ASTM D5421-05(2010)

(Specification)Standard Specification for Contact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

Standard Specification for Contact Molded "Fiberglass" (Glass-Fiber-Reinforced Thermosetting Resin) Flanges

ABSTRACT

This specification covers the requirements for materials, workmanship, performance, and dimensions of circular contact-molded "fiberglass" (glass fiber reinforced thermosetting resin) flanges for use in pipe systems and tank nozzles. This specification does not address flange design or gasket selection. Flanges may be produced as integral flanges (Type A) or flange-on-pipe (Type B). They may be made of either epoxy resin (Grade 1), polyester resin (Grade 2), phenolic resin (Grade 3), vinylester resin (Grade 4), or furan resin (Grade 5). Flanges are also grouped into classes according to pressure and thrust capability as Class I (hoop and axial pressure) and Class II (hoop pressure only). Specimens shall undergo tests for which performance requirements must be met for sealing, short-term rupture strength, and maximum bolt torque.

SCOPE

1.1 This specification covers circular contact-molded fiberglass reinforced-thermosetting-resin flanges for use in pipe systems and tank nozzles. Included are requirements for materials, workmanship, performance, and dimensions.

1.2 Flanges (see Fig. 1) may be produced as integral flanges, Type A, or flange-on-pipe, Type B.

1.3 This specification is based on flange performance and does not cover design.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D5421 −05(Reapproved 2010) An American National Standard

Standard Specification for

Contact Molded “Fiberglass” (Glass-Fiber-Reinforced

Thermosetting Resin) Flanges

This standard is issued under the fixed designation D5421; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope D883 Terminology Relating to Plastics

D1599 Test Method for Resistance to Short-Time Hydraulic

1.1 This specification covers circular contact-molded fiber-

Pressure of Plastic Pipe, Tubing, and Fittings

glass reinforced-thermosetting-resin flanges for use in pipe

D1600 Terminology forAbbreviatedTerms Relating to Plas-

systems and tank nozzles. Included are requirements for

tics

materials, workmanship, performance, and dimensions.

D2310 Classification for Machine-Made “Fiberglass”

1.2 Flanges(seeFig.1)maybeproducedasintegralflanges,

(Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

Type A, or flange-on-pipe, Type B.

D2996 Specification for Filament-Wound “Fiberglass’’

1.3 This specification is based on flange performance and (Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

D2997 Specification for Centrifugally Cast “Fiberglass”

does not cover design.

(Glass-Fiber-Reinforced Thermosetting-Resin) Pipe

1.4 These flanges are designed for use with pipe and tanks

D3262 Specification for “Fiberglass” (Glass-Fiber-

that are manufactured to Specifications D2996, D2997, D3262,

Reinforced Thermosetting-Resin) Sewer Pipe

D3299, D3517, D3754, D3982, and D4097.

D3299 Specification for Filament-Wound Glass-Fiber-

1.5 Selection of gaskets is not covered in this specification,

Reinforced Thermoset Resin Corrosion-Resistant Tanks

refer to the manufacturer’s recommendation.

D3517 Specification for “Fiberglass” (Glass-Fiber-

Reinforced Thermosetting-Resin) Pressure Pipe

1.6 The values stated in inch-pound units are to be regarded

D3754 Specification for “Fiberglass” (Glass-Fiber-

as the standard. The SI units given in parentheses are for

Reinforced Thermosetting-Resin) Sewer and Industrial

information only.

Pressure Pipe

1.7 The following precautionary caveat pertains only to the

D3982 SpecificationforContactMolded“Fiberglass”(Glass

test methods portion, Section 9, of this specification:This

Fiber Reinforced Thermosetting Resin) Ducts

standard does not purport to address the safety problems, if

D4097 Specification for Contact-Molded Glass-Fiber-

any, associated with its use. It is the responsibility of the user

Reinforced Thermoset Resin Corrosion-Resistant Tanks

of this standard to establish appropriate safety and health

2.2 ANSI Standards:

practices and determine the applicability of regulatory limita-

B 16.1 Cast Iron Pipe Flanges and Flanged Fittings

tions prior to use.

B 16.5 Pipe Flanges and Flanged Fittings

NOTE 1—There is no known ISO equivalent to this standard. 3

B 27.2 Type “A” Narrow Washers

2. Referenced Documents

3. Terminology

2.1 ASTM Standards:

3.1 Definitions:

C582 Specification for Contact-Molded ReinforcedThermo-

3.1.1 Definitions are in accordance withTerminology D883.

setting Plastic (RTP) Laminates for Corrosion-Resistant

Abbreviations are in accordance with Terminology D1600,

Equipment

unless otherwise indicated. The abbreviation for reinforced-

thermosetting-resin pipe is RTRP.

