ASTM C1270-97(2003)

(Practice)Standard Practice for Detection Sensitivity Mapping of In-Plant Walk-Through Metal Detectors

Standard Practice for Detection Sensitivity Mapping of In-Plant Walk-Through Metal Detectors

SCOPE

1.1 This standard practice covers a procedure for determining the weakest detection path through the portal aperture and the worst-case orthogonal orientation of metallic test objects. It results in detection sensitivity maps, which model the detection zone in terms related to detection sensitivity and identify the weakest detection paths. Detection sensitivity maps support sensitivity adjustment and performance evaluation procedures (see Practices C1269 and C1309).

Note 1—Unsymmetrical metal objects possessing a primary longitudinal component, such as handguns and knives, usually have one particular orientation that produces the weakest detection signal. The orientation and the path through the detector aperture where the weakest response is produced may not be the same for all test objects, even those with very similar appearance.

Note 2—In the case of multiple specified test objects or for test objects that are orientation sensitive, it may be necessary to map each object several times to determine the worst-case test object or orientation, or both.

1.2 This practice is one of several developed to assist operators of walk-through metal detectors with meeting the metal detection performance requirements of the responsible regulatory authority. (See Appendix X2)

1.3 This practice is neither intended to set performance levels, nor limit or constrain operational technologies.

1.4 This practice does not address safety or operational issues associated with the use of walk-through metal detectors.

1.5 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:C1270–97(Reapproved2003)

Standard Practice for

Detection Sensitivity Mapping of In-Plant Walk-Through

Metal Detectors

This standard is issued under the fixed designation C1270; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

Nuclear regulatory authorities require personnel entering designated security areas to be screened

for concealed weapons. Additionally, in security areas containing specified quantities of special

nuclearmaterials,exitingpersonnelarerequiredtobescreenedformetallicnuclearshieldingmaterial.

Walk-through metal detectors are widely used to implement these requirements.

A number of environmental conditions, architectural and electrical arrangements near the detector,

and detector characteristics affect the detection of metallic objects passing through the walk-through

metal detector.These external effects and detector characteristics are discussed in Practices F1468 and

C1269, and Guide C1238. This practice is intended to minimize the effects of these variables on

detector operation by providing the operator with baseline information on the metal detection

sensitivity within the portal aperture, particularly the location of any weak areas of detection.The data

is obtained by mapping the detection zone (volume within the portal) of each detector at its field

location, under normal operating conditions, and using the target test object. The maps, when applied

to detector operation, ensure that the effects of the fixed environmental conditions, architectural and

electrical arrangements, and detector characteristics are taken into account during operational

sensitivity adjustment, performance evaluation, and general operation of detectors.

1. Scope 1.2 This practice is one of several developed to assist

operators of walk-through metal detectors with meeting the

1.1 This standard practice covers a procedure for determin-

metal detection performance requirements of the responsible

ing the weakest detection path through the portal aperture and

regulatory authority. (See Appendix X2)

the worst-case orthogonal orientation of metallic test objects. It

1.3 This practice is neither intended to set performance

resultsindetectionsensitivitymaps,whichmodelthedetection

levels, nor limit or constrain operational technologies.

zone in terms related to detection sensitivity and identify the

1.4 This practice does not address safety or operational

weakest detection paths. Detection sensitivity maps support

issues associated with the use of walk-through metal detectors.

sensitivity adjustment and performance evaluation procedures

1.5 The values stated in SI units are to be regarded as the

(see Practices C1269 and C1309).

standard. The values given in parentheses are for information

NOTE 1—Unsymmetrical metal objects possessing a primary longitudi-

only.

nal component, such as handguns and knives, usually have one particular

orientation that produces the weakest detection signal.The orientation and

2. Referenced Documents

the path through the detector aperture where the weakest response is

2.1 ASTM Standards:

produced may not be the same for all test objects, even those with very

C1238 Guide for Installation of Walk-Through Metal De-

similar appearance.

NOTE 2—In the case of multiple specified test objects or for test objects tectors

that are orientation sensitive, it may be necessary to map each object

C1269 Practice for Adjusting the Operational Sensitivity

several times to determine the worst-case test object or orientation, or

Setting of In-Plant Walk-Through Metal Detectors

both.

C1309 Practice for Performance Evaluation of In-Plant

Walk-Through Metal Detectors

This practice is under the jurisdiction of ASTM Committee C26 on Nuclear

Fuel Cycle and is the direct responsibility of Subcommittee C26.12 on Safeguard

Applications. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 10, 2003. Published February 2003. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1994. Last previous edition approved in 1997 as C1270 – 97. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C1270-97R03. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

C1270–97 (2003)

F1468 Practice for Evaluation of Metallic Weapons Detec- the worst case orthogonal orientation for all the test paths (the

tors for Controlled Access Search and Screening entiredetectionzone).Thetwoarecoincidentinthecriticaltest

path.

