ASTM E605-93(2000)

(Test Method)Standard Test Methods for Thickness and Density of Sprayed Fire-Resistive Material (SFRM) Applied to Structural Members

Standard Test Methods for Thickness and Density of Sprayed Fire-Resistive Material (SFRM) Applied to Structural Members

SCOPE

1.1 These test methods cover procedures for determining thickness and density of sprayed fire-resistive material (SFRM) used in structural assemblies. These include sprayed fiber and cementitious types. The test methods are applicable to both laboratory and field procedures, as indicated in Section 7.

1.2 These test methods require the application of SFRM in accordance with the manufacturers' published instructions. The apparatus, materials, and procedure used to apply the SFRM for laboratory tests shall be the same as is used for the construction of either of the test assemblies described in Test Methods E119 and E84.

1.3 There is no intent in these test methods to establish levels of performance.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation:E605–93 (Reapproved 2000)

Standard Test Methods for

Thickness and Density of Sprayed Fire-Resistive Material

(SFRM) Applied to Structural Members

This standard is issued under the fixed designation E 605; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 3.2.2 sprayed fire-resistive materials, n— materials that are

sprayed onto substrates to provide fire-resistive protection of

1.1 These test methods cover procedures for determining

the substrates.

thicknessanddensityofsprayedfire-resistivematerial(SFRM)

3.2.3 thickness, n—the distance measured from the sub-

used in structural assemblies. These include sprayed fiber and

strate sprayed with the SFRM, through the SFRM, to the outer

cementitious types. The test methods are applicable to both

surface of the SFRM.

laboratory and field procedures, as indicated in Section 7.

1.2 These test methods require the application of SFRM in

4. Summary of Test Methods

accordance with the manufacturers’ published instructions.

4.1 The basic properties of density and thickness are deter-

The apparatus, materials, and procedure used to apply the

minedusingathicknessgage,scales,steelrules,andtemplates.

SFRM for laboratory tests shall be the same as is used for the

construction of either of the test assemblies described in Test

5. Significance and Use

Methods E 119 and E 84.

5.1 Certain properties, namely thickness and density, of

1.3 There is no intent in these test methods to establish

SFRMarebasic.Itistheintentofthesetestmethodstoprovide

levels of performance.

procedures to determine these properties.

1.4 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

6. Apparatus

responsibility of the user of this standard to establish appro-

6.1 Steel Rule, graduated in at least 1 mm ( ⁄16 in.) intervals.

priate safety and health practices and determine the applica-

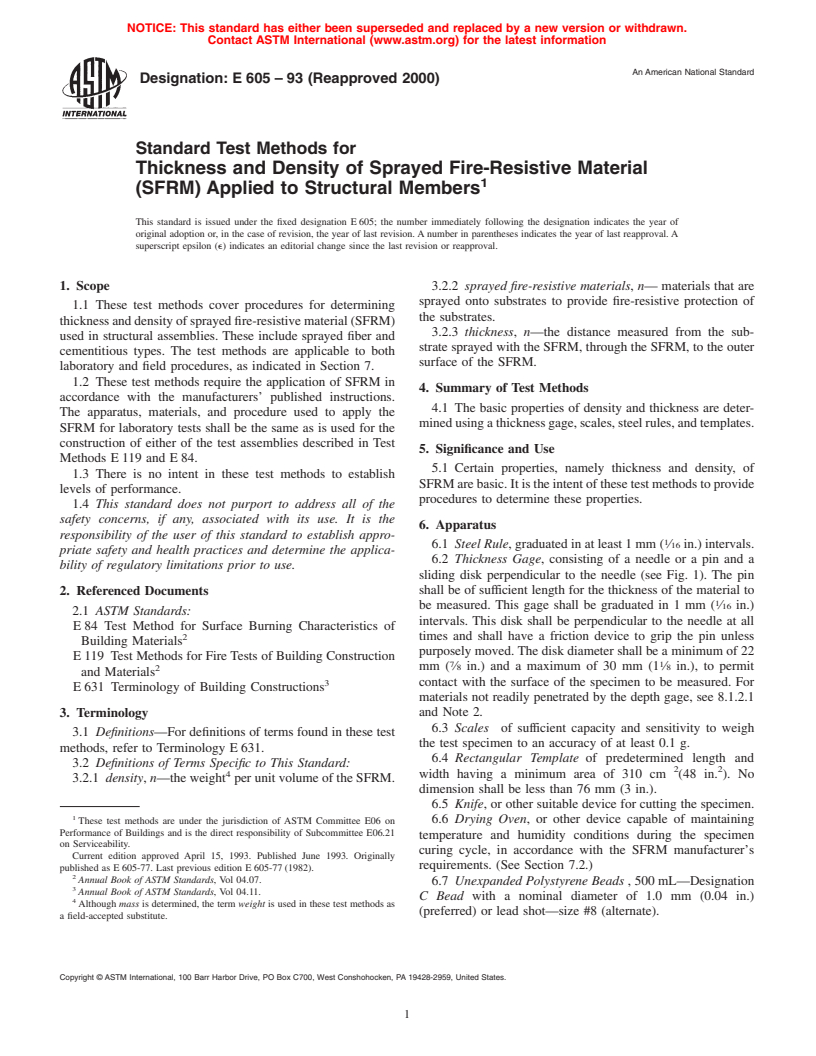

6.2 Thickness Gage, consisting of a needle or a pin and a

bility of regulatory limitations prior to use.

sliding disk perpendicular to the needle (see Fig. 1). The pin

shall be of sufficient length for the thickness of the material to

2. Referenced Documents

be measured. This gage shall be graduated in 1 mm ( ⁄16 in.)

