ASTM B826-03

(Test Method)Standard Test Method for Monitoring Atmospheric Corrosion Tests by Electrical Resistance Probes

Standard Test Method for Monitoring Atmospheric Corrosion Tests by Electrical Resistance Probes

SCOPE

1.1 This test method provides a means for monitoring corrosivity of environmental tests that involve exposure to corrosive gases.

1.2 This test method uses a resistance monitor (RM) probe fabricated from a chosen metal conductor, with one conductor segment uncovered to permit exposure of the chosen metal conductor to the corrosive gas mixture and the second conductor segment covered to protect the metal conductor of this segment from direct attack by the corrosive gas mixture. The covered conductor segment provides a reference for evaluating changes in the uncovered segment. The ratio of the resistance of the exposed segment to that of the covered segment provides a measure of the amount of metal conductor that has reacted with the corrosive gas test environment to form poorly conducting corrosion product, thus providing a measure of test corrosivity.

1.3 Resistance monitoring is applicable to a broad range of test conditions by selection of the appropriate metal conductor and initial metal thickness.

1.4 This method is similar in intent to Test Methods B 808.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to become familiar with all hazards including those identified in the appropriate Material Safety Data Sheet for this product/material as provided by the manufacturer, to establish appropriate safety and health practices, and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

Designation:B826–03

Standard Test Method for

Monitoring Atmospheric Corrosion Tests by Electrical

1

Resistance Probes

This standard is issued under the fixed designation B826; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope B808 Test Method for Monitoring of Atmospheric Corro-

2

sion Chambers by Quartz Crystal Microbalances

1.1 This test method provides a means for monitoring

B810 Test Method for Calibration of Atmospheric Corro-

corrosivity of environmental tests that involve exposure to

sion Test Chambers by Change in Mass of Copper Cou-

corrosive gases.

2

pons

1.2 This test method uses a resistance monitor (RM) probe

B827 Practice for Conducting Mixed Flowing Gas (MFG)

fabricated from a chosen metal conductor, with one conductor

3

Environmental Tests

segment uncovered to permit exposure of the chosen metal

G96 Guide for Online Monitoring of Corrosion in Plant

conductor to the corrosive gas mixture and the second conduc-

Equipment (Electrical and Electrochemical Methods)

tor segment covered to protect the metal conductor of this

segment from direct attack by the corrosive gas mixture. The

3. Summary of Test Method

covered conductor segment provides a reference for evaluating

3.1 The corrosivity of an atmospheric corrosion test such as

changes in the uncovered segment. The ratio of the resistance

a mixed flowing gas (MFG) type test is measured by monitor-

oftheexposedsegmenttothatofthecoveredsegmentprovides

ing the loss in electrical conductivity of a metal element whose

a measure of the amount of metal conductor that has reacted

surface corrodes to form poorly conducting corrosion product.

with the corrosive gas test environment to form poorly con-

Thiscorrosionproductconsumesmetalfromaconductionpath

ducting corrosion product, thus providing a measure of test

causing an increase in electrical resistance. The resistance of

corrosivity.

the degraded conduction path is compared with a similar path

1.3 Resistance monitoring is applicable to a broad range of

whose surface is covered to prevent corrosion. This compari-

test conditions by selection of the appropriate metal conductor

sonresistancealsoprovidesatemperaturecorrectionreference.

and initial metal thickness.

The ratio of the electrical resistance of the path exposed to the

1.4 This method is similar in intent to Test Methods B808.

corrosive gases to that of the covered path is monitored during

1.5 This standard does not purport to address all of the

thetestandcomparedtoanexpectedratio-versus-timecurveto

safety concerns, if any, associated with its use. It is the

establish the relationship of the test corrosivity to expected test

responsibility of the user of this standard to become familiar

corrosivity. Alternatively, the ratio-versus-time curve for a

with all hazards including those identified in the appropriate

given atmosphere can be compared with the behavior of other

Material Safety Data Sheet for this product/material as pro-

corrosiveatmospherestoevaluatetherelativecorrosivityofthe

vided by the manufacturer, to establish appropriate safety and

various atmospheres.

health practices, and determine the applicability of regulatory

limitations prior to use.

