sheet or welded from steel plate, used to

transfer loads from a joist to a header member or wall in

building construction. Face-mount joist hangers contact the

side surface of the header and do not contact the top of the

header. Top-mount hangers are joist hangers that contact the

side and top surface of the header.

3.2.4 structural composite lumber—see Specification

D5456.

3.2.5 structural glued laminated timber—see Practice

D3737.

3.2.6 wood I-joists—see Specification D5055.

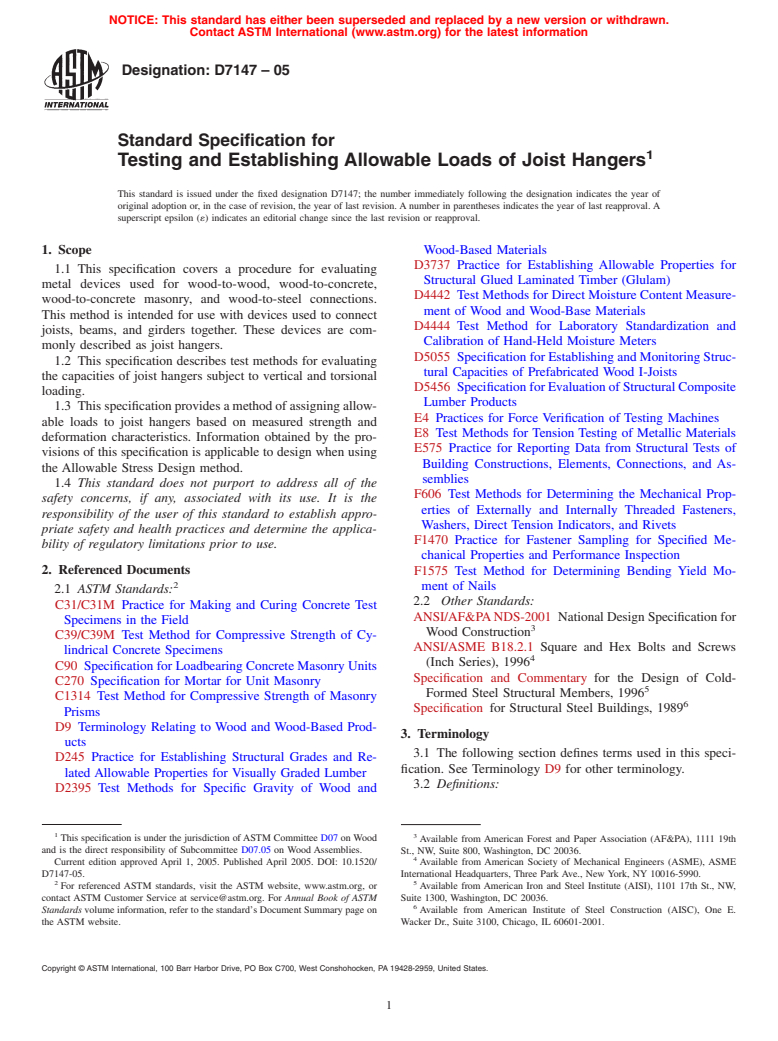

FIG. 2 Typical Uplift Test Setup

4. Significance and Use

4.1 Joist hangers are used to transfer vertical loads from a

joist to a header in building construction. In addition to vertical

5.1.2 Loads applied vertically upward with reference to the

load transfer, joist hangers may provide torsional resistance for

intended application of the joist hanger, shall be classified as

the ends of a joist. The performance of this connection is

uplift (see Fig. 2).

influenced by a number of variables, such as the properties of

5.2 Torsional Moment Test (optional)—A test method is

the hanger, the joist material, the header material, and the

provided in Appendix X1 for torsional moment capacity

fasteners. The test described in this specification provide for

evaluation of hangers. This test consists of a joist supported by

consistency in evaluating the performance of such assembled

two joist hangers attached to headers (see Figs. X1.1 and

units.

X1.2).The movement of the joist with respect to the headers is

measured and recorded to provide data for calculating angular

5. Summary of Test Method

rotation and load-deflection relationships.

5.1 Vertical Load Test—Test specimens consisting of a

length of joist supported by joist hangers attached to two

6. Apparatus

headers are subjected to a vertical load by a suitable testing

6.1 Testing Machine—A testing machine that is capable of

machine (see Figs. 1-3), while the vertical load and corre-

operationataconstantrateofmotionofthemovablecrosshead

sponding deflection of the joist are measured and recorded to

or a constant rate of loading and a force-measuring device that

provide load-slip data.

is calibrated in accordance with Practices E4.

5.1.1 Loads applied vertically downward with reference to

6.2 Displacement Gage—All tests shall use a dial gage(s),

the intended application of the joist hanger, shall be classified

or equivalent, to measure the relative movement between the

as downward (see Fig. 1).

joist and header. Devices used for this purpose shall have a

least reading of 0.001 in. (0.02 mm).

