ASTM D5128-90(1999)e1

(Test Method)Standard Test Method for On-Line pH Measurement of Water of Low Conductivity

Standard Test Method for On-Line pH Measurement of Water of Low Conductivity

SCOPE

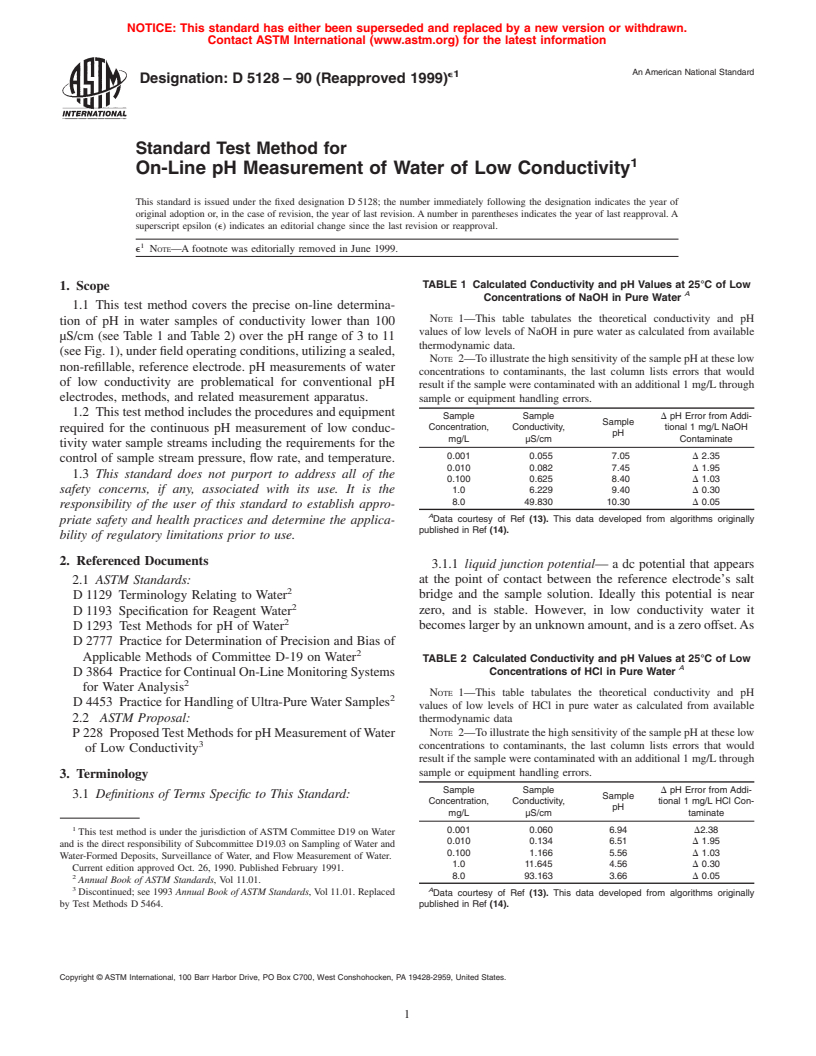

1.1 This test method covers the precise on-line determination of pH in water samples of conductivity lower than 100 [mu]S/cm (see Tables 1 and 2) over the pH range of 3 to 11 (see Fig. 1), under field operating conditions, utilizing a sealed, non-refillable, reference electrode. pH measurements of water of low conductivity are problematical for conventional pH electrodes, methods, and related measurement apparatus.

1.2 This test method includes the procedures and equipment required for the continuous pH measurement of low conductivity water sample streams including the requirements for the control of sample stream pressure, flow rate, and temperature.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation: D 5128 – 90 (Reapproved 1999)

Standard Test Method for

On-Line pH Measurement of Water of Low Conductivity

This standard is issued under the fixed designation D5128; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—A footnote was editorially removed in June 1999.

TABLE 1 Calculated Conductivity and pH Values at 25°C of Low

1. Scope

A

Concentrations of NaOH in Pure Water

1.1 This test method covers the precise on-line determina-

NOTE 1—This table tabulates the theoretical conductivity and pH

tion of pH in water samples of conductivity lower than 100

values of low levels of NaOH in pure water as calculated from available

µS/cm (see Table 1 and Table 2) over the pH range of 3 to 11

thermodynamic data.

