ASTM F2085-12(2019)

(Specification)Standard Consumer Safety Specification for Portable Bed Rails

Standard Consumer Safety Specification for Portable Bed Rails

SCOPE

1.1 This consumer safety specification establishes requirements for the performance of portable bed rails. It also contains requirements for labeling and instructional literature. This consumer safety specification does not cover guardrails that fall under the scope of Consumer Safety Specification F1821 or guardrails that are designed for a specific model of bed and which attaches at the headboard or footboard.

1.2 This consumer safety specification is intended to minimize hazards to children resulting from normal use and reasonably foreseeable misuse of portable bed rails.

1.3 For the purpose of this consumer safety specification, a portable bed rail is a device intended to be installed on an adult bed to prevent children from falling out of bed. These bed rails are intended for children who can get in and out of an adult bed unassisted (typically from 2 to 5 years of age).

1.4 No bed rail as defined in 3.1.1 that is produced after the approval date of this consumer safety specification shall, either by label or other means, indicate compliance with this specification unless it conforms to all the requirements contained herein.

1.5 This consumer safety specification includes the following sections:

Title

Section

Scope

1

Referenced Documents

2

Terminology

3

Calibration and Standardization

4

General Requirements

5

Performance Requirements

6

Structural Integrity

6.1

Openings

6.2

Enclosed Openings

6.3

Openings Created by Bed Rail Displacement of Adjacent

Style Portable Bed Rails

6.4

Openings Created by Displacement of Mattress-Top Portable

Bed Rails

6.5

Openings Created by Displacement of Portable Bed Rails

Intended for Use on Specific Manufacturers' Beds

6.6

Protrusions

6.7

Openings Between Bedposts (Headboard, Footboards, Etc.)

and Ends of Portable Bed Rail

6.8

Bedrail components requiring consumer assembly

6.9

Test Equipment

7

Test Beds

7.1

Torso Probe

7.2

Wedge Probe

7.3

Ring Gauge

7.4

Weight Gauge

7.5

Force Gauge

7.6

Test Methods

8

Test Method for Structural Integrity

8.1

Test Method for Enclosed Openings Within Portable Bed Rail

8.2

Test Method for Displacement of Adjacent Style

Portable Bed Rails

8.3

Test Method for Displacement of "Mattress-Top" Style

Portable Bed Rails

8.4

Test Method for Portable Bed Rails Intended for Use on a

Specific Manufacturer’s Bed

8.5

Test Method for Entanglement on Protrusions

8.6

Marking and Labeling

9

Permanency of Labels and Warnings

10

Instructional Literature

11

Keywords

12

Rationale

Appendix X1

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

1.7 The following precautionary caveat pertains only to the test methods portion in Section 8 of this specification. This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory requirements prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F2085 −12 (Reapproved 2019)

Standard Consumer Safety Specification for

Portable Bed Rails

This standard is issued under the fixed designation F2085; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This consumer safety specification addresses portable bed rail incidents that were identified by the

U.S. Consumer Product Safety Commission (CPSC).

In response to incident data supplied by the CPSC, this consumer safety specification attempts to

minimize the following type of potential hazard through labeling and performance requirements:

entrapment between the portable bed rail and mattress in the bed rail structure and entanglement on

protrusions. Entrapment of a child by the head or neck can result in asphyxiation.

This consumer safety specification is written within the current state-of-the-art of portable bed rail

technology. It is intended that this specification will be updated whenever substantive information

becomes available that necessitates additional requirements or justifies the revision of existing

requirements.

This consumer safety specification is not intended to address all the hazards of bed rails that are

either blatantly misused or used in a careless manner that disregards the instructional literature and

warning statements provided with each bed rail.

1. Scope by label or other means, indicate compliance with this speci-

fication unless it conforms to all the requirements contained

1.1 This consumer safety specification establishes require-

herein.

mentsfortheperformanceofportablebedrails.Italsocontains

1.5 This consumer safety specification includes the follow-

requirements for labeling and instructional literature. This

ing sections:

consumer safety specification does not cover guardrails that

fallunderthescopeofConsumerSafetySpecificationF1821or Title Section

Scope 1

guardrails that are designed for a specific model of bed and

Referenced Documents 2

which attaches at the headboard or footboard.

