ASTM D6770-07(2015)

(Test Method)Standard Test Method for Abrasion Resistance of Textile Webbing (Hex Bar Method)

Standard Test Method for Abrasion Resistance of Textile Webbing (Hex Bar Method)

SIGNIFICANCE AND USE

5.1 The measurement of the resistance to abrasion of textile webbing is very complex. The resistance to abrasion is affected by many factors that include the inherent mechanical properties of the fibers; the dimensions of the fibers; the structure of the yarns; the construction of the webbing; the type, kind, and amount of treatment added to the fibers, yarns, or webbing; the nature of the abradant; the variable action of the abradant over the specimen area abraded; the tension on the specimen; the pressure between the specimen and the abradant; and the dimensional changes in the specimen.

5.2 The resistance of textile webbing to abrasion as measured by this test method does not include all the factors which account for wear performance or durability in actual use. While the abrasion resistance stated in terms of the number of cycles and durability (defined as the ability to withstand deterioration or wearing out in use, including the effects of abrasion) are frequently related, the relationship varies with different end uses. Different factors may be necessary in any calculation of predicted durability from specific abrasion data.

5.3 Laboratory tests may be reliable as an indication of relative end use in cases where the difference in abrasion resistance of various materials is large, but they should not be relied upon where differences in laboratory test findings are small. In general, the results should not be relied upon for prediction of performance during actual wear life for specific end uses unless there are data showing the specific relationship between laboratory abrasion tests and actual wear in the intended end use.

5.4 While there has not been extensive interlaboratory testing prior to development of this standard, there has been some quality control testing by manufacturers. An intralaboratory test was conducted to initiate this test method, using a single product. This data will be used to determine a preliminary statement on precision and b...

SCOPE

1.1 This test method covers the determination of abrasion resistance of textile webbing using a hex bar abrasion tester.

1.1.1 The resistance is expressed as a percentage of retained break strength.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D6770 − 07 (Reapproved 2015)

Standard Test Method for

Abrasion Resistance of Textile Webbing (Hex Bar Method)

This standard is issued under the fixed designation D6770; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers the determination of abrasion 4.1 Abrasionresistanceismeasuredbysubjectingthespeci-

resistance of textile webbing using a hex bar abrasion tester. men to unidirectional reciprocal rubbing over a specific bar

1.1.1 Theresistanceisexpressedasapercentageofretained under specified conditions of tension, stroke length and time.

break strength. Resistance to abrasion is evaluated by determining the percent

retention of breaking force of an abraded specimen compared

1.2 This standard does not purport to address all of the

to an unabraded specimen.

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

5. Significance and Use

priate safety and health practices and determine the applica-

5.1 The measurement of the resistance to abrasion of textile

bility of regulatory limitations prior to use.

webbingisverycomplex.Theresistancetoabrasionisaffected

bymanyfactorsthatincludetheinherentmechanicalproperties

2. Referenced Documents

of the fibers; the dimensions of the fibers; the structure of the

2.1 ASTM Standards:

yarns; the construction of the webbing; the type, kind, and

D123Terminology Relating to Textiles

amountoftreatmentaddedtothefibers,yarns,orwebbing;the

D1776Practice for Conditioning and Testing Textiles

nature of the abradant; the variable action of the abradant over

D4850Terminology Relating to Fabrics and Fabric Test

the specimen area abraded; the tension on the specimen; the

Methods

pressure between the specimen and the abradant; and the

2.2 Other Standard:

dimensional changes in the specimen.

Federal Standard 191, Method 4108 “Strength and

5.2 The resistance of textile webbing to abrasion as mea-

Elongation, Breaking;TextileWebbing,Tape and Braided

suredbythistestmethoddoesnotincludeallthefactorswhich

Items”

accountforwearperformanceordurabilityinactualuse.While

the abrasion resistance stated in terms of the number of cycles

3. Terminology

and durability (defined as the ability to withstand deterioration

3.1 For all terminology relating to Fabrics, refer to Termi-

or wearing out in use, including the effects of abrasion) are

nology D4850.

frequently related, the relationship varies with different end

3.2 The following terms are relevant to this standard:

uses. Different factors may be necessary in any calculation of

abrasion, abrasion cycle, breaking force, standard atmosphere

predicted durability from specific abrasion data.

for preconditioning textiles, standard atmosphere for testing

5.3 Laboratory tests may be reliable as an indication of

textiles, stroke, in hex bar abrasion testing, webbing.

relative end use in cases where the difference in abrasion

3.3 For all other terminology related to textiles, refer to

resistance of various materials is large, but they should not be

Terminology D123.

relied upon where differences in laboratory test findings are

small. In general, the results should not be relied upon for

prediction of performance during actual wear life for specific

ThistestmethodisunderthejurisdictionofASTMCommitteeD13onTextiles

endusesunlesstherearedatashowingthespecificrelationship

and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods,

between laboratory abrasion tests and actual wear in the

Specific.

intended end use.