7. Test Materials

7.1 Wood—All wood materials shall be of structural quality

with allowable values substantiated by accepted procedures,

such as those found in Section 2. The specific gravity and

moisture content of the joists and headers shall be determined

in accordance with Test Methods D2395 and D4442 or D4444,

respectively. All specific gravities shall be reported on an

oven-dry basis in accordance with Test Methods D2395.

Specificgravitymeasurementstakenatmoisturecontentsother

than oven-dry shall be adjusted to the oven-dry moisture

content in accordance with Appendix X1 of Test Methods

D2395.

7.2 Concrete or Masonry:

7.2.1 If concrete is used, a minimum of two concrete test

cylinders shall be prepared, stored, and cured in accordance

with Practice C31/C31M from the same batch of concrete used

FIG. 1 Typical Vertical Downward Test Setup in the joist hanger test specimen. Cylinders shall be tested in

D7147 – 05

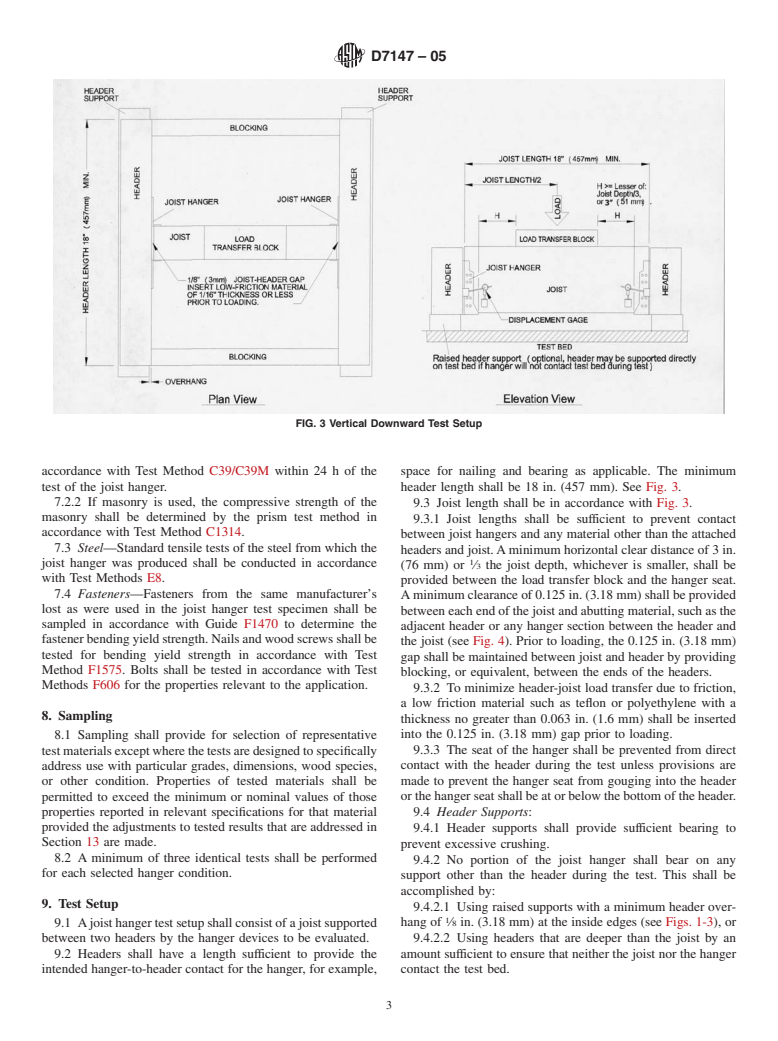

FIG. 3 Vertical Downward Test Setup

accordance with Test Method C39/C39M within 24 h of the space for nailing and bearing as applicable. The minimum

test of the joist hanger. header length shall be 18 in. (457 mm). See Fig. 3.

7.2.2 If masonry is used, the compressive strength of the

9.3 Joist length shall be in accordance with Fig. 3.

masonry shall be determined by the prism test method in

9.3.1 Joist lengths shall be sufficient to prevent contact

accordance with Test Method C1314.

between joist hangers and any material other than the attached

7.3 Steel—Standard tensile tests of the steel from which the

headers and joist.Aminimum horizontal clear distance of 3 in.

joist hanger was produced shall be conducted in accordance

(76 mm) or ⁄3 the joist depth, whichever is smaller, shall be

with Test Methods E8.

provided between the load transfer block and the hanger seat.