Terminology 3

Calibration and Standardization 4

1.2 This consumer safety specification is intended to mini-

General Requirements 5

mize hazards to children resulting from normal use and

Performance Requirements 6

Structural Integrity 6.1

reasonably foreseeable misuse of portable bed rails.

Openings 6.2

1.3 For the purpose of this consumer safety specification, a Enclosed Openings 6.3

Openings Created by Bed Rail Displacement of Adjacent 6.4

portable bed rail is a device intended to be installed on an adult

Style Portable Bed Rails

bed to prevent children from falling out of bed. These bed rails

Openings Created by Displacement of Mattress-Top Portable 6.5

areintendedforchildrenwhocangetinandoutofanadultbed Bed Rails

Openings Created by Displacement of Portable Bed Rails 6.6

unassisted (typically from 2 to 5 years of age).

Intended for Use on Specific Manufacturers’ Beds

Protrusions 6.7

1.4 No bed rail as defined in 3.1.1 that is produced after the

Openings Between Bedposts (Headboard, Footboards, Etc.) 6.8

approval date of this consumer safety specification shall, either

and Ends of Portable Bed Rail

Bedrail components requiring consumer assembly 6.9

Test Equipment 7

Test Beds 7.1

Torso Probe 7.2

This consumer safety specification is under the jurisdiction ofASTM Commit-

Wedge Probe 7.3

tee F15 on Consumer Products and is the direct responsibility of Subcommittee

Ring Gauge 7.4

F15.11 on Bed Rails.

Weight Gauge 7.5

Current edition approved May 1, 2019. Published June 2019. Originally

Force Gauge 7.6

approved in 2001. Last previous edition approved in 2012 as F2085 – 12. DOI:

Test Methods 8

10.1520/F2085-12R19.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2085−12 (2019)

