ASTM C497-13e1

(Test Method)Standard Test Methods for Concrete Pipe, Manhole Sections, or Tile

Standard Test Methods for Concrete Pipe, Manhole Sections, or Tile

ABSTRACT

These test methods cover production and acceptance tests for concrete pipes, manhole sections, and tiles. Tests include procedures for evaluating external load crushing strength, flat slab top, core strength, absorption, hydrostatic, permeability, manhole step, cylinder, gasket lubricant, joint shear, alkalinity, and gasket measurements. Aside from the procedures, this standard also details the significance and use of and the required test apparatus for each test.

SCOPE

1.1 These test methods cover testing of concrete pipe, manhole sections, and tile. The test methods described are used in production testing and acceptance testing to evaluate the properties provided for in the specifications.

1.2 The test methods appear in the following order:

Section

External Load Crushing Strength

4

Flat Slab Top

5

Core Strength

6

Absorption

7

Hydrostatic

8

Permeability

Manhole Step

9

10

Cylinder Strength

11

Gasket Lubricant

12

Joint Shear

13

Alkalinity

14

Gasket Measurements

15

1.3 The test specimens shall not have been exposed to a temperature below 40°F for the 24 h immediately preceding the test.

1.4 If any test specimen fails because of mechanical reasons such as failure of testing equipment or improper specimen preparation, it shall be discarded and another specimen taken.

1.5 Specimens shall be selected in accordance with the specifications for the type of pipe or tile being tested.

1.6 A complete metric companion to Test Methods C497 has been developed—C497M; therefore, no metric equivalents are presented in these methods.

1.7 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: C497 − 13

StandardTest Methods for

1

Concrete Pipe, Manhole Sections, or Tile

This standard is issued under the fixed designation C497; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1

ε NOTE—Editorially corrected figure reference in 16.4.1 in April 2014.

1. Scope 2. Referenced Documents

2

1.1 These test methods cover testing of concrete pipe, 2.1 ASTM Standards:

manhole sections, and tile.The test methods described are used C31/C31M Practice for Making and Curing Concrete Test

in production testing and acceptance testing to evaluate the Specimens in the Field

properties provided for in the specifications. C39/C39M Test Method for Compressive Strength of Cylin-

drical Concrete Specimens

1.2 The test methods appear in the following order:

C42/C42M Test Method for Obtaining and Testing Drilled

Section

Cores and Sawed Beams of Concrete

External Load Crushing Strength 4

Flat Slab Top 5 C617 Practice for Capping Cylindrical Concrete Specimens

Core Strength 6

C670 Practice for Preparing Precision and Bias Statements

Absorption 7

for Test Methods for Construction Materials

Hydrostatic 8

Permeability 9 C822 Terminology Relating to Concrete Pipe and Related

Manhole Step 10

Products

Cylinder Strength 11

C1231/C1231M Practice for Use of Unbonded Caps in

Gasket Lubricant 12

Joint Shear 13

DeterminationofCompressiveStrengthofHardenedCon-

Alkalinity 14

crete Cylinders

Gasket Measurements 15

D2240 Test Method for Rubber Property—Durometer Hard-

1.3 The test specimens shall not have been exposed to a

ness

temperature below 40°F for the 24 h immediately preceding

E4 Practices for Force Verification of Testing Machines

the test.

3. Terminology

1.4 If any test specimen fails because of mechanical reasons

such as failure of testing equipment or improper specimen

3.1 Definitions—Fordefinitionsoftermsrelatingtoconcrete

preparation, it shall be discarded and another specimen taken.

pipe, see Terminology C822.

1.5 Specimens shall be selected in accordance with the

4. External Load Crushing Strength Test by the Three-

specifications for the type of pipe or tile being tested.

