ASTM C444M-03

(Specification)Standard Specification for Perforated Concrete Pipe (Metric)

Standard Specification for Perforated Concrete Pipe (Metric)

ABSTRACT

This specification covers perforated concrete pipe intended to be used for underdrainage. Pipe manufactured to this specification shall be of two classes, Type 1 and Type 2, describing two arrangements of perforations for pipe manufactured to the standard specifications for plain or reinforced concrete pipe, and their classifications. The acceptability of the pipe shall be determined by the results of all applicable tests prescribed for the type and class of pipe specified. The joints shall be of such design and the ends of the concrete pipe sections so formed that the pipe can be laid together to make a continuous line of pipe.

SCOPE

1.1 This specification covers perforated concrete pipe intended to be used for underdrainage.

1.2 This specification is the metric counterpart of Specification C 444.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C 444M – 03

Standard Specification for

1

Perforated Concrete Pipe (Metric)

This standard is issued under the fixed designation C 444M; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

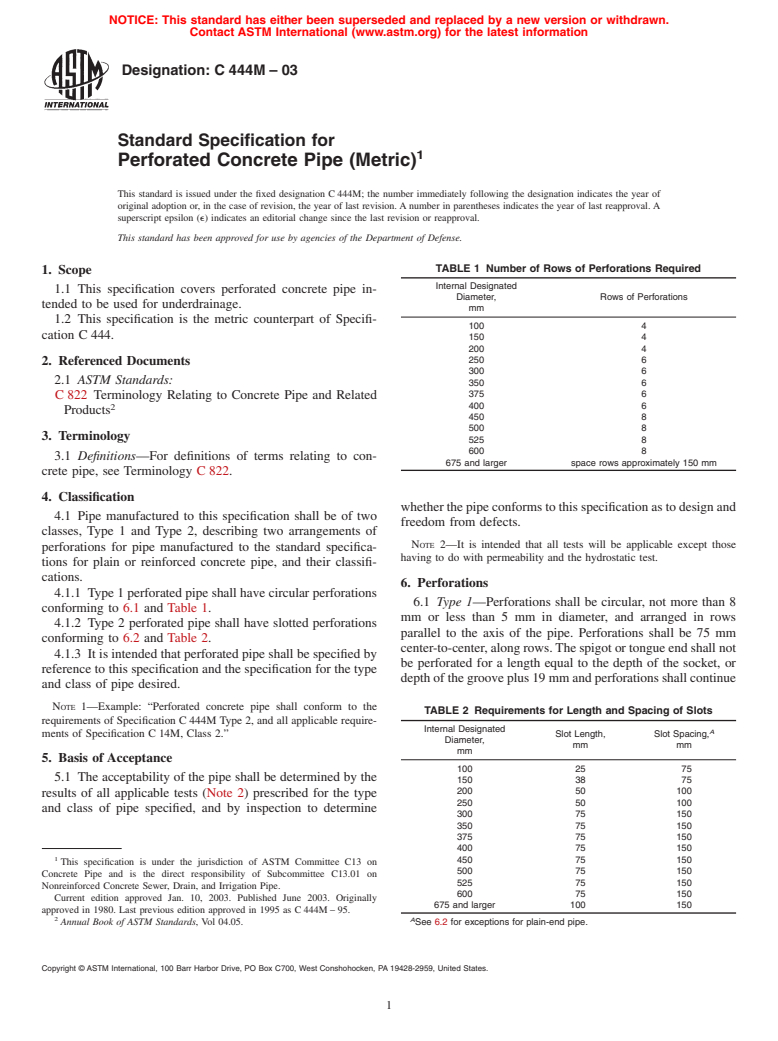

TABLE 1 Number of Rows of Perforations Required

1. Scope

Internal Designated

1.1 This specification covers perforated concrete pipe in-

Diameter, Rows of Perforations

tended to be used for underdrainage.

mm

1.2 This specification is the metric counterpart of Specifi-

100 4

cation C 444.