3. Terminology

3.1.3 critical sensitivity setting, n—the lowest sensitivity

setting of a detector at which the critical test object in its

3.1 Definitions of Terms Specific to This Standard:

critical orientation is consistently detected (10 out of 10 test

3.1.1 clean-tester, n—a person who does not carry any

passes) when passed through the detection zone on the critical

extraneous metallic objects that would significantly alter the

test path.

signal produced when the person carries a test object.

3.1.4 critical test element, n—see test element.

3.1.1.1 Discussion—By example but not limitation, such

extraneous metallic objects may include: metallic belt buckles, 3.1.5 critical test object, n—see test object.

metal buttons, cardiac pacemakers, coins, metal frame eye 3.1.6 critical test path, n—the straight-line shortest-course

glasses, hearing aids, jewelry, keys, mechanical pens and

path through the portal aperture, as defined by an element on

pencils, shoes with metal shanks or arch supports, metallic the detection sensitivity map, that produces the smallest

surgical implants, undergarment support metal, metal zippers,

detection signal or weakest detection for a test object in its

etc. In the absence of other criteria, a clean tester passing critical orientation. (see Figs. 2 and 3)

through a metal detector shall not cause a disturbance signal

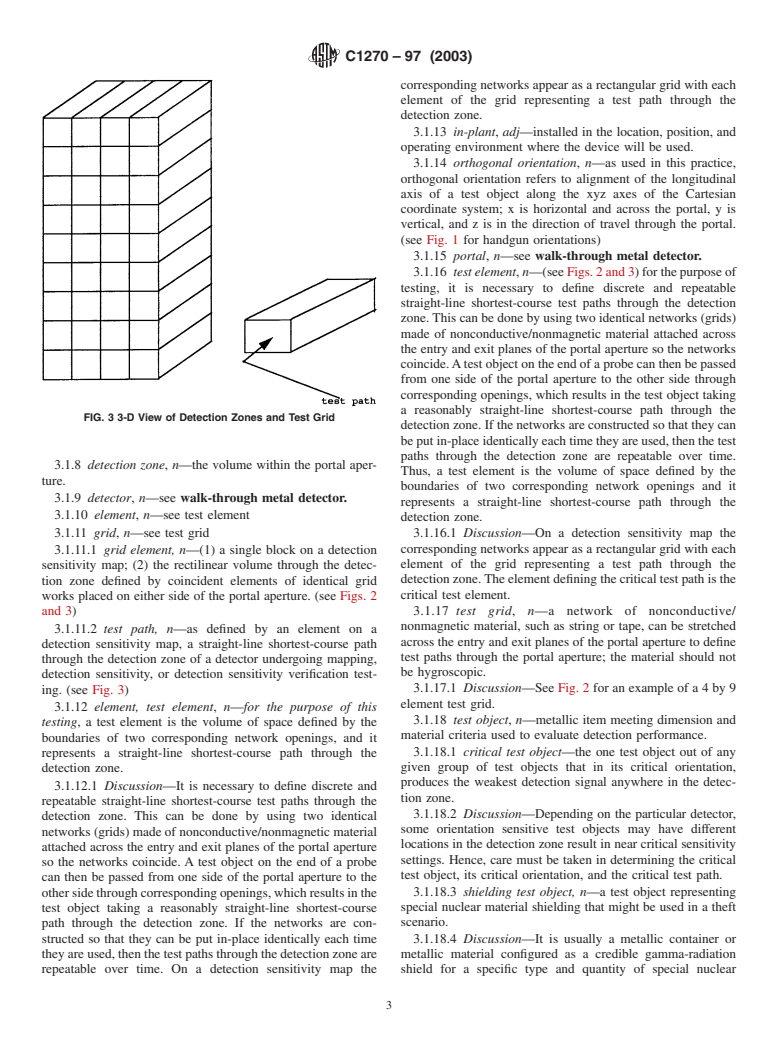

3.1.7 detection sensitivity map, n—(see Figs. 2 and 1)a

greater than 10 % of that produced when carrying the critical

depiction of the grid used to define test paths through the

test object through the detector. Test objects requiring very

detection zone, with each element of the grid containing a

high sensitivity settings for detection require more complete

value, usually the sensitivity setting of the detector, that is

elimination of extraneous metal to obtain less than 10 % signal

indicative of the detectability of the test object.

disturbance.