2.1 ASTM Standards:

intervals. This disk shall be perpendicular to the needle at all

E 84 Test Method for Surface Burning Characteristics of

times and shall have a friction device to grip the pin unless

Building Materials

purposely moved. The disk diameter shall be a minimum of 22

E 119 Test Methods for Fire Tests of Building Construction

7 1

mm ( ⁄8 in.) and a maximum of 30 mm (1 ⁄8 in.), to permit

and Materials

3 contact with the surface of the specimen to be measured. For

E 631 Terminology of Building Constructions

materials not readily penetrated by the depth gage, see 8.1.2.1

3. Terminology and Note 2.

6.3 Scales of sufficient capacity and sensitivity to weigh

3.1 Definitions—For definitions of terms found in these test

the test specimen to an accuracy of at least 0.1 g.

methods, refer to Terminology E 631.

6.4 Rectangular Template of predetermined length and

3.2 Definitions of Terms Specific to This Standard:

2 2

width having a minimum area of 310 cm (48 in. ). No

3.2.1 density, n—the weight per unit volume of the SFRM.

dimension shall be less than 76 mm (3 in.).

6.5 Knife, or other suitable device for cutting the specimen.

These test methods are under the jurisdiction of ASTM Committee E06 on 6.6 Drying Oven, or other device capable of maintaining

Performance of Buildings and is the direct responsibility of Subcommittee E06.21

temperature and humidity conditions during the specimen

on Serviceability.

curing cycle, in accordance with the SFRM manufacturer’s

Current edition approved April 15, 1993. Published June 1993. Originally

requirements. (See Section 7.2.)

published as E 605-77. Last previous edition E 605-77 (1982).

Annual Book of ASTM Standards, Vol 04.07.

6.7 Unexpanded Polystyrene Beads , 500 mL—Designation

Annual Book of ASTM Standards, Vol 04.11.

C Bead with a nominal diameter of 1.0 mm (0.04 in.)

Although mass is determined, the term weight is used in these test methods as

(preferred) or lead shot—size #8 (alternate).

a field-accepted substitute.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

E605–93 (2000)

FIG. 1 Thickness Gage

member. Also, some fire rating assemblies have different thickness

6.8 Graduated Cylinders, two 250 cm .

requirements for crests and valleys of floor decks and should be averaged

6.9 Funnel—Polypropylene funnel having a top diameter of

apart.

150 mm (6 in.) and a bottom diameter of 28 mm (1.1 in.).

NOTE 2—Medium and high density SFRM may be too hard to test for

6.10 Beaker, 400 mL smooth wall type.

thickness by standard procedure. It is recommended to check thicknesses

6.11 Screed, minimum 150 mm (6 in.) long rigid straight

immediately after application, and before curing.

edge.

The applicator shall adjust the thickness of the freshly applied SFRM to

6.12 Pan—Two flat pans minimum 150 mm (6 in.) diameter yield thickness after cure, in accordance with the SFRM manufacturer’s

recommendations.

with minimum 150 mm high rim.

If the product is cured and too hard to insert the thickness gage, drill

small diameter holes into the product just large enough to accommodate

7. Test Specimen

the thickness gage pin.The thickness gage is then inserted into these holes

7.1 Laboratory Tests:

and thickness is determined by the standard procedure. These holes are to

7.1.1 The test specimens shall be SFRM applied to 1.5 mm

be closed off immediately following the test using the same SFRM.

(0.06 in. (16 ga.)), 400 by 400 mm (16 by 16 in.) bare or

8.1.3 Conducting Thickness Testing—One bay per floor or

galvanized steel plates.

one bay for each 10 000 ft , whichever provides the greater

7.1.2 The specimens shall be conditioned for a period of not

number of tests. Thickness determinations for the following

less than 72 h at room temperature, 20° 6 5°C (68°6 9°F) and

structural elements shall be conducted in each randomly

a relative humidity not greater than 60 %, until successive

selected bay: one selected area of metal deck, concrete slab, or

weightreadings,takenat24hintervals,differbylessthan1 %.

wall section; one column; and one beam (joist or truss).

7.2 Field Tests:

7.2.1 As an alternate to 7.1.2, the specimens shall be force NOTE 3—The applicable building code governs. Consult the applicable

building code for exact requirements and tolerances.

dried at a temperature of 43° 6 6°C (109°6 10°F) and a

relative humidity not greater than 60 % until successive read-

8.1.4 Tests for the Deck and Wall Section:

ings, taken at 8 h intervals, differ by less than 1 %.

