ASTM F2659-23

(Guide)Standard Guide for Preliminary Evaluation of Comparative Moisture Condition of Concrete, Gypsum Cement and Other Floor Slabs and Screeds Using a Non-Destructive Electronic Moisture Meter

Standard Guide for Preliminary Evaluation of Comparative Moisture Condition of Concrete, Gypsum Cement and Other Floor Slabs and Screeds Using a Non-Destructive Electronic Moisture Meter

SIGNIFICANCE AND USE

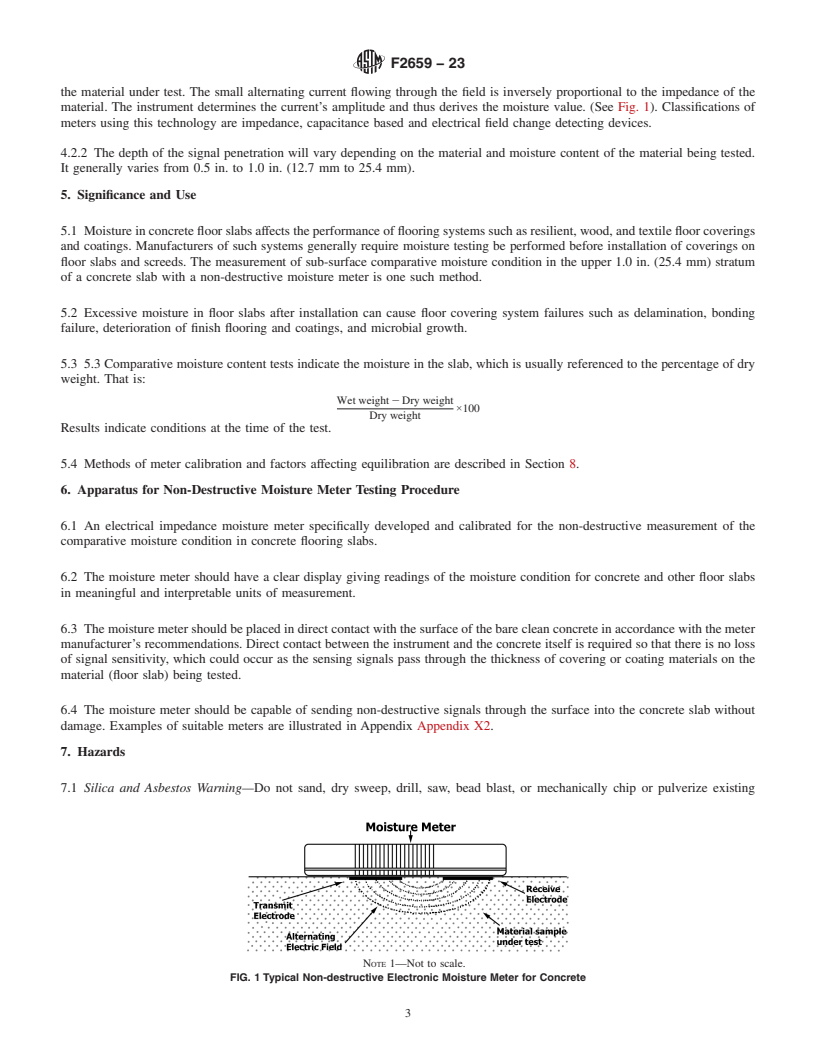

5.1 Moisture in concrete floor slabs affects the performance of flooring systems such as resilient, wood, and textile floor coverings and coatings. Manufacturers of such systems generally require moisture testing be performed before installation of coverings on floor slabs and screeds. The measurement of sub-surface comparative moisture condition in the upper 1.0 in. (25.4 mm) stratum of a concrete slab with a non-destructive moisture meter is one such method.

5.2 Excessive moisture in floor slabs after installation can cause floor covering system failures such as delamination, bonding failure, deterioration of finish flooring and coatings, and microbial growth.

5.3 5.3 Comparative moisture content tests indicate the moisture in the slab, which is usually referenced to the percentage of dry weight. That is:

Results indicate conditions at the time of the test.