3.1.7.1 Discussion—These values are relative and describe

3.1.1.2 Discussion—The tester shall have a weight between

the detection sensitivity pattern within the detection zone for

50 to 104 kg (110 to 230 lb) and a height between 1.44 to 1.93

the specific test object. The values are derived by identically

m (57 to 75 in.). Should a given detector be sensitive to body

testing each defined test path using a specific test object in a

size because of design or desired sensitivity, the physical size

single orthogonal orientation. The value is usually the mini-

of testers should be smaller and within a narrower range.

mum sensitivity setting of the detector that will cause a

3.1.1.3 Discussion—It is recommended that the clean tester

consistent alarm (10 out of 10 test passes) when the test object

be surveyed with a high sensitivity hand-held metal detector to

is passed through the detection field.Appendix X3 is a sample

ensure that no metal is present.

form for a potential detection sensitivity map configuration.

3.1.2 critical orientation, n—the orthogonal orientation of a

test object that produces the smallest detection signal or

weakest detection anywhere in the detection zone; the orthogo-

nal orientation of a test object that requires a higher sensitivity

setting to be detected compared to the sensitivity setting

required to detect the object in all other orthogonal orienta-

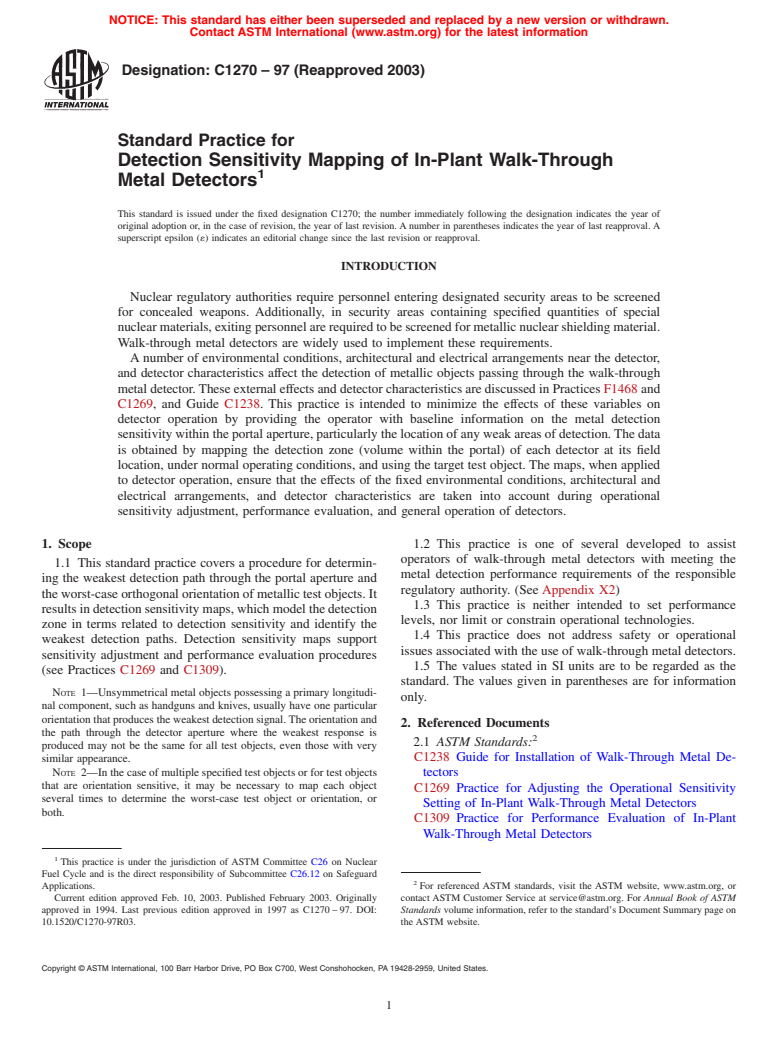

tions. See Fig. 1 for handgun orientations.

3.1.2.1 Discussion—Critical orientations are determined by

testing using a mapping procedure such as described in

Practice C1270.

3.1.2.2 Discussion—The term critical orientation can refer

to the worst case orthogonal orientation in a single test path or

NOTE 1—Numbers are sensitivity setting values for a hypothetical

detector. The numbers represent the lowest sensitivity setting at which the

object was detected ten out of ten consecutive test passes through the

indicated test path.

NOTE 2—Important: ensure that the location of the transmitter and

receiverareidentified.Ifthedetectordoesnothaveadedicatedtransmitter

and receiver, note the side from which testing is performed relative to the

protected area.

FIG. 1 Six Standard Orthogonal Orientations for a Handgun FIG. 2 Example of Detection Sensitivity Map

C1270–97 (2003)

corresponding networks appear as a rectangular grid with each

element of the grid representing a test path through the

detection zone.