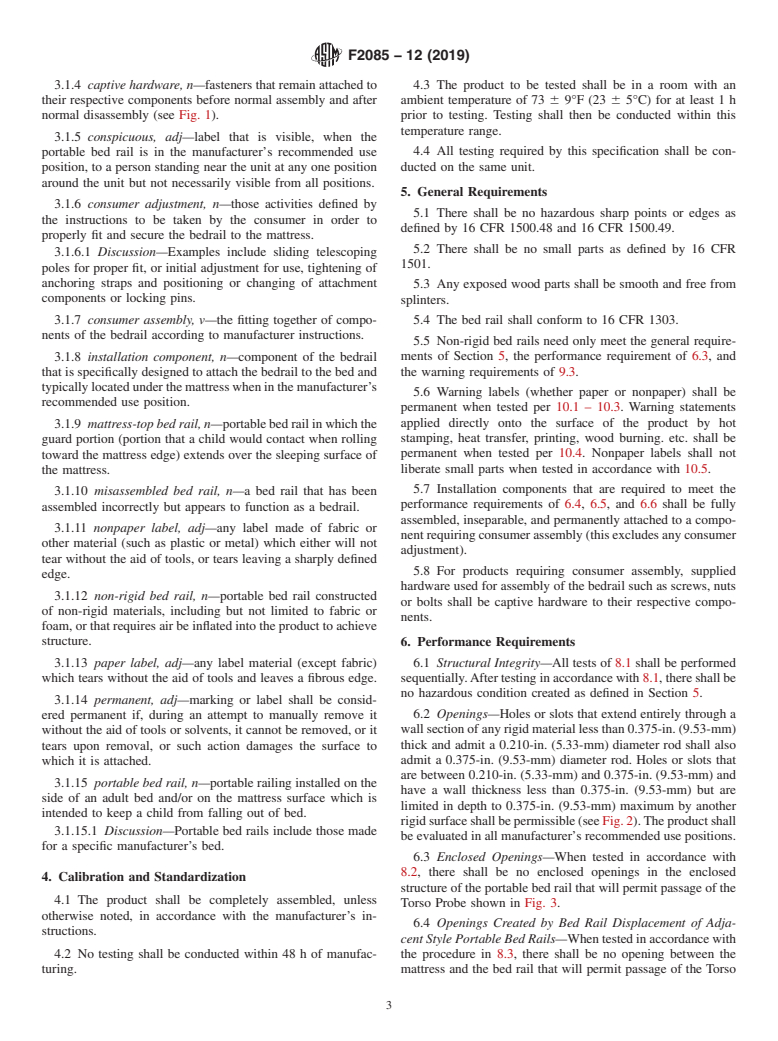

FIG. 1Captive Hardware

F1487 ConsumerSafetyPerformanceSpecificationforPlay-

Test Method for Structural Integrity 8.1

Test Method for Enclosed Openings Within Portable Bed Rail 8.2

ground Equipment for Public Use

Test Method for Displacement of Adjacent Style 8.3

F1821 Consumer Safety Specification for Toddler Beds

Portable Bed Rails

Test Method for Displacement of 9Mattress-Top9 Style 8.4

2.2 Federal Standards:

Portable Bed Rails

16 CFR 1303 Ban of Lead-Containing Paint and Certain

Test Method for Portable Bed Rails Intended for Use on a 8.5

Consumer Products Bearing Lead-Containing Paint

Specific Manufacturer’s Bed

Test Method for Entanglement on Protrusions 8.6

16 CFR Part 1500 Federal Hazardous Substances Act

Marking and Labeling 9

Regulations, including Sections:

Permanency of Labels and Warnings 10

16 CFR 1500.48 Technical Requirements for Determining a

Instructional Literature 11

Keywords 12

Sharp Point in Toys and Other Articles Intended for Use

Rationale Appendix X1

by Children Under 8 Years of Age

1.6 The values stated in inch-pound units are to be regarded

16 CFR 1500.49 Technical Requirements for Determining a

as standard. The values given in parentheses are mathematical

Sharp Metal or Glass Edge in Toys and Other Articles

conversions to SI units that are provided for information only

Intended for Use by Children Under 8 Years of Age

and are not considered standard.

16 CFR 1501 Method for Identifying Toys and Other Ar-

ticles Intended for Use by Children Under 3 Years ofAge

1.7 The following precautionary caveat pertains only to the

which Present Choking, Aspiration, or Ingestion Hazards

test methods portion in Section 8 of this specification. This

Because of Small Parts

standard does not purport to address all of the safety concerns,

if any, associated with its use. It is the responsibility of the user

3. Terminology

of this standard to establish appropriate safety, health, and

environmental practices and determine the applicability of

3.1 Definitions of Terms Specific to This Standard:

regulatory requirements prior to use.

3.1.1 adjacent type bed rail, n—portable bed rail in which

1.8 This international standard was developed in accor-

the guard portion (portion that a child would contact when

dance with internationally recognized principles on standard-

rolling toward the mattress edge) of the unit is essentially a

ization established in the Decision on Principles for the

vertical plane that is pushed against the side of the mattress.

Development of International Standards, Guides and Recom-

The guard remains immediately next to the mattress and does

mendations issued by the World Trade Organization Technical

not extend over the mattress surface.

Barriers to Trade (TBT) Committee.

3.1.2 arm, n—for the purpose of this specification, a de-

vice(s) attached to a bed rail that extends between the mattress

2. Referenced Documents

and mattress foundation and is intended to secure the bed rail

2.1 ASTM Standards:

to the bed.

D3359 Test Methods for Rating Adhesion by Tape Test

3.1.3 bed manufacturer specific type portable bed rail,

D3574 Test Methods for Flexible Cellular Materials—Slab,

n—portable bed rail that is intended for use on a certain type or

Bonded, and Molded Urethane Foams

model(s) of bed as specified by the manufacturer of the bed or

bed rail, or both.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on AvailablefromU.S.GovernmentPrintingOfficeSuperintendentofDocuments,

the ASTM website. 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

F2085−12 (2019)

3.1.4 captive hardware, n—fasteners that remain attached to 4.3 The product to be tested shall be in a room with an

their respective components before normal assembly and after ambient temperature of 73 6 9°F (23 6 5°C) for at least 1 h

normal disassembly (see Fig. 1). prior to testing. Testing shall then be conducted within this

temperature range.

3.1.5 conspicuous, adj—label that is visible, when the

4.4 All testing required by this specification shall be con-

portable bed rail is in the manufacturer’s recommended use

position, to a person standing near the unit at any one position ducted on the same unit.

around the unit but not necessarily visible from all positions.