This specification is under the jurisdiction of ASTM Committee D20 on

3.2 Definitions of Terms Specific to This Standard:

Plastics and is the direct responsibility of Subcommittee D20.23 on Reinforced

3.2.1 contact molding (CM)—a method of fabrication

Plastic Piping Systems and Chemical Equipment.

Current edition approved Nov. 1, 2010. Published March 2011. Originally

wherein the glass fiber reinforcement is applied to the mold in

approved in 1993. Last previous edition approve in 2005 as D5421 - 05. DOI:

the form of all chopped-strand mat, or chopped-strand mat and

10.1520/D5421-05R10.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D5421−05 (2010)

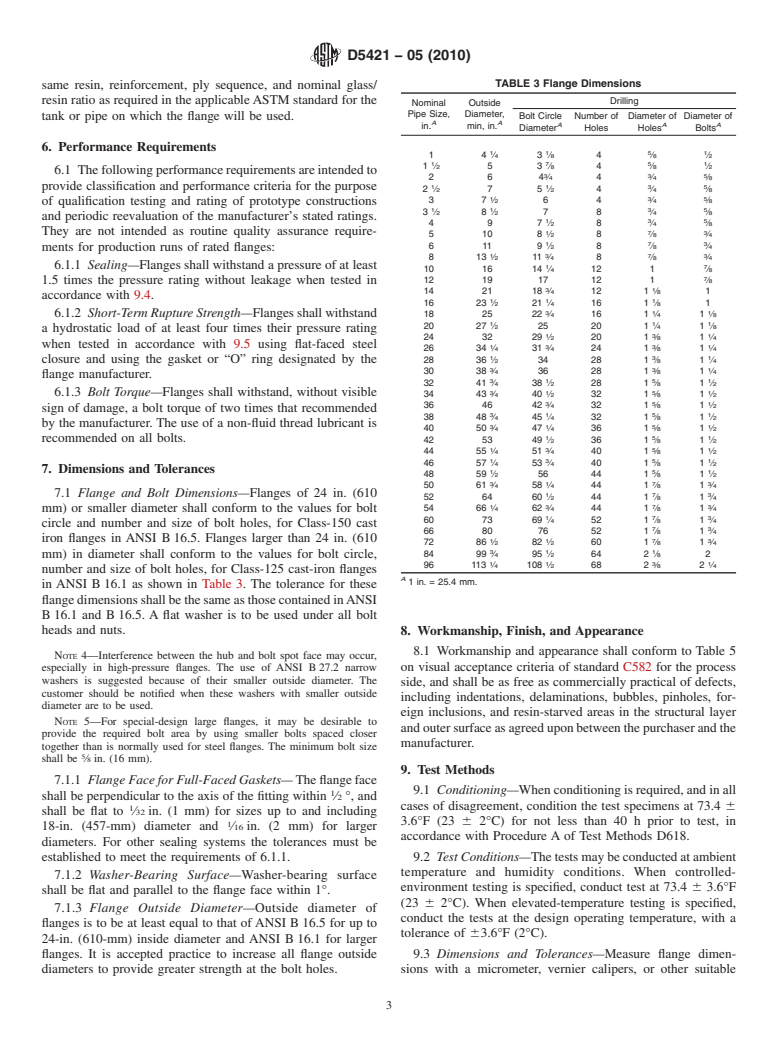

TABLE 1 Pressure Categories

A

Pressure Rating

Designation

psi MPa

A 25 0.173

B 50 0.345

C 75 0.517

D 100 0.690

E 125 0.862

F 150 1.034

A

Flanges with higher pressure ratings are available by agreement between the

purchaser and the manufacturer.

FIG. 1 Flange Types

TABLE 2 Short-Term Rupture Pressure and Sealing-Test

A

Pressure

woven roving, in alternate plies by hand with the resin matrix

Property/Cell Classification 123456

applied by brush or roller and the laminate consolidated by a

roller.

Short-Term Rupture 100 200 300 400 500 600

Pressure, psi (MPa) (0.69) (1.38) (2.07) (2.76) (3.45) (4.14)

3.2.2 fiberglass pipe—a tubular product containing glass-

Sealing-test pressure, psi 37.5 75 112.5 150 187.5 225

fiber reinforcements embedded in or surrounded by cured

(MPa) (0.26) (0.52) (0.78) (1.03) (1.29) (1.55)

thermosetting resin; the composite structure may contain

A

Refer to Test Method D1599 for explanation of failure.

aggregate, granular or platelet fillers, thixotropic agents, pig-

ments or dyes; thermoplastic or thermosetting liners or coat-

ings may be included.

by the type as a capital letter, grade as anArabic numeral, class

4. Classification

as a Roman numeral, and the pressure-rating category as a

4.1 General—This specification covers reinforced- capital letter and two Arabic numbers identifying the cell-

thermosetting-resin flanges defined by type (method of classification designations of the short-term rupture pressure

manufacture), grade (generic type of resin), class (pressure end and sealing-test pressure, respectively. Thus, a complete

thrust capability), and pressure rating. Flanges complying with flange-designation code shall consist of three letters, one

this specification are also given numerical classifications relat- Arabic numeral, one Roman numeral, one letter and two

numerals.

ing to rupture pressure and sealing test pressure.

