ASTM D6735-01(2009)

(Test Method)Standard Test Method for Measurement of Gaseous Chlorides and Fluorides from Mineral Calcining Exhaust Sources—Impinger Method (Withdrawn 2018)

Standard Test Method for Measurement of Gaseous Chlorides and Fluorides from Mineral Calcining Exhaust Sources—Impinger Method (Withdrawn 2018)

SIGNIFICANCE AND USE

This field-test method provides chloride and fluoride concentration results on a dry basis. Concentration data for gaseous chlorides and fluorides are assumed to be hydrochloric acid gas, and hydrofluoric acid gas when calculating mass emission rates.

Mass emission rates of HCl and HF can be calculated if the effluent volumetric flow rate is known. Volumetric flow rates can be calculated by conducting EPA Methods 1–4 or their equivalents.

This field test method provides data having bias and precision for HCl consistent with the values in Section 14. In addition, the test-specific bias can be assessed for each test by conducting the post-test quality assurance check. The procedure is identified as optional, and the performance of this procedure depends on the test specific data quality objectives, and end use of the data.

The test-specific precision may be determined by conducting paired-runs. Paired runs aid in identifying possible suspect data and provide backup in the event one train is invalidated. Performing paired runs depends on the test-specific data quality objectives.

The reaction of gaseous HCl with ammonia (NH3) to form solid ammonium chloride (NH4Cl) is well known. At stack temperatures common to the exits of baghouses and ESPs at mineral calcining facilities (that is, 250 to 450°F or 121 to 232°C), an equilibration between the gaseous HCl/NH3, the condensed NH4Cl(s), and the effluent particulate matter can exist. It is impossible to know the exact partition ratio between the gas and particulate phases of these compounds in the sampling system. Furthermore, it is very difficult to control the effects of these partitioning reactions within the various sampling system components.

Note 4—Use of this method is cautioned when trying to quantify HCl (g) in the presence of ammonium chloride and ammonia.

SCOPE

1.1 This method will measure the concentration of gaseous hydrochloric and hydrofluoric acids, and other gaseous chlorides and fluorides that pass through a particulate matter filter maintained at 177°C (350°F). This method is specific for sampling combustion effluent from mineral calcining industries and other stationary sources where the reactive/adsorptive nature of the particulate matter may affect measurements.

1.2 This method utilizes ion chromatography to quantify the aqueous samples, and thus measures only the C1- and F- ions.

1.3 Based on a one-hour sampling run, the method will provide results of known accuracy and precision for chloride and fluoride in-stack concentrations of 0.5 ppm (v) dry or greater. Extending the run duration and sampling a greater volume of effluent will extend the range to lower concentrations.

1.4 This method includes optional post-test quality assurance procedures to assess the bias of the test results, and optional paired sample train runs to assess the precision of test results.

WITHDRAWN RATIONALE

This method will measure the concentration of gaseous hydrochloric and hydrofluoric acids, and other gaseous chlorides and fluorides that pass through a particulate matter filter maintained at 177°C (350°F).

Formerly under the jurisdiction of Committee D22 on Air Quality, this test method was withdrawn in January 2018 in accordance with section 10.6.3 of the Regulations Governing ASTM Technical Committees, which requires that standards shall be updated by the end of the eighth year since the last approval date.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6735 − 01 (Reapproved 2009)

Standard Test Method for

Measurement of Gaseous Chlorides and Fluorides from

Mineral Calcining Exhaust Sources—Impinger Method

This standard is issued under the fixed designation D6735; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

INTRODUCTION

The bias and precision statements included in Section 14 of this test method are based on field test

measurements at limestone calcining sources. Procedures for assessing the test-specific bias and the

precision at each source are included in the body of the method.

Additional optional procedures are included in Appendix X1 that can be used to demonstrate the

biasandprecisionofthemethodforspecificsourcecategories.Theseprocedureswereusedtodevelop

the bias and precision statements included in Section 14 and may be applied when using the method

at sources where no previous test data have been acquired.

