ASTM B338-17

(Specification)Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers

Standard Specification for Seamless and Welded Titanium and Titanium Alloy Tubes for Condensers and Heat Exchangers

ABSTRACT

This specification covers 28 grades of seamless and welded titanium alloy tubes for surface condensers, evaporators, and heat exchangers. Seamless tube shall be made from hollow billet by any cold reducing or cold drawing process that will yield a product meeting the requirements prescribed. Welded tube shall be made from flat-rolled product by an automatic arc-welding process. The welded tube shall be sufficiently cold worked to final size in order to transform the cast weld microstructure into a typical equiaxed microstructure in the weld upon subsequent heat treatment. The titanium shall conform to the chemical requirements prescribed. The room temperature tensile properties of the tube in the condition normally supplied shall conform to the requirements prescribed. Tubing shall withstand, without cracking, flattening under a load applied gradually at room temperature until the distance between the load platens is not more than the required height. Welded tube shall be subjected to a reverse flattening test in accordance with supplement II of test methods and definitions A 370. Welded tubing shall be tested using both a non-destructive electromagnetic test and an ultrasonic test method. Seamless and welded/cold worked tubing shall be tested using an ultrasonic test method. Welded tubing shall be tested with a hydrostatic or pneumatic test method. Seamless tubing shall be tested with an electromagnetic or hydrostatic or pneumatic test method.

SCOPE

1.1 This specification2 covers the requirements for 28 grades of titanium and titanium alloy tubing intended for surface condensers, evaporators, and heat exchangers, as follows:

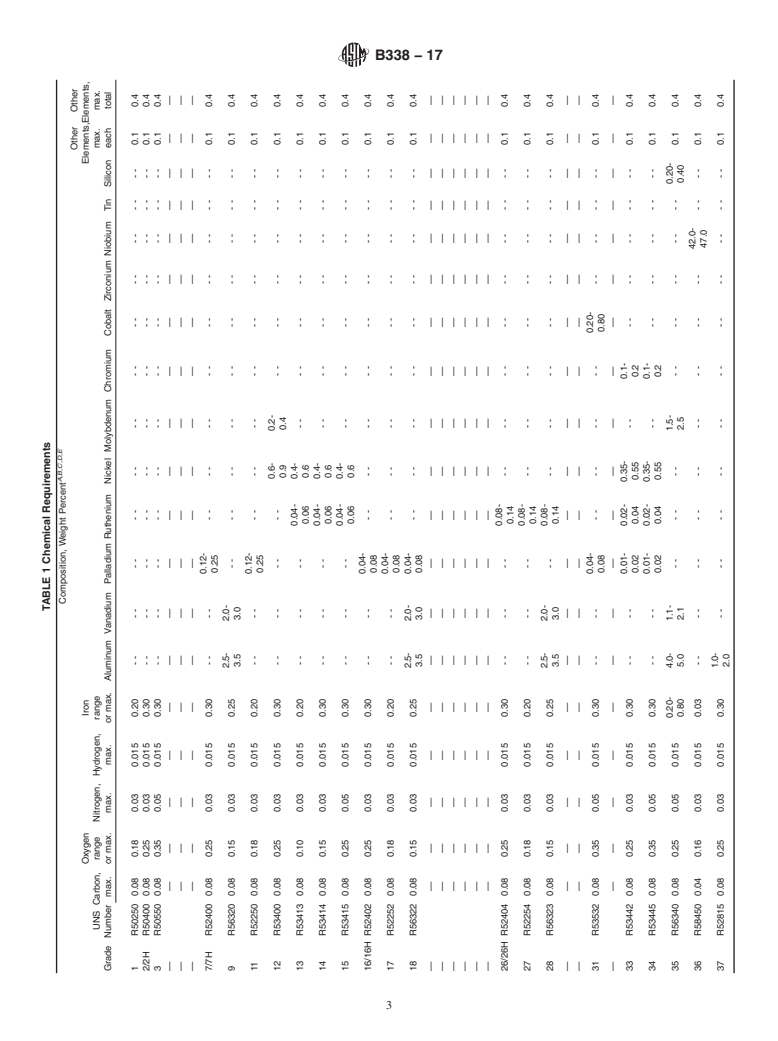

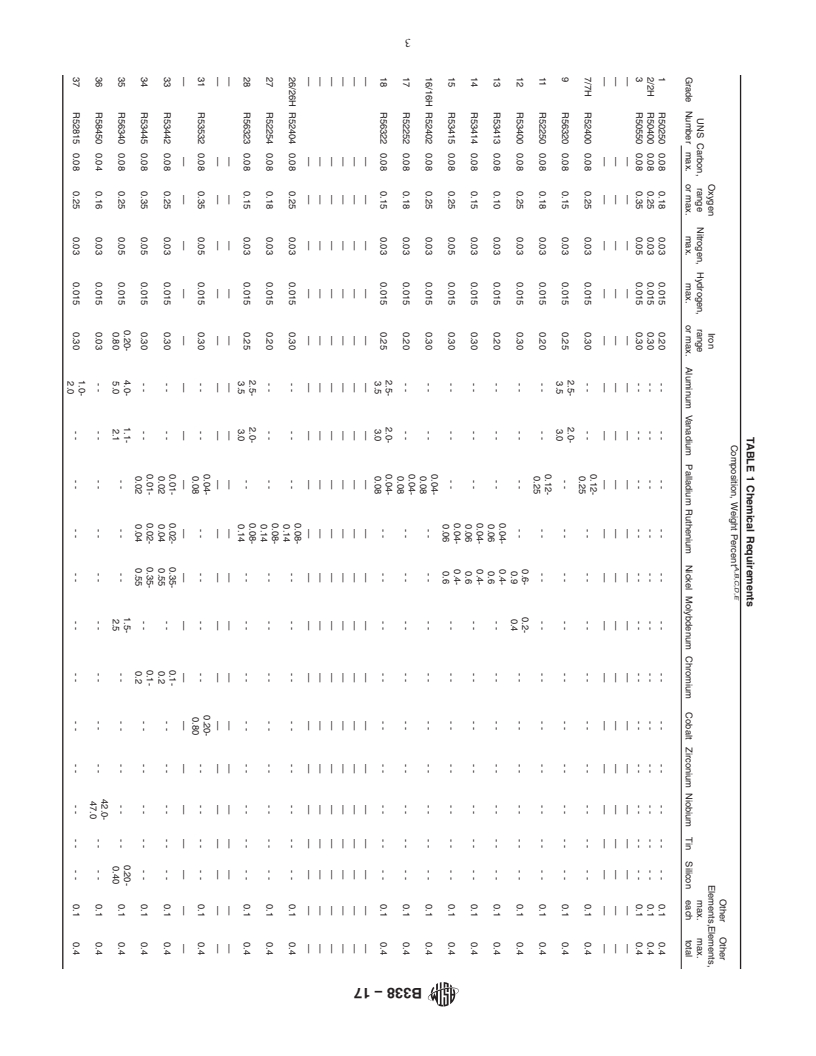

1.1.1 Grade 1—UNS R50250. Unalloyed titanium,

1.1.2 Grade 2—UNS R50400. Unalloyed titanium,

1.1.2.1 Grade 2H—UNS R50400. Unalloyed titanium (Grade 2 with 58 ksi (400 MPa) minimum UTS),

1.1.3 Grade 3—UNS R50550. Unalloyed titanium,

1.1.4 Grade 7—UNS R52400. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.4.1 Grade 7H—UNS R52400. Unalloyed titanium plus 0.12 to 0.25 % palladium (Grade 7 with 58 ksi (400 MPa) minimum UTS),

1.1.5 Grade 9—UNS R56320. Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.1.6 Grade 11—UNS R52250. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.7 Grade 12—UNS R53400. Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.8 Grade 13—UNS R53413. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.9 Grade 14—UNS R53414. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.10 Grade 15—UNS R53415. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.11 Grade 16—UNS R52402. Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.11.1 Grade 16H—UNS R52402. Unalloyed titanium plus 0.04 to 0.08 % palladium (Grade 16 with 58 ksi (400 MPa) minimum UTS),

1.1.12 Grade 17—UNS R52252. Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.13 Grade 18—UNS R56322. Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.04 to 0.08 % palladium,

1.1.14 Grade 26—UNS R52404. Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.14.1 Grade 26H—UNS R52404. Unalloyed titanium plus 0.08 to 0.14 % ruthenium (Grade 26 with 58 ksi (400 MPa) minimum UTS),

1.1.15 Grade 27—UNS R52254. Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.16 Grade 28—UNS R56323. Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.08 to 0.14 % ruthenium,

1.1.17 Grade 30—UNS R53530. Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.18 Grade 31—UNS R53532. Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.19 Grade 33—UNS R53442. Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.20 Grade 34—UNS R53445. Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.21 Grade 35—UNS R56340. Titanium alloy (4.5 % aluminum, 2 % molybdenum, 1.6 % vanadium, 0.5 % iron, 0.3 % silicon),

1.1.22 Grade 36—UNS R58450. Titanium alloy (45 % niobium),

1.1.23 Grade 37—UNS R5281...

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:B338 −17

Standard Specification for

Seamless and Welded Titanium and Titanium Alloy Tubes

1

for Condensers and Heat Exchangers

This standard is issued under the fixed designation B338; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope* 1.1.12 Grade 17—UNS R52252. Unalloyed titanium plus