(seeFig.1),underfieldoperatingconditions,utilizingasealed,

NOTE 2—ToillustratethehighsensitivityofthesamplepHattheselow

non-refillable, reference electrode. pH measurements of water

concentrations to contaminants, the last column lists errors that would

of low conductivity are problematical for conventional pH

result if the sample were contaminated with an additional 1 mg/Lthrough

electrodes, methods, and related measurement apparatus.

sample or equipment handling errors.

1.2 Thistestmethodincludestheproceduresandequipment

Sample Sample D pH Error from Addi-

Sample

Concentration, Conductivity, tional 1 mg/L NaOH

required for the continuous pH measurement of low conduc-

pH

mg/L µS/cm Contaminate

tivity water sample streams including the requirements for the

0.001 0.055 7.05 D 2.35

control of sample stream pressure, flow rate, and temperature.

0.010 0.082 7.45 D 1.95

1.3 This standard does not purport to address all of the

0.100 0.625 8.40 D 1.03

safety concerns, if any, associated with its use. It is the

1.0 6.229 9.40 D 0.30

8.0 49.830 10.30 D 0.05

responsibility of the user of this standard to establish appro-

A

Data courtesy of Ref (13). This data developed from algorithms originally

priate safety and health practices and determine the applica-

published in Ref (14).

bility of regulatory limitations prior to use.

2. Referenced Documents

3.1.1 liquid junction potential— a dc potential that appears

at the point of contact between the reference electrode’s salt

2.1 ASTM Standards:

bridge and the sample solution. Ideally this potential is near

D1129 Terminology Relating to Water

D1193 Specification for Reagent Water zero, and is stable. However, in low conductivity water it

becomeslargerbyanunknownamount,andisazerooffset.As

D1293 Test Methods for pH of Water

D2777 Practice for Determination of Precision and Bias of

Applicable Methods of Committee D-19 on Water

TABLE 2 Calculated Conductivity and pH Values at 25°C of Low

A

Concentrations of HCl in Pure Water

D3864 PracticeforContinualOn-LineMonitoringSystems

for Water Analysis

NOTE 1—This table tabulates the theoretical conductivity and pH

D4453 PracticeforHandlingofUltra-PureWaterSamples

values of low levels of HCl in pure water as calculated from available

2.2 ASTM Proposal: thermodynamic data

NOTE 2—ToillustratethehighsensitivityofthesamplepHattheselow

P228 ProposedTestMethodsforpHMeasurementofWater

concentrations to contaminants, the last column lists errors that would

of Low Conductivity

result if the sample were contaminated with an additional 1 mg/Lthrough

sample or equipment handling errors.

3. Terminology

Sample Sample D pH Error from Addi-

3.1 Definitions of Terms Specific to This Standard: Sample

Concentration, Conductivity, tional 1 mg/L HCl Con-

pH

mg/L µS/cm taminate

0.001 0.060 6.94 D2.38

This test method is under the jurisdiction ofASTM Committee D19 on Water

0.010 0.134 6.51 D 1.95

and is the direct responsibility of Subcommittee D19.03 on Sampling of Water and

0.100 1.166 5.56 D 1.03

Water-Formed Deposits, Surveillance of Water, and Flow Measurement of Water.

1.0 11.645 4.56 D 0.30

Current edition approved Oct. 26, 1990. Published February 1991.

8.0 93.163 3.66 D 0.05

Annual Book of ASTM Standards, Vol 11.01.

3 A

Discontinued; see 1993 Annual Book of ASTM Standards, Vol 11.01. Replaced Data courtesy of Ref (13). This data developed from algorithms originally

by Test Methods D5464. published in Ref (14).

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

D 5128 – 90 (1999)

4.2 Thistestmethoddescribestheapparatusandprocedures

to be used for the continuous on-line pH measurement of low

conductivity water sample streams. The type of pH sensor

assembly and pH instrument interface module are described in

detail. The requirements for sample stream manifolds for the

conditioning of sample pressure and flow rate are defined, and

arrangements for this associated equipment are illustrated.