1. Scope mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

1.1 This method will measure the concentration of gaseous

hydrochloric and hydrofluoric acids, and other gaseous chlo-

2. Referenced Documents

rides and fluorides that pass through a particulate matter filter

2.1 ASTM Standards:

maintained at 177°C (350°F). This method is specific for

samplingcombustioneffluentfrommineralcalciningindustries D1356 Terminology Relating to Sampling and Analysis of

Atmospheres

and other stationary sources where the reactive/adsorptive

nature of the particulate matter may affect measurements. D2986 Practice for Evaluation of Air Assay Media by the

Monodisperse DOP (Dioctyl Phthalate) Smoke Test

1.2 Thismethodutilizesionchromatographytoquantifythe

- - (Withdrawn 2004)

aqueous samples, and thus measures only the C1 and F ions.

D3195 Practice for Rotameter Calibration

1.3 Based on a one-hour sampling run, the method will

D6348 Test Method for Determination of Gaseous Com-

provide results of known accuracy and precision for chloride

pounds by Extractive Direct Interface Fourier Transform

and fluoride in-stack concentrations of 0.5 ppm (v) dry or

Infrared (FTIR) Spectroscopy

greater. Extending the run duration and sampling a greater

2.2 EPA Standards:

volume of effluent will extend the range to lower concentra-

Method 1—Sample and Velocity Traverses for Stationary

tions.

Sources

1.4 This method includes optional post-test quality assur-

Method 2—Determination of Stack Gas Velocity and Volu-

ance procedures to assess the bias of the test results, and

metric Flow Rate (Type S Pitot Tube)

optional paired sample train runs to assess the precision of test

Method 3—Gas Analysis for Carbon Dioxide, Oxygen,

results.

Excess Air, and Dry Molecular Weight

Method 4—Determination of Moisture Content in Stack

1.5 This international standard was developed in accor-

Gases

dance with internationally recognized principles on standard-

ization established in the Decision on Principles for the

Development of International Standards, Guides and Recom-

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

This test method is under the jurisdiction of ASTM Committee D22 on Air the ASTM website.

Quality and is the direct responsibility of Subcommittee D22.03 on Ambient The last approved version of this historical standard is referenced on

Atmospheres and Source Emissions. www.astm.org.

Current edition approved Oct. 1, 2009. Published December 2009. Originally United States Environmental Protection Agency Code of Federal Regulations,

approved in 2001. Last previous edition approved in 2001 as D6735 – 01. DOI: 40 CFR Parts 60 and 63, available from the Government Printing Office,

10.1520/D6735-01R09. Washington, DC.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6735 − 01 (2009)

Method 301—Field Validation of Pollutant Measurement 3.2.16 spiked train, n—atraininwhichHCl(g)orHF(g)has

Methods from Various Waste Media been added after the test run to determine measurement system

bias.

3. Terminology

3.2.17 “u” tubes, n—connecting tubes constructed of either

glass or TFE-fluorocarbon to assemble the impinger train.

3.1 See Terminology D1356 for definition of terms used in

this test method.

3.2.18 volatile compounds, n—compounds that are gases at

the effluent temperature.

3.2 Definitions of Terms Specific to This Standard:

3.2.1 analyte spike, n—the optional procedure contained in

4. Summary of Test Method

this method to assess bias attributed to the measurement

system. The analyte spike procedure consists of adding a

4.1 Sampling:

known amount of the certified compressed gas into the

4.1.1 This method involves collecting an integrated sample

impinger train upstream of the particulate filter after the end of

of stack gas in a series of five midget impingers. Two of the

a run.

five impingers contain 0.1 N H SO , two are empty and one

2 4

3.2.2 blanktrain,n—animpingertrainthatisassembledand contains silica gel.

recovered but does not collect effluent gas. The blank train 4.1.2 Sampling is conducted from a single point within the

provides an estimate of the amount of contamination that can stackorductataconstantsamplingrateof2L/min(65 %)for

occur during a field test. a period of at least one h per sample run.

