ASTM F1606-05

(Practice)Standard Practice for Rehabilitation of Existing Sewers and Conduits with Deformed Polyethylene (PE) Liner

Standard Practice for Rehabilitation of Existing Sewers and Conduits with Deformed Polyethylene (PE) Liner

SIGNIFICANCE AND USE

This practice is to provide guidance for designers and specifiers, regulatory agencies, owners, and inspection organizations who are involved in the rehabilitation of conduits. Modifications may be required depending on specific job conditions to establish a project specification. The manufacturer of the product should be consulted for design and installation information.

SCOPE

1.1 This practice covers the requirements for the installation of deformed polyethylene (PE) liner for pipeline rehabilitation.

1.2 This practice describes a method by which the PE liner may be installed with little or no excavation.

1.3 This practice applies to the rehabilitation of 3 to 18- in. (76 to 457-mm) diameter pipe in terms of installation. The specifier determines what DR is used based on conditions of the specific application.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F1606 − 05 AnAmerican National Standard

Standard Practice for

Rehabilitation of Existing Sewers and Conduits with

1

Deformed Polyethylene (PE) Liner

This standard is issued under the fixed designation F1606; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 NASSCO Standard:

Recommended Specifications for Sewer Collection System

1.1 Thispracticecoverstherequirementsfortheinstallation

3

Rehabilitation

ofdeformedpolyethylene(PE)linerforpipelinerehabilitation.

1.2 This practice describes a method by which the PE liner

3. Terminology

may be installed with little or no excavation.

3.1 General—Abbreviations used in this practice are in

1.3 This practice applies to the rehabilitation of 3 to 18- in.

accordance with Terminology D1600, and definitions are in

(76 to 457-mm) diameter pipe in terms of installation. The

accordance with Terminology F412, unless otherwise indi-

specifier determines what DR is used based on conditions of

cated.

the specific application.

3.2 Definitions of Terms Specific to This Standard:

1.4 This standard does not purport to address all of the

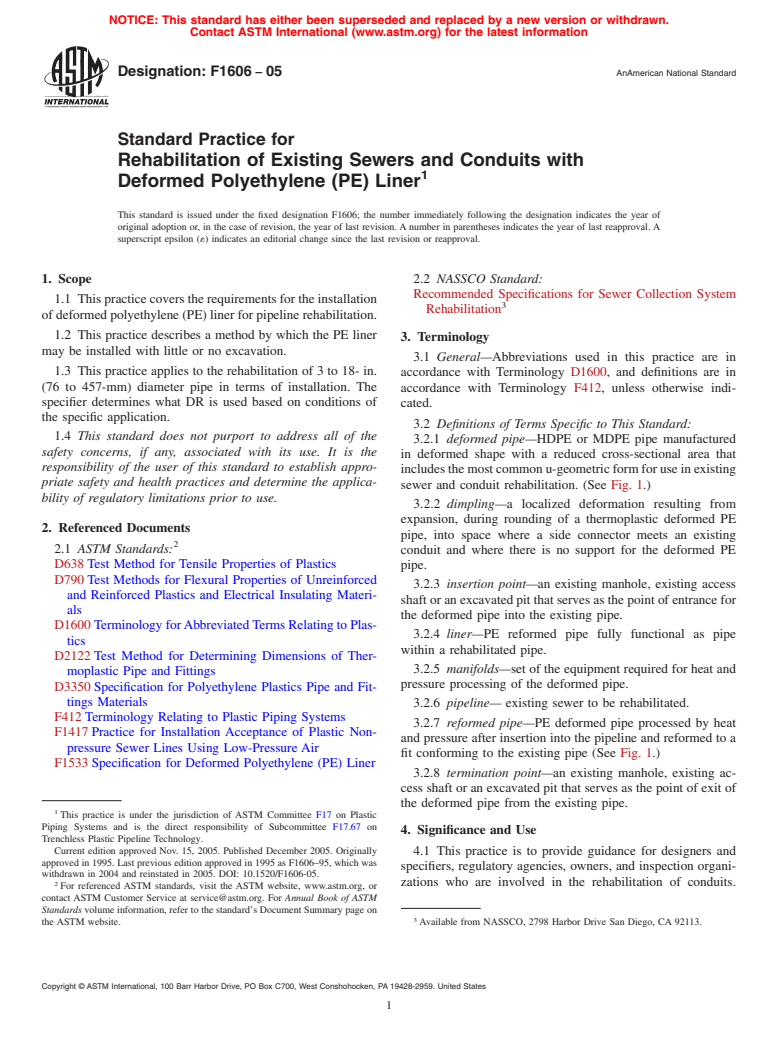

3.2.1 deformed pipe—HDPE or MDPE pipe manufactured

safety concerns, if any, associated with its use. It is the

in deformed shape with a reduced cross-sectional area that

responsibility of the user of this standard to establish appro-

includesthemostcommonu-geometricformforuseinexisting

priate safety and health practices and determine the applica-

sewer and conduit rehabilitation. (See Fig. 1.)

bility of regulatory limitations prior to use.

3.2.2 dimpling—a localized deformation resulting from

expansion, during rounding of a thermoplastic deformed PE

2. Referenced Documents

pipe, into space where a side connector meets an existing

2

2.1 ASTM Standards: conduit and where there is no support for the deformed PE

D638Test Method for Tensile Properties of Plastics

pipe.

