ASTM D1494-97(2001)e1

(Test Method)Standard Test Method for Diffuse Light Transmission Factor of Reinforced Plastics Panels

Standard Test Method for Diffuse Light Transmission Factor of Reinforced Plastics Panels

SIGNIFICANCE AND USE

The purpose of this test method is to obtain the diffuse light transmittance factor of both flat and corrugated translucent building panels by the use of simple apparatus and by employing as a light source a combination of fluorescent tubes whose energy distribution closely approximates CIE Source C.

SCOPE

1.1 This test method covers the determination of the diffuse light transmission factor of translucent reinforced plastics building panels.

1.2 The values stated in SI units are to be regarded as the standard. The values given in the parentheses are for information only.

1.3 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in Tables and Figures) shall not be considered as requirements of this standard.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

Note 1—There are no ISO standards covering the subject matter of this specification.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:D 1494–97 (Reapproved 2001)

Standard Test Method for

Diffuse Light Transmission Factor of Reinforced Plastics

Panels

This standard is issued under the fixed designation D 1494; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

e NOTE—Adjunct references were corrected editorially in April 2006.

1. Scope* Test Cabinet for Diffuse Light Transmission Factor of

Reinforced Panels

1.1 This test method covers the determination of the diffuse

light transmission factor of translucent reinforced plastics

3. Terminology

building panels.

3.1 General—Definitions are in accordance with Terminol-

1.2 The values stated in SI units are to be regarded as the

ogy D 883 and abbreviations withTerminology D 1600, unless

standard. The values given in the parentheses are for informa-

otherwise indicated.

tion only.

1.3 The text of this standard references notes and footnotes

4. Significance and Use

which provide explanatory material. These notes and footnotes

4.1 The purpose of this test method is to obtain the diffuse

(excluding those inTables and Figures) shall not be considered

light transmittance factor of both flat and corrugated translu-

as requirements of this standard.

cent building panels by the use of simple apparatus and by

1.4 This standard does not purport to address all of the

employing as a light source a combination of fluorescent tubes

safety concerns, if any, associated with its use. It is the

whose energy distribution closely approximates CIE Source C.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

5. Apparatus

bility of regulatory limitations prior to use.

