ASTM C947-03(2009)

(Test Method)Standard Test Method for Flexural Properties of Thin-Section Glass-Fiber-Reinforced Concrete (Using Simple Beam With Third-Point Loading)

Standard Test Method for Flexural Properties of Thin-Section Glass-Fiber-Reinforced Concrete (Using Simple Beam With Third-Point Loading)

SIGNIFICANCE AND USE

Flexural properties determined by this test method are useful for quality control of glass-fiber reinforced concrete products, ascertaining compliance with the governing specifications, research and development, and generating data for use in product design.

SCOPE

1.1 This test method covers determination of the flexural ultimate strength in bending and the yield strength of glass-fiber reinforced concrete sections by the use of a simple beam of 1.0 in. (25.4 mm) or less in depth using third-point loading.

1.2 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C947 −03(Reapproved 2009)

Standard Test Method for

Flexural Properties of Thin-Section Glass-Fiber-Reinforced

Concrete (Using Simple Beam With Third-Point Loading)

This standard is issued under the fixed designation C947; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope exceed 61.0 %ofthemaximumforceexpectedtobemeasured

shall be used. The testing machine shall be equipped with a

1.1 This test method covers determination of the flexural

deflection measuring and recording device. The stiffness of the

ultimate strength in bending and the yield strength of glass-

testing machine shall be such that the total elastic deformation

fiber reinforced concrete sections by the use of a simple beam

of the system does not exceed 1.0 % of the total deflection of

of 1.0 in. (25.4 mm) or less in depth using third-point loading.

the test specimen during the test, or appropriate corrections

1.2 The values stated in inch-pound units are to be regarded

shall be made. The force-indicating mechanism shall be

as the standard. The values given in parentheses are for

essentially free of inertial lag at the crosshead rate used. The

information only.

accuracy of the testing machine shall be verified in accordance

1.3 This standard does not purport to address all of the

with Practices E4 and Specification D76.