Current edition approved July 1, 2015. Published September 2015. Originally

approvedin2002.Lastpreviouseditionapprovedin2011asD6770–07(2011).DOI:

5.4 While there has not been extensive interlaboratory

10.1520/D6770-07R15.

testing prior to development of this standard, there has been

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

some quality control testing by manufacturers.An intralabora-

Standards volume information, refer to the standard’s Document Summary page on

tory test was conducted to initiate this test method, using a

the ASTM website.

single product. This data will be used to determine a prelimi-

Available from Superintendent of Documents, Government Printing Office,

Washington, DC 20402. nary statement on precision and bias. Subsequent to approval

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6770 − 07 (2015)

ofthisstandard,aformalizedinterlaboratoryprocedurewillbe N(1000to3000lb)and2400 660g(5.2 62lb)forbreaking

initiated under the direction of a professional statistician and strengths over 13500 N (3000 lb).

will produce a research report. Samples used in this controlled 6.1.2 Steel hexagonal rods “C” shall be 6.35 6 0.03 mm

test will be representative of end use applications. (0.250 6 0.001 in.) when measured across opposite flat sides

and the radius shall be 0.5 6 0.2 mm (0.020 6 0.008 in.).The

5.5 These general observations apply to most webbings that

steel shall have a cold drawn finish and a Rockwell Hardness

are used in automotive, aerospace, industrial, and military

of B-91 to B-101. The edges of the hexagonal rods shall not

applications.

have any burrs, nicks or scale.

5.6 This test method can be used for acceptance testing of

6.1.3 The mechanism “D” shall have a nominal outside

commercial shipments but comparisons should be made with

diameter of 400 mm (16 in.) or be some mechanism able to

caution because estimates of between-laboratory precision are

produceareciprocatingmotionofatleast300mm(12in.)over

incomplete.

thehexrodwithasuitablemeansforattachingthespecimento

be tested without damage to the specimen.

5.7 If there are differences of practical significance between

reported test results for two laboratories (or more), compara- 6.1.4 Thecrank-arm“F”shallbeattachedtothemechanism

tive tests should be performed to determine if there is a “D” and to the driver disk “E” in such a manner that when the

specimen is attached to the mechanism, the specimen during

statistical bias between them, using competent statistical assis-

tance. As a minimum, use samples for such comparative tests the test will oscillate over the hexagonal rod the required

distance during each stroke and at the required rate (see 10.4).

thatareashomogenousaspossible,drawnfromthesamelotof

material as the samples that resulted in disparate results during 6.1.5 The hexagonal rod shall be so placed that specimen

“A” with the weight attached to one end and the other end

initialtesting,andrandomlyassignedinequalnumberstoeach

laboratory. The test results from the laboratories involved passing over the hexagonal rod and attached to the drive

mechanism will form an angle of 85 6 2° “H”.

shouldbecomparedusingastatisticaltestforunpaireddata,at

a probability level chosen prior to the testing series. If bias is 4

6.2 Tensile Testing Machine , CRE-Type equipped with

found, either its cause must be found and corrected, or future

split-drum webbing clamps as described in Federal Test

test results must be adjusted in consideration of the known

Method 191b, Method 4108.

bias.