4.1.3 The sampling system heated components must be

3.2.3 certified compressed gas, n—an HCl or HF gas stan-

maintained at a temperature of 350 6 15°F (177 6 8°C). The

dard that is certified by the manufacturer to a known degree of

sampling system is conditioned before conducting the first run

accuracy. For HCl and HF compressed gas standards the

by sampling 120 Lof stack gas at 2 L/min, and then discarding

accuracy is often certified to 5–10 % of the certified value.

the impinger solutions.

3.2.4 conditioning run, n—a sampling run conducted before

4.1.4 A test is comprised of three or more sample runs.

the first run of the test series. The impinger contents from the

conditioning run are not analyzed nor included in the test NOTE 1—The conditioning run is to minimize HCl and/or HF adsorp-

tion during the ensuing sampling runs by passivating active sites in the

results.

probe and filter box components.

3.2.5 cylinder gas analysis, n—a procedure to verify the

NOTE 2—The impingers from the conditioning run are rinsed thor-

concentration of the certified compressed gas and to provide

oughly with deionized water before recharging to start the first run.

Rinsing the probe and filter assembly must not be performed.

the direct cylinder value. See 11.2.7.4.

NOTE 3—The particulate matter from mineral calcining facilities

3.2.6 direct cylinder value, n—the value of the certified

adsorbs HCl and HF to varying degrees. The amount of adsorption

cylinder gas, or the value obtained from conducting the

dependsonprocessparametersandthephysical/chemicalpropertiesofthe

dust. Measures such as turning the probe nozzle opening away from the

cylinder gas analysis. See 11.2.7.4.

stack or duct flow minimize collection of particulate matter on the filter

3.2.7 hazardous air pollutants (HAPs), n—approximately

material and thus reduce the adsorption of HCl and HF. Other measures

188 compounds or groups of compounds identified in Title III

that reduce collection of particulate matter are acceptable. Such measures

include installing a shrouded large pore sintered filter (> 20 microns) on

of the Clean Air Act Amendments.

the end of the probe. This apparatus will reduce collecting particulate

3.2.8 impinger train, n—a series of midget impingers con-

matter while allowing gases and small particles to enter.

nected together by glass or TFE-fluorocarbon u-tubes.

4.2 Analysis:

3.2.9 midget impinger, n—cylindrical glass (or other appro-

4.2.1 Quantification of chloride and fluoride ions is accom-

priate material) containers that hold approximately 50 mL.

plished by analyzing an aliquot of the impinger solution using

3.2.10 mineral calcining industry, n—industries that use

ion chromatography.

thermal devices to remove CO and other compounds from

4.2.2 The total mass of chloride or fluoride ions collected in

non-ferrous mineral material.

the impinger solution sample is a product of the ion chromato-

graphic (IC) output in either mg or µg and the total volume of

3.2.11 paired runs, n—two impinger trains operated simul-

the sample. For example, if the IC analysis for chloride is 0.02

taneously at the same sampling location.

mg,andthetotalsamplevolumeis100mL,thenthetotalmass

3.2.12 partition ratio, n—the amount of a substance at

of chloride collected for the run is equivalent to 2 mg

equilibrium with its gas and particulate phases.

(assuming a 1-mL injection into the IC).

3.2.13 proportional controllers, n—a temperature control

4.2.3 Usethefollowingequationtodeterminethetotalmass

device that uses a sensor to make small adjustments to the

of chloride or fluoride ions in the sample.

power output. These types of controllers prevent wide fluctua-

~IC/IV!*~SV! 5 mg of ion in total sample (1)

tions in the temperature of the heated measurement system

components.

where:

3.2.14 reagent blank, n—a 20–30 mL sample of the 0.1 N IC = ion chromatographic results in mg,

IV = volume of sample injected into ion chromatograph in

H SO impinger solution that is diluted to 100 mL.

