ASTM D4282-15(2022)

(Test Method)Standard Test Method for Determination of Free Cyanide in Water and Wastewater by Microdiffusion

Standard Test Method for Determination of Free Cyanide in Water and Wastewater by Microdiffusion

SIGNIFICANCE AND USE

5.1 This test method is useful in distinguishing between the potentially available free cyanide (total cyanide) and the free cyanide actually present.

5.2 This test method provides a convenient technique for making on-site free cyanide determinations.

SCOPE

1.1 This test method covers the determination of free cyanides in waters and wastewaters. Free cyanide is here defined as the cyanide which diffuses as cyanide (HCN), at room temperature, from a solution at pH 6.2

1.2 This test method does not include complexes that resist dissociation, such as hexacyanoferrates and gold cyanide, nor does it include thiocyanate and cyanohydrin.

1.3 This test method may be applied to water and wastewater samples containing free cyanide from 10 to 150 μg/L. Greater concentrations may be determined by appropriate dilution.

1.4 This test method has been fully validated by collaborative testing as specified by Practice D2777.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 8.6, 8.9, Section 9, and 12.2.1.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D4282 − 15 (Reapproved 2022)

Standard Test Method for

Determination of Free Cyanide in Water and Wastewater by

Microdiffusion

This standard is issued under the fixed designation D4282; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

1.1 This test method covers the determination of free 2.1 ASTM Standards:

cyanides in waters and wastewaters. Free cyanide is here D1129Terminology Relating to Water

defined as the cyanide which diffuses as cyanide (HCN), at D1192Guide for Equipment for Sampling Water and Steam

2 4

room temperature, from a solution at pH 6. in Closed Conduits (Withdrawn 2003)

D1193Specification for Reagent Water

1.2 This test method does not include complexes that resist

D2777Practice for Determination of Precision and Bias of

dissociation, such as hexacyanoferrates and gold cyanide, nor

Applicable Test Methods of Committee D19 on Water

does it include thiocyanate and cyanohydrin.

D3370Practices for Sampling Water from Flowing Process

1.3 This test method may be applied to water and wastewa-

Streams

ter samples containing free cyanide from 10 to 150 µg/L.

D3856Guide for Management Systems in Laboratories

Greater concentrations may be determined by appropriate

Engaged in Analysis of Water

dilution.

D4210Practice for Intralaboratory Quality Control Proce-

dures and a Discussion on Reporting Low-Level Data

1.4 This test method has been fully validated by collabora-

tive testing as specified by Practice D2777. (Withdrawn 2002)

D5788Guide for Spiking Organics into Aqueous Samples

1.5 The values stated in SI units are to be regarded as

D5789Practice for Writing Quality Control Specifications

standard. No other units of measurement are included in this

for Standard Test Methods for Organic Constituents

standard.

(Withdrawn 2002)

1.6 This standard does not purport to address all of the

D5847Practice for Writing Quality Control Specifications

safety concerns, if any, associated with its use. It is the

for Standard Test Methods for Water Analysis

responsibility of the user of this standard to establish appro-

E275PracticeforDescribingandMeasuringPerformanceof

priate safety, health, and environmental practices and deter-

Ultraviolet and Visible Spectrophotometers

mine the applicability of regulatory limitations prior to use.

For specific hazard statements, see 8.6, 8.9, Section 9, and 3. Terminology

12.2.1.

3.1 Definitions:

1.7 This international standard was developed in accor-

3.1.1 For definitions of terms used in this standard, refer to

dance with internationally recognized principles on standard-

Terminology D1129.

ization established in the Decision on Principles for the

3.2 Definitions of Terms Specific to This Standard:

Development of International Standards, Guides and Recom-

3.2.1 free cyanide—those simple cyanides or loosely held

mendations issued by the World Trade Organization Technical

cyanide complexes that diffuse at pH 6, at room temperature.

Barriers to Trade (TBT) Committee.

4. Summary of Test Method

4.1 The reactions are carried out in a microdiffusion cell.

This test method is under the jurisdiction ofASTM Committee D19 on Water

andisthedirectresponsibilityofSubcommitteeD19.06onMethodsforAnalysisfor

4.2 The sample is treated with cadmium ion to precipitate

Organic Substances in Water.

the hexacyanoferrates.

