ASTM D3387-11

(Test Method)Standard Test Method for Compaction and Shear Properties of Bituminous Mixtures by Means of the U.S. Corps of Engineers Gyratory Testing Machine (GTM) (Withdrawn 2020)

Standard Test Method for Compaction and Shear Properties of Bituminous Mixtures by Means of the U.S. Corps of Engineers Gyratory Testing Machine (GTM) (Withdrawn 2020)

SCOPE

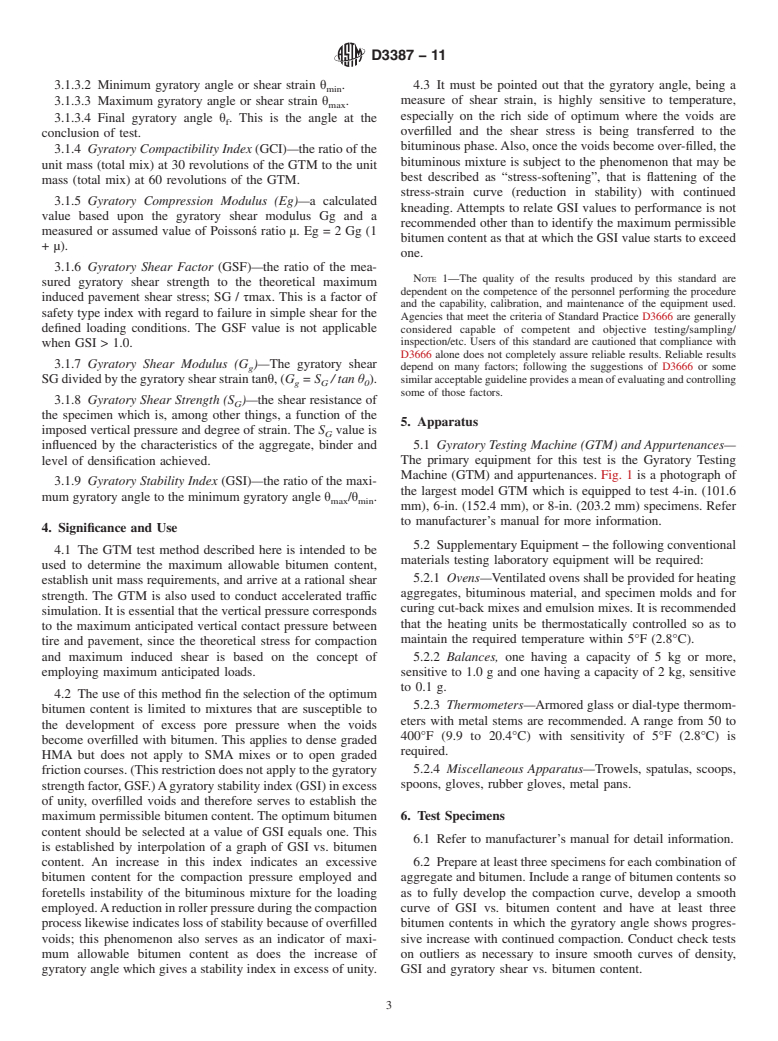

1.1 This method employs a testing machine (Fig. 1) that generates a precisely controlled gyratory kneading process which is used to prepare and test specimens of bituminous paving mixtures. This method is intended for use in bituminous mixtures design and control testing as well as accelerated traffic simulation. The objective is to compact to the ultimate in place density under the anticipated vertical stress while monitoring the process in terms of unit mass, and shearing resistance including the plastic properties. Particular attention is given to the development of the plastic properties associated with the compaction phenomenon. The maximum permissible bitumen content is indicated directly by the first evidence of a progressive increase in shear strain (as indicated by a progressive increase in the gyratory angle) accompanied by a progressive reduction in shear strength (as indicated by a progressive reduction in roller pressure.) The procedures described here are for mix design and plant control as well as accelerated traffic simulation.

1.2 This test method covers two separate modes of operation of the Gyratory Testing Machine (GTM), namely: (1) GTM oil-filled roller mode; and (2) GTM air-filled roller mode. With the air filled roller, the GTM machine angle varies according to the resistance encountered during the gyratory kneading process. Thus the GTM using the air-filled roller is considered a better mechanical analog of the interaction between pneumatic tire and pavement structure.

1.3 This test method is for use with mixtures containing asphalt cement, asphalt binder cutback asphalt, asphalt emulsion. Test molds are available in 4- in. (101.6 mm), 6-in. ( 152.4 mm), and 8-in. (203.2 mm)diameters with corresponding height of 8-in (203.2 mm), 10-in.(254.0 mm), and 12-in. (304.8 mm) respectively. These molds can accommodate maximum particle sizes of 1 in. (25.4 mm) 1.5-in. (38.1 mm) and 2.0-in. (50.8 mm) respectively.