safety concerns, if any, associated with its use. It is the

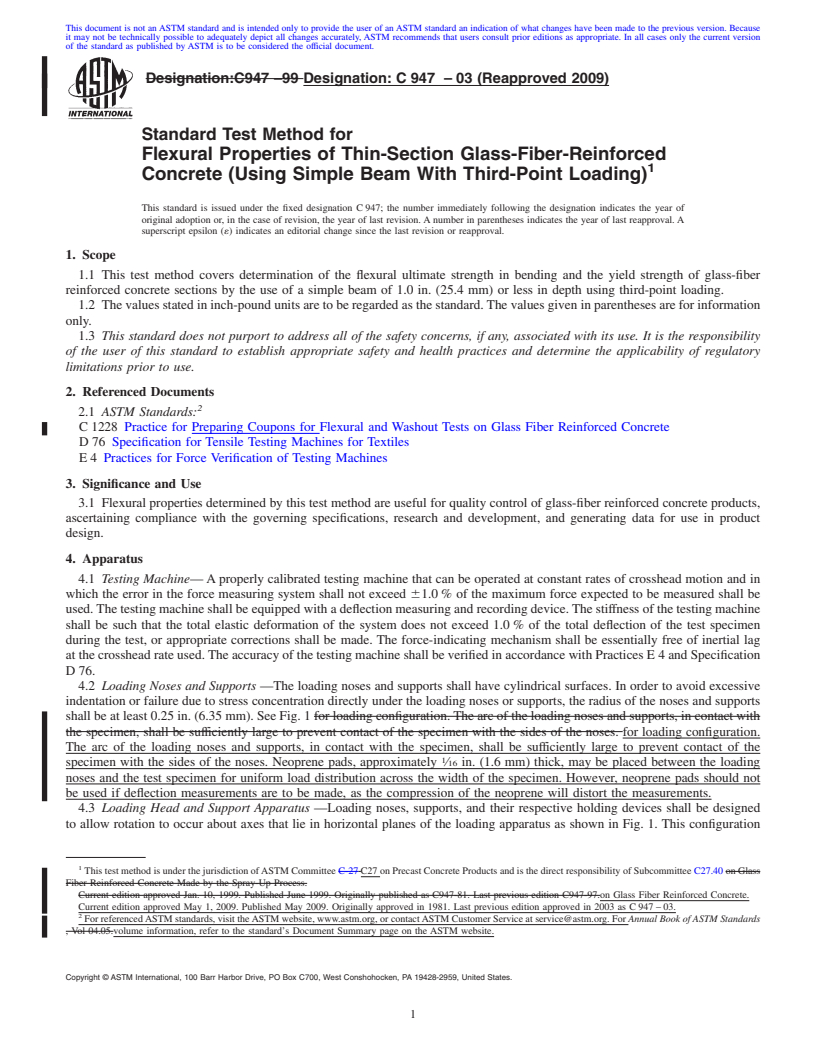

4.2 Loading Noses and Supports —The loading noses and

responsibility of the user of this standard to establish appro-

supports shall have cylindrical surfaces. In order to avoid

priate safety and health practices and determine the applica-

excessive indentation or failure due to stress concentration

bility of regulatory limitations prior to use.

directly under the loading noses or supports, the radius of the

2. Referenced Documents

nosesandsupportsshallbeatleast0.25in.(6.35mm).SeeFig.

1 for loading configuration. The arc of the loading noses and

2.1 ASTM Standards:

supports, in contact with the specimen, shall be sufficiently

C1228 Practice for Preparing Coupons for Flexural and

large to prevent contact of the specimen with the sides of the

Washout Tests on Glass Fiber Reinforced Concrete

noses. Neoprene pads, approximately ⁄16 in. (1.6 mm) thick,

D76 Specification for Tensile Testing Machines for Textiles

maybeplacedbetweentheloadingnosesandthetestspecimen

E4 Practices for Force Verification of Testing Machines

for uniform load distribution across the width of the specimen.

3. Significance and Use

However, neoprene pads should not be used if deflection

measurements are to be made, as the compression of the

3.1 Flexural properties determined by this test method are

neoprene will distort the measurements.

useful for quality control of glass-fiber reinforced concrete

products, ascertaining compliance with the governing

4.3 LoadingHeadandSupportApparatus—Loading noses,

specifications, research and development, and generating data

supports,andtheirrespectiveholdingdevicesshallbedesigned

for use in product design.

to allow rotation to occur about axes that lie in horizontal

planes of the loading apparatus as shown in Fig. 1. This

4. Apparatus

configuration of loading head and support apparatus will

4.1 Testing Machine— A properly calibrated testing ma-

ensure that forces applied to the specimen will be initially

chinethatcanbeoperatedatconstantratesofcrossheadmotion

perpendicular to the surfaces of the specimen and applied

and in which the error in the force measuring system shall not

without eccentricity.

4.4 Specimen Depth and Width Measuring Device—A cali-

This test method is under the jurisdiction ofASTM Committee C27 on Precast

per or micrometer or other suitable device that is able to

Concrete Products and is the direct responsibility of Subcommittee C27.40 on Glass

measure sample depth accurate to 0.005 in. (0.13 mm) and

Fiber Reinforced Concrete.

Current edition approved May 1, 2009. Published May 2009. Originally

width accurate to 0.01 in. (0.25 mm).

approved in 1981. Last previous edition approved in 2003 as C947 – 03. DOI:

10.1520/C0947-03R09.

2 5. Sampling

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

5.1 Test boards shall be manufactured in accordance with

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. governing specifications.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

C947−03 (2009)

8.4 Center the specimen on the supports with equal lengths

of specimen projecting outside of the supports with the long

axis of the specimen perpendicular to the loading noses and

supports.

8.5 Test three specimens with the mold face in tension and

three specimens with the opposite face (or trowelled face) in

tension.

8.6 Set the crosshead speed of the testing machine at 0.05 to

0.20 in./min (1.27 to 5.1 mm/min). Set the chart speed to 75 6

25 times the crosshead speed being used. Set the initial load

measuring range such that the flexural yield strength (F ) load

y

occurs at not less than 30 % of full scale. Apply force at a

constant crosshead speed to specimen failure. Examine the

failure location of the specimen. If failure occurs outside the

minor span, discard the specimen and specimen test data.