Current edition approved May 1, 2022. Published May 2022. Originally

approved in 1983. Last previous edition approved in 2015 as D4282–15. DOI:

10.1520/D4282-15R22. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

The paper by J. M. Kruse and L. E. Thibault, “Determination of Free Cyanide contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

in Ferro- and Ferricyanides,”Analytical Chemistry, 45(13): 2260–2261; 1973 Nov., Standards volume information, refer to the standard’s Document Summary page on

recommendsadiffusionatpH7.TheANSImodification(ANSIPH4.41-1978)uses the ASTM website.

pH 6. Using the conditions of the ANSI method, diffusion is completed within 4 The last approved version of this historical standard is referenced on

hoursatpH6.LongerdiffusiontimewasrequiredatpH7onthesamplesanalyzed. www.astm.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D4282 − 15 (2022)

4.3 The sample is buffered at pH 6 and allowed to stand for used provided it is first ascertained that the reagent is of

4h. sufficient purity to permit its use without lessening the accu-

racy of the determination.

4.4 The HCN diffuses into sodium hydroxide solution.

8.2 Purity of Water—Unless otherwise indicated, reference

4.5 An aliquot of the sodium hydroxide solution is treated

towatershallbeunderstoodtomeanreagentwaterconforming

with chloramine-T, and the cyanogen chloride formed is

to Type II of Specification D1193.

reacted with barbituric acid in pyridine. The absorbance of the

color formed is measured using a spectrophotometer at a 8.3 Cadmium Chloride Solution (10 g/L), CdCl —Dissolve

wavelength of 580 nm. 10.0 g of anhydrous cadmium chloride in 750 mL of water in

a 1 L volumetric flask. Dilute to volume with water.

5. Significance and Use

8.4 Chloramine-T Reagent (10 g/L)—Dissolve 1.00 g of

5.1 This test method is useful in distinguishing between the

chloramine-Tin 50 mLof water in a 100 mLvolumetric flask.

potentially available free cyanide (total cyanide) and the free

Dilute to volume with water. Make this reagent fresh daily.

cyanide actually present.

−

8.5 Cyanide Solution, Standard (1.00 mL=2 µg CN )

5.2 This test method provides a convenient technique for

—Pipet 2.00 mL of cyanide stock solution (approximately 1.0

−

making on-site free cyanide determinations.

g/LCN )intoa1Lvolumetricflaskanddilutetovolumewith

sodium hydroxide solution (2.05 g/L).

6. Interferences

8.6 Cyanide Solution Stock—Dissolve 2.51 g of potassium

6.1 Decomposition of Hexacyanoferrates During Diffusion:

cyanide, KCN, in 500 mL of sodium hydroxide solution (2.05

6.1.1 This decomposition is virtually eliminated by allow-

g/L) ina1L volumetric flask. Dilute to volume with sodium

ing the sample to diffuse in the dark, and by precipitating the

hydroxide solution (2.05 g/L). This solution contains approxi-

hexacyanoferrates with cadmium ion.

−

mately 1.0 g/L cyanide (CN ). (Warning—KCN is highly

6.2 Instability of Free Cyanide in Effluents—The reactivity toxic, avoid contact or inhalation. Prepare and standardize this

of free cyanide with such chemicals as aldehydes or oxidizing

solution weekly.)

agents, is not really a method interference. However, because 8.6.1 Standardizing Cyanide Stock Solution:

of this instability, it is important for the diffusion to begin as

8.6.1.1 Using a silver electrode and a reference electrode,

soon after sampling as possible. It is beyond the scope of this titrate 20.0 mL of the cyanide stock solution (in a beaker also

testmethodtolistallthepossiblecyanidereactionsthatmaybe

containing 50 mL of sodium hydroxide solution (2.05 g/L))

encountered. with the silver nitrate standard solution.

