ASTM E1561-93(2003)

(Practice)Standard Practice for Analysis of Strain Gage Rosette Data

Standard Practice for Analysis of Strain Gage Rosette Data

ABSTRACT

This practice defines a reference axis for each of the two principal types of rosette configurations and the equations used for three-element strain gage rosette data analysis. The primary uses of this analysis procedure are to determine the directions and magnitudes of the principal surface strains, and to determine residual stresses. This is important for consistency in reporting results and for avoiding ambiguity in data analysis, especially when computers are used. There are several possible sets of equations, but the set presented herein is perhaps the most common.

SCOPE

1.1 The two primary uses of three-element strain gage rosettes are (a) to determine the directions and magnitudes of the principal surface strains and (b) to determine residual stresses. Residual stresses are treated in a separate ASTM standard, Test Method E837. This practice defines a reference axis for each of the two principal types of rosette configurations used and presents equations for data analysis. This is important for consistency in reporting results and for avoiding ambiguity in data analysis-especially when computers are used. There are several possible sets of equations, but the set presented here is perhaps the most common.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E 1561 – 93 (Reapproved 2003)

Standard Practice for

Analysis of Strain Gage Rosette Data

This standard is issued under the fixed designation E 1561; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

There can be considerable confusion in interpreting and reporting the results of calculations

involving strain gage rosettes, particularly when data are exchanged between different laboratories.

Thus, it is necessary that users adopt a common convention for identifying the positions of the gages

and for analyzing the data.

1. Scope

1.1 The two primary uses of three-element strain gage

rosettes are (a) to determine the directions and magnitudes of

the principal surface strains and (b) to determine residual

stresses. Residual stresses are treated in a separate ASTM

standard, Test Method E 837. This practice defines a reference

axis for each of the two principal types of rosette configura-

tions used and presents equations for data analysis. This is

important for consistency in reporting results and for avoiding

ambiguity in data analysis—especially when computers are

used. There are several possible sets of equations, but the set

presented here is perhaps the most common.