5. General Requirements

3.1.6 consumer adjustment, n—those activities defined by

5.1 There shall be no hazardous sharp points or edges as

the instructions to be taken by the consumer in order to

defined by 16 CFR 1500.48 and 16 CFR 1500.49.

properly fit and secure the bedrail to the mattress.

5.2 There shall be no small parts as defined by 16 CFR

3.1.6.1 Discussion—Examples include sliding telescoping

1501.

poles for proper fit, or initial adjustment for use, tightening of

anchoring straps and positioning or changing of attachment

5.3 Any exposed wood parts shall be smooth and free from

components or locking pins.

splinters.

3.1.7 consumer assembly, v—the fitting together of compo- 5.4 The bed rail shall conform to 16 CFR 1303.

nents of the bedrail according to manufacturer instructions.

5.5 Non-rigid bed rails need only meet the general require-

3.1.8 installation component, n—component of the bedrail ments of Section 5, the performance requirement of 6.3, and

that is specifically designed to attach the bedrail to the bed and the warning requirements of 9.3.

typicallylocatedunderthemattresswheninthemanufacturer’s

5.6 Warning labels (whether paper or nonpaper) shall be

recommended use position.

permanent when tested per 10.1 – 10.3. Warning statements

applied directly onto the surface of the product by hot

3.1.9 mattress-topbedrail,n—portablebedrailinwhichthe

stamping, heat transfer, printing, wood burning. etc. shall be

guard portion (portion that a child would contact when rolling

permanent when tested per 10.4. Nonpaper labels shall not

toward the mattress edge) extends over the sleeping surface of

liberate small parts when tested in accordance with 10.5.

the mattress.

5.7 Installation components that are required to meet the

3.1.10 misassembled bed rail, n—a bed rail that has been

performance requirements of 6.4, 6.5, and 6.6 shall be fully

assembled incorrectly but appears to function as a bedrail.

assembled, inseparable, and permanently attached to a compo-

3.1.11 nonpaper label, adj—any label made of fabric or

nentrequiringconsumerassembly(thisexcludesanyconsumer

other material (such as plastic or metal) which either will not

adjustment).

tear without the aid of tools, or tears leaving a sharply defined

5.8 For products requiring consumer assembly, supplied

edge.

hardware used for assembly of the bedrail such as screws, nuts

3.1.12 non-rigid bed rail, n—portable bed rail constructed

or bolts shall be captive hardware to their respective compo-

of non-rigid materials, including but not limited to fabric or

nents.

foam, or that requires air be inflated into the product to achieve

structure.

6. Performance Requirements

3.1.13 paper label, adj—any label material (except fabric) 6.1 Structural Integrity—All tests of 8.1 shall be performed

which tears without the aid of tools and leaves a fibrous edge. sequentially.Aftertestinginaccordancewith8.1,thereshallbe

no hazardous condition created as defined in Section 5.