8.6.1.2 Record the mLof titration for use in the calculation

7. Apparatus

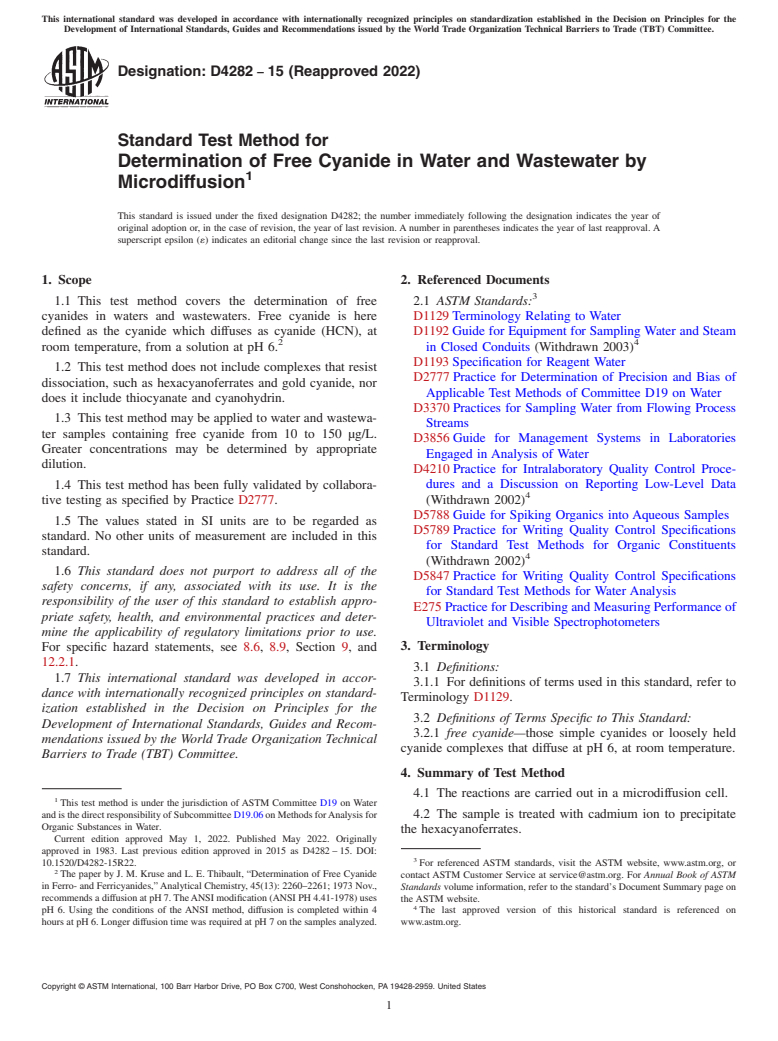

(see Fig. 1 for an example of a typical titration curve).

8.6.1.3 Calculate the concentration of the cyanide stock

7.1 Diffusion Cell, microdiffusion cell, Conway type, 68

solution using the following equation:

mm outside diameter.

50 3 mLsilvernitrate 5mg/L CN instocksolution

~ !

7.2 Micropipets, 0.10 mL, 1.00 mL.

1.00mLofsilvernitratesolutionisequalto1 mgofCN .

7.3 Spectrophotometer, conforming to Practice E275.

8.7 Potassium Phosphate Buffer Solution (Acidified)—Add

7.4 Spectrophotometer Cell, 1 cm equipped with a stopper.

8.0mLofconcentratedphosphoricacid(spgr1.69),H PO,to

3 4

7.5 Pipet or Syringe, adjustable (to deliver 1.30 mL).

100 mL of potassium phosphate solution.

7.6 Calomel Reference Electrode, with saturated KNO

electrolyte, or the equivalent.

7.7 pH Meter.

7.8 Silver Electrode.

8. Reagents

8.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

reagents shall conform to the specifications of the Committee

on Analytical Reagents of the American Chemical Society

where such specifications are available. Other grades may be

One source of supply for these cells is Arthur H. Thomas, No. 3806-F-10.

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

Standard-Grade Reference Materials, American Chemical Society, Washington,

DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

NOTE 1—Twenty millilitres of 2.51 g/L KCN titrated with AgNO .