7.4 Fasteners—Fasteners from the same manufacturer’s

Aminimum clearance of 0.125 in. (3.18 mm) shall be provided

lost as were used in the joist hanger test specimen shall be

between each end of the joist and abutting material, such as the

sampled in accordance with Guide F1470 to determine the

adjacent header or any hanger section between the header and

fastenerbendingyieldstrength.Nailsandwoodscrewsshallbe

the joist (see Fig. 4). Prior to loading, the 0.125 in. (3.18 mm)

tested for bending yield strength in accordance with Test

gap shall be maintained between joist and header by providing

Method F1575. Bolts shall be tested in accordance with Test

blocking, or equivalent, between the ends of the headers.

Methods F606 for the properties relevant to the application.

9.3.2 To minimize header-joist load transfer due to friction,

a low friction material such as teflon or polyethylene with a

8. Sampling

thickness no greater than 0.063 in. (1.6 mm) shall be inserted

into the 0.125 in. (3.18 mm) gap prior to loading.

8.1 Sampling shall provide for selection of representative

testmaterialsexceptwherethetestsaredesignedtospecifically 9.3.3 The seat of the hanger shall be prevented from direct

contact with the header during the test unless provisions are

address use with particular grades, dimensions, wood species,

or other condition. Properties of tested materials shall be made to prevent the hanger seat from gouging into the header

orthehangerseatshallbeatorbelowthebottomoftheheader.

permitted to exceed the minimum or nominal values of those

properties reported in relevant specifications for that material 9.4 Header Supports:

provided the adjustments to tested results that are addressed in

9.4.1 Header supports shall provide sufficient bearing to

Section 13 are made.

prevent excessive crushing.

8.2 A minimum of three identical tests shall be performed

9.4.2 No portion of the joist hanger shall bear on any

for each selected hanger condition.

support other than the header during the test. This shall be

accomplished by:

9. Test Setup

9.4.2.1 Using raised supports with a minimum header over-

hang of ⁄8 in. (3.18 mm) at the inside edges (see Figs. 1-3), or

9.1 Ajoisthangertestsetupshallconsistofajoistsupported

between two headers by the hanger devices to be evaluated. 9.4.2.2 Using headers that are deeper than the joist by an

9.2 Headers shall have a length sufficient to provide the amount sufficient to ensure that neither the joist nor the hanger

intended hanger-to-header contact for the hanger, for example, contact the test bed.

D7147 – 05

FIG. 4 Required Gap When Portion of Joist Hanger Exists Between Header and Joist

9.4.3 The test bed or any header supports shall not contact 11. Procedure

the joist or joist hanger at any time during the test.

11.1 The following properties must be determined for ma-

terials used in the test:

NOTE 1—A ⁄8-in. overhang of the header beyond the inside edge of the

support has historically been provided to ensure contact does not occur

(1) tensile strength of hanger steel,

between the joist hanger and the header support.

(2) specific gravity of wood materials as outlined in 13.5.2-

9.5 Reinforcement of joist members at the area of load

13.5.4, and

application shall be permitted to prevent member failure in

(3) bending yield strength of the fasteners.

bending, shear, or compression perpendicular-to-grain at the

11.2 Vertical movement of the joist with respect to each

applied load, so as to produce a failure in the joist hanger, or of

header shall be measured with a minimum of two dial gages or

the fasteners between the joist hanger and the joist or header

other suitable device as depicted in Fig. 3. The dial gage shall

member(s)orajoistbearingfailureatthehanger.Thelengthof

measure movement of any point along the depth of the joist

joist reinforcement shall be no closer than 2 in. (51 mm) from

(top, bottom, or side) located within 1.5 in. (38 mm) from the

the end of each hanger.

end of the joist. Dial gage bases shall be attached to the bottom

9.6 Blockingbetweentheheadersoralternatemethodsshall

half of the header to the center of the gage base or attached to

be provided to prevent rotation of the headers inward towards

the test machine bed.

the joist. Tensile reinforcement between the headers shall be

11.2.1 Exception—Whenthejoistsetupisinvertedforuplift

permittedtopreventrotationoftheheadersoutwardawayfrom

testing, the dial gage or other suitable device shall be located

the joist. Such reinforcement shall not contact the joist hangers

on the joist within 1 in. (25 mm) from the end of the hanger

or otherwise interfere with their performance.

seat.

9.7 Where a hanger device is of a design that is not

11.3 The load shall be centered over the joist and be

adaptable to the test setup described above, necessary depar-

transferredfromthecrossheadtothetestspecimeninamanner

tures shall be permitted, provided the altered setup will

thatwillassureequaldistributionoftheloadtobothendsofthe

perform the essential function of testing the joist hanger

joist. The load shall be applied over a sufficient joist length to

device, and provided that such departures are reported in the

prevent excessive crushing under the loading head and shall

test report in detail.

conform to the requirements of Section 9.

10. Conditioning 11.4 For downward

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.