5.1 The apparatus for this test method shall consist of a

NOTE 1—TherearenoISOstandardscoveringthesubjectmatterofthis

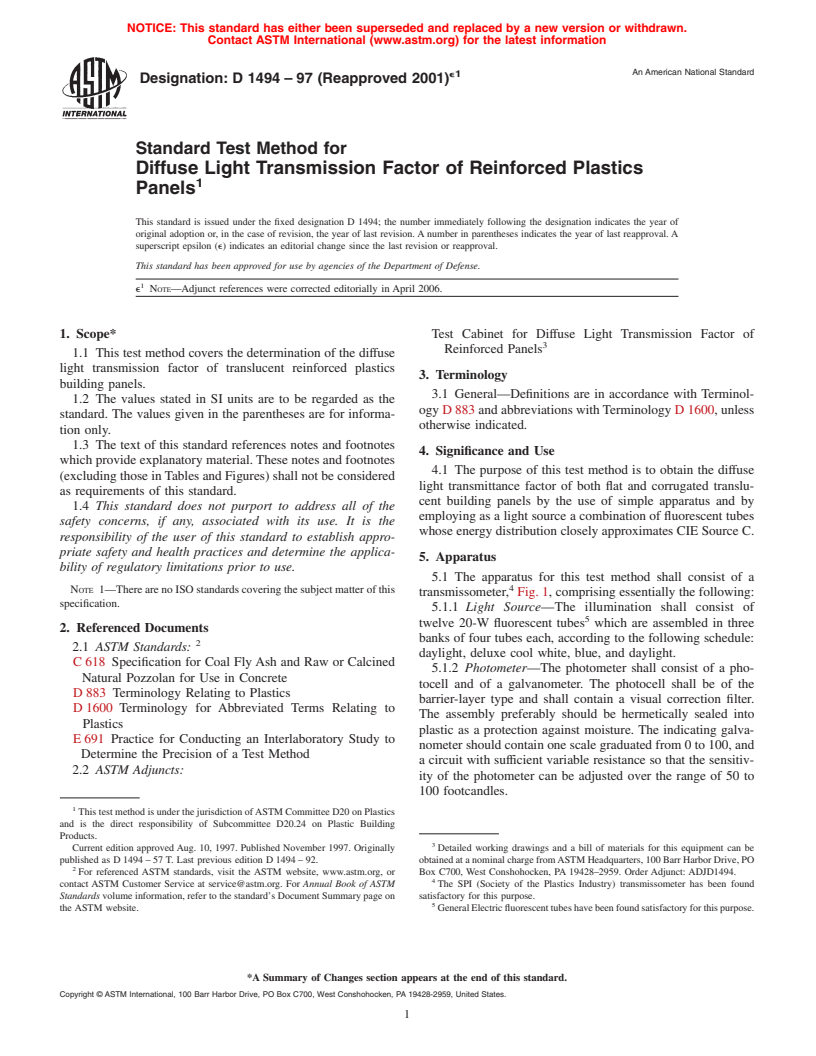

transmissometer, Fig. 1, comprising essentially the following:

specification.

5.1.1 Light Source—The illumination shall consist of

twelve 20-W fluorescent tubes which are assembled in three

2. Referenced Documents

banks of four tubes each, according to the following schedule:

2.1 ASTM Standards:

daylight, deluxe cool white, blue, and daylight.

C 618 Specification for Coal Fly Ash and Raw or Calcined

5.1.2 Photometer—The photometer shall consist of a pho-

Natural Pozzolan for Use in Concrete

tocell and of a galvanometer. The photocell shall be of the

D 883 Terminology Relating to Plastics

barrier-layer type and shall contain a visual correction filter.

D 1600 Terminology for Abbreviated Terms Relating to

The assembly preferably should be hermetically sealed into

Plastics

plastic as a protection against moisture. The indicating galva-

E 691 Practice for Conducting an Interlaboratory Study to

nometer should contain one scale graduated from 0 to 100, and

Determine the Precision of a Test Method

a circuit with sufficient variable resistance so that the sensitiv-

2.2 ASTM Adjuncts:

ity of the photometer can be adjusted over the range of 50 to

100 footcandles.

This test method is under the jurisdiction ofASTM Committee D20 on Plastics

and is the direct responsibility of Subcommittee D20.24 on Plastic Building

Products.

Current edition approved Aug. 10, 1997. Published November 1997. Originally Detailed working drawings and a bill of materials for this equipment can be

published as D 1494 – 57 T. Last previous edition D 1494 – 92. obtained at a nominal charge fromASTM Headquarters, 100 Barr Harbor Drive, PO

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Box C700, West Conshohocken, PA 19428–2959. Order Adjunct: ADJD1494.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM The SPI (Society of the Plastics Industry) transmissometer has been found

Standards volume information, refer to the standard’s Document Summary page on satisfactory for this purpose.

the ASTM website. GeneralElectricfluorescenttubeshavebeenfoundsatisfactoryforthispurpose.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 1494–97 (2001)

