ASTM B523/B523M-01

(Specification)Standard Specification for Seamless and Welded Zirconium and Zirconium Alloy Tubes

Standard Specification for Seamless and Welded Zirconium and Zirconium Alloy Tubes

SCOPE

1.1 This specification covers three grades of zirconium and zirconium alloy seamless and welded tubes.

1.2 Unless a single unit is used, for example corrosion mass gain in mg/dm2, the values stated in either inch-pound or SI units are to be regarded separately as standard. The values stated in each system are not exact equivalents; therefore, each system must be used independently of the other. SI values cannot be mixed with inch-pound values.

1.3 The following precautionary caveat pertains only to the test methods portion of this specification: This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

Designation: B 523/B 523M – 01

Standard Specification for

Seamless and Welded Zirconium and Zirconium Alloy

Tubes

This standard is issued under the fixed designation B 523/B 523M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3. Terminology

1.1 This specification covers three grades of zirconium and 3.1 Definitions of Terms Specific to This Standard:

zirconium alloy seamless and welded tubes. 3.1.1 annealed—for purposes of this specification “an-

1.2 Unless a single unit is used, for example corrosion mass nealed” denotes material that exhibits a recrystallized grain

gain in mg/dm , the values stated in either inch-pound or SI structure.

units are to be regarded separately as standard. The values 3.2 Lot Definitions:

stated in each system are not exact equivalents; therefore, each 3.2.1 castings—a lot shall consist of all castings produced

system must be used independently of the other. SI values from the same pour.

cannot be mixed with inch-pound values. 3.2.2 ingot—no definition required.

1.3 The following precautionary caveat pertains only to the 3.2.3 rounds, flats, tubes, and wrought powder metallurgical

test methods portion of this specification: This standard does products (single definition, common to nuclear and non-

not purport to address all of the safety concerns, if any, nuclear standards)—a lot shall consist of a material of the

associated with its use. It is the responsibility of the user of this same size, shape, condition, and finish produced from the same

standard to establish appropriate safety and health practices ingot or powder blend by the same reduction schedule and the

and determine the applicability of regulatory limitations prior same heat treatment parameters. Unless otherwise agreed

to use. between manufacturer and purchaser, a lot shall be limited to

the product of an 8 h period for final continuous anneal, or to

2. Referenced Documents

a single furnace load for final batch anneal.

2.1 ASTM Standards: 3.2.4 sponge—a lot shall consist of a single blend produced

A 370 Test Methods and Definitions for Mechanical Testing

at one time.

of Steel Products 3.2.5 weld fittings—definition is to be mutually agreed upon

B 551 Specification for Zirconium and Zirconium Alloy

between manufacturer and the purchaser.

Strip, Sheet, and Plate

4. Classification

E 8 Test Methods for Tension Testing of Metallic Materials

E 29 Practice for Using Significant Digits in Test Data to 4.1 The tubes are furnished in three grades as follows:

Determine Conformance with Specifications 4.1.1 Grade R60702—Unalloyed zirconium.

E 213 Practice for Ultrasonic Examination of Metal Pipe 4.1.2 Grade R60704—Zirconium-tin alloy.

and Tubing 4.1.3 Grade R60705—Zirconium-niobium alloy.

E 426 Practice for Electromagnetic (Eddy-Current) Exami-

5. Ordering Information

nation of Seamless and Welded Tubular Products, Austen-

itic Stainless Steel and Similar Alloys 5.1 Orders for material under this specification should

include the following information:

5.1.1 Quantity (weight or number of pieces, or both),

This specification is under the jurisdiction of ASTM Committee B10 on

5.1.2 Name of material (zirconium seamless or welded

Reactive and Refractory Metals and Alloys and is the direct responsibility of

tube),

Subcommittee B10.02 on Zirconium and Hafnium.

Current edition approved Nov. 10, 2001. Published January 2002. Originally

5.1.3 Dimensions (diameter, wall thickness, lengths),

published as B 523 – 70. Last previous edition B 523 – 97.

5.1.4 ASTM designation and year of issue,

For ASME Boiler and Pressure Vessel Code Applications, see related Specifi-

5.1.5 Grade number (see 4.1), and

cation SB–523 in Section II of that Code.

Annual Book of ASTM Standards, Vol 01.03. 5.1.6 Additions to the specification and supplementary re-

Annual Book of ASTM Standards, Vol 02.04.

quirements, if required.

Annual Book of ASTM Standards, Vol 03.01.

Annual Book of ASTM Standards, Vol 14.02.