150 4

200 4

250 6

2. Referenced Documents

300 6

2.1 ASTM Standards:

350 6

375 6

C 822 Terminology Relating to Concrete Pipe and Related

400 6

2

Products

450 8

500 8

3. Terminology

525 8

600 8

3.1 Definitions—For definitions of terms relating to con-

675 and larger space rows approximately 150 mm

crete pipe, see Terminology C 822.

4. Classification

whetherthepipeconformstothisspecificationastodesignand

4.1 Pipe manufactured to this specification shall be of two

freedom from defects.

classes, Type 1 and Type 2, describing two arrangements of

NOTE 2—It is intended that all tests will be applicable except those

perforations for pipe manufactured to the standard specifica-

having to do with permeability and the hydrostatic test.

tions for plain or reinforced concrete pipe, and their classifi-

cations.

6. Perforations

4.1.1 Type 1 perforated pipe shall have circular perforations

6.1 Type 1—Perforations shall be circular, not more than 8

conforming to 6.1 and Table 1.

mm or less than 5 mm in diameter, and arranged in rows

4.1.2 Type 2 perforated pipe shall have slotted perforations

parallel to the axis of the pipe. Perforations shall be 75 mm

conforming to 6.2 and Table 2.

center-to-center,alongrows.Thespigotortongueendshallnot

4.1.3 It is intended that perforated pipe shall be specified by

be perforated for a length equal to the depth of the socket, or

reference to this specification and the specification for the type

depthofthegrooveplus19mmandperforationsshallcontinue

and class of pipe desired.

NOTE 1—Example: “Perforated concrete pipe shall conform to the

TABLE 2 Requirements for Length and Spacing of Slots

requirements of Specification C 444M Type 2, and all applicable require-

Internal Designated

A

ments of Specification C 14M, Class 2.” Slot Length, Slot Spacing,

Diameter,

mm mm

mm

5. Basis of Acceptance

100 25 75

5.1 The acceptability of the pipe shall be determined by the

150 38 75

200 50 100

results of all applicable tests (Note 2) prescribed for the type

250 50 100

and class of pipe specified, and by inspection to determine

300 75 150

350 75 150

375 75 150

400 75 150

1

450 75 150

This specification is under the jurisdiction of ASTM Committee C13 on

500 75 150

Concrete Pipe and is the direct responsibility of Subcommittee C13.01 on

525 75 150

Nonreinforced Concrete Sewer, Drain, and Irrigation Pipe.

600 75 150

Current edition approved Jan. 10, 2003. Published June 2003. Originally

675 and larger 100 150

approved in 1980. Last previous edition approved in 1995 as C 444M – 95.

2 A

Annual Book of ASTM Standards, Vol 04.05. See 6.2 for exceptions for plain-end pipe.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

C444M–03

at uniform spacing along the length of the barrel. The number the spacing of holes or slots in any row, shall be 613 mm

of rows shall be as shown inTable 1.The rows shall be spaced except as required to provide specified cover for reinforcing

over not more than 165° of circumference. Rows shall be steel.

symmetrically arranged with respect to the intended top or

9. Repairs

bottom of the pipe.

9.1 Pipe repaired because of imperfections in manufacture

6.2 Type 2—Slots shall be circumferential in direction, not

or damage during handling will be acceptable, if in the opinion

more than 5 mm or less than 3 mm in width, and of the lengths

of the owner, the repairs are sound and properly finished and

showninTable2.Thereshallbetworowsofslots,spaced165°

cured and the repaired pipe conforms to the requirements of

apart, and centered, in the case of elliptically reinforced pipe,

this specification.

abouttheminoraxisofthereinforcing.Slotsshallbespacedas

showninTable2,exceptasmodifiedhereinforplain-endpipe.

10. Marking of Rejected Specimens

The distance from the spigot end, or from the shoulder of the

10.1 All rejected pipe shall be marked clearly by the owner

tongue end, to the first pair of slots shall be not more than 25

and shall be

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.