3.1.14 permanent, adj—marking or label shall be consid-

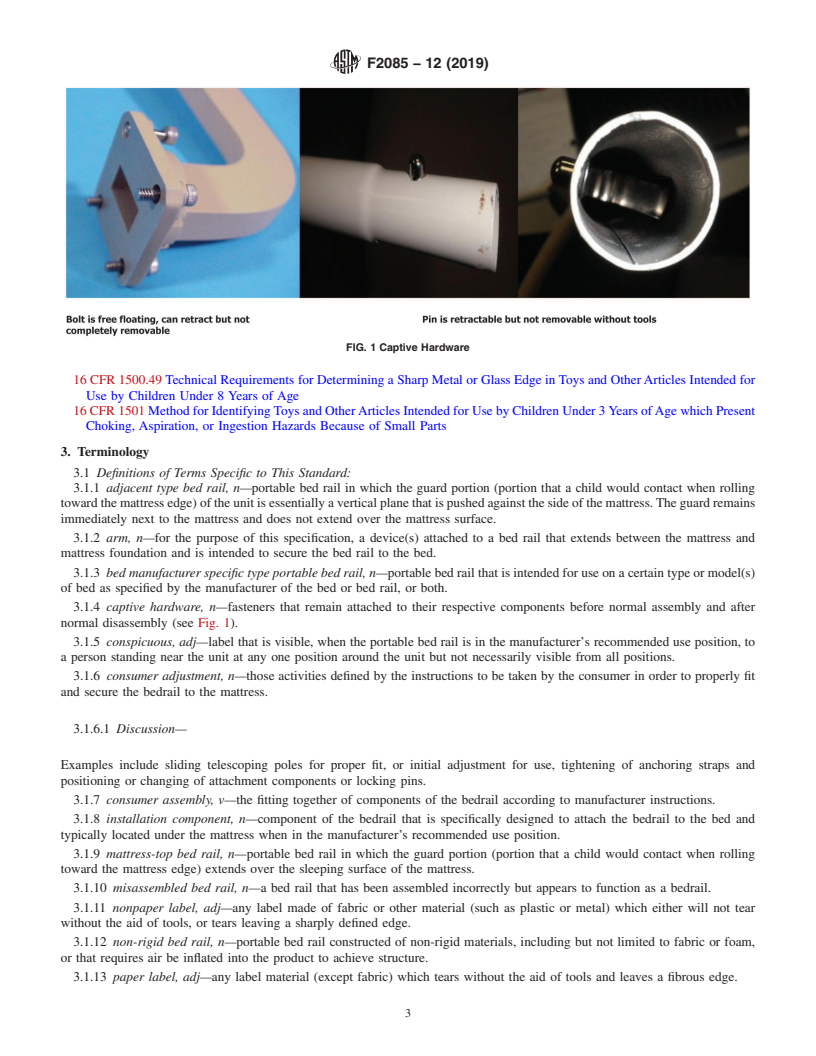

ered permanent if, during an attempt to manually remove it 6.2 Openings—Holes or slots that extend entirely through a

wallsectionofanyrigidmateriallessthan0.375-in.(9.53-mm)

without the aid of tools or solvents, it cannot be removed, or it

tears upon removal, or such action damages the surface to thick and admit a 0.210-in. (5.33-mm) diameter rod shall also

admit a 0.375-in. (9.53-mm) diameter rod. Holes or slots that

which it is attached.

are between 0.210-in. (5.33-mm) and 0.375-in. (9.53-mm) and

3.1.15 portable bed rail, n—portable railing installed on the

have a wall thickness less than 0.375-in. (9.53-mm) but are

side of an adult bed and/or on the mattress surface which is

limited in depth to 0.375-in. (9.53-mm) maximum by another

intended to keep a child from falling out of bed.

rigidsurfaceshallbepermissible(seeFig.2).Theproductshall

3.1.15.1 Discussion—Portable bed rails include those made

be evaluated in all manufacturer’s recommended use positions.

for a specific manufacturer’s bed.

6.3 Enclosed Openings—When tested in accordance with

8.2, there shall be no enclosed openings in the enclosed

4. Calibration and Standardization

structure of the portable bed rail that will permit passage of the

4.1 The product shall be completely assembled, unless

Torso Probe shown in Fig. 3.

otherwise noted, in accordance with the manufacturer’s in-

6.4 Openings Created by Bed Rail Displacement of Adja-

structions.

cent Style Portable Bed Rails—Whentestedinaccordancewith

4.2 No testing shall be conducted within 48 h of manufac- the procedure in 8.3, there shall be no opening between the

turing. mattress and the bed rail that will permit passage of the Torso

F2085−12 (2019)

FIG. 2Opening Example

Probe shown in Fig. 3. Passage is defined as the entire Torso 6.5.1 Bed rails that are marketed as being usable on a bed

Probe passing the horizontal plane that extends from the top that has a mattress support that is solid rather than a box spring

surface of the mattress toward the guard portion of the bed rail. shall be tested on Platform 3, as defined in 7.1.3, in accordance

8.3.

with

6.4.1 Bed rails that are marketed as being usable on a bed

that has a mattress support that is solid rather than a box spring

6.6 Openings Created by Displacement of Portable Bed

shall be tested on Platform 3, as defined in 7.1.3, in accordance

Rails Intended for Use on Specific Manufacturers’ Beds—

with 8.3.