NOTE 1—A typical ordering description is as follows: 1000 pieces of

Annual Book of ASTM Standards, Vol 03.03.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 523/B 523M

TABLE 2 Permissible Variation in Product Analysis Between

seamless zirconium tubes, 2 in. (50 mm) in outside diameter by 0.06 in.

Different Laboratories

(15 mm) in wall thickness by 10 ft (3 m) in length, ASTM B 523, dated

___, Grade R60702.

Permissible Variation in Product

Element

Analysis, %

6. Materials and Manufacture

Hydrogen 0.002

Nitrogen 0.01

6.1 Seamless tube shall be made by any seamless method

Carbon 0.01

that will yield a product meeting the requirements of this

Hafnium 0.1

specification.

Iron + chromium 0.025

Tin 0.05

6.2 Welded tube shall be made from sheet or strip meeting

Niobium 0.05

the requirements of Specification B 551 by an automatic

Oxygen 0.02

arc-welding process or other method of welding that will yield

a product meeting the requirements of this specification. Filler

metal shall not be used. Welded tubing shall be supplied as

TABLE 3 Tensile Requirements

follows:

UNS Grade Designation

6.2.1 As welded, and

R60702 R60704 R60705

6.2.2 As welded and further reduced.

Tensile strength, 55 (380) 60 (415) 80 (550)

6.3 The tube shall be furnished annealed.

min, ksi (MPa)

Yield strength, min, 30 (205) 35 (240) 55 (380)

ksi (MPa)

7. Chemical Composition

Elongation in 2 in. 16 14 16

7.1 The material shall conform to the requirements as to

or 50 mm, min, %

chemical composition prescribed in Table 1.

7.2 The manufacturer’s ingot analysis shall be considered

the chemical analysis for tubing, except for hydrogen and

of ⁄8 in. (3.2 mm) for each 10 ft (3 m) or fraction thereof shall

nitrogen, which shall be determined on the finished product.

be permissible up to ⁄2 in. (13 mm), maximum.

7.3 When requested by the purchaser and stated in the

9.3 Straightness—The tube shall be free of bends or kinks

purchase order, a product analysis for any elements listed in

and the maximum uniform bow shall not exceed the values

Table 1 shall be made on the finished product.

shown in Table 5.

7.3.1 The manufacturer’s analysis shall be considered as

9.4 Squareness of Cut—The angle of cut of the end of any

verified if the check analysis confirms the manufacturer’s

tube up to 1 ⁄2 in. (40 mm) in outside diameter may depart from

reported values within the tolerances prescribed in Table 2.

square not more than 0.016 in./in. (mm/mm).

8. Tensile Requirements

10. Workmanship and Quality Level Requirements

8.1 The material, as represented by the test specimens, shall

10.1 The finished tube shall be clean and free of foreign

conform to the tensile properties prescribed in Table 3.

material, shall have smooth ends, free of burrs, and shall be

free of injurious external and internal imperfections in accor-

9. Permissible Variation in Dimensions

dance with standards of acceptability agreed upon between the

9.1 Diameter—Variations in outside diameter shall not ex-

manufacturer and the purchaser. Minor defects may be re-

ceed those prescribed in Table 4.

moved provided the dimensional tolerances of Table 4 are not

9.2 Length—When tubes are ordered cut to length, the

exceeded.

length shall be not less than that specified, but a variation of ⁄8

in. (3.2 mm) will be permitted on tube up to 10 ft (3 m),

11. Significance of Numerical Limits

inclusive. For lengths over 10 ft, an additional over-tolerance

11.1 For the purpose of determining compliance with the

specified limits for requirements of the properties listed in the

A

TABLE 1 Chemical Requirements

following table, an observed value or a calculated value shall

Composition, %

be rounded as indicated in accordance with the rounding

methods of Practice E 29.

Element UNS Grade Designation

Rounded Unit for Observed

R60702 R60704 R60705

Property or Calculated Value

B

Zirconium + hafnium, min 99.2 97.5 95.5

Hafnium, max 4.5 4.5 4.5

Chemical composition, and toler- nearest unit in the last right-hand

Iron + chromium 0.2 max 0.2 to 0.4 0.2 max

ances (when expressed as decimals) place of figures of the specified limit

Tin . . . 1.0 to 2.0 . . .

Tensile strength and yield strength nearest 1000 psi (10 MPa)

Hydrogen, max 0.005 0.005 0.005

Elongation nearest 1 %

Nitrogen, max 0.025 0.025 0.025

Carbon, max 0.05 0.05 0.05

12. Number of Tests and Retests

Niobium . . . . . . 2.0 to 3.0

Oxygen, max 0.16 0.18 0.18

12.1 One longitudinal tension test, see 13.1, shall be made

A

from each lot.