7. Sampling and Test Specimens

6. Apparatus

7.1 Lot Sample—Take a lot sample as directed in the

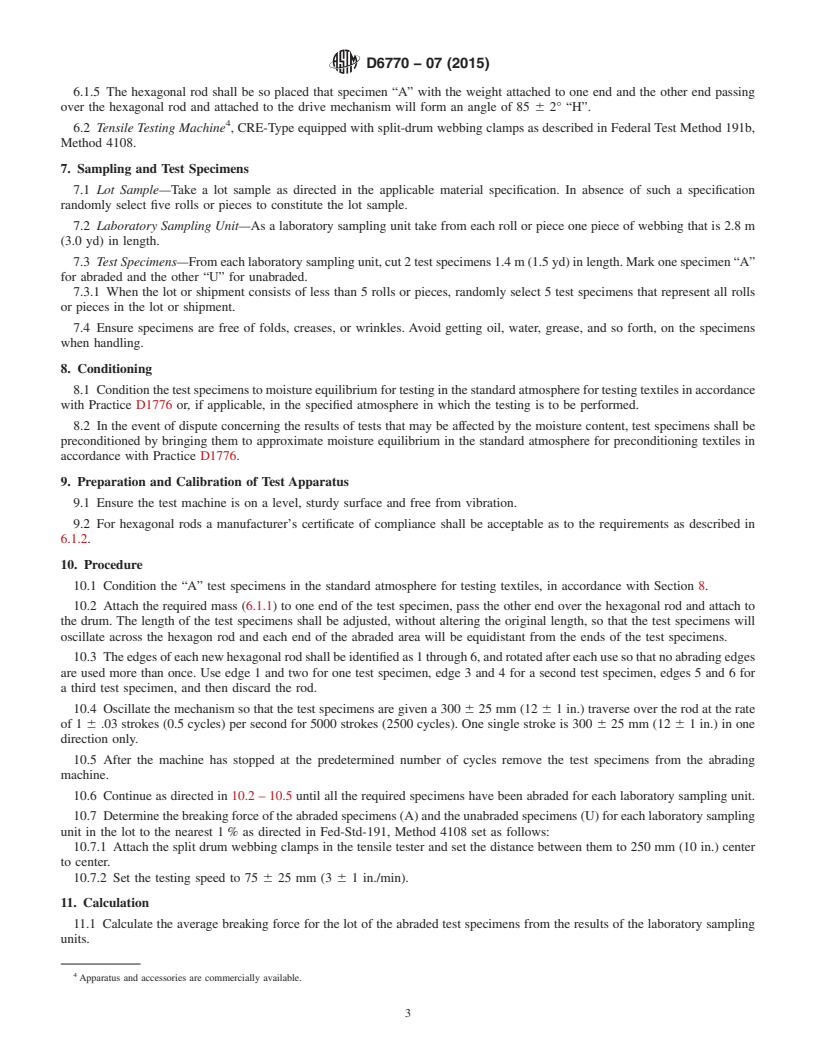

6.1 Webbing Abrasion Tester—The webbing abrasion tester

applicable material specification. In absence of such a specifi-

consists of a suitable mechanism that will provide a recipro-

cation randomly select five rolls or pieces to constitute the lot

catingmotionofthewebbingoverastandardizedhexbar.One

sample.

end of each specimen is attached to the mechanism and the

7.2 Laboratory Sampling Unit—As a laboratory sampling

other end passing over a hexagonal steel rod is attached to a

unit take from each roll or piece one piece of webbing that is

weight.Thehexagonalrodissofixedastosubjectthewebbing

2.8 m (3.0 yd) in length.

specimentoabrasionontwoadjacentedgesasthedrummoves

7.3 Test Specimens—From each laboratory sampling unit,

the specimen across the rod. One example of such a mecha-

cut 2 test specimens 1.4 m (1.5 yd) in length. Mark one

nism is a reciprocating drum as illustrated in Fig. 1.

specimen “A” for abraded and the other “U” for unabraded.

6.1.1 Mass “B” shall be 900 660g(2lb 6 2 oz) for

webbing with breaking strengths up to 4500 N (1000 lb), 1800

660g(4lb 6 2 oz) for breaking strengths of 4500 to 13500 Apparatus and accessories are commercially available.

FIG. 1 Webbing Abrasion Tester

D6770 − 07 (2015)

7.3.1 When the lot or shipment consists of less than 5 rolls 10.7.1 Attach the split drum webbing clamps in the tensile

or pieces, randomly select 5 test specimens that represent all tester and set the distance between them to 250 mm (10 in.)

rolls or pieces in the lot or shipment. center to center.

10.7.2 Setthetestingspeedto75 625mm(3 61in./min).

7.4 Ensurespecimensarefreeoffolds,creases,orwrinkles.

Avoidgettingoil,water,grease,andsoforth,onthespecimens

11. Calculation

when handling.