0.04 to 0.08 % palladium,

2

1.1 This specification covers the requirements for 28

1.1.13 Grade 18—UNS R56322. Titanium alloy (3 %

grades of titanium and titanium alloy tubing intended for

aluminum, 2.5 % vanadium) plus 0.04 to 0.08 % palladium,

surface condensers, evaporators, and heat exchangers, as fol-

1.1.14 Grade 26—UNS R52404. Unalloyed titanium plus

lows:

0.08 to 0.14 % ruthenium,

1.1.1 Grade 1—UNS R50250. Unalloyed titanium,

1.1.14.1 Grade 26H—UNS R52404. Unalloyed titanium

1.1.2 Grade 2—UNS R50400. Unalloyed titanium,

plus 0.08 to 0.14 % ruthenium (Grade 26 with 58 ksi (400

1.1.2.1 Grade 2H—UNS R50400. Unalloyed titanium

MPa) minimum UTS),

(Grade 2 with 58 ksi (400 MPa) minimum UTS),

1.1.15 Grade 27—UNS R52254. Unalloyed titanium plus

1.1.3 Grade 3—UNS R50550. Unalloyed titanium,

0.08 to 0.14 % ruthenium,

1.1.4 Grade 7—UNS R52400. Unalloyed titanium plus 0.12

1.1.16 Grade 28—UNS R56323. Titanium alloy (3 %

to 0.25 % palladium,

aluminum, 2.5 % vanadium) plus 0.08 to 0.14 % ruthenium,

1.1.4.1 Grade 7H—UNS R52400. Unalloyed titanium plus

1.1.17 Grade 30—UNS R53530. Titanium alloy (0.3 %

0.12 to 0.25 % palladium (Grade 7 with 58 ksi (400 MPa)

cobalt, 0.05 % palladium),

minimum UTS),

1.1.18 Grade 31—UNS R53532. Titanium alloy (0.3 %

1.1.5 Grade 9—UNS R56320. Titanium alloy (3 %

cobalt, 0.05 % palladium),

aluminum, 2.5 % vanadium),

1.1.19 Grade 33—UNS R53442. Titanium alloy (0.4 %

1.1.6 Grade 11—UNS R52250. Unalloyed titanium plus

nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 %

0.12 to 0.25 % palladium,

chromium),

1.1.7 Grade 12—UNS R53400. Titanium alloy (0.3 %

1.1.20 Grade 34—UNS R53445. Titanium alloy (0.4 %

molybdenum, 0.8 % nickel),

nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 %

1.1.8 Grade 13—UNS R53413. Titanium alloy (0.5 %

chromium),

nickel, 0.05 % ruthenium),

1.1.21 Grade 35—UNS R56340. Titanium alloy (4.5 %

1.1.9 Grade 14—UNS R53414. Titanium alloy (0.5 %

aluminum, 2 % molybdenum, 1.6 % vanadium, 0.5 % iron,

nickel, 0.05 % ruthenium),

0.3 % silicon),

1.1.10 Grade 15—UNS R53415. Titanium alloy (0.5 %

1.1.22 Grade 36—UNS R58450. Titanium alloy (45 %

nickel, 0.05 % ruthenium),

niobium),

1.1.11 Grade 16—UNS R52402. Unalloyed titanium plus

1.1.23 Grade 37—UNS R52815. Titanium alloy (1.5 %

0.04 to 0.08 % palladium,

aluminum),

1.1.11.1 Grade 16H—UNS R52402. Unalloyed titanium

1.1.24 Grade 38—UNS R54250. Titanium alloy (4 %

plus 0.04 to 0.08 % palladium (Grade 16 with 58 ksi (400

aluminum, 2.5 % vanadium, 1.5 % iron), and

MPa) minimum UTS),

1.1.25 Grade 39—UNS R53390. Titanium alloy (0.25 %

iron, 0.4 % silicon).

1

NOTE 1—H grade material is identical to the corresponding numeric

This specification is under the jurisdiction of ASTM Committee B10 on

grade (that is, Grade 2H = Grade 2) except for the higher guaranteed

Reactive and Refractory Metals and Alloys and is the direct responsibility of

Subcommittee B10.01 on Titanium. minimum UTS, and may always be certified as meeting the requirements

Current edition approved July 1, 2017. Published July 2017. Originally approved of its corresponding numeric grade. Grades 2H, 7H, 16H, and 26H are

in 1958. Last previous edition approved in 2014 as B338 – 14. DOI: 10.1520/

intended primarily for pressure vessel use.

B0338-17.

2

1.2 The values stated in inch-pound units are to be regarded

For ASME Boiler and Pressure Vessel Code applications, see related Specifi-

cation SB-338 in Section II of that Code. as standard. The values given in parentheses are mathematical

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B338−17

conversions to SI units that are provided for information only the product of an 8 h period for final continuous anneal, or to

and are not considered standard. a single furnace load for final batch anneal.