Edge Bearing Test Method

1.6 AcompletemetriccompaniontoTestMethodsC497has

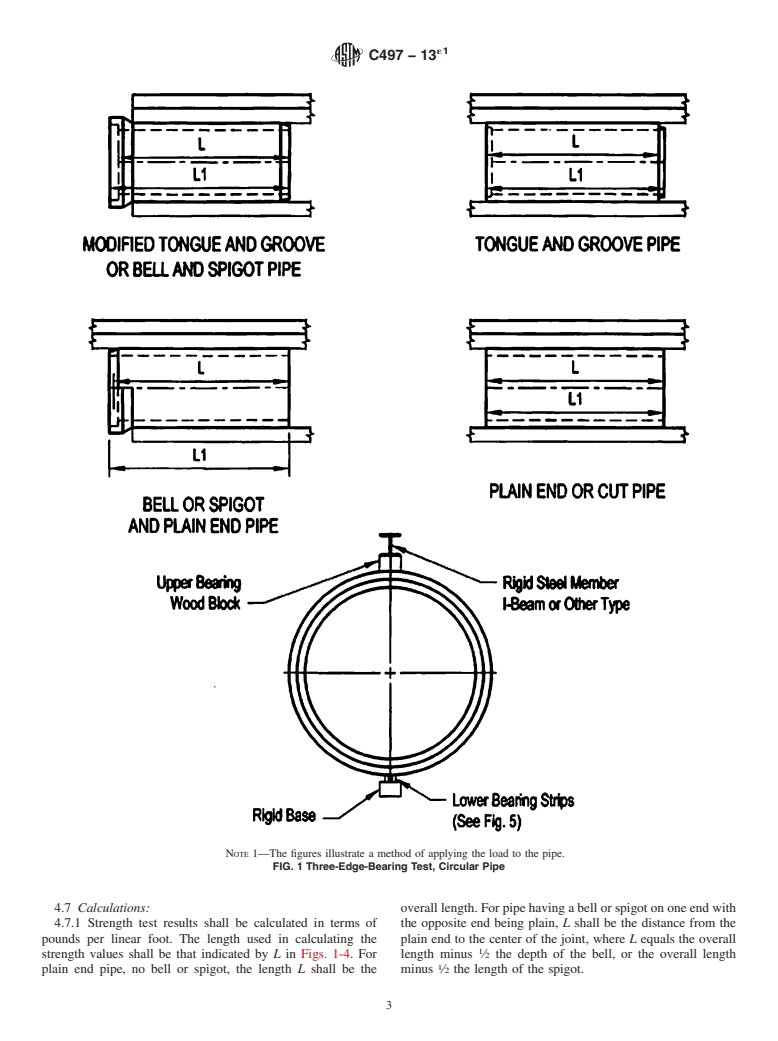

4.1 Summary of Test Method—The test specimen is tested in

been developed—C497M; therefore, no metric equivalents are

a machine designed to apply a crushing force upon the

presented in these methods.

specimen in a plane through the vertical axis extending along

1.7 This standard does not purport to address all of the

the length of the specimen.

safety concerns, if any, associated with its use. It is the

4.2 Significance and Use—The crushing test shall be either

responsibility of the user of this standard to establish appro-

a quality control test performed to establish that the finished,

priate safety and health practices and determine the applica-

shippable pipe has sufficient strength to withstand the crushing

bility of regulatory limitations prior to use.

loads stated in the specifications or a proof of design test

performed to prove the adequacy of design.

1

These test methods are under the jurisdiction of ASTM Committee C13 on

Concrete Pipe and are the direct responsibility of Subcommittee C13.09 on Methods

2

of Test. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Feb. 1, 2013. Published March 2013. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

approved in 1962. Last previous edition approved in 2005 as C497 – 05. DOI: Standards volume information, refer to the standard’s Document Summary page on

10.1520/C0497-13E01. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

´1

C497 − 13

4.3 Apparatus: a single point or at multiple points dependent on the length of

the specimen being tested and the rigidity of the test frame.

4.3.1 The testing machine shall be of any type of sufficient

capacity and shall be capable of providing the rate of loading

NOTE 1—The user of these test methods is advised that multiple points

prescribed in 4.5.3. of load appllications to the upper bearing will permit use of lighter beams

without excessive deflection.

4.3.2 The testing machine shall be substantial and rigid

4.4 Calibration—The loading device shall be one which

throughout, so that the distribution of the load will not be

shall provide an accuracy of 62 % at the specified test

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.