11.1 Calculate the average breaking force for the lot of the

8. Conditioning

abraded test specimens from the results of the laboratory

8.1 Conditionthetestspecimenstomoistureequilibriumfor

sampling units.

testing in the standard atmosphere for testing textiles in

11.2 Calculate the average breaking force for the lot of the

accordance with Practice D1776 or, if applicable, in the

unabraded test specimens from the results of the laboratory

specified atmosphere in which the testing is to be performed.

sampling units.

8.2 In the event of dispute concerning the results of tests

11.3 Calculate the percentage of retained breaking force to

that may be affected by the moisture content, test specimens

the nearest 1 % for the lot using Eq 1:

shall be preconditioned by bringing them to approximate

100A

moisture equilibrium in the standard atmosphere for precondi-

AR 5 (1)

U

tioning textiles in accordance with Practice D1776.

where:

9. Preparation and Calibration of Test Apparatus

AR = abrasion resistance, %,

9.1 Ensurethetestmachineisonalevel,sturdysurfaceand

A = average breaking force of the abraded specimens, N

free from vibration.

(lb), and

9.2 For hexagonal rods a manufacturer’s certificate of com-

U = average breaking force of the unabraded specimens, N

pliance shall be acceptable as to the requirements as described (lb).

in 6.1.2.

11.3.1 When data are automatically computer processed,

calculationsaregenerallycontainedintheassociatedsoftware.

10. Procedure

It is recommended that computer-processed data be verified

10.1 Condition the “A” test specimens in the standard

againstknownpropertyvaluesanditssoftwaredescribedinthe

atmosphere for testing textiles, in accordance with Section 8.

report.

10.2 Attach the required mass (6.1.1) to one end of the test

specimen,passtheotherendoverthehexagonalrodandattach

12. Report

tothedrum.Thelengthofthetestspecimensshallbeadjusted,

12.1 Report that the abrasion resistance was determined in

without altering the original length, so that the test specimens

accordance with Test Method D6770. Describe the material or

will oscillate across the hexagon rod and each end of the

product sampled.

abraded area will be equidistant from the ends of the test

12.2 Report the following information for the laboratory

specimens.

sampling unit and for the lot as applicable to a material

10.3 The edges of each new hexagonal rod shall be identi-

specification or contract order:

fied as 1 through 6, and rotated after each use so that no

12.2.1 Abrasion resistance, percent retained in breaking

abrading edges are used more than once. Use edge 1 and two

force.

foronetestspecimen,edge3and4forasecondtestspecimen,

12.2.2 Breaking force of abraded test specimens.

edges 5 and 6 for a third test specimen, and then discard the

12.2.3 Breaking force of unabraded test specimens.

rod.

12.2.4 For computer-processed data, identify the program

10.4 Oscillate the mechanism so that the test specimens are

(software) used.

given a 300 6 25 mm (12 6 1 in.) traverse over the rod at the

rateof1 6.03strokes(0.5cycles)persecondfor5000strokes

13. Precision and Bias

(2500 cycles). One single stroke is 300 6 25 mm (12 6 1 in.)

13.1 An intralaboratory test was conducted for the determi-

in one direction only.

nation of precision and bias of this test method. The results of

10.5 After the machine has stopped at the predetermined

the test are attached as Table 1.

number of cycles remove the test specimens from the abrading

NOTE 1—Because the intralaboratory test included less than the

machine.

recommended five laboratories, estimates of precision data may be either

underestimated or overestimated to a considerable extent and should be

10.6 Continue as directed in 10.2 – 10.5 until all the

used with special caution.

required specimens have been abraded for each laboratory

sampling unit. 13.2 Precision—A statement on the precision of this test

method is being developed. The results will be included when

10.7 Determinethebreakingforceoftheabradedspecimens

available.

(A) and the unabraded specimens (U) for each laboratory

sampling unit in the lot to the nearest 1% as directed in 13.3 Bias—Theprocedureofthistestmethodprovidesatest

Fed-Std-191, Method 4108 set as follows: value that can be defined only in terms of this test method.

D6770 − 07 (2015)

TABLE 1 Raw Data from Intralaboratory Test

Material 1—Before Abrasion Material 2—After Abrasion

Total Opr.

