ASTM A291-03

(Specification)Standard Specification for Steel Forgings, Carbon and Alloy, for Pinions, Gears and Shafts for Reduction Gears

Standard Specification for Steel Forgings, Carbon and Alloy, for Pinions, Gears and Shafts for Reduction Gears

SCOPE

1.1 This specification covers normalized and tempered carbon steel and quenched and tempered alloy steel forgings for pinions, gears, and shafts.

1.2 Several grades of steel are covered as follows:

1.2.1 Grade 1 Class A is normalized and tempered carbon steel.

1.2.2 Grade 2 Class B, Grade 3 Class C, Grade 3A Class D, Grades 4 to 7 Classes E, F, G, and H, Grade 8 Class I, and Grade 9 Class J are liquid quenched and tempered alloy steel.

1.3 All grades and classes are considered weldable under proper conditions. Welding technique is of fundamental importance and it is presupposed that welding procedure and inspection shall be in accordance with approved methods for the class of material used.

1.4 The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

Designation: A 291 – 03

Standard Specification for

Steel Forgings, Carbon and Alloy, for Pinions, Gears and

1

Shafts for Reduction Gears

This standard is issued under the fixed designation A 291; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope* 4. Heat Treatment

1.1 This specification covers normalized and tempered car- 4.1 Preliminary Heat Treatment:

bon steel and quenched and tempered alloy steel forgings for 4.1.1 The forgings shall be given such preliminary heat

pinions, gears, and shafts. treatment as is proper for the design and composition. The

1.2 Several grades of steel are covered as follows: forgings shall be heated to a suitable temperature for a

1.2.1 Grade 1 Class A is normalized and tempered carbon sufficientlengthoftimeforaustenitizationandshallbesuitably

steel. cooled to bring about complete transformation.

1.2.2 Grade 2 Class B, Grade 3 Class C, Grade 3AClass D, 4.1.2 Forgings may be immediately treated for mechanical

Grades 4 to 7 Classes E, F, G, and H, Grade 8 Class I, and properties after preliminary heat treatment or may be rough

Grade 9 Class J are liquid quenched and tempered alloy steel. turned prior to treatment for mechanical properties.

1.3 All grades and classes are considered weldable under 4.2 Heat Treatment for Mechanical Properties—The forg-

proper conditions. Welding technique is of fundamental impor- ing shall be reheated to a temperature above the upper critical

tance and it is presupposed that welding procedure and temperature and held a sufficient length of time for complete

inspection shall be in accordance with approved methods for austenitization. Grade 1 shall be air cooled while Grades 2

the class of material used. through 9 shall be liquid quenched.

1.4 The values stated in inch-pound units are to be regarded 4.3 Tempering—The forgings shall be tempered to develop

as the standard. The values given in parentheses are for the specified properties. Minimum tempering temperatures

information only. shall be as follows:

Minimum Tempering Temperature

2. Referenced Documents

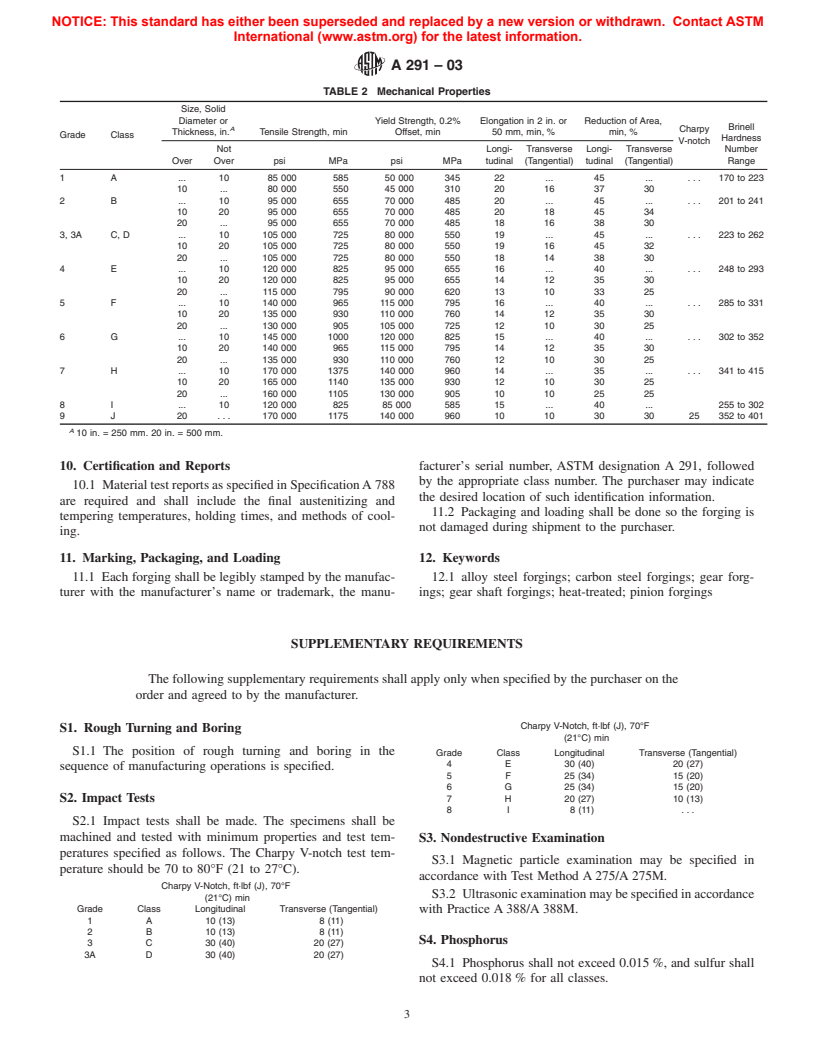

Grade Class °F (°C)

1 and 2 A and B 1150 (620)

2.1 ASTM Standards:

3, 3A, and 4 C, D, and E 1075 (580)

A 275/A 275M Test Method for Magnetic Particle Exami-

5, 6, 7 F, G, and H 1050 (565)

2

8 I 1100 (595)

nation of Steel Forgings

9 J 1000 (540)

A 388/A 388M Practice for Ultrasonic Examination of

2

Heavy Steel Forgings The charge shall be cooled under uniform conditions in the

A 788 Specification for Steel Forgings, General Require- furnace at a maximum rate of 100°F (55°C) per h to 600°F

2

ments (316°C).

4.4 Stress Relief—If the manufacturer elects to heat treat for

3. Ordering Information

mechanical properties prior to machining, the forgings shall be

3.1 Instructions for purchasing forgings to this specification stress relieved after machining (4.5) at a temperature that is 50

should be in accordance with Specification A 788. In addition, to 100°F (28 to 55°C) below the last previous tempering

a detailed drawing, sketch, or written description of the forging temperature but in no case below 1000°F (540°C). The

should be included with the inquiry or order. forgings shall be cooled under uniform conditions in the

3.2 Supplementary requirements are provided and shall furnace at a maximum rate of 100°F (55°C)/h to 600°F

apply only when specified in the purchase order. (316°C).

4.5 Machining:

4.5.1 Rough machining before heat treatment for mechani-

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

cal properties may be performed at the option of the manufac-

Stainless Steel and RelatedAlloys, and is the direct responsibility of Subcommittee

turer.

A01.06 on Steel Forgings and Billets.

Current edition approved Apr. 10, 2003. Published June 2003. Originally

approved in 1946. Last previous edition approved in 2002 as A291 – 02.

2

Annual Book of ASTM Standards, Vol 01.05.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn. Contact ASTM

International (www.astm.org) for the latest information.

A 291–03

4.5.2 If the producer elects to heat treat for mechanical may be tested in lots; the number of forgings to make up a lot

properties prior to machining, the forgings shall be stress shall be by mutual agreement.

relieved after machining. 7.1.3.2 Tension and impact test specimens shall be tak

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.