ASTM A1-00(2005)

(Specification)Standard Specification for Carbon Steel Tee Rails

Standard Specification for Carbon Steel Tee Rails

ABSTRACT

This specification deals with carbon steel tee rails for use in railway track, including export and industrial applications. Rails shall be furnished by as-rolling, head hardening, or fully heat treatment processes. Hydrogen content shall be measured either during the continuous casting process or during ingot teeming. The rails shall conform to the chemical requirements for carbon, manganese, phosphorus, sulfur, and silicon. Rail soundness shall be evaluated by macroetch testing for both ingot and continuously cast steel. The rails shall conform to the Brinell hardness test requirements for standard carbon rails and high-strength rails.

SCOPE

1.1 This specification covers carbon steel tee rails of nominal weights of 60 lb/yd (29.8 kg/m) and over for use in railway track, including export and industrial applications.

1.2 Supplementary requirementsS1and S2 shall apply only when specified by the purchaser in the order.

1.3 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A1 – 00 (Reapproved 2005)

Standard Specification for

1

Carbon Steel Tee Rails

This standard is issued under the fixed designationA1; the number immediately following the designation indicates the year of original

adoptionor,inthecaseofrevision,theyearoflastrevision.Anumberinparenthesesindicatestheyearoflastreapproval.Asuperscript

epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

1. Scope 3.1.3 Quantity (tons or pieces as appropriate).

3.1.4 Full identification of section with dimensional draw-

1.1 This specification covers carbon steel tee rails of nomi-

ing, if required.

nalweightsof60lb/yd(29.8kg/m)andoverforuseinrailway

3.1.5 Arrangement of drilled bolt holes, if any, with dimen-

track, including export and industrial applications.

sional drawing, if required.

1.2 SupplementaryrequirementsS1andS2shallapplyonly

3.1.6 Quantity of right-hand and left-hand (Note 1) drilled

when specified by the purchaser in the order.

rails, drilled both-end rails, and undrilled (blank) rails desired.

1.3 The values stated in inch-pound units are to be regarded

3.1.7 Supplementary requirements that shall apply (see S1

as the standard. The values given in parentheses are for

and S2).

information only.

3.1.8 Dispositionofvariousclassificationsofrails(see8.3.6

2. Referenced Documents

and 8.3.7).

2

2.1 ASTM Standards:

NOTE 1—The right-hand or left-hand end of the rail is determined by

A29/A29M Specification for Steel Bars, Carbon andAlloy,

facing the side of the rail on which the brand (raised characters) appears.

Hot-Wrought, General Requirements for

4. Materials and Manufacture

A700 PracticesforPackaging,Marking,andLoadingMeth-

ods for Steel Products for Shipment 4.1 Rail Types—Rails shall be furnished as-rolled (standard

E10 TestMethodforBrinellHardnessofMetallicMaterials and alloy), head hardened (on-line or off-line processes), or

E127 Practice for Fabricating and Checking Aluminum fullyheattreatedasagreeduponbetweenthepurchaserandthe

Alloy Ultrasonic Standard Reference Blocks manufacturer.

E428 Practice for Fabrication and Control of Metal, Other 4.2 Melting Practice—Thesteelshallbemadebyanyofthe

than Aluminum, Reference Blocks Used in Ultrasonic following processes: basic-oxygen or electric-furnace.

Testing 4.2.1 The steel shall be cast by a continuous process, in

2.2 American Railway Engineering and Maintenance of hot-topped ingots, or by other methods agreed upon between

Way Association (AREMA) Manual for Railway Engineering: the purchaser and the manufacturer.

3,4

Specifications for Steel Rails, Chapter 4, Part 2 4.3 Discard—Sufficient discard shall be taken from the

bloom or ingot to ensure freedom from injurious segregation

3. Ordering Information

and pipe.

3.1 Ordersforrailsunderthisspecificationshallincludethe 4.4 Hydrogen Elimination:

following information:

4.4.1 Applicability:

3.1.1 ASTM designation and year of issue. 4.4.1.1 Rails 60 through 70 lb/yd (29.8 through 34.8 kg/m)

3.1.2 Type of rail desired.

are not subject to treatment for hydrogen elimination.