4.1.1 Types: 4.2.1 Example—Contact molded fiberglass is CM-AlID-46.

This designation described a stub flange, made using glass-

4.1.1.1 Type A—Integral flange, contact molded with the

stub integral with the flange. fiber-reinforced epoxy resin for full-axial pressure thrust. The

flange has a 100-psi (0.69-MPa) pressure rating, a short-term

4.1.1.2 Type B—Flange on pipe, contact molded onto an

existing pipe or fitting. rupture pressure of 400-psi (2.76-MPa), and a sealing-test

pressure of 225-psi (1. 55-MPa).

4.1.2 Grades:

4.1.2.1 Grade 1—Epoxy resin.

4.3 Attachment of Flanges to Pipe, Pipe Fittings, or Tanks:

4.1.2.2 Grade 2—Polyester resin.

4.3.1 Type “A” flanges are to be butt and strap welded to

4.1.2.3 Grade 3—Phenolic resin.

pipe described in Specifications D2996, D2997, D3262,

4.1.2.4 Grade 4—Vinylester resin.

D3517, D3754, and D3982 or using overlay joint into a tank as

4.1.2.5 Grade 5—Furan resin.

described in Specifications D3299 and D4097.

4.1.3 Classes:

4.3.2 Type “B” flanges are built onto elbows, reducers, or

4.1.3.1 Class I—Hoop and axial-pressure.

otherpartswheretheuseofanintegralflange(Type“A”)isnot

4.1.3.2 Class II—Hoop pressure only.

practical or required.

NOTE 2—All combinations of type, liner, grade, and class may not be

5. Materials and Manufacture

commercially available. Additional type, liner, grade, and class may be

added as they become commercially available. The purchaser should

5.1 Flanges manufactured in accordance with this specifi-

solely determine or consult with the manufacturer for the proper class,

cation shall be composed of reinforcement embedded in or

type, liner, and grade to be used under the installation and operating

surrounded by cured thermosetting resin.

conditions that will exist for the project in which the flange is to be used.

4.1.4 Pressure Rating—Pressure rating shall be categorized 5.2 The resins, reinforcements, and other materials, when

bysingle-letterdesignation.Pressuredesignationsareshownin combined into composite structure, shall produce a flange that

Table 1. will meet the performance requirements of this specification.

4.1.5 Short-term rupture pressure and sealing-test pressure

NOTE 3—The term “other materials” does not include recycled or

limits shall be categorized by single arabic number designa-

reprocessed thermosetting plastics which might otherwise be added as

tions as indicated by the cell classification system of Table 2.

fillers.

4.2 Designation Code—The flange-designation code shall 5.3 Flanges manufactured in accordance with this specifi-

consist of the abbreviation for contact molded (CM) followed cation shall have an inner corrosion barrier fabricated with the

D5421−05 (2010)

TABLE 3 Flange Dimensions

same resin, reinforcement, ply sequence, and nominal glass/

resin ratio as required in the applicableASTM standard for the Drilling

Nominal Outside

Pipe Size, Diameter,

tank or pipe on which the flange will be used. Bolt Circle Number of Diameter of Diameter of

A A

A A A

in. min, in.

Diameter Holes Holes Bolts

6. Performance Requirements

1 1 5 1

14 ⁄4 3 ⁄8 4 ⁄8 ⁄2

1 7 5 1

1 ⁄2 53 ⁄8 4 ⁄8 ⁄2

6.1 Thefollowingperformancerequirementsareintendedto

3 3 5

26 4 ⁄4 4 ⁄4 ⁄8

provide classification and performance criteria for the purpose 1 1 3 5

2 ⁄2 75 ⁄2 4 ⁄4 ⁄8

1 3 5

37 ⁄2 64 ⁄4 ⁄8

of qualification testing and rating of prototype constructions

1 1 3 5

3 ⁄2 8 ⁄2 78 ⁄4 ⁄8

and periodic reevaluation of the manufacturer’s stated ratings.

1 3 5

49 7 ⁄2 8 ⁄4 ⁄8

They are not intended as routine quality assurance require- 1 7 3

510 8 ⁄2 8 ⁄8 ⁄4

1 7 3

611 9 ⁄2 8 ⁄8 ⁄4

ments for production runs of rated flanges:

1 3 7 3

813 ⁄2 11 ⁄4 8 ⁄8 ⁄4

6.1.1 Sealing—Flanges shall withstand a pressure of at least

1 7

10 16 14 ⁄4 12 1 ⁄8

12 19 17 12 1 ⁄8

1.5 times the pressure rating without leakage when tested in

3 1

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.