4. Significance and Use

4.1 Corrosivity monitoring of test environments provides a

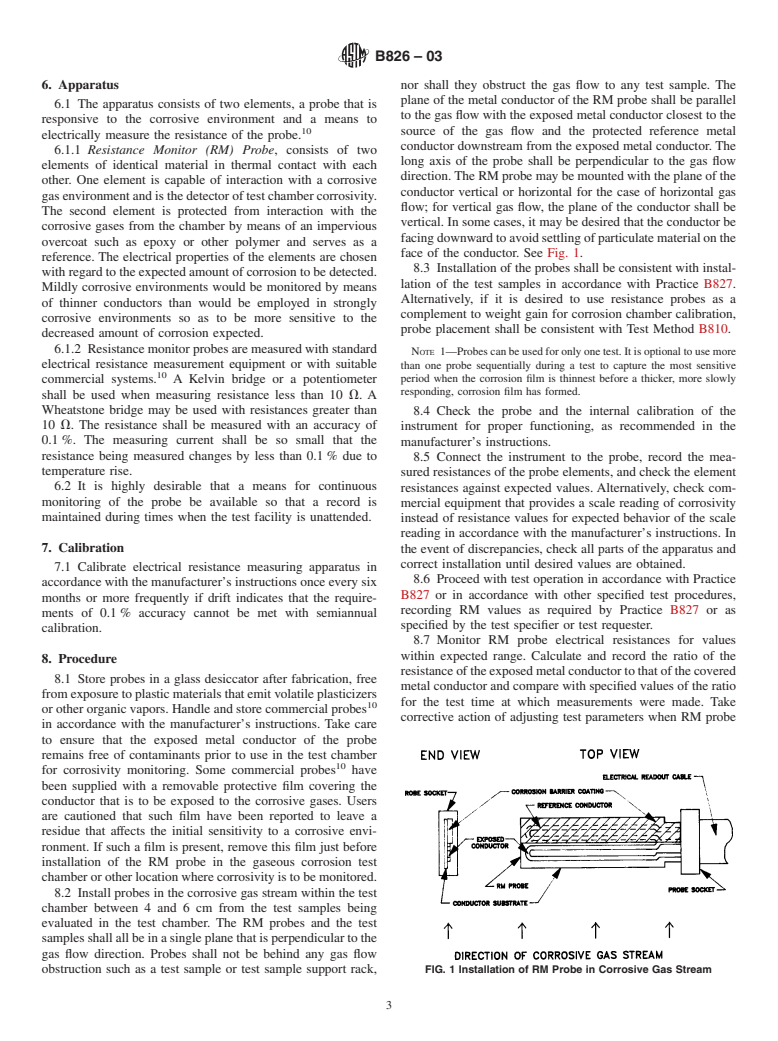

2. Referenced Documents

2

means to monitor an integrated value of test corrosivity which

2.1 ASTM Standards:

cannot be evaluated from test parameters themselves, such as

temperature, humidity, and gas concentration. As such the

1

This test method is under the jurisdiction of ASTM Committee B02 on

monitor value can be used for specification purposes such as

Nonferrous Metals and Alloys and is the direct responsibility of Subcommittee

B02.11 on Electrical Contact Test Methods.

Current edition approved June 10, 2003. Published July 2003. Originally

approved in 1997. Last previous edition approved in 1997 as B826 - 97. DOI:

10.1520/B0826-03.

2 3

Annual Book of ASTM Standards, Vol 03.04. Annual Book of ASTM Standards, Vol 03.02.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

B826–03

test validation. Electrical resistance monitoring of conductors product, which grows out from the edges of the conductor

4,5,6,7

exposed to corrosive media is a well-established practice. paths, can contact adjacent paths; when such contacting cor-

4.2 The resistance method assumes uniform corrosion over

rosion films are formed from conducting corrosion products

the entire surface of the exposed metal

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.