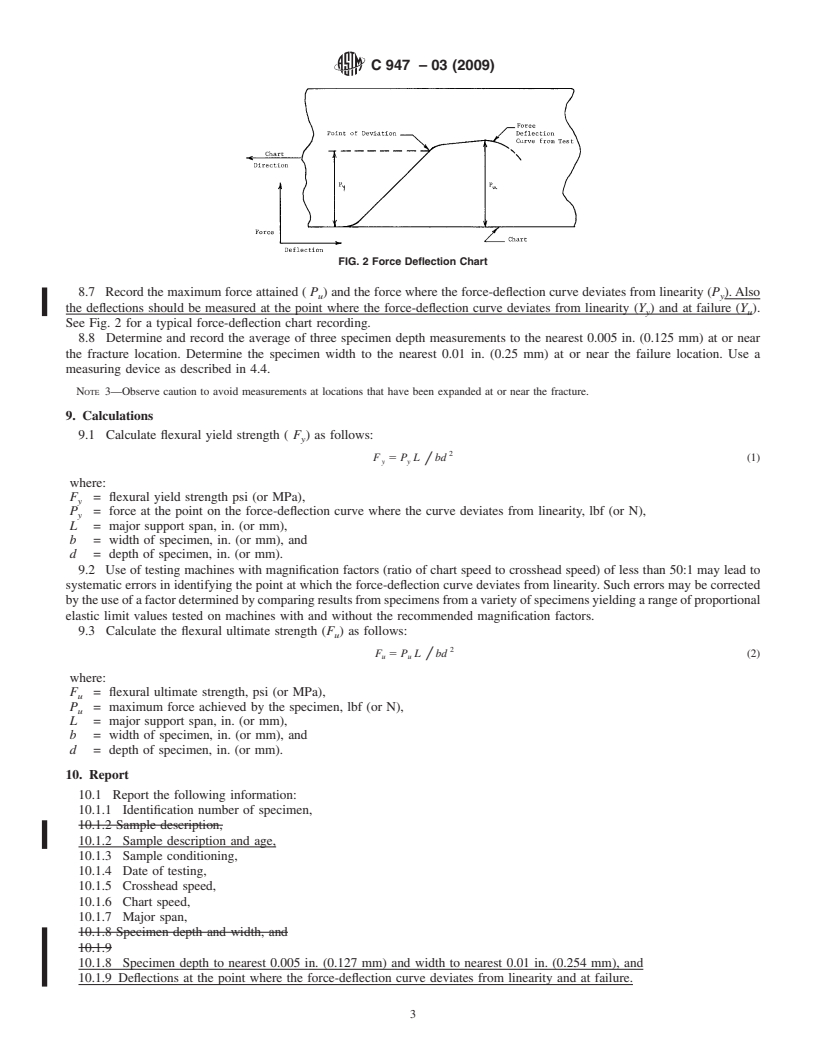

NOTE 2—The chart speed may be reduced or stopped after the

force-deflection curve reaches its point of deviation from linearity (P in

y

Fig. 2) to conserve chart paper.

8.7 Record the maximum force attained ( P ) and the force

u

FIG. 1 Loading Configuration for Flexural Testing

where the force-deflection curve deviates from linearity (P ).

y

Also the deflections should be measured at the point where the

force-deflectioncurvedeviatesfromlinearity(Y )andatfailure

y

(Y ). See Fig. 2 for a typical force-deflec

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation:C947 –99 Designation: C 947 – 03 (Reapproved 2009)

Standard Test Method for

Flexural Properties of Thin-Section Glass-Fiber-Reinforced

Concrete (Using Simple Beam With Third-Point Loading)

This standard is issued under the fixed designation C 947; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers determination of the flexural ultimate strength in bending and the yield strength of glass-fiber

reinforced concrete sections by the use of a simple beam of 1.0 in. (25.4 mm) or less in depth using third-point loading.

1.2 The values stated in inch-pound units are to be regarded as the standard.The values given in parentheses are for information

only.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

C 1228 Practice for Preparing Coupons for Flexural and Washout Tests on Glass Fiber Reinforced Concrete

D76 Specification for Tensile Testing Machines for Textiles

E4 Practices for Force Verification of Testing Machines

3. Significance and Use

3.1 Flexural properties determined by this test method are useful for quality control of glass-fiber reinforced concrete products,

ascertaining compliance with the governing specifications, research and development, and generating data for use in product

design.

