ASTM F2973-14

(Specification)Standard Specification for Insulating Lifting Links for Load Lifting Equipment Working Near Energized Power Lines

Standard Specification for Insulating Lifting Links for Load Lifting Equipment Working Near Energized Power Lines

SCOPE

1.1 This specification covers insulating lifting links used for protection of workers positioning a load from accidental contact of the load lifting equipment with live electrical conductors, apparatus, and circuits.

1.2 This specification includes design, material, and testing requirements for the manufacturer and in-service inspection, testing and care requirements for the user or the agent of the user.

1.3 Insulating links whose primary application does not pertain to power line electrical safety are not within the scope of this specification.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2973 −14

StandardSpecification for

Insulating Lifting Links for Load Lifting Equipment Working

Near Energized Power Lines

This standard is issued under the fixed designation F2973; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 ISO Standard:

ISO 7500–1Metallic materials - Verification of static uni-

1.1 Thisspecificationcoversinsulatingliftinglinksusedfor

axial testing machines - Part 1: Tensile testing machines -

protection of workers positioning a load from accidental

Corrigendum

contact of the load lifting equipment with live electrical

conductors, apparatus, and circuits.

3. Terminology

1.2 This specification includes design, material, and testing

3.1 Definitions—Terminologyusedinthisspecificationisin

requirements for the manufacturer and in-service inspection,

accordance with Terminology F819.

testing and care requirements for the user or the agent of the

3.2 Definitions of Terms Specific to This Standard:

user.

3.2.1 design verification test, n—test made on a sample

1.3 Insulating links whose primary application does not

treated as representative of an industrial product.

pertain to power line electrical safety are not within the scope

3.2.2 electrical test, n—a test ensuring that a product meets

of this specification.

the minimum electrical requirements of the standard.

1.4 The values stated in SI units are to be regarded as

3.2.3 flashover, n—adisruptivedischargeoverthesurfaceof

standard. No other units of measurement are included in this

the insulating link.

standard.

3.2.4 mechanical test, n—a test confirming that a product

1.5 This standard does not purport to address all of the

meets the minimum mechanical requirements of a standard.

safety concerns, if any, associated with its use. It is the

3.2.5 proof load, n—specific mechanical load applied in the

responsibility of the user of this standard to establish appro-

performance of the proof load test.

priate safety and health practices and determine the applica-

3.2.6 proof test, n—mechanical and electrical tests per-

bility of regulatory limitations prior to use.

formed by the manufacturer on all production units.

2. Referenced Documents 3.2.7 puncture, n—disruptive discharge through an insula-

tor.

2.1 ASTM Standards:

3.2.8 qualified personnel, n—personnel who, by possession

E4Practices for Force Verification of Testing Machines

of a recognized degree, certificate, professional standing, or

F819Terminology Relating to Electrical Protective Equip-

skill, and who, by knowledge, training, and experience, have

ment for Workers

demonstrated the ability to deal with problems relating to the

2.2 IEEE Standard:

subject matter, the work, or the project.

IEEE 4Standard Techniques for High-Voltage Testing

3.2.9 rated load, n—the maximum working load.

3.2.10 visual inspection, n—visual check made to detect

defects that impede the performance of a product(s).

This specification is under the jurisdiction of ASTM Committee F18 on

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.55 on Inspection and Non-Destructive Test Methods for Aerial 4. Materials and Manufacture

Devices.

4.1 The mechanical design factor shall not be less than 5.0

Current edition approved Oct. 1, 2014. Published October 2014. DOI: 10.1520/

F2973-14 times its rated load for ratings up to 100 tons and 4.0 times

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

rated load for ratings 100 tons and up.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

445 Hoes Ln., Piscataway, NJ 08854, http://www.ieee.org. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2973−14

4.2 The electrical design factor of the link shall not be less 6.3 The electrical test set up shall provide the operator

than 2 times it rated use voltage. protection in the performance of his duties and isolate the

specimen to guard against accidental contact by persons in the

4.3 The insulation system shall not absorb water and shall

vicinity.

have a water repellent surface.

6.4 The ambient temperature for the test location shall not

4.4 Weather shields shall be made of impact resistant

be lower than 15.5 °C.

nonconductive material.

6.5 Electrical discharge characteristics and measured cur-

4.5 UV resistant polymers should be employed by the

rent of a test object can be affected by its general arrangement,

manufacturer if, without them, electrical performance may be

such as the clearance from other energized or grounded

affected.

structures,theheightabovegroundlevel,orthearrangementof

4.6 Steel used shall meet ASTM or AISI standards.

the high-voltage lead that may affect flashover voltages. For

thatreason,thegeneralarrangementshouldbeasshowninFig.

5. Workmanship and Finish

1 for testing links that are not installed on load lifting

5.1 The insulating surface of the links shall be free of

equipment.

cracks, nicks, gouges, damage to the insulating surface that

6.6 Clearance to nearby structures that are equal to or

would affect its insulating properties in both dry and wet

greater than two times the length of the shortest possible

conditions.

electrical discharge path on the test object should make any

5.2 Markings—Each link should bear permanent,

proximity effects negligible.

accessible, and readily visible markings that include, at a

minimum, the manufacturer’s mark, ASTM XXX, unit serial

7. Design Verification Tests

number, rated voltage, and rated load.