Whentestedinaccordancewiththeprocedurein8.5thereshall

be no opening between the mattress and bed rail that will

6.5 Openings Created by Displacement of Mattress-Top

permit passage of the Torso Probe (Fig. 3). Passage is defined

Portable Bed Rails—When tested in accordance with the

as the entire Torso Probe passing the horizontal plane toward

procedure in 8.4, the Wedge Probe (Fig. 4) shall not penetrate

the guard position of the bed rail.

to a depth greater than 4.5 in. (114 mm) and the bed rail shall

notdisplacehorizontallysuchthattheinneredgeofthebedrail 6.7 Protrusions—Neither string on the weight gauge shall

moves off the top mattress surface. The inner edge of the bed stay attached to a protrusion when tested in accordance with

rail is the edge where the Wedge Probe is inserted. the procedure in 8.6.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: F2085 − 12 F2085 − 12 (Reapproved 2019)

Standard Consumer Safety Specification for

Portable Bed Rails

This standard is issued under the fixed designation F2085; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

This consumer safety specification addresses portable bed rail incidents that were identified by the

U.S. Consumer Product Safety Commission (CPSC).

In response to incident data supplied by the CPSC, this consumer safety specification attempts to

minimize the following type of potential hazard through labeling and performance requirements:

entrapment between the portable bed rail and mattress in the bed rail structure and entanglement on

protrusions. Entrapment of a child by the head or neck can result in asphyxiation.

This consumer safety specification is written within the current state-of-the-art of portable bed rail

technology. It is intended that this specification will be updated whenever substantive information

becomes available that necessitates additional requirements or justifies the revision of existing

requirements.

This consumer safety specification is not intended to address all the hazards of bed rails that are

either blatantly misused or used in a careless manner that disregards the instructional literature and

warning statements provided with each bed rail.

1. Scope

1.1 This consumer safety specification establishes requirements for the performance of portable bed rails. It also contains

requirements for labeling and instructional literature. This consumer safety specification does not cover guardrails that fall under

the scope of Consumer Safety Specification F1821 or guardrails that are designed for a specific model of bed and which attaches

at the headboard or footboard.

1.2 This consumer safety specification is intended to minimize hazards to children resulting from normal use and reasonably

foreseeable misuse of portable bed rails.

1.3 For the purpose of this consumer safety specification, a portable bed rail is a device intended to be installed on an adult bed

to prevent children from falling out of bed. These bed rails are intended for children who can get in and out of an adult bed

unassisted (typically from 2 to 5 years of age).

1.4 No bed rail as defined in 3.1.1 that is produced after the approval date of this consumer safety specification shall, either by

label or other means, indicate compliance with this specification unless it conforms to all the requirements contained herein.

1.5 This consumer safety specification includes the following sections:

Title Section

Scope 1

Referenced Documents 2

Terminology 3

Calibration and Standardization 4

General Requirements 5

Performance Requirements 6

Structural Integrity 6.1

Openings 6.2

Enclosed Openings 6.3

Openings Created by Bed Rail Displacement of Adjacent 6.4

Style Portable Bed Rails

This consumer safety specification is under the jurisdiction of ASTM Committee F15 on Consumer Products and is the direct responsibility of Subcommittee F15.11

on Bed Rails.

Current edition approved Jan. 1, 2012May 1, 2019. Published January 2012June 2019. Originally approved in 2001. Last previous edition approved in 20102012 as

F2085 – 10a.F2085 – 12. DOI: 10.1520/F2085-12.10.1520/F2085-12R19.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

F2085 − 12 (2019)