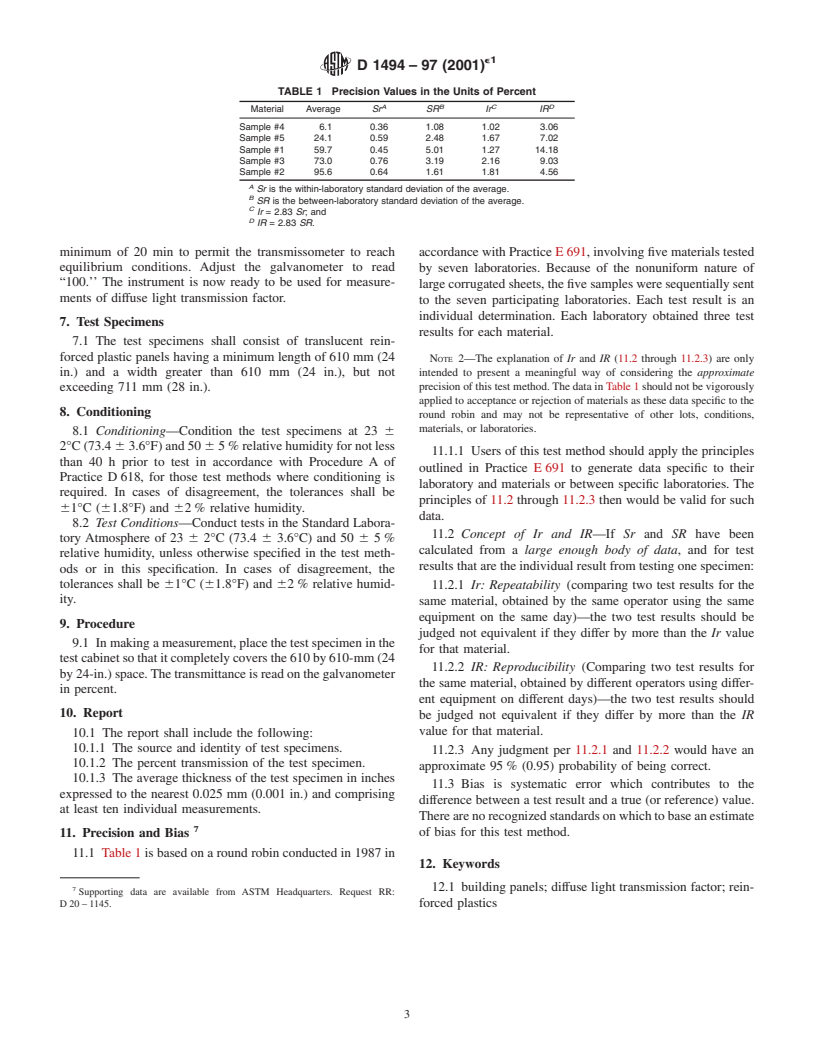

Metric Equivalents

in. mm in. mm in. mm in. mm

1 3 3 3

⁄32 0.8 ⁄4 19.1 8 ⁄4 222 24 ⁄4 634

3 1 3 1

⁄16 4.8 1 ⁄4 31.8 9 ⁄4 248 25 ⁄2 648

7 1

⁄37 5.6 1 ⁄2 38.1 12 305 28 711

1 1

⁄4 6.4 2 50.8 14 356 29 ⁄2 749

9 3 1

⁄32 7.1 6 ⁄4 172 24 610 38 ⁄2 978

⁄8 9.5

FIG. 1 Assembly Drawing of Transmissometer

5.1.3 Test Cabinet, constructed in accordance with the 5.1.3.4 The photocell shall be positioned below the center

following dimensions. axis of the test specimen so that the distance from the bottom

of the specimen to the top of the cell is 283 6 0.8 mm (11 ⁄8

5.1.3.1 The transmitted area of the test specimen shall be

1 1

6 ⁄32 in.).

610 6 1.6 mm by 610 6 1.6 mm (24 6 ⁄16 in. by 24 6 ⁄16

5.1.3.5 A masking plate containing a 31.8-mm (1 ⁄4-in.)

in.).

diameter hole in its center shall be placed between the test

5.1.3.2 The distance from the bottom of the fluorescent

specimen and the photocell so that the distance from the

tubes to the bottom of the test specimen shall be 203 6 0.8 mm

bottom of the test specimen to the bottom of the masking plate

(8 6 ⁄32 in.).

3 1

shall be 233 6 0.8 mm (9 ⁄4 6 ⁄32 in.).

5.1.3.3 A 4.8-mm ( ⁄16-in.) thick, white, standard outdoor,

translucent diffusing plate shall be placed between the light

6. Standardization of Transmissometer

source and the test specimen so that the distance from the

6.1 Center the photocell beneath the 31.8-mm (1 ⁄4-in.)

bottom of the diffusing plate to the bottom of the test specimen

diameter hole in the bottom masking plate. Place the galva-

1 1

is 31.8 6 0.8 mm (1 ⁄4 6 ⁄32 in.).

nometer in a flat level position. Ensure that no current flows in

the electrical circu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.