7.1 Design verification tests are to be performed on at least

5.3 Manuals—The manufacturer shall provide a manual

one representative unit from each class of insulating link, and

with each link. The manual shall contain:

thiswillqualifythatclassoflinkmodelsofvariableratedloads

5.3.1 Descriptions, specifications, and ratings of the link.

for a given rated voltage. A test unit is considered to be

5.3.2 Ambient temperature range for which the link is

representative of its group if it meets the following require-

designed.

ments:

5.3.3 Precautions concerning weather.

7.1.1 Thesamestructuralanddielectricmaterials,structural

5.3.4 Instructions regarding routine and frequency of in-

designs, manufacturing, and assembly methods apply to all

spections and maintenance.

links in the group,

7.1.2 The same structural stress and loading analysis can be

6. General Test Requirements

applied to all the links in the group,

6.1 Personnel responsible for the tests outlined in this

7.1.3 The test unit has the same or smaller electrical

document shall be qualified individuals as per 3.2.8, knowl-

creepage and arcing distances per kV of rating.

edgeable in the use of the test equipment used for tensile

loading and high-voltage testing.

7.2 Mechanical Design Verification Test Procedure:

6.2 The electrical test equipment shall meet the require- 7.2.1 The insulating link shall withstand a tensile load test

ments of IEEE 4-1995. The metering systems including mea- of 5.0 times its rated load for rating up to 100 tons and 4.0

surementcableusedtomeasureACcurrentshallhaveasystem times rated load for ratings 100 tons and up for 60 s without

error of5%or less. separation.Thetensileloadtestistobeperformedonatestbed

FIG. 1Suggested Test Set Up for Insulated Links

F2973−14

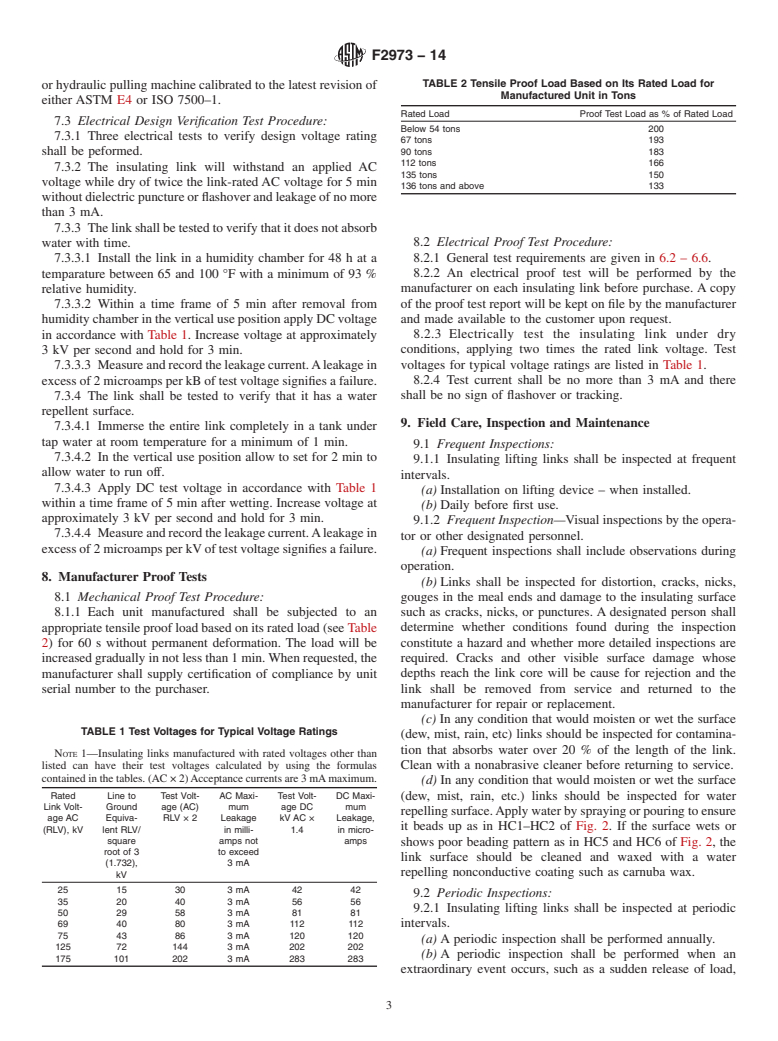

TABLE 2 Tensile Proof Load Based on Its Rated Load for

orhydraulicpullingmachinecalibratedtothelatestrevisionof

Manufactured Unit in Tons

either ASTM E4 or ISO 7500–1.

Rated Load Proof Test Load as % of Rated Load

7.3 Electrical Design Verification Test Procedure:

Below 54 tons 200

7.3.1 Three electrical tests to verify design voltage rating

67 tons 193

shall be peformed. 90 tons 183

112 tons 166

7.3.2 The insulating link will withstand an applied AC

135 tons 150

voltage while dry of twice the link-ratedAC voltage for 5 min

136 tons and above 133

withoutdielectricpunctureorflashoverandleakageofnomore

than 3 mA.

7.3.3 Thelinkshallbetestedtoverifythatitdoesnotabsorb

water with time. 8.2 Electrical Proof Test Procedure:

8.2.1 General test requirements are given in 6.2 – 6.6.

7.3.3.1 Install the link in a humidity chamber for 48 h at a

temparature between 65 and 100 °F with a minimum of 93 % 8.2.2 An electrical proof test will be performed by the

manufacturer on each insulating link before purchase. A copy

relative humidity.

7.3.3.2 Within a time frame of 5 min after removal from oftheprooftestreportwillbekeptonfilebythemanufacturer

humiditychamberintheverticalusepositionapplyDCvoltage and made available to the customer upon request.

in accordance with Table 1. Increase voltage at approximately 8.2.3 Electrically test the insulating link under dry

3 kV per second and hold for 3 min. conditions, applying two times the rated link voltage. Test

voltages for typical voltage ratings are listed in Table 1.

7.3.3.3 Measureandrecordtheleakagecurrent.Aleakagein

excessof2microampsperkBoftestvoltagesignifiesafailure. 8.2.4 Test current s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.