ASTM F2973-21

(Specification)Standard Specification for Insulating Lifting Links for Load Lifting Equipment Working Near Energized Power Lines

Standard Specification for Insulating Lifting Links for Load Lifting Equipment Working Near Energized Power Lines

SCOPE

1.1 This specification covers insulating lifting links used for protection of workers positioning a load from accidental contact of the load lifting equipment with live electrical conductors, apparatus, and circuits.

1.2 This specification includes design, material, and testing requirements for the manufacturer and in-service inspection, testing and care requirements for the user or the agent of the user.

1.3 Insulating links whose primary application does not pertain to power line electrical safety are not within the scope of this specification.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:F2973 −21

Standard Specification for

Insulating Lifting Links for Load Lifting Equipment Working

1

Near Energized Power Lines

This standard is issued under the fixed designation F2973; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope F819 Terminology Relating to Electrical Protective Equip-

ment for Workers

1.1 This specification covers insulating lifting links used for

3

2.2 IEEE Standard:

protection of workers positioning a load from accidental

IEEE 4 Standard Techniques for High-Voltage Testing

contact of the load lifting equipment with live electrical

4

2.3 ISO Standard:

conductors, apparatus, and circuits.

ISO 7500–1 Metallic Materials—Verification of Static Uni-

1.2 This specification includes design, material, and testing

axial Testing Machines—Part 1: Tensile Testing

requirements for the manufacturer and in-service inspection,

Machines—Corrigendum

testing and care requirements for the user or the agent of the

user.

3. Terminology

1.3 Insulating links whose primary application does not

3.1 Definitions—Terminology used in this specification is in

pertain to power line electrical safety are not within the scope

accordance with Terminology F819.

of this specification.

3.2 Definitions of Terms Specific to This Standard:

1.4 The values stated in SI units are to be regarded as

3.2.1 design verification test, n—test made on a sample

standard. No other units of measurement are included in this

treated as representative of an industrial product.

standard.

3.2.2 electrical test, n—a test ensuring that a product meets

1.5 This standard does not purport to address all of the

the minimum electrical requirements of the standard.

safety concerns, if any, associated with its use. It is the

3.2.3 flashover, n—adisruptivedischargeoverthesurfaceof

responsibility of the user of this standard to establish appro-

the insulating link.

priate safety, health, and environmental practices and deter-

3.2.4 mechanical test, n—a test confirming that a product

mine the applicability of regulatory limitations prior to use.

meets the minimum mechanical requirements of a standard.

1.6 This international standard was developed in accor-

dance with internationally recognized principles on standard- 3.2.5 proof load, n—specific mechanical load applied in the

ization established in the Decision on Principles for the

performance of the proof load test.

Development of International Standards, Guides and Recom-

3.2.6 proof test, n—mechanical and electrical tests per-

mendations issued by the World Trade Organization Technical

formed by the manufacturer on all production units.

Barriers to Trade (TBT) Committee.

3.2.7 puncture, n—disruptive discharge through an insula-

tor.

2. Referenced Documents

3.2.8 qualified personnel, n—personnel who, by possession

2

2.1 ASTM Standards:

of a recognized degree, certificate, professional standing, or

E4 Practices for Force Verification of Testing Machines

skill, and who, by knowledge, training, and experience, have

demonstrated the ability to deal with problems relating to the

subject matter, the work, or the project.

1

This specification is under the jurisdiction of ASTM Committee F18 on

3.2.9 rated load, n—the maximum working load.

Electrical Protective Equipment for Workers and is the direct responsibility of

Subcommittee F18.55 on Inspection and Non-Destructive Test Methods for Aerial

3.2.10 visual inspection, n—visual check made to detect

Devices.

defects that impede the performance of a product(s).

Current edition approved May 1, 2021. Published May 2021. Originally

approved in 2014. Last previous edition approved in 2016 as F2973 – 16. DOI:

10.1520/F2973-21

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE),

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 445 Hoes Ln., Piscataway, NJ 08854, http://www.ieee.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2973−21