4. Apparatus

4.1 Testing Machine—Aproperly calibrated testing machine that can be operated at constant rates of crosshead motion and in

which the error in the force measuring system shall not exceed 61.0 % of the maximum force expected to be measured shall be

used.The testing machine shall be equipped with a deflection measuring and recording device.The stiffness of the testing machine

shall be such that the total elastic deformation of the system does not exceed 1.0 % of the total deflection of the test specimen

during the test, or appropriate corrections shall be made. The force-indicating mechanism shall be essentially free of inertial lag

at the crosshead rate used.The accuracy of the testing machine shall be verified in accordance with Practices E 4 and Specification

D 76.

4.2 Loading Noses and Supports —The loading noses and supports shall have cylindrical surfaces. In order to avoid excessive

indentation or failure due to stress concentration directly under the loading noses or supports, the radius of the noses and supports

shall be at least 0.25 in. (6.35 mm). See Fig. 1 for loading configuration.The arc of the loading noses and supports, in contact with

the specimen, shall be sufficiently large to prevent contact of the specimen with the sides of the noses. for loading configuration.

The arc of the loading noses and supports, in contact with the specimen, shall be sufficiently large to prevent contact of the

specimen with the sides of the noses. Neoprene pads, approximately ⁄16 in. (1.6 mm) thick, may be placed between the loading

noses and the test specimen for uniform load distribution across the width of the specimen. However, neoprene pads should not

be used if deflection measurements are to be made, as the compression of the neoprene will distort the measurements.

4.3 Loading Head and Support Apparatus —Loading noses, supports, and their respective holding devices shall be designed

to allow rotation to occur about axes that lie in horizontal planes of the loading apparatus as shown in Fig. 1. This configuration

This test method is under the jurisdiction ofASTM Committee C-27 C27 on Precast Concrete Products and is the direct responsibility of Subcommittee C27.40 on Glass

Fiber Reinforced Concrete Made by the Spray-Up Process.

Current edition approved Jan. 10, 1999. Published June 1999. Originally published as C947-81. Last previous edition C947-97.on Glass Fiber Reinforced Concrete.

Current edition approved May 1, 2009. Published May 2009. Originally approved in 1981. Last previous edition approved in 2003 as C 947 – 03.

For referencedASTM standards, visit theASTM website, www.astm.org, or contactASTM Customer Service at service@astm.org. ForAnnualBookofASTMStandards

, Vol 04.05.volume information, refer to the standard’s Document Summary page on the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C 947 – 03 (2009)

FIG. 1 Loading Configuration for Flexural Testing

of loading head and support apparatus will ensure that forces applied to the specimen will be initially perpendicular to the surfaces

of the specimen and applied without eccentricity.

4.4 Specimen Depth and Width Measuring Device—A caliper or micrometer or other suitable device that is able to measure

sample depth accurate to 0.005 in. (0.13 mm) and width accurate to 0.01 in. (0.25 mm).

5. Sampling

5.1 Test boards shall be manufactured in accordance with governing specifications.

6. Test Specimen

6.1 Six test specimens shall be prepared in accordance with Practice C 1228.

6.2 The test specimen shall have a ratio of the specimen major span length to the specimen depth between 16 to 1 and 30 to

1.Thetotalspecimenlengthshallbeaminimumof1in.(25mm)longerthanthespecimen’smajorspan.Nominalspecimenwidth

shall be 2 in. (50 mm).

7. Conditioning

7.1 The sample or specimens shall be transported to the testing laboratory packaged so that no damage will take place.

7.2 Condition the samples or specimens in water at 73 6 5°F (23 6 3°C) for a period of 34 6 14minimum 24 h and maximum

72 h to ensure complete saturation and test immediately upon removal. Remove specimens from water bath individually and test.

Do not allow specimen surfaces to dry out either prior to or during the test. Specimen surfaces may be sprayed with water during

testing if indications of surface drying are prese

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.