Openings Created by Bed Rail Displacement of Adjacent 6.4

Style Portable Bed Rails

Openings Created by Displacement of Mattress-Top Portable 6.5

Bed Rails

Openings Created by Displacement of Mattress-Top Portable 6.5

Bed Rails

Openings Created by Displacement of Portable Bed Rails 6.6

Intended for Use on Specific Manufacturers’ Beds

Openings Created by Displacement of Portable Bed Rails 6.6

Intended for Use on Specific Manufacturers’ Beds

Protrusions 6.7

Openings Between Bedposts (Headboard, Footboards, Etc.) 6.8

and Ends of Portable Bed Rail

Openings Between Bedposts (Headboard, Footboards, Etc.) 6.8

and Ends of Portable Bed Rail

Bedrail components requiring consumer assembly 6.9

Test Equipment 7

Test Beds 7.1

Torso Probe 7.2

Wedge Probe 7.3

Ring Gauge 7.4

Weight Gauge 7.5

Force Gauge 7.6

Test Methods 8

Test Method for Structural Integrity 8.1

Test Method for Enclosed Openings Within Portable Bed Rail 8.2

Test Method for Displacement of Adjacent Style 8.3

Portable Bed Rails

Test Method for Displacement of Adjacent Style 8.3

Portable Bed Rails

Test Method for Displacement of 9Mattress-Top9 Style 8.4

Portable Bed Rails

Test Method for Displacement of 9Mattress-Top9 Style 8.4

Portable Bed Rails

Test Method for Portable Bed Rails Intended for Use on a 8.5

Specific Manufacturer’s Bed

Test Method for Portable Bed Rails Intended for Use on a 8.5

Specific Manufacturer’s Bed

Test Method for Entanglement on Protrusions 8.6

Marking and Labeling 9

Permanency of Labels and Warnings 10

Instructional Literature 11

Keywords 12

Rationale Appendix X1

1.6 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.7 The following precautionary caveat pertains only to the test methods portion in Section 8 of this specification. This standard

does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this

standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the applicability of

regulatory requirements prior to use.

1.8 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2.1 ASTM Standards:

D3359 Test Methods for Rating Adhesion by Tape Test

D3574 Test Methods for Flexible Cellular Materials—Slab, Bonded, and Molded Urethane Foams

F1487 Consumer Safety Performance Specification for Playground Equipment for Public Use

F1821 Consumer Safety Specification for Toddler Beds

2.2 Federal Standards:

16 CFR 1303 Ban of Lead-Containing Paint and Certain Consumer Products Bearing Lead-Containing Paint

16 CFR Part 1500 Federal Hazardous Substances Act Regulations, including Sections:

16 CFR 1500.48 Technical Requirements for Determining a Sharp Point in Toys and Other Articles Intended for Use by Children

Under 8 Years of Age

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from U.S. Government Printing Office Superintendent of Documents, 732 N. Capitol St., NW, Mail Stop: SDE, Washington, DC 20401.

F2085 − 12 (2019)

FIG. 1 Captive Hardware

16 CFR 1500.49 Technical Requirements for Determining a Sharp Metal or Glass Edge in Toys and Other Articles Intended for

Use by Children Under 8 Years of Age

16 CFR 1501 Method for Identifying Toys and Other Articles Intended for Use by Children Under 3 Years of Age which Present

Choking, Aspiration, or Ingestion Hazards Because of Small Parts

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 adjacent type bed rail, n—portable bed rail in which the guard portion (portion that a child would contact when rolling

toward the mattress edge) of the unit is essentially a vertical plane that is pushed against the side of the mattress. The guard remains

immediately next to the mattress and does not extend over the mattress surface.

3.1.2 arm, n—for the purpose of this specification, a device(s) attached to a bed rail that extends between the mattress and

mattress foundation and is intended to secure the bed rail to the bed.

3.1.3 bed manufacturer specific type portable bed rail, n—portable bed rail that is intended for use on a certain type or model(s)

of bed as specified by the manufacturer of the bed or bed rail, or both.

3.1.4 captive hardware, n—fasteners that remain attached to their respective components before normal assembly and after

normal disassembly (see Fig. 1).

3.1.5 conspicuous, adj—label that is visible, when the portable bed rail is in the manufacturer’s recommended use position, to

a person standing near the unit at any one position around the unit but not necessarily visible from all positions.

3.1.6 consumer adjustment, n—those activities defined by the instructions to be taken by the consumer in order to properly fit

and secure the bedrail to the mattress.

3.1.6.1 Discussion—

Examples include sliding telescoping poles for proper fit, or initial adjustment for use, tightening of anchoring straps and

positioning or changing of attachment components or locking pins.

3.1.7 consumer assembly, v—the fitting together of components of the bedrail according to manufacturer instructions.

3.1.8 installation component, n—component of the bedrail that is specifically designed to attach the bedrail to the bed and

typically located under the mattress when in the manufacturer’s recommended use position.

3.1.9 mattress-top bed rail, n—portable bed rail in which the guard portion (portion that a child would contact when rolling

toward the mattress edge) extends over the sleeping surface of the mattress.

3.1.10 misassembled bed rail, n—a bed rail that has been assembled incorrectly but appears to function as a bedrail.

3.1.11 nonpaper label, adj—any label made of fabric or other material (such as plastic or metal) which either will not tear

without the aid of tools, or tears leaving a sharply defined edge.