Guidelines for the proper installation and calibration of the pH

sensor and associated sample manifold are discussed along

with the precautions that must be considered concerning

sample contamination and representative sampling for calibra-

tion purposes.

4.3 The apparatus and procedures described in this test

method are intended to be used with most state-of-the-art,

process-grade,pHanalyzer/transmitterinstrumentscurrentlyin

use or available from the major manufacturers of such instru-

mentation.

5. Significance and Use

5.1 pH measurements are typically made in solutions that

contain relatively large amounts of acid, base, or dissolved

salts. Under these conditions, pH determinations may be made

quicklyandprecisely.Continuouson-linepHmeasurementsin

water samples of low conductivity are more difficult (4, 5).

These low ionic strength solutions are susceptible to contami-

nation from the atmosphere, sample stream hardware, and the

pH electrodes. Variations in the constituent concentration of

low conductivity waters cause liquid junction potential shifts

(see 3.1.1) resulting in pH measurement errors.The aggressive

FIG. 1 Restrictions Imposed by the Conductivity pH Relationship

nature and the high electrical resistance of pure and ultra-pure,

low conductivity waters may degrade the pH measurement

long as it remains stable its effect can be minimized by “grab

electrodes resulting in unstable and drifting pH output signals.

sample” calibration (1).

5.2 It is essential to make on-line pH measurements of low

3.1.2 streaming potential—thestaticelectricalchargethatis

conductivity water as accurately as possible to determine the

induced by the movement of a low ionic strength solution

propercontrolofpHadjustmentchemicals,theeffectivenessof

having a high electrical resistivity or low electrical conductiv-

demineralizer equipment, the event and nature of impurity

ity (such as pure water), across relatively non-conductive

contamination of the water, and information pertaining to the

surfaces such as the pH measurement electrode’s glass mem-

overall status of the pure water system.

brane or other non-conductive wetted materials found in

flowing sample streams.

6. Interferences

3.2 Definitions: Definitions—For definitions of other terms

6.1 Samplesystemsforhighpurity,lowconductivitywaters

used in this test method, refer to Terminology D1129 and

are especially sensitive to contamination from atmospheric

Practice D3864.

gases (especially carbon dioxide, see Appendix X1 and Table

3) from collection of “crud” (insoluble deposits of iron oxide

4. Summary of Test Method

and other by-products of metallic corrosion that are present

4.1 pH is measured by a pair of electrodes contained in an

throughout the system) in sample lines, from exposure to high

all stainless steel flow cell. The pH measurement half cell is

constructed of a glass membrane suitable for continuous

TABLE 3 Calculated pH and Conductivity Values at 25°C of

serviceinlowconductivitywater.ManymodernpHelectrodes

A

Water Solutions Containing Only Ammonia and Carbon Dioxide

are available that perform well in this service. However, the

pH Shift

bulb impedance should be kept low to minimize the effects of“

Carbon Dioxide Carbon Dioxide

Caused by

0 mg/L 0.2 mg/L

streaming potential” (see 3.1.2). The reference half cell is

Ammonia 0.2 mg/L

mg/L CO

sealed (requiring no electrolyte replenishment) and is con-

Contamination

µS/cm pH µS/cm pH

structed in such a manner that the salt bridge, while making

of Sample

diffusion contact to the sample, resists significant dilution for

0 0.056 7.00 0.508 5.89 D 1.11 pH

periods up to several months on continuous operation.

0.12 1.462 8.73 1.006 8.18 D 0.55 pH

0.51 4.308 9.20 4.014 9.09 D 0.11 pH

0.85 6.036 9.34 5.788 9.26 D 0.08 pH

1.19 7.467 9.44 7.246 9.38 D 0.06 pH

The boldface numbers given in parentheses refer to a list of references at the

A

end of this standard. Data extracted from Ref (15).

e1

D 5128 – 90 (1999)