4.4.1.2 Rails over 70 through 84 lb/yd (over 34.8 through

41.7 kg/m) may be subjected to treatment for hydrogen

1

This specification is under the jurisdiction ofASTM CommitteeA01 on Steel,

elimination at the option of the manufacturer.

Stainless Steel and RelatedAlloys and is the direct responsibility of Subcommittee

A01.01 on Steel Rails and Accessories. 4.4.1.3 Rails over 84 lb/yd (41.7 kg/m) shall be processed

Current edition approved March 1, 2005. Published March 2005. Originally

by methods that prevent the formation of shatter cracks as

approved in 1901. Last previous edition approved in 2000 as A1–00. DOI:

agreed upon between the purchaser and the manufacturer.

10.1520/A0001-00R05.

2

4.4.2 Rail heats shall be tested for hydrogen content using

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

either a sampling/analytical method or a direct measurement

Standards volume information, refer to the standard’s Document Summary page on

methodoftheliquidsteel.Thetestingshallbeperformedeither

the ASTM website.

during the continuous casting process or during ingot teeming.

3

AvailablefromAmericanRailwayEngineeringandMaintenanceofWayAssn.,

Hydrogencontentshallberecordedandavailableforreviewor

8201 Corporate Drive, Suite 1125, Landover, MD 20785.

4

Adapted from AREMA Specifications for Steel Rails (see 2.2).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

A1 – 00 (2005)

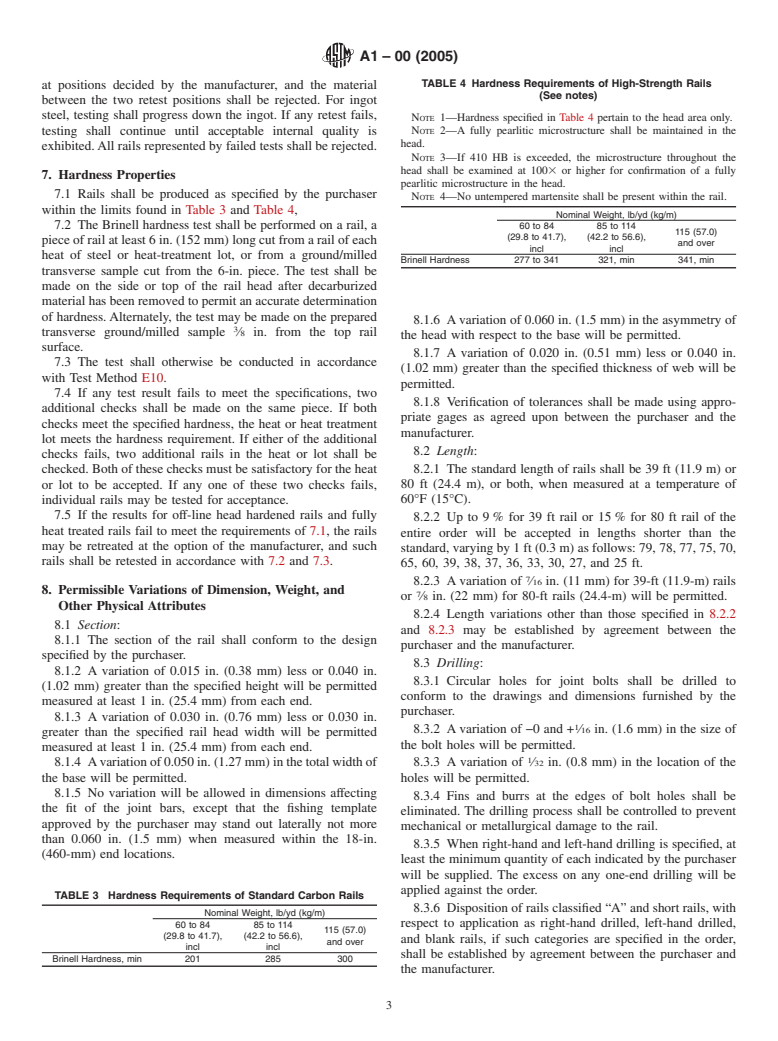

TABLE 1 Chemical Requirements—Heat Analysis

reporting at the request of the purchaser. The producer sha

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.