5.4 Methods of meter calibration and factors affecting equilibration are described in Section 8.

SCOPE

1.1 This guide focuses on obtaining the comparative moisture condition within the upper 1.0 in. (25.4 mm) stratum in concrete, gypsum, anhydrite floor slabs and screeds for field tests. Due to the wide variation of material mixtures and additives used in floor slabs and screeds, this methodology may not be appropriate for all applications. See 1.2 through 1.8 and Section 11. Where appropriate or when specified, use further testing as outlined in Test Methods F1869 or F2170 before installing a resilient floor covering.

1.2 This guide is intended for use to determine if there are moisture-related conditions existing on, or in, the floor slabs that could adversely impact the successful application and performance of resilient flooring products.

1.3 This guide may be used to aid in the diagnosis of failures of installed resilient flooring.

1.4 This guide is intended to be used in conjunction with meter manufacturer’s operation instructions and interpretive data where available.

1.5 Where possible or when results need to be quantified, use this guide to determine where additional testing such as Test Methods F1869 or F2170 as specified to characterize the floor slab and the test area environment for moisture, humidity and temperature conditions.

1.6 This guide may not be suitable for areas that have surface applied moisture migration systems, curing compounds or coatings that cannot be removed or cleaned off sufficiently to allow the moisture to move upwards through the slab. For a floor slab of 6 in. (150 mm) plus thickness, low porosity slabs, slabs with no vapor retarder installed, and slabs where the above surface environmental conditions can have a greater than normal influence on the moisture reduction gradient of the floor slab or screed, consider Test Method F2170 (below surface in situ rh method) as a more suitable test method under these circumstances.

1.7 This guide is not intended to provide quantitative results as a basis for acceptance of a floor for installation of moisture sensitive flooring finishes systems. Test Methods F1869 or F2170 provide quantitative information for determining if moisture levels are within specific limits. Results from this guide do not provide vital information when evaluating thick slabs, slabs without effective vapor retarders directly under the slab, lightweight aggregate concrete floors, and slabs with curing compound or sealers on the surface.

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use...

General Information

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: F2659 − 23

Standard Guide for

Preliminary Evaluation of Comparative Moisture Condition

of Concrete, Gypsum Cement and Other Floor Slabs and

1

Screeds Using a Non-Destructive Electronic Moisture Meter

This standard is issued under the fixed designation F2659; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope slab or screed, consider Test Method F2170 (below surface in

situ rh method) as a more suitable test method under these

1.1 This guide focuses on obtaining the comparative mois-

circumstances.

ture condition within the upper 1.0 in. (25.4 mm) stratum in

1.7 This guide is not intended to provide quantitative results

concrete, gypsum, anhydrite floor slabs and screeds for field

as a basis for acceptance of a floor for installation of moisture

tests. Due to the wide variation of material mixtures and

sensitive flooring finishes systems. Test Methods F1869 or

additives used in floor slabs and screeds, this methodology may

F2170 provide quantitative information for determining if

not be appropriate for all applications. See 1.2 through 1.8 and

moisture levels are within specific limits. Results from this

Section 11. Where appropriate or when specified, use further

guide do not provide vital information when evaluating thick

testing as outlined in Test Methods F1869 or F2170 before

slabs, slabs without effective vapor retarders directly under the

installing a resilient floor covering.

slab, lightweight aggregate concrete floors, and slabs with

1.2 This guide is intended for use to determine if there are

curing compound or sealers on the surface.

moisture-related conditions existing on, or in, the floor slabs

1.8 The values stated in inch-pound units are to be regarded

that could adversely impact the successful application and

as standard. The values given in parentheses are mathematical

performance of resilient flooring products.

conversions to SI units that are provided for information only

1.3 This guide may be used to aid in the diagnosis of

and are not considered standard.

failures of installed resilient flooring.

1.9 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.4 This guide is intended to be used in conjunction with

responsibility of the user of this standard to establish appro-

meter manufacturer’s operation instructions and interpretive

priate safety, health, and environmental practices and deter-

data where available.

mine the applicability of regulatory limitations prior to use.

1.5 Where possible or when results need to be quantified,

Specific warnings are given in Section 7.

use this guide to determine where additional testing such as

1.10 This international standard was developed in accor-

Test Methods F1869 or F2170 as specified to characterize the

dance with internationally recognized principles on standard-

floor slab and the test area environment for moisture, humidity

ization established in the Decision on Principles for the

and temperature conditions.