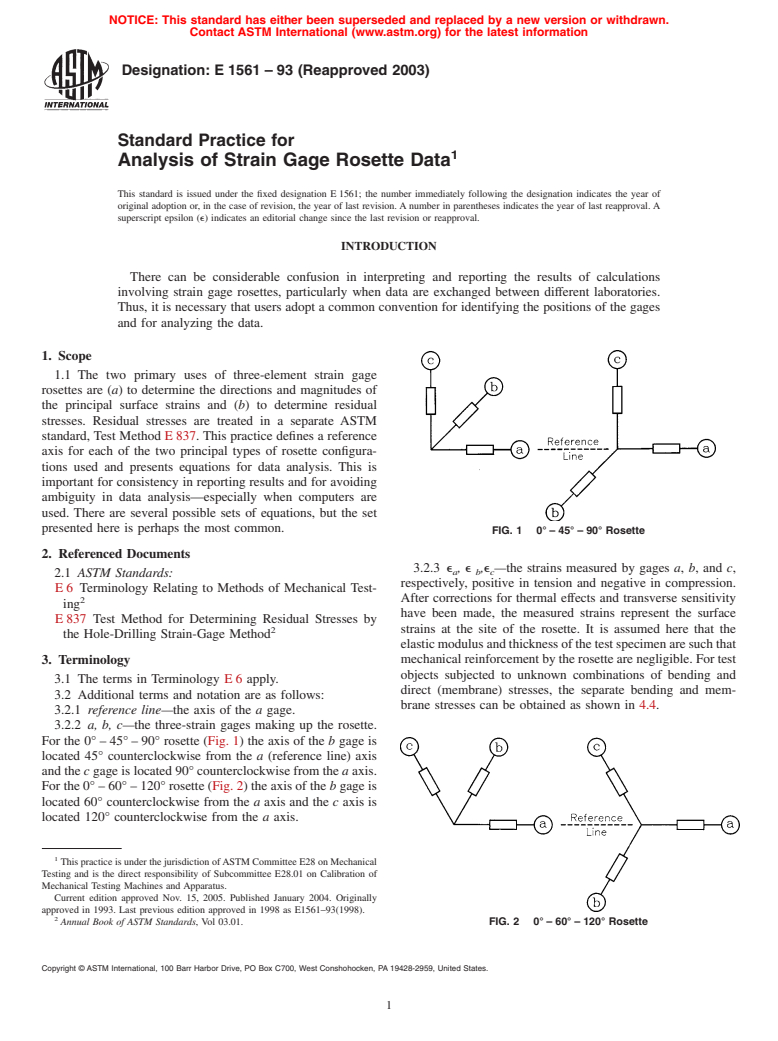

FIG. 1 0° – 45° – 90° Rosette

2. Referenced Documents

3.2.3 e , e ,e —the strains measured by gages a, b, and c,

a b c

2.1 ASTM Standards:

respectively, positive in tension and negative in compression.

E6 Terminology Relating to Methods of Mechanical Test-

2 After corrections for thermal effects and transverse sensitivity

ing

have been made, the measured strains represent the surface

E 837 Test Method for Determining Residual Stresses by

2 strains at the site of the rosette. It is assumed here that the

the Hole-Drilling Strain-Gage Method

elasticmodulusandthicknessofthetestspecimenaresuchthat

3. Terminology mechanical reinforcement by the rosette are negligible. For test

objects subjected to unknown combinations of bending and

3.1 The terms in TerminologyE6 apply.

direct (membrane) stresses, the separate bending and mem-

3.2 Additional terms and notation are as follows:

brane stresses can be obtained as shown in 4.4.

3.2.1 reference line—the axis of the a gage.

3.2.2 a, b, c—the three-strain gages making up the rosette.

For the 0° – 45° – 90° rosette (Fig. 1) the axis of the b gage is

located 45° counterclockwise from the a (reference line) axis

and the c gage is located 90° counterclockwise from the a axis.

For the 0° – 60° – 120° rosette (Fig. 2) the axis of the b gage is

located 60° counterclockwise from the a axis and the c axis is

located 120° counterclockwise from the a axis.

This practice is under the jurisdiction ofASTM Committee E28 on Mechanical

Testing and is the direct responsibility of Subcommittee E28.01 on Calibration of

Mechanical Testing Machines and Apparatus.

Current edition approved Nov. 15, 2005. Published January 2004. Originally

approved in 1993. Last previous edition approved in 1998 as E1561–93(1998).

Annual Book of ASTM Standards, Vol 03.01. FIG. 2 0° – 60° – 120° Rosette

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E 1561 – 93 (2003)

3.2.4 e8 , e8 , e8 —reduced membrane strain components

a b c

(4.4).

3.2.5 e9 , e9 ,e9 —reducedbendingstraincomponents(4.4).

a b c

3.2.6 e —the calculated maximum (more tensile or less

compressive) principal strain.

3.2.7 e —the calculated minimum (less tensile or more

compressive) principal strain.

3.2.8 g —the calculated maximum shear strain.

M

FIG. 4 Differential Element on the Undeformed Surface

3.2.9 u —the angle from the reference line to the direction

of e . This angle is less than or equal to 180° in magnitude.

3.2.10 C, R—values used in the calculations. C is the

location, along the e-axis, of the center of the Mohr’s circle for

strain and R is the radius of that circle.

4. Procedure

4.1 Fig. 3 shows a typical Mohr’s circle of strain for a

0° – 45° – 90° rosette. The calculations when e , e , e , are

a b c

given are:

FIG. 5 Deformed Shape of Differential Element

e 1e

a c

C 5 (1)

2 2

R 5 =~e 2 C! 1 ~e 2 C! (2)

a b

e 5 C 1 R (3)

e 5 C 2 R

g 5 2R

M

tan 2u 5 2 ~e 2 C! / e 2e (4)

1 b a c

4.1.1 If e

b 1

reference line.

4.1.2 If e >C, then the e -axis is counterclockwise from the

b 1

FIG. 6 Planes of Maximum Shear Strain

reference line.