By agreement between the purchaser and the manufacturer, analysis may be

required and limits established for elements and compounds not specified in the

12.2 One chemistry test, see 7.2 and 13.7, for hydrogen and

table of chemical composition.

nitrogen shall be made from each lot of finished product.

B

The value for zirconium + hafnium, min, is a warranted but not a measured

value. 12.3 One flare test, see 13.5, shall be made from each lot.

NOTICE: This standard has either been superseded and replaced by a new version or discontinued.

Contact ASTM International (www.astm.org) for the latest information.

B 523/B 523M

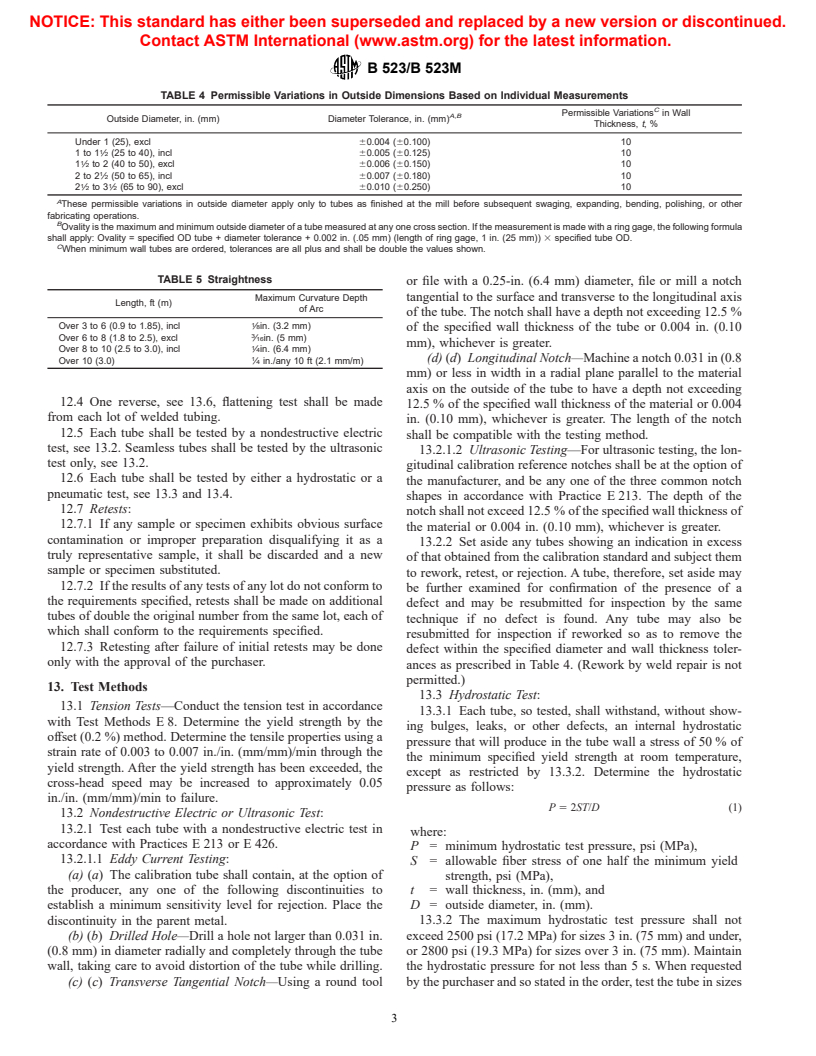

TABLE 4 Permissible Variations in Outside Dimensions Based on Individual Measurements

C

Permissible Variations in Wall

A,B

Outside Diameter, in. (mm) Diameter Tolerance, in. (mm)

Thickness, t,%

Under 1 (25), excl 60.004 (60.100) 10

1to1 ⁄2 (25 to 40), incl 60.005 (60.125) 10

1 ⁄2 to 2 (40 to 50), excl 60.006 (60.150) 10

2to2 ⁄2 (50 to 65), incl 60.007 (60.180) 10

1 1

2 ⁄2 to 3 ⁄2 (65 to 90), excl 60.010 (60.250) 10

A

These permissible variations in outside diameter apply only to tubes as finished at the mill before subsequent swaging, expanding, bending, polishing, or other

fabricating operations.

B

Ovality is the maximum and minimum outside diameter of a tube measured at any one cross section. If the measurement is made with a ring gage, the following formula

shall apply: Ovality = specified OD tube + diameter tolerance + 0.002 in. (.05 mm) (length of ring gage, 1 in. (25 mm)) 3 specified tube OD.

C

When minimum wall tubes are ordered, tolerances are all plus and shall be double the values shown.

TABLE 5 Straightness

or file with a 0.25-in. (6.4 m

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.