1.4 Units—The values stated in inch pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.5 The text of this standard references notes and footnotes which provide explanatory material. These notes and footnotes (excluding those in tables and figures) shall not be considered as requirements of the standard.

1.6 This standard may involve hazardous materials, operations, and equipment. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

FIG. 1 Largest Model of Gyratory Testing Machine

WITHDRAWN RATIONALE

This method employed a testing machine that generated a precisely controlled gyratory kneading process which is used to prepare and test specimens of bituminous paving mixtures.

Formerly under the jurisdiction of Committee D04 on Road and Paving Materials, this test method was withdrawn in January 2020 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D3387 − 11

Standard Test Method for

Compaction and Shear Properties of Bituminous Mixtures

by Means of the U.S. Corps of Engineers Gyratory Testing

1

Machine (GTM)

This standard is issued under the fixed designation D3387; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope particle sizes of 1 in. (25.4 mm) 1.5-in. (38.1 mm) and 2.0-in.

(50.8 mm) respectively.

1.1 This method employs a testing machine (Fig. 1) that

1.4 Units—The values stated in inch pound units are to be

generates a precisely controlled gyratory kneading process

regarded as standard. The values given in parentheses are

which is used to prepare and test specimens of bituminous

mathematical conversions to SI units that are provided for

pavingmixtures.Thismethodisintendedforuseinbituminous

information only and are not considered standard.

mixtures design and control testing as well as accelerated

trafficsimulation.Theobjectiveistocompacttotheultimatein

1.5 The text of this standard references notes and footnotes

place density under the anticipated vertical stress while moni-

which provide explanatory material.These notes and footnotes

toring the process in terms of unit mass, and shearing resis-

(excluding those in tables and figures) shall not be considered

tance including the plastic properties. Particular attention is

as requirements of the standard.

given to the development of the plastic properties associated

1.6 This standard may involve hazardous materials,

with the compaction phenomenon. The maximum permissible

operations, and equipment. This standard does not purport to

bitumen content is indicated directly by the first evidence of a

address all of the safety concerns, if any, associated with its

progressive increase in shear strain (as indicated by a progres-

use. It is the responsibility of the user of this standard to

sive increase in the gyratory angle) accompanied by a progres-

establish appropriate safety and health practices and deter-

sive reduction in shear strength (as indicated by a progressive

mine the applicability of regulatory limitations prior to use.

reductioninrollerpressure.)Theproceduresdescribedhereare

for mix design and plant control as well as accelerated traffic

2. Referenced Documents

simulation.

2

2.1 ASTM Standards:

1.2 This test method covers two separate modes of opera-

D3666Specification for Minimum Requirements for Agen-

tion of the Gyratory Testing Machine (GTM), namely: (1)

cies Testing and Inspecting Road and Paving Materials

GTMoil-filledrollermode;and(2)GTMair-filledrollermode.

E1Specification for ASTM Liquid-in-Glass Thermometers

With the air filled roller, the GTM machine angle varies

according to the resistance encountered during the gyratory 3. Terminology

kneading process. Thus the GTM using the air-filled roller is

3.1 Definitions:

considered a better mechanical analog of the interaction

3.1.1 Critical roller pressure, p’—the roller pressure re-

between pneumatic tire and pavement structure.

quired for a Gyratory Shear Factor (GSF) equal to unity. That

is, the roller pressure when SG = τmax. (See Annex A1.)

1.3 This test method is for use with mixtures containing

asphalt cement, asphalt binder cutback asphalt, asphalt emul-

3.1.2 Equilibrium density—density when a rate of densifi-

3 3

sion. Test molds are available in 4- in. (101.6 mm), 6-in. (

cation of 1 lb/ft (16 kg/m ) per 100 revolutions of the GTM

152.4mm),and8-in.(203.2mm)diameterswithcorresponding

roller carriage is reached. This rate of densification is intended

heightof8-in(203.2mm),10-in.(254.0mm),and12-in.(304.8

to duplicate the ultimate in place density.

mm) respectively. These molds can accommodate maximum

3.1.3 Gyratory Angle—measure of the magnitude of the

gyratory strain θ. Four pertinent angles are defined as follows:

3.1.3.1 Machine angle (machine setting) θ .

0

1

This test method is under the jurisdiction of ASTM Committee D04 on Road

and Paving Materials and is the direct responsibility of Subcommittee D04.26 on

2

Fundamental/Mechanistic Tests. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Aug. 1, 2011. Published September 2011. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1974. Last previous edition approved in 2003 as D3387– 03. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/D3387-11. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.