U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

copeial Convention, Inc. (USPC), Rockville, MD. FIG. 1 Typical Titration Curve Standardizing KCN Solution

D4282 − 15 (2022)

8.8 Potassium Phosphate Solution, 190 g/L—Add 400 mL 9.2.5 Make the seal between the microdiffusion cell and lid

of water toa2L beaker. Add and dissolve 14.5 g of sodium airtight.

hydroxide, NaOH. Add and dissolve 190 g of potassium 9.2.6 It is important to observe the specified time periods in

phosphate, monobasic, KH PO . Add water to 950 mL to aid those steps where such is noted. In particular, make the

2 4

dissolution. Adjust the pH of the solution to pH 5.9 to 6.1, spectrophotometer measurements in the 3 to 6 min interval.

using100g/Lsodiumhydroxidesolution.Transferthesolution 9.2.7 Full color development in the spectrophotometer cell

toa1L volumetric flask, and dilute to volume with water. requires that after each addition, mix the solution thoroughly

without loss of material.

8.9 Pyridine-Barbituric Acid Reagent—Add 15.0 g of bar-

bituricacidtoa250mLvolumetricflask.Washdownthesides

10. Sampling and Sample Preservation

of the flask with just enough water to moisten the barbituric

10.1 Collect the sample in accordance with Guide D1192

acid. Add 75 mL of pyridine and swirl to mix. Slowly add

and Practices D3370.

15mLofconcentratedhydrochloricacid(spgr1.19)andswirl

to mix. Cool the solution to room temperature. Dilute to

10.2 A satisfactory preservation technique is not available.

−

volume and mix. It is recommended that this reagent be

Reactions between CN and aldehydes, oxidizing agents, or

prepared fresh weekly and stored in a dark place. (Warning—

sulfides will continue. However, if the sample cannot be

Pyridine is toxic; avoid contact or inhalation. Prepare this

analyzed immediately, some steps can be taken to slow down

reagent in an exhaust hood.)

the reactions taking place.

10.2.1 Adjust the sample to pH 12 or more.This minimizes

8.10 Silver Nitrate Solution, Standard (1 mL=1 mg of

−

−

CN losses due to vaporization.

CN )—Weigh 3.2647 g of silver nitrate on an analytical

10.2.2 Store the samples in the dark to prevent hexacyano-

balance. Quantitatively transfer the silver nitrate toa1L

ferrate breakdown.

volumetric flask. Dissolve and dilute to volume with water.

10.2.3 Keepthesamplecool(forexample,inarefrigerator).

Store in a dark glass bottle.

8.11 Sodium Hydroxide Solution (4.1 g/L), NaOH—Add

11. Calibration

4.10 g of sodium hydroxide to 800 mL of water ina1L

11.1 Calibration Standards—Pipet 0.00 mL (Note 2),

volumetric flask. Stir until dissolved, and cool the solution to

5.00mL, 10.0mL, and 15.0 mL of the 2.00 mg/L cyanide

room temperature before adjusting the final volume to 1 L.

standard solution into four 200 mL volumetric flasks. Dilute

8.12 Sodium Hydroxide Solution (2.05 g/L), NaOH—Add

each of the flasks to volume with sodium hydroxide solution

2.05 g of sodium hydroxide to 800 mL of water ina1L

(2.05 g/L). These dilutions yield calibration standards that are

−

volumetric flask. Stir until dissolved, and cool the solution to

approximately 0, 50, 100, and 150 µg/L of CN , respectively.

roomtemperaturebeforeadjustingthefinalvolumeto1L.(An

NOTE 1—The 0.00 sample can also be considered the blank.