8.1.4.1 Flat Decks—In the preselected area, lay out a 300

mm (12 in.) square. Take four random symmetrical measure-

8. Procedure

ments within that square and report as an average. (See Note

8.1 Thickness:

1.)

8.1.1 Selected areas to be measured for thickness shall be a

8.1.4.2 Fluted Decks—In the preselected area, lay out a 300

predetermined, repetitive pattern to ensure obtaining represen-

mm (12 in.) square. Take four random symmetrical measure-

tative average thickness.

ments within that square, one each of the following: valley,

8.1.2 Determine the thickness by inserting the penetrating

crest, and sides, and report as an average. (See Note 1.)

pin of the thickness gage perpendicular to and through the

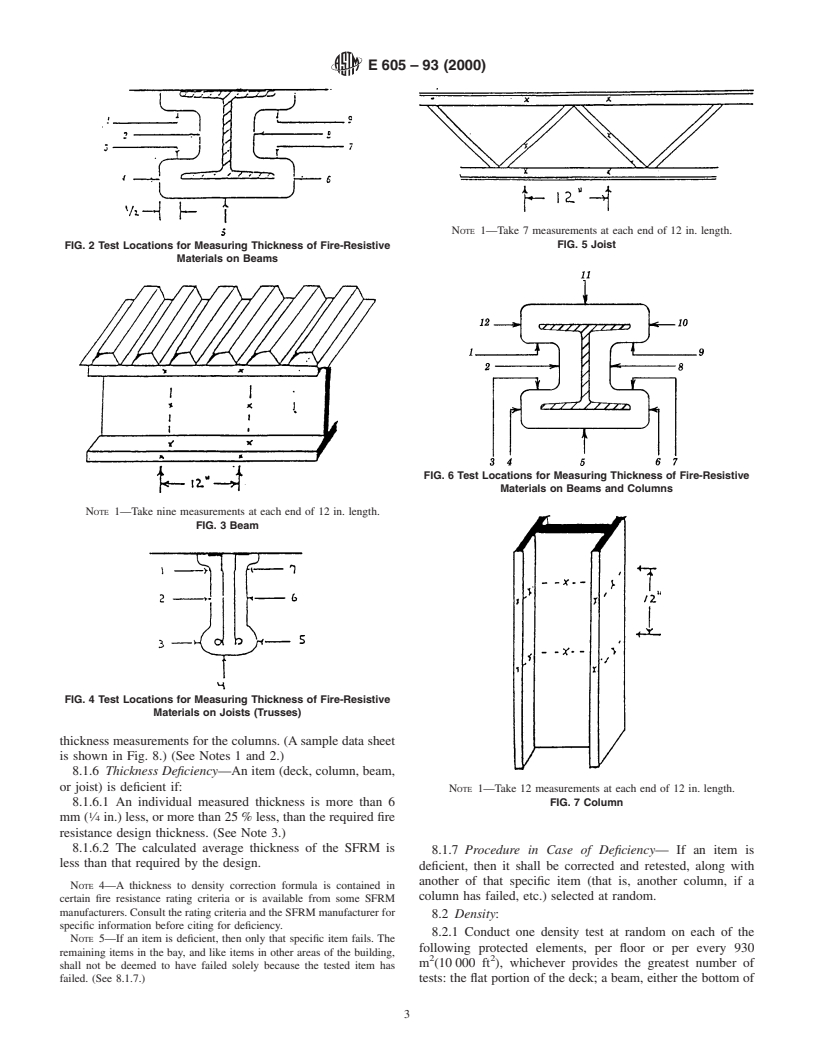

8.1.5 Test for Beams, Joists (Trusses), and Columns:

SFRM, to the substrate. When the point of the pin touches the

8.1.5.1 Beams—For each preselected beam, lay out one 300

substrate, move the sliding disk to the SFRM surface with

mm (12 in.) length and take nine thickness measurements (see

sufficient force on the disk to register the average plane of the

Fig. 2) at each end of the 300 mm length (see Fig. 3). (See

surface. Withdraw the gage to read the thickness in 1 mm ( ⁄16

Notes 1 and 2.)

in.) increments as shown by the position of the sliding clip

8.1.5.2 Joists (Trusses)—For each preselected joist (truss),

indicator.

lay out one 300 mm (12 in.) length and take seven thickness

8.1.2.1 For the purpose of averaging measurements, any

measurements (see Fig. 4) at each end of the 300 mm length

measurement 6 mm ( ⁄4 in.) or more, over the required design

(see Fig. 5). (See Notes 1 and 2.)

thickness, shall be recorded as the design thickness plus 6 mm.

8.1.5.3 Columns—For each preselected column, lay out one

No individual measured thickness shall be more than 6 mm

300 mm (12 in.) length and take twelve thickness measure-

less, or more than 25 % less, than the required design thick-

ments (see Fig. 6) at each end of the 300 mm length (see Fig.

ness.

7). (See Notes 1 and 2.)

8.1.5.4 Beams, Joists (Trusses), and Columns—Average,

NOTE 1—Specific fire

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.