3.1.13 in-plant, adj—installed in the location, position, and

operating environment where the device will be used.

3.1.14 orthogonal orientation, n—as used in this practice,

orthogonal orientation refers to alignment of the longitudinal

axis of a test object along the xyz axes of the Cartesian

coordinate system; x is horizontal and across the portal, y is

vertical, and z is in the direction of travel through the portal.

(see Fig. 1 for handgun orientations)

3.1.15 portal, n—see walk-through metal detector.

3.1.16 test element, n—(seeFigs.2and3)forthepurposeof

testing, it is necessary to define discrete and repeatable

straight-line shortest-course test paths through the detection

zone. This can be done by using two identical networks (grids)

made of nonconductive/nonmagnetic material attached across

the entry and exit planes of the portal aperture so the networks

coincide.Atest object on the end of a probe can then be passed

from one side of the portal aperture to the other side through

corresponding openings, which results in the test object taking

a reasonably straight-line shortest-course path through the

FIG. 3 3-D View of Detection Zones and Test Grid

detection zone. If the networks are constructed so that they can

beputin-placeidenticallyeachtimetheyareused,thenthetest

paths through the detection zone are repeatable over time.

3.1.8 detection zone, n—the volume within the portal aper-

Thus, a test element is the volume of space defined by the

ture.

boundaries of two corresponding network openings and it

3.1.9 detector, n—see walk-through metal detector.

represents a straight-line shortest-course path through the

3.1.10 element, n—see test element

detection zone.

3.1.11 grid, n—see test grid

3.1.16.1 Discussion—On a detection sensitivity map the

3.1.11.1 grid element, n—(1) a single block on a detection corresponding networks appear as a rectangular grid with each

element of the grid representing a test path through the

sensitivity map; (2) the rectilinear volume through the detec-

detection zone.The element defining the critical test path is the

tion zone defined by coincident elements of identical grid

critical test element.

works placed on either side of the portal aperture. (see Figs. 2

and 3) 3.1.17 test grid, n—a network of nonconductive/

nonmagnetic material, such as string or tape, can be stretched

3.1.11.2 test path, n—as defined by an element on a

across the entry and exit planes of the portal aperture to define

detection sensitivity map, a straight-line shortest-course path

test paths through the portal aperture; the material should not

through the detection zone of a detector undergoing mapping,

be hygroscopic.

detection sensitivity, or detection sensitivity verification test-

3.1.17.1 Discussion—See Fig. 2 for an example ofa4by9

ing. (see Fig. 3)

element test grid.

3.1.12 element, test element, n—for the purpose of this

3.1.18 test object, n—metallic item meeting dimension and

testing, a test element is the volume of space defined by the

material criteria used to evaluate detection performance.

boundaries of two corresponding network openings, and it

3.1.18.1 critical test object—the one test object out of any

represents a straight-line shortest-course path through the

given group of test objects that in its critical orientation,

detection zone.

produces the weakest detection signal anywhere in the detec-

3.1.12.1 Discussion—It is necessary to define discrete and

tion zone.

repeatable straight-line shortest-course test paths through the

3.1.18.2 Discussion—Depending on the particular detector,

detection zone. This can be done by using two identical

some orientation sensitive test objects may have different

networks (grids) made of nonconductive/nonmagnetic material

locations in the detection zone result in near critical sensitivity

attached across the entry and exit planes of the portal aperture

settings. Hence, care must be taken in determining the critical

so the networks coincide. A test object on the end of a probe

test object, its critical orientation, and the critical test path.

can then be passed from one side of the portal aperture to the

3.1.18.3 shielding test object, n—a test object representing

othersidethroughcorrespondingopenings,whichresultsinthe

special nuclear material shielding that might be used in a theft

test object taking a reasonably straight-line shortest-course

scenario.

path through the detection zone. If the networks are con-

structed so that they can be put in-place identically each time 3.1.18.4 Discussion—It is usually a metallic container or

they are used, then the test paths through the detection zone are metallic material configured as a credible gamma-radiation

repeatable over time. On a detection sensitivity map the shield for a specific type and quantity of special nuclear

C1270–97 (2003)

material. The object is specified by a regulatory authority or is 4.3 Testobjectsthatareorientationsensitivemusthaveeach

based on the facility threat analysis, or both. orthogonal orientation tested to determine the worst-case

orientation.

3.1.18.5 weapon test object, n—a handgun(s) or simulated

handgun designated by or satisfying the regulatory authority

5. Significance and Use

requirement for a test object.

3.1.18.6 Discussion—Care must be taken when selecting or 5.1 A complex set of variables affect metal detection and

designing a mock handgun. Simple blocks of metal shaped like detection sensitivity. Some physical characteristics of metal

a handgu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.