Lab. Opr. Test 1 Test 2 Test 3 Test 4 Test 5 Opr. Sum Test 1 Test 2 Test 3 Test 4 Test 5 Opr. Sum

Sum

Set 1 1 4.720 4.820 4.600 4.700 4.600 23.440 4.620 4.460 4.680 4.600 4.620 22.980 46.420

2 4.600 4.720 4.700 4.720 4.680 23.420 4.640 4.600 4.580 4.680 4.600 23.100 46.520

3 4.580 4.720 4.720 4.560 4.720 23.300 4.620 4.480 4.400 4.520 4.480 22.500 45.800

4 4.740 4.740 4.520 4.720 4.740 23.460 4.500 4.420 4.640 4.540 4.620 22.720 46.180

5 4.700 4.660 4.600 4.700 4.680 23.340 4.620 4.620 4.500 4.520 4.380 22.640 45.980

6 4.600 4.680 4.500 4.480 4.540 22.800 4.380 4.480 4.520 4.400 4.560 22.340 45.140

Lab Sum 139.760 136.280 276.040

Set 2 1 4.600 4.720 4.600 4.720 4.680 23.320 4.420 4.220 4.180 4.320 4.280 21.420 44.740

2 4.680 4.700 4.660 4.700 4.640 23.380 4.520 4.500 4.560 4.520 4.640 22.740 46.120

3 4.660 4.720 4.660 4.660 4.640 23.340 4.460 4.540 4.640 4.500 4.580 22.720 46.060

4 4.760 4.740 4.640 4.660 4.380 23.180 4.

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: D6770 − 07 (Reapproved 2011) D6770 − 07 (Reapproved 2015)

Standard Test Method for

Abrasion Resistance of Textile Webbing (Hex Bar Method)

This standard is issued under the fixed designation D6770; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This test method covers the determination of abrasion resistance of textile webbing using a hex bar abrasion tester.

1.1.1 The resistance is expressed as a percentage of retained break strength.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

D123 Terminology Relating to Textiles

D1776 Practice for Conditioning and Testing Textiles

D4850 Terminology Relating to Fabrics and Fabric Test Methods

2.2 Other Standard:

Federal Standard 191, Method 4108 “Strength and Elongation, Breaking; Textile Webbing, Tape and Braided Items”

3. Terminology

3.1 For all terminology relating to Fabrics, refer to Terminology D4850.

3.2 The following terms are relevant to this standard: abrasion, abrasion cycle, breaking force, standard atmosphere for

preconditioning textiles, standard atmosphere for testing textiles, stroke, in hex bar abrasion testing, webbing.

3.3 For all other terminology related to textiles, refer to Terminology D123.

4. Summary of Test Method

4.1 Abrasion resistance is measured by subjecting the specimen to unidirectional reciprocal rubbing over a specific bar under

specified conditions of tension, stroke length and time. Resistance to abrasion is evaluated by determining the percent retention

of breaking force of an abraded specimen compared to an unabraded specimen.

5. Significance and Use

5.1 The measurement of the resistance to abrasion of textile webbing is very complex. The resistance to abrasion is affected by

many factors that include the inherent mechanical properties of the fibers; the dimensions of the fibers; the structure of the yarns;

the construction of the webbing; the type, kind, and amount of treatment added to the fibers, yarns, or webbing; the nature of the

abradant; the variable action of the abradant over the specimen area abraded; the tension on the specimen; the pressure between

the specimen and the abradant; and the dimensional changes in the specimen.

5.2 The resistance of textile webbing to abrasion as measured by this test method does not include all the factors which account

for wear performance or durability in actual use. While the abrasion resistance stated in terms of the number of cycles and

durability (defined as the ability to withstand deterioration or wearing out in use, including the effects of abrasion) are frequently

related, the relationship varies with different end uses. Different factors may be necessary in any calculation of predicted durability

from specific abrasion data.

This test method is under the jurisdiction of ASTM Committee D13 on Textiles and is the direct responsibility of Subcommittee D13.60 on Fabric Test Methods, Specific.

Current edition approved May 1, 2011July 1, 2015. Published July 2011September 2015. Originally approved in 2002. Last previous edition approved in 20072011 as

D6770D6770–07(2011).–07. DOI: 10.1520/D6770-07R11.10.1520/D6770-07R15.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from Superintendent of Documents, Government Printing Office, Washington, DC 20402.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D6770 − 07 (2015)

5.3 Laboratory tests may be reliable as an indication of relative end use in cases where the difference in abrasion resistance of

various materials is large, but they should not be relied upon where differences in laboratory test findings are small. In general,

the results should not be relied upon for prediction of performance during actual wear life for specific end uses unless there are

data showing the specific relationship between laboratory abrasion tests and actual wear in the intended end use.