D790Test Methods for Flexural Properties of Unreinforced

3.2.3 insertion point—an existing manhole, existing access

and Reinforced Plastics and Electrical Insulating Materi-

shaftoranexcavatedpitthatservesasthepointofentrancefor

als

the deformed pipe into the existing pipe.

D1600TerminologyforAbbreviatedTermsRelatingtoPlas-

3.2.4 liner—PE reformed pipe fully functional as pipe

tics

within a rehabilitated pipe.

D2122Test Method for Determining Dimensions of Ther-

3.2.5 manifolds—set of the equipment required for heat and

moplastic Pipe and Fittings

pressure processing of the deformed pipe.

D3350Specification for Polyethylene Plastics Pipe and Fit-

tings Materials

3.2.6 pipeline— existing sewer to be rehabilitated.

F412Terminology Relating to Plastic Piping Systems

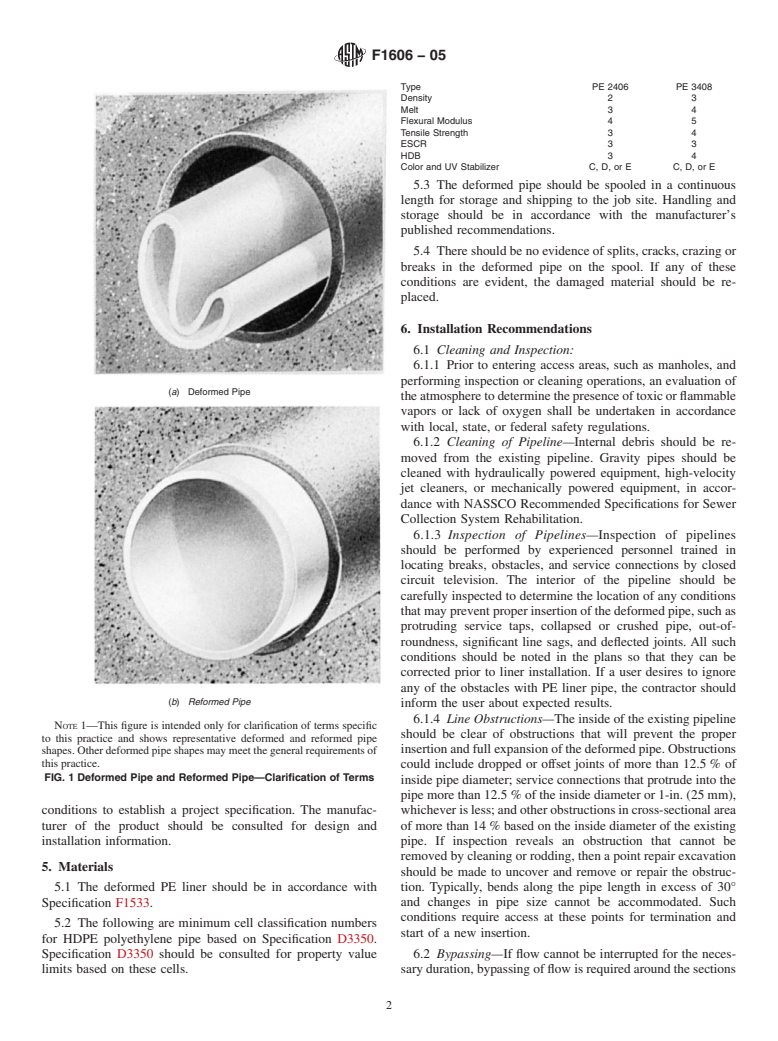

3.2.7 reformed pipe—PE deformed pipe processed by heat

F1417Practice for Installation Acceptance of Plastic Non-

and pressure after insertion into the pipeline and reformed to a

pressure Sewer Lines Using Low-Pressure Air

fit conforming to the existing pipe (See Fig. 1.)

F1533Specification for Deformed Polyethylene (PE) Liner

3.2.8 termination point—an existing manhole, existing ac-

cess shaft or an excavated pit that serves as the point of exit of

the deformed pipe from the existing pipe.

1

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

Piping Systems and is the direct responsibility of Subcommittee F17.67 on

4. Significance and Use

Trenchless Plastic Pipeline Technology.

Current edition approved Nov. 15, 2005. Published December 2005. Originally

4.1 This practice is to provide guidance for designers and

approved in 1995. Last previous edition approved in 1995 as F1606–95, which was

specifiers, regulatory agencies, owners, and inspection organi-

withdrawn in 2004 and reinstated in 2005. DOI: 10.1520/F1606-05.

zations who are involved in the rehabilitation of conduits.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

3

the ASTM website. Available from NASSCO, 2798 Harbor Drive San Diego, CA 92113.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F1606 − 05

Modifications may be required depending on specific job

1

---------------------- Page: 2 ----------------------

F1606 − 05

Type PE 2406 PE 3408

Density 2 3

Melt 3 4

Flexural Modulus 4 5

Tensile Strength 3 4

ESCR 3 3

HDB 3 4

Color and UV Stabilizer C, D, or E C, D, or E

5.3 The deformed pipe should be spooled in a continuous

length for

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.