3.1.12 non-rigid bed rail, n—portable bed rail constructed of non-rigid materials, including but not limited to fabric or foam,

or that requires air be inflated into the product to achieve structure.

3.1.13 paper label, adj—any label material (except fabric) which tears without the aid of tools and leaves a fibrous edge.

F2085 − 12 (2019)

3.1.14 permanent, adj—marking or label shall be considered permanent if, during an attempt to manually remove it without the

aid of tools or solvents, it cannot be removed, or it tears upon removal, or such action damages the surface to which it is attached.

3.1.15 portable bed rail, n—portable railing installed on the side of an adult bed and/or on the mattress surface which is intended

to keep a child from falling out of bed.

3.1.15.1 Discussion—

Portable bed rails include those made for a specific manufacturer’s bed.

4. Calibration and Standardization

4.1 The product shall be completely assembled, unless otherwise noted, in accordance with the manufacturer’s instructions.

4.2 No testing shall be conducted within 48 h of manufacturing.

4.3 The product to be tested shall be in a room with an ambient temperature of 73 6 9°F (23 6 5°C) for at least 1 h prior to

testing. Testing shall then be conducted within this temperature range.

4.4 All testing required by this specification shall be conducted on the same unit.

5. General Requirements

5.1 There shall be no hazardous sharp points or edges as defined by 16 CFR 1500.48 and 16 CFR 1500.49.

5.2 There shall be no small parts as defined by 16 CFR 1501.

5.3 Any exposed wood parts shall be smooth and free from splinters.

5.4 The bed rail shall conform to 16 CFR 1303.

5.5 Non-rigid bed rails need only meet the general requirements of Section 5, the performance requirement of 6.3, and the

warning requirements of 9.3.

5.6 Warning labels (whether paper or nonpaper) shall be permanent when tested per 10.1 – 10.3. Warning statements applied

directly onto the surface of the product by hot stamping, heat transfer, printing, wood burning. etc. shall be permanent when tested

per 10.4. Nonpaper labels shall not liberate small parts when tested in accordance with 10.5.

5.7 Installation components that are required to meet the performance requirements of 6.4, 6.5, and 6.6 shall be fully assembled,

inseparable, and permanently attached to a component requiring consumer assembly (this excludes any consumer adjustment).

5.8 For products requiring consumer assembly, supplied hardware used for assembly of the bedrail such as screws, nuts or bolts

shall be captive hardware to their respective components.

6. Performance Requirements

6.1 Structural Integrity—All tests of 8.1 shall be performed sequentially. After testing in accordance with 8.1, there shall be no

hazardous condition created as defined in Section 5.

6.2 Openings—Holes or slots that extend entirely through a wall section of any rigid material less than 0.375-in. (9.53-mm)

thick and admit a 0.210-in. (5.33-mm) diameter rod shall also admit a 0.375-in. (9.53-mm) diameter rod. Holes or slots that are

between 0.210-in. (5.33-mm) and 0.375-in. (9.53-mm) and have a wall thickness less than 0.375-in. (9.53-mm) but are limited in

depth to 0.375-in. (9.53-mm) maximum by another rigid surface shall be permissible (see Fig. 2). The product shall be evaluated

in all manufacturer’s recommended use positions.

6.3 Enclosed Openings—When tested in accordance with 8.2, there shall be no enclosed openings in the enclosed structure of

the portable bed rail that will permit passage of the Torso Probe shown in Fig. 3.

6.4 Openings Created by Bed Rail Displacement of Adjacent Style Portable Bed Rails—When tested in accordance with the

procedure in 8.3, there shall be no opening between the mattress and the bed rail that will permit passage of the Torso Probe shown

in Fig. 3. Passage is defined as the entire Torso Probe passing the horizontal plane that extends from the top surface of the mattress

toward the guard portion of the bed rail.

6.4.1 Bed rails that are marketed as being usable on a bed that has a mattress support that is solid rather than a box spring shall

be tested on Platform 3, as defined in 7.1.3, in accordance with 8.3.

6.5 Openings Created by Displacement of Mattress-Top Portable Bed Rails—When tested in accordance with the procedure in

8.4, the Wedge Probe (Fig. 4) shall not pen

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.