2 4

mL, and

3.2.15 samplingsystemleakcheck,n—aprocedurethattests

SV = sample volume in mL.

the sampling system for negative pressure leaks.

D6735 − 01 (2009)

4.2.4 The equivalent in-stack concentration of the sample is 6.2 Analytical Interferences—Ensuring that the chromato-

equivalent to the mg catch of anion in the impinger solution graphic conditions are optimized for separating chloride and

sample divided by the gas sample volume at standard condi- fluoride from other ions minimizes analytical interferences.

tions.

7. Apparatus

5. Significance and Use

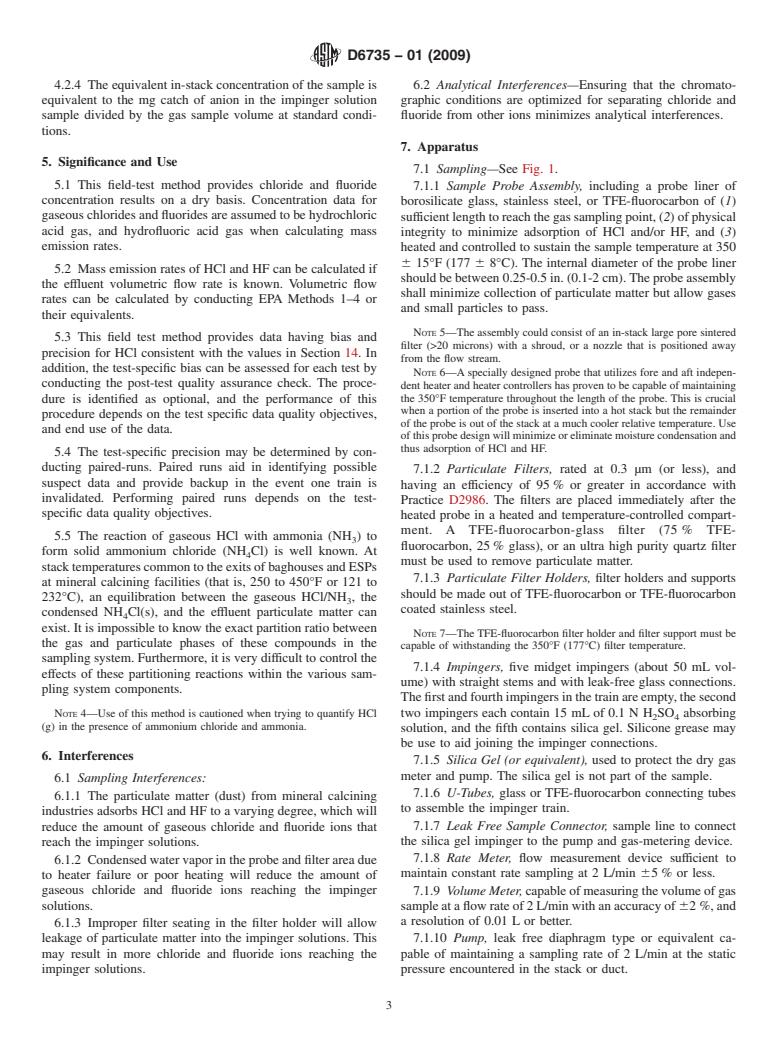

7.1 Sampling—See Fig. 1.

5.1 This field-test method provides chloride and fluoride

7.1.1 Sample Probe Assembly, including a probe liner of

concentration results on a dry basis. Concentration data for

borosilicate glass, stainless steel, or TFE-fluorocarbon of (1)

gaseouschloridesandfluoridesareassumedtobehydrochloric

sufficientlengthtoreachthegassamplingpoint,(2)ofphysical

acid gas, and hydrofluoric acid gas when calculating mass

integrity to minimize adsorption of HCl and/or HF, and (3)

emission rates.

heated and controlled to sustain the sample temperature at 350

6 15°F (177 6 8°C). The internal diameter of the probe liner

5.2 Mass emission rates of HCl and HF can be calculated if

shouldbebetween0.25-0.5in.(0.1-2cm).Theprobeassembly

the effluent volumetric flow rate is known. Volumetric flow

shall minimize collection of particulate matter but allow gases

rates can be calculated by conducting EPA Methods 1–4 or

and small particles to pass.

their equivalents.