1.3 This international standard was developed in accor-

3.1.4 sponge, n—a lot shall consist of a single blend

dance with internationally recognized principles on standard-

produced at one time.

ization established in the Decision on Principles for the

3.1.5

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B338 − 14 B338 − 17

Standard Specification for

Seamless and Welded Titanium and Titanium Alloy Tubes

1

for Condensers and Heat Exchangers

This standard is issued under the fixed designation B338; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope*

2

1.1 This specification covers the requirements for 28 grades of titanium and titanium alloy tubing intended for surface

condensers, evaporators, and heat exchangers, as follows:

1.1.1 Grade 1—UNS R50250. Unalloyed titanium,

1.1.2 Grade 2—UNS R50400. Unalloyed titanium,

1.1.2.1 Grade 2H—UNS R50400. Unalloyed titanium (Grade 2 with 58 ksi (400 MPa) minimum UTS),

1.1.3 Grade 3—UNS R50550. Unalloyed titanium,

1.1.4 Grade 7—UNS R52400. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.4.1 Grade 7H—UNS R52400. Unalloyed titanium plus 0.12 to 0.25 % palladium (Grade 7 with 58 ksi (400 MPa) minimum

UTS),

1.1.5 Grade 9—UNS R56320. Titanium alloy (3 % aluminum, 2.5 % vanadium),

1.1.6 Grade 11—UNS R52250. Unalloyed titanium plus 0.12 to 0.25 % palladium,

1.1.7 Grade 12—UNS R53400. Titanium alloy (0.3 % molybdenum, 0.8 % nickel),

1.1.8 Grade 13—UNS R53413. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.9 Grade 14—UNS R53414. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.10 Grade 15—UNS R53415. Titanium alloy (0.5 % nickel, 0.05 % ruthenium),

1.1.11 Grade 16—UNS R52402. Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.11.1 Grade 16H—UNS R52402. Unalloyed titanium plus 0.04 to 0.08 % palladium (Grade 16 with 58 ksi (400 MPa)

minimum UTS),

1.1.12 Grade 17—UNS R52252. Unalloyed titanium plus 0.04 to 0.08 % palladium,

1.1.13 Grade 18—UNS R56322. Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.04 to 0.08 % palladium,

1.1.14 Grade 26—UNS R52404. Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.14.1 Grade 26H—UNS R52404. Unalloyed titanium plus 0.08 to 0.14 % ruthenium (Grade 26 with 58 ksi (400 MPa)

minimum UTS),

1.1.15 Grade 27—UNS R52254. Unalloyed titanium plus 0.08 to 0.14 % ruthenium,

1.1.16 Grade 28—UNS R56323. Titanium alloy (3 % aluminum, 2.5 % vanadium) plus 0.08 to 0.14 % ruthenium,

1.1.17 Grade 30—UNS R53530. Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.18 Grade 31—UNS R53532. Titanium alloy (0.3 % cobalt, 0.05 % palladium),

1.1.19 Grade 33—UNS R53442. Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.20 Grade 34—UNS R53445. Titanium alloy (0.4 % nickel, 0.015 % palladium, 0.025 % ruthenium, 0.15 % chromium),

1.1.21 Grade 35—UNS R56340. Titanium alloy (4.5 % aluminum, 2 % molybdenum, 1.6 % vanadium, 0.5 % iron, 0.3 %

silicon),

1.1.22 Grade 36—UNS R58450. Titanium alloy (45 % niobium),

1.1.23 Grade 37—UNS R52815. Titanium alloy (1.5 % aluminum),

1.1.24 Grade 38—UNS R54250. Titanium alloy (4 % aluminum, 2.5 % vanadium, 1.5 % iron), and

1.1.25 Grade 39—UNS R53390. Titanium alloy (0.25 % iron, 0.4 % silicon).

1

This specification is under the jurisdiction of ASTM Committee B10 on Reactive and Refractory Metals and Alloys and is the direct responsibility of Subcommittee

B10.01 on Titanium.

Current edition approved Jan. 15, 2014July 1, 2017. Published January 2014July 2017. Originally approved in 1958. Last previous edition approved in 20132014 as

B338 – 13a.B338 – 14. DOI: 10.1520/B0338-14.10.1520/B0338-17.

2

For ASME Boiler and Pressure Vessel Code applications, see related Specification SB-338 in Section II of that Code.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B338 − 17

NOTE 1—H grade material is identical to the corresponding numeric grade (that is, Grade 2H = Grade 2) except for the higher guaranteed minimum

UTS, and may always be certified as meeting the requirements of its corresponding numeric grade. Grades 2H, 7H, 16H, and 26H are intended primarily

for pressure vessel use.

1.2 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

1.3 This internation

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.