A

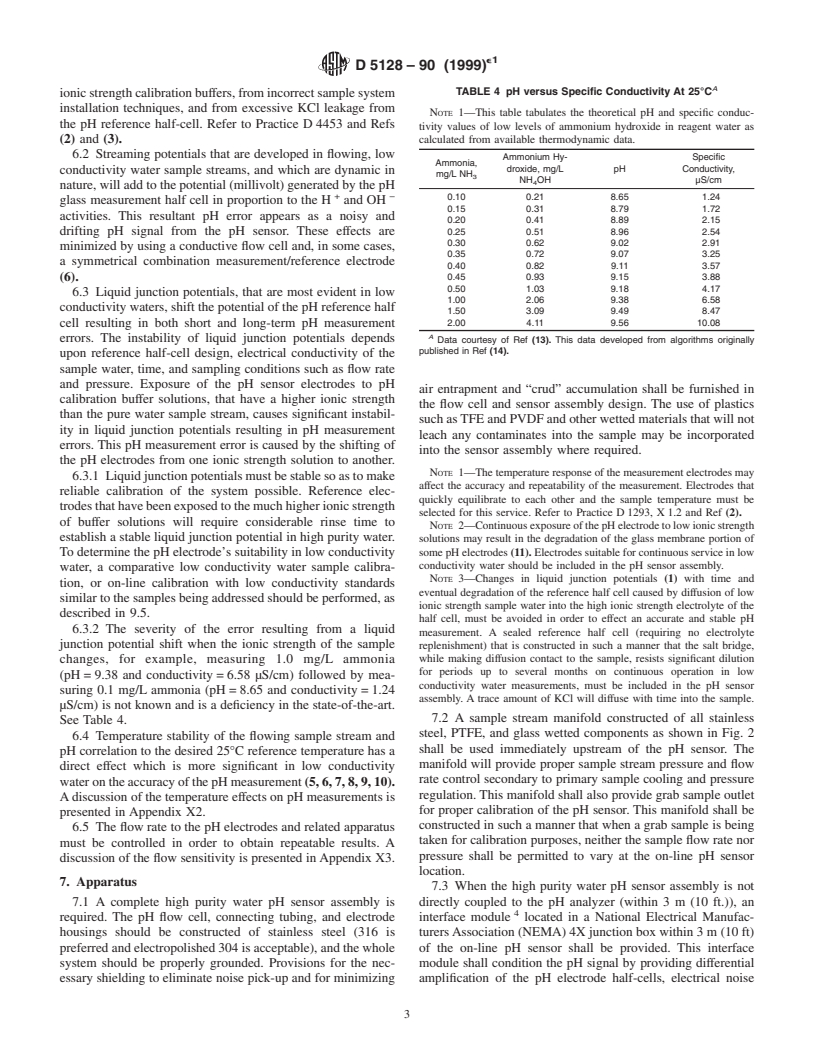

TABLE 4 pH versus Specific Conductivity At 25°C

ionicstrengthcalibrationbuffers,fromincorrectsamplesystem

installation techniques, and from excessive KCl leakage from

NOTE 1—This table tabulates the theoretical pH and specific conduc-

the pH reference half-cell. Refer to Practice D4453 and Refs

tivity values of low levels of ammonium hydroxide in reagent water as

(2) and (3). calculated from available thermodynamic data.

6.2 Streaming potentials that are developed in flowing, low

Ammonium Hy- Specific

Ammonia,

droxide, mg/L pH Conductivity,

conductivity water sample streams, and which are dynamic in

mg/L NH

NH OH µS/cm

nature,willaddtothepotential(millivolt)generatedbythepH

+ −

0.10 0.21 8.65 1.24

glass measurement half cell in proportion to the H and OH

0.15 0.31 8.79 1.72

activities. This resultant pH error appears as a noisy and

0.20 0.41 8.89 2.15

0.25 0.51 8.96 2.54

drifting pH signal from the pH sensor. These effects are

0.30 0.62 9.02 2.91

minimized by using a conductive flow cell and, in some cases,

0.35 0.72 9.07 3.25

a symmetrical combination measurement/reference electrode

0.40 0.82 9.11 3.57

(6). 0.45 0.93 9.15 3.88

0.50 1.03 9.18 4.17

6.3 Liquid junction potentials, that are most evident in low

1.00 2.06 9.38 6.58

conductivitywaters,shiftthepotentialofthepHreferencehalf

1.50 3.09 9.49 8.47

cell resulting in both short and long-term pH measurement 2.00 4.11 9.56 10.08

A

errors. The instability of liquid junction potentials depends

Data courtesy of Ref (13). This data developed from algorithms originally

published in Ref (14).