Development of International Standards, Guides and Recom-

mendations issued by the World Trade Organization Technical

1.6 This guide may not be suitable for areas that have

Barriers to Trade (TBT) Committee.

surface applied moisture migration systems, curing compounds

or coatings that cannot be removed or cleaned off sufficiently to

2. Referenced Documents

allow the moisture to move upwards through the slab. For a

2

2.1 ASTM Standards:

floor slab of 6 in. (150 mm) plus thickness, low porosity slabs,

slabs with no vapor retarder installed, and slabs where the D4259 Practice for Preparation of Concrete by Abrasion

Prior to Coating Application

above surface environmental conditions can have a greater than

normal influence on the moisture reduction gradient of the floor F1869 Test Method for Measuring Moisture Vapor Emission

Rate of Concrete Subfloor Using Anhydrous Calcium

Chloride

1

This guide is under the jurisdiction of ASTM Committee F06 on Resilient Floor

2

Coverings and is the direct responsibility of Subcommittee F06.40 on Practices. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved March 15, 2023. Published April 2023. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 2010. Last previous edition approved in 2022 as F2659 – 22. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2659 − 22 F2659 − 23

Standard Guide for

Preliminary Evaluation of Comparative Moisture Condition

of Concrete, Gypsum Cement and Other Floor Slabs and

1

Screeds Using a Non-Destructive Electronic Moisture Meter

This standard is issued under the fixed designation F2659; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This guide focuses on obtaining the comparative moisture condition within the upper 1.0 in. (25.4 mm) stratum in concrete,

gypsum, anhydrite floor slabs and screeds for field tests. Due to the wide variation of material mixtures and additives used in floor

slabs and screeds, this methodology may not be appropriate for all applications. See 1.2 through 1.8 and Section 11. Where

appropriate or when specified, use further testing as outlined in Test Methods F1869 or F2170 before installing a resilient floor

covering.

1.2 This guide is intended for use to determine if there are moisture-related conditions existing on, or in, the floor slabs that could

adversely impact the successful application and performance of resilient flooring products.

1.3 This guide may be used to aid in the diagnosis of failures of installed resilient flooring.

1.4 This guide is intended to be used in conjunction with meter manufacturer’s operation instructions and interpretive data where

available.

1.5 Where possible or when results need to be quantified, use this guide to determine where additional testing such as Test

Methods F1869 or F2170 as specified to characterize the floor slab and the test area environment for moisture, humidity and

temperature conditions.

1.6 This guide may not be suitable for areas that have surface applied moisture migration systems, curing compounds or coatings

that cannot be removed or cleaned off sufficiently to allow the moisture to move upwards through the slab. For a floor slab of 6

in. (150 mm) plus thickness, low porosity slabs, slabs with no vapor retarder installed, and slabs where the above surface

environmental conditions can have a greater than normal influence on the moisture reduction gradient of the floor slab or screed,

consider Test Method F2170 (below surface in situ rh method) as a more suitable test method under these circumstances.

1.7 This guide is not intended to provide quantitative results as a basis for acceptance of a floor for installation of moisture

sensitive flooring finishes systems. Test Methods F1869 or F2170 provide quantitative information for determining if moisture

levels are within specific limits. Results from this guide do not provide vital information when evaluating thick slabs, slabs without

effective vapor retarders directly under the slab, lightweight aggregate concrete floors, and slabs with curing compound or sealers

on the surface.

1

This guide is under the jurisdiction of ASTM Committee F06 on Resilient Floor Coverings and is the direct responsibility of Subcommittee F06.40 on Practices.

Current edition approved June 15, 2022March 15, 2023. Published July 2022April 2023. Originally approved in 2010. Last previous edition approved in 2015 as F2659-10

(2015). DOI: 10.1520/F2659-22.2022 as F2659 – 22. DOI: 10.1520/F2659-23.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

F2659 − 23

1.8 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.9 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of

regulatory limitations prior to use. Specific warnings are given in Section 7.

1.10 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

D4259 Practice for Preparation of Conc

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.