5.4 While there has not been extensive interlaboratory testing prior to development of this standard, there has been some quality

control testing by manufacturers. An intralaboratory test was conducted to initiate this test method, using a single product. This

data will be used to determine a preliminary statement on precision and bias. Subsequent to approval of this standard, a formalized

interlaboratory procedure will be initiated under the direction of a professional statistician and will produce a research report.

Samples used in this controlled test will be representative of end use applications.

5.5 These general observations apply to most webbings that are used in automotive, aerospace, industrial, and military

applications.

5.6 This test method can be used for acceptance testing of commercial shipments but comparisons should be made with caution

because estimates of between-laboratory precision are incomplete.

5.7 If there are differences of practical significance between reported test results for two laboratories (or more), comparative

tests should be performed to determine if there is a statistical bias between them, using competent statistical assistance. As a

minimum, use samples for such comparative tests that are as homogenous as possible, drawn from the same lot of material as the

samples that resulted in disparate results during initial testing, and randomly assigned in equal numbers to each laboratory. The

test results from the laboratories involved should be compared using a statistical test for unpaired data, at a probability level chosen

prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results must be adjusted in

consideration of the known bias.

6. Apparatus

6.1 Webbing Abrasion Tester—The webbing abrasion tester consists of a suitable mechanism that will provide a reciprocating

motion of the webbing over a standardized hex bar. One end of each specimen is attached to the mechanism and the other end

passing over a hexagonal steel rod is attached to a weight. The hexagonal rod is so fixed as to subject the webbing specimen to

abrasion on two adjacent edges as the drum moves the specimen across the rod. One example of such a mechanism is a

reciprocating drum as illustrated in Fig. 1.

6.1.1 Mass “B” shall be 900 6 60 g (2 lb 6 2 oz) for webbing with breaking strengths up to 4500 N (1000 lb), 1800 6 60 g

(4 lb 6 2 oz) for breaking strengths of 4500 to 13 500 N (1000 to 3000 lb) and 2400 6 60 g (5.2 6 2 lb) for breaking strengths

over 13 500 N (3000 lb).

6.1.2 Steel hexagonal rods “C” shall be 6.35 6 0.03 mm (0.250 6 0.001 in.) when measured across opposite flat sides and the

radius shall be 0.5 6 0.2 mm (0.020 6 0.008 in.). The steel shall have a cold drawn finish and a Rockwell Hardness of B-91 to

B-101. The edges of the hexagonal rods shall not have any burrs, nicks or scale.

6.1.3 The mechanism “D” shall have a nominal outside diameter of 400 mm (16 in.) or be some mechanism able to produce

a reciprocating motion of at least 300 mm (12 in.) over the hex rod with a suitable means for attaching the specimen to be tested

without damage to the specimen.

6.1.4 The crank-arm “F” shall be attached to the mechanism “D” and to the driver disk “E” in such a manner that when the

specimen is attached to the mechanism, the specimen during the test will oscillate over the hexagonal rod the required distance

during each stroke and at the required rate (see 10.4).

FIG. 1 Webbing Abrasion Tester

D6770 − 07 (2015)

6.1.5 The hexagonal rod shall be so placed that specimen “A” with the weight attached to one end and the other end passing

over the hexagonal rod and attached to the drive mechanism will form an angle of 85 6 2° “H”.

6.2 Tensile Testing Machine , CRE-Type equipped with split-drum webbing clamps as described in Federal Test Method 191b,

Method 4108.

7. Sampling and Test Specimens

7.1 Lot Sample—Take a lot sample as directed in the applicable material specification. In absence of such a specification

randomly select five rolls or pieces to constitute the lot sample.

7.2 Laboratory Sampling Unit—As a laboratory sampling unit take from each roll or piece one piece of webbing that is 2.8 m

(3.0 yd) in length.

7.3 Test Specimens—From each laboratory sampling unit, cut 2 test specimens 1.4 m (1.5 yd) in length. Mark one specimen “A”

for abraded and the other “U” for unabraded.

7.3.1 When the lot or shipment consists of less than 5 rolls or pieces, randomly select 5 test specimens that represent all rolls

or pieces in the lot or shipment.

7.4 Ensure specimens are free of folds, creases, or wrinkles. Avoid getting oil, water, grease, and so forth, on the specimens

when handling.