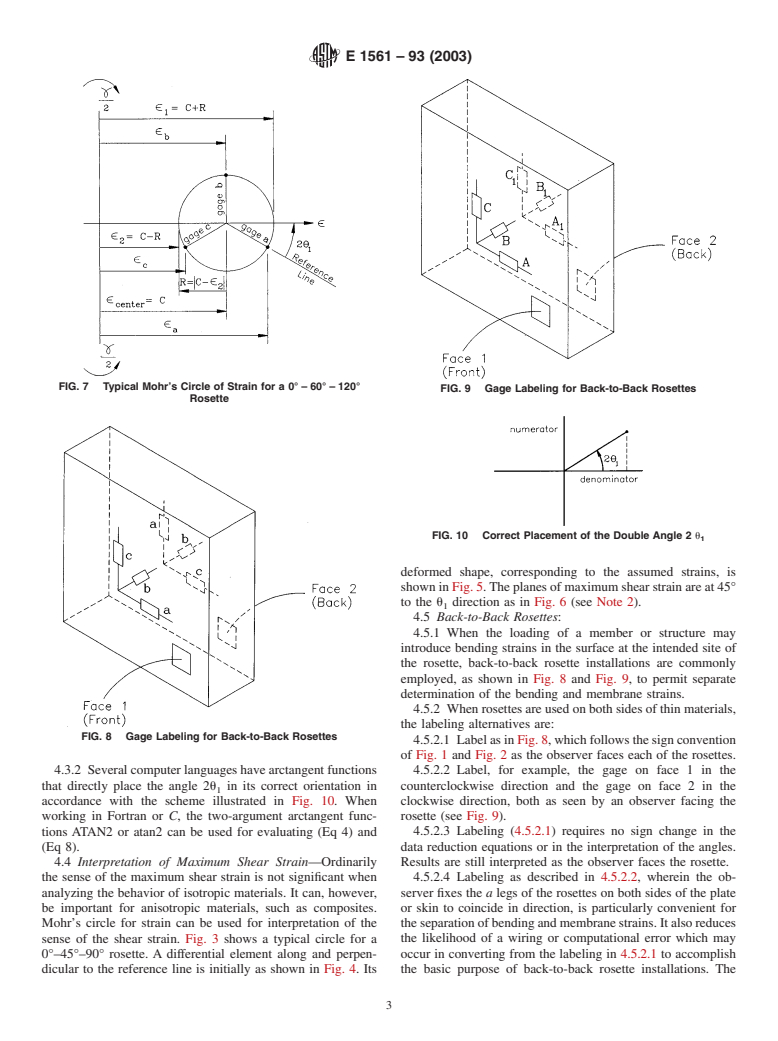

4.2 Fig. 7 shows a typical Mohr’s circle of strain for a

2 2 2

R 5 =2 3@~e 2 C! 1 ~e 2 C! 1 ~e 2 C! # (6)

/ a b c

0° – 60° – 120° rosette. The calculations when e , e , e , are

a b c

e 5 C 1 R (7)

given are:

e 5 C 2 R

e 1e 1e

a b c

C 5 (5)

g 5 2R

M

~e 2e !

b c

tan 2u 5 (8)

3~e 2 C!

=

a

4.2.1 If e − e < 0, then the e -axis is counterclockwise

c b 1

from the reference line.

4.2.2 If e − e = 0, then u = 0°.

c b 1

4.2.3 If e − e > 0, then the e -axis is clockwise from the

c b 1

reference line (see Note 1).

4.3 Identification of the Maximum Principal Strain Direc-

tion:

4.3.1 Care must be taken when determining the angle u

using (Eq 4) or (Eq 8) so that the calculated angle refers to the

direction of the maximum principal strain e rather than the

minimum principal strain e . Fig. 10 shows how the double

angle 2u can be placed in its correct orientation relative to the

reference line shown in Fig. 1 and Fig. 2. The terms “numera-

tor”and“denominator”refertothenumeratoranddenominator

of the right-hand sides of (Eq 4) and (Eq 8). When both

numerator and denominator are positive, as shown in Fig. 10,

the double angle 2u lies within the range 0° # 2u# 90°

1 1

counterclockwise of the reference line. Therefore, in this

particularcase,thecorrespondingangle u lieswithintherange

FIG. 3 Typical Mohr’s Circle of Strain for a 0° – 45° – 90° 1

Rosette 0°# u# 45° counterclockwise of the reference line.

E 1561 – 93 (2003)

FIG. 7 Typical Mohr’s Circle of Strain for a 0° – 60° – 120°

FIG. 9 Gage Labeling for Back-to-Back Rosettes

Rosette

FIG. 10 Correct Placement of the Double Angle 2 u

deformed shape, corresponding to the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.