upon reference half-cell design, electrical conductivity of the

sample water, time, and sampling conditions such as flow rate

and pressure. Exposure of the pH sensor electrodes to pH

air entrapment and “crud” accumulation shall be furnished in

calibration buffer solutions, that have a higher ionic strength

the flow cell and sensor assembly design. The use of plastics

than the pure water sample stream, causes significant instabil-

suchasTFEandPVDFandotherwettedmaterialsthatwillnot

ity in liquid junction potentials resulting in pH measurement

leach any contaminates into the sample may be incorporated

errors. This pH measurement error is caused by the shifting of

into the sensor assembly where required.

the pH electrodes from one ionic strength solution to another.

NOTE 1—Thetemperatureresponseofthemeasurementelectrodesmay

6.3.1 Liquidjunctionpotentialsmustbestablesoastomake

affect the accuracy and repeatability of the measurement. Electrodes that

reliable calibration of the system possible. Reference elec-

quickly equilibrate to each other and the sample temperature must be

trodesthathavebeenexposedtothemuchhigherionicstrength

selected for this service. Refer to Practice D1293, X1.2 and Ref (2).

of buffer solutions will require considerable rinse time to

NOTE 2—ContinuousexposureofthepHelectrodetolowionicstrength

establish a stable liquid junction potential in high purity water.

solutions may result in the degradation of the glass membrane portion of

somepHelectrodes(11).Electrodessuitableforcontinuousserviceinlow

TodeterminethepHelectrode’ssuitabilityinlowconductivity

conductivity water should be included in the pH sensor assembly.

water, a comparative low conductivity water sample calibra-

NOTE 3—Changes in liquid junction potentials (1) with time and

tion, or on-line calibration with low conductivity standards

eventual degradation of the reference half cell caused by diffusion of low

similartothesamplesbeingaddressedshouldbeperformed,as

ionic strength sample water into the high ionic strength electrolyte of the

described in 9.5.

half cell, must be avoided in order to effect an accurate and stable pH

6.3.2 The severity of the error resulting from a liquid

measurement. A sealed reference half cell (requiring no electrolyte

junction potential shift when the ionic strength of the sample

replenishment) that is constructed in such a manner that the salt bridge,

while making diffusion contact to the sample, resists significant dilution

changes, for example, measuring 1.0 mg/L ammonia

for periods up to several months on continuous operation in low

(pH=9.38 and conductivity=6.58 µS/cm) followed by mea-

conductivity water measurements, must be included in the pH sensor

suring 0.1 mg/L ammonia (pH=8.65 and conductivity=1.24

assembly. A trace amount of KCl will diffuse with time into the sample.

µS/cm) is not known and is a deficiency in the state-of-the-art.

7.2 A sample stream manifold constructed of all stainless

See Table 4.

steel, PTFE, and glass wetted components as shown in Fig. 2

6.4 Temperature stability of the flowing sample stream and

shall be used immediately upstream of the pH sensor. The

pH correlation to the desired 25°C reference temperature has a

manifold will provide proper sample stream pressure and flow

direct effect which is more significant in low conductivity

rate control secondary to primary sample cooling and pressure

waterontheaccuracyofthepHmeasurement(5,6,7,8,9,10).

regulation.This manifold shall also provide grab sample outlet

AdiscussionofthetemperatureeffectsonpHmeasurementsis

for proper calibration of the pH sensor. This manifold shall be

presented in Appendix X2.

constructed in such a manner that when a grab sample is being

6.5 The flow rate to the pH electrodes and related apparatus

taken for calibration purposes, neither the sample flow rate nor

must be controlled in order to obtain repeatable results. A

pressure shall be permitted to vary at the on-line pH sensor

discussion of the flow sensitivity is presented inAppendix X3.

location.

7. Apparatus

7.3 When the high purity water pH sensor assembly is not

7.1 A complete high purity water pH sensor assembly is directly coupled to the pH anal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.