8. Conditioning

8.1 Condition the test specimens to moisture equilibrium for testing in the standard atmosphere for testing textiles in accordance

with Practice D1776 or, if applicable, in the specified atmosphere in which the testing is to be performed.

8.2 In the event of dispute concerning the results of tests that may be affected by the moisture content, test specimens shall be

preconditioned by bringing them to approximate moisture equilibrium in the standard atmosphere for preconditioning textiles in

accordance with Practice D1776.

9. Preparation and Calibration of Test Apparatus

9.1 Ensure the test machine is on a level, sturdy surface and free from vibration.

9.2 For hexagonal rods a manufacturer’s certificate of compliance shall be acceptable as to the requirements as described in

6.1.2.

10. Procedure

10.1 Condition the “A” test specimens in the standard atmosphere for testing textiles, in accordance with Section 8.

10.2 Attach the required mass (6.1.1) to one end of the test specimen, pass the other end over the hexagonal rod and attach to

the drum. The length of the test specimens shall be adjusted, without altering the original length, so that the test specimens will

oscillate across the hexagon rod and each end of the abraded area will be equidistant from the ends of the test specimens.

10.3 The edges of each new hexagonal rod shall be identified as 1 through 6, and rotated after each use so that no abrading edges

are used more than once. Use edge 1 and two for one test specimen, edge 3 and 4 for a second test specimen, edges 5 and 6 for

a third test specimen, and then discard the rod.

10.4 Oscillate the mechanism so that the test specimens are given a 300 6 25 mm (12 6 1 in.) traverse over the rod at the rate

of 1 6 .03 strokes (0.5 cycles) per second for 5000 strokes (2500 cycles). One single stroke is 300 6 25 mm (12 6 1 in.) in one

direction only.

10.5 After the machine has stopped at the predetermined number of cycles remove the test specimens from the abrading

machine.

10.6 Continue as directed in 10.2 – 10.5 until all the required specimens have been abraded for each laboratory sampling unit.

10.7 Determine the breaking force of the abraded specimens (A) and the unabraded specimens (U) for each laboratory sampling

unit in the lot to the nearest 1 % as directed in Fed-Std-191, Method 4108 set as follows:

10.7.1 Attach the split drum webbing clamps in the tensile tester and set the distance between them to 250 mm (10 in.) center

to center.

10.7.2 Set the testing speed to 75 6 25 mm (3 6 1 in./min).

11. Calculation

11.1 Calculate the average breaking force for the lot of the abraded test specimens from the results of the laboratory sampling

units.

Apparatus and accessories are commercially available.

D6770 − 07 (2015)

11.2 Calculate the average breaking force for the lot of the unabraded test specimens from the results of the laboratory sampling

units.

11.3 Calculate the percentage of retained breaking force to the nearest 1 % for the lot using Eq 1:

100A

AR 5 (1)

U

where:

AR = abrasion resistance, %,

A = average breaking force of the abraded specimens, N (lb), and

U = average breaking force of the unabraded specimens, N (lb).

11.3.1 When data are automatically computer processed, calculations are generally contained in the associated software. It is

recommended that computer-processed data be verified against known property values and its software described in the report.

12. Report

12.1 Report that the abrasion resistance was determined in accordance with Test Method D6770. Describe the material or

product sampled.

12.2 Report the following information for the laboratory sampling unit and for the lot as applicable to a material specification

or contract order:

12.2.1 Abrasion resistance, percent retained in breaking force.

12.2.2 Breaking force of abraded test specimens.

12.2.3 Breaking force of unabraded test specimens.

12.2.4 For computer-processed data, identify the program (software) used.

13. Precision and Bias

13.1 An intralaboratory test was conducted for the determination of precision and bias of this test method. The results of the

test are attached as Table 1.

NOTE 1—Because the intralaboratory test included less than the recommended five laboratories, estimates of precision data may be either

underestimated or overestimated to a considerable extent and should be used with special caution.

13.2 Precision—A statement on the precision of this test method is being developed. The results will be included when

available.

13.3 Bias—The procedure of this test method provides a test value that can be defined only in terms of this test method. There

is no independent, referee method by which bias may be determined. No known bias has been determined for this test method.

14. Keywords

14.1 hex-bar abrasion resistance webbing

D6770 − 07 (2015)

TABLE 1 Raw Data from Intralaboratory Test

Material 1—Before Abrasion Material 2—After Abrasion

Total O

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.