alternative preparation is to dilute 0.10 N sodium hydroxide

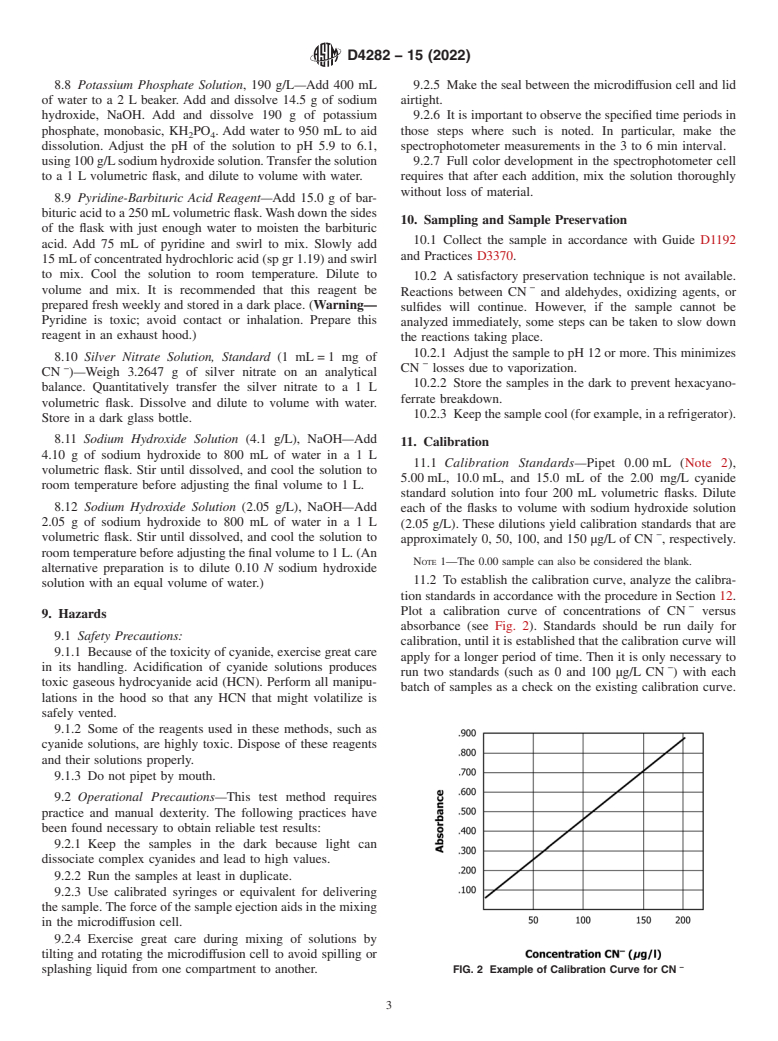

11.2 To establish the calibration curve, analyze the calibra-

solution with an equal volume of water.)

tion standards in accordance with the procedure in Section 12.

−

Plot a calibration curve of concentrations of CN versus

9. Hazards

absorbance (see Fig. 2). Standards should be run daily for

9.1 Safety Precautions:

calibration, until it is established that the calibration curve will

9.1.1 Because of the toxicity of cyanide, exercise great care

apply for a longer period of time. Then it is only necessary to

in its handling. Acidification of cyanide solutions produces −

run two standards (such as 0 and 100 µg/L CN ) with each

toxic gaseous hydrocyanide acid (HCN). Perform all manipu-

batch of samples as a check on the existing calibration curve.

lations in the hood so that any HCN that might volatilize is

safely vented.

9.1.2 Some of the reagents used in these methods, such as

cyanide solutions, are highly toxic. Dispose of these reagents

and their solutions properly.

9.1.3 Do not pipet by mouth.

9.2 Operational Precautions—This test method requires

practice and manual dexterity. The following practices have

been found necessary to obtain reliable test results:

9.2.1 Keep the samples in the dark because light can

dissociate complex cyanides and lead to high values.

9.2.2 Run the samples at least in duplicate.

9.2.3 Use calibrated syringes or equivalent for delivering

thesample.Theforceofthesampleejectionaidsinthemixing

in the microdiffusion cell.

9.2.4 Exercise great care during mixing of solutions by

tilting and rotating the microdiffusion cell to avoid spilling or

−

splashing liquid from one compartment to another. FIG. 2 Example of Calibration Curve for CN

D4282 − 15 (2022)

12. Procedure 12.1.3 At this time, smear the ground glass side of a glass

cell cover plate with a sufficiently heavy layer of petroleum

12.1 Microdiffusion of Free Cyanide:

jelly or stopcock grease to achieve an airtight seal.

12.1.1 Pipet 3.00 mLof sample or calibration standard into

12.1.4 Usingamicropipet,pipet0.5mLof10g/Lcadmium

the outer ring of a clean, dry, microdiffusion cell (see Fig. 3).

12.1.2 Usingacalibratedsyringe(oradjustablepipet),pipet chloridesolution(10g/L)intothesampleinth

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.