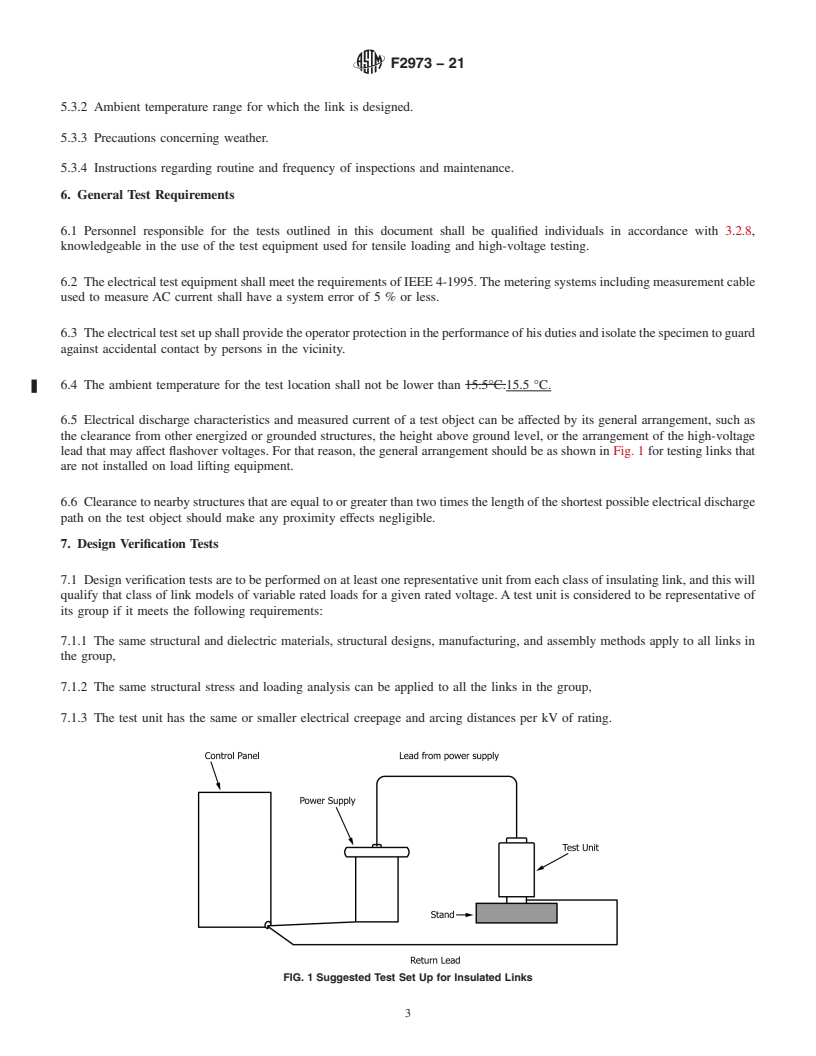

4. Materials and Manufacture 6.2 The electrical test equipment shall meet the require-

men

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2973 − 16 F2973 − 21

Standard Specification for

Insulating Lifting Links for Load Lifting Equipment Working

1

Near Energized Power Lines

This standard is issued under the fixed designation F2973; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers insulating lifting links used for protection of workers positioning a load from accidental contact of

the load lifting equipment with live electrical conductors, apparatus, and circuits.

1.2 This specification includes design, material, and testing requirements for the manufacturer and in-service inspection, testing

and care requirements for the user or the agent of the user.

1.3 Insulating links whose primary application does not pertain to power line electrical safety are not within the scope of this

specification.

1.4 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.6 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

E4 Practices for Force Verification of Testing Machines

F819 Terminology Relating to Electrical Protective Equipment for Workers

3

2.2 IEEE Standard:

IEEE 4 Standard Techniques for High-Voltage Testing

4

2.3 ISO Standard:

ISO 7500–1 Metallic Materials—Verification of Static Uniaxial Testing Machines—Part 1: Tensile Testing Machines—

Corrigendum

1

This specification is under the jurisdiction of ASTM Committee F18 on Electrical Protective Equipment for Workers and is the direct responsibility of Subcommittee

F18.55 on Inspection and Non-Destructive Test Methods for Aerial Devices.

Current edition approved Oct. 1, 2016May 1, 2021. Published November 2016May 2021. Originally approved in 2014. Last previous edition approved in 20152016 as

F2973 – 15.16. DOI: 10.1520/F2973-1610.1520/F2973-21

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from Institute of Electrical and Electronics Engineers, Inc. (IEEE), 445 Hoes Ln., Piscataway, NJ 08854, http://www.ieee.org.

4

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2973 − 21

3. Terminology

3.1 Definitions—Terminology used in this specification is in accordance with Terminology F819.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 design verification test, n—test made on a sample treated as representative of an industrial product.

3.2.2 electrical test, n—a test ensuring that a product meets the minimum electrical requirements of the standard.

3.2.3 flashover, n—a disruptive discharge over the surface of the insulating link.

3.2.4 mechanical test, n—a test confirming that a product meets the minimum mechanical requirements of a standard.

3.2.5 proof load, n—specific mechanical load applied in the performance of the proof load test.

3.2.6 proof test, n—mechanical and electrical tests performed by the manufacturer on all production units.

3.2.7 puncture, n—disruptive discharge through an insulator.

3.2.8 qualified personnel, n—personnel who, by possession of a recognized degree, certificate, professional standing, or skill, and

who, by knowledge, training, and experience, have demonstrated the ability to deal with problems relating to the subject matter,

the work, or the project.

3.2.9 rated load, n—the maximum working load.

3.2.10 visu

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.