NOTE 5—The assembly could consist of an in-stack large pore sintered

5.3 This field test method provides data having bias and

filter (>20 microns) with a shroud, or a nozzle that is positioned away

precision for HCl consistent with the values in Section 14.In

from the flow stream.

addition, the test-specific bias can be assessed for each test by

NOTE 6—Aspecially designed probe that utilizes fore and aft indepen-

conducting the post-test quality assurance check. The proce-

dent heater and heater controllers has proven to be capable of maintaining

the 350°F temperature throughout the length of the probe. This is crucial

dure is identified as optional, and the performance of this

when a portion of the probe is inserted into a hot stack but the remainder

procedure depends on the test specific data quality objectives,

of the probe is out of the stack at a much cooler relative temperature. Use

and end use of the data.

ofthisprobedesignwillminimizeoreliminatemoisturecondensationand

thus adsorption of HCl and HF.

5.4 The test-specific precision may be determined by con-

ducting paired-runs. Paired runs aid in identifying possible

7.1.2 Particulate Filters, rated at 0.3 µm (or less), and

suspect data and provide backup in the event one train is

having an efficiency of 95 % or greater in accordance with

invalidated. Performing paired runs depends on the test-

Practice D2986. The filters are placed immediately after the

specific data quality objectives.

heated probe in a heated and temperature-controlled compart-

ment. A TFE-fluorocarbon-glass filter (75 % TFE-

5.5 The reaction of gaseous HCl with ammonia (NH)to

fluorocarbon, 25 % glass), or an ultra high purity quartz filter

form solid ammonium chloride (NH Cl) is well known. At

must be used to remove particulate matter.

stacktemperaturescommontotheexitsofbaghousesandESPs

7.1.3 Particulate Filter Holders, filter holders and supports

at mineral calcining facilities (that is, 250 to 450°F or 121 to

should be made out of TFE-fluorocarbon or TFE-fluorocarbon

232°C), an equilibration between the gaseous HCl/NH , the

coated stainless steel.

condensed NH Cl(s), and the effluent particulate matter can

exist. It is impossible to know the exact partition ratio between

NOTE 7—The TFE-fluorocarbon filter holder and filter support must be

the gas and particulate phases of these compounds in the

capable of withstanding the 350°F (177°C) filter temperature.

sampling system. Furthermore, it is very difficult to control the

7.1.4 Impingers, five midget impingers (about 50 mL vol-

effects of these partitioning reactions within the various sam-

ume) with straight stems and with leak-free glass connections.

pling system components.

Thefirstandfourthimpingersinthetrainareempty,thesecond

NOTE 4—Use of this method is cautioned when trying to quantify HCl two impingers each contain 15 mL of 0.1 N H SO absorbing

2 4

(g) in the presence of ammonium chloride and ammonia.

solution, and the fifth contains silica gel. Silicone grease may

be use to aid joining the impinger connections.

6. Interferences

7.1.5 Silica Gel (or equivalent), used to protect the dry gas

meter and pump. The silica gel is not part of the sample.

6.1 Sampling Interferences:

7.1.6 U-Tubes, glass or TFE-fluorocarbon connecting tubes

6.1.1 The particulate matter (dust) from mineral calcining

to assemble the impinger train.

industries adsorbs HCl and HF to a varying degree, which will

7.1.7 Leak Free Sample Connector, sample line to connect

reduce the amount of gaseous chloride and fluoride ions that

the silica gel i

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.