ASTM D6207-03(2007)

(Test Method)Standard Test Method for Dimensional Stability of Fabrics to Changes in Humidity and Temperature

Standard Test Method for Dimensional Stability of Fabrics to Changes in Humidity and Temperature

SIGNIFICANCE AND USE

The measured dimensional stability of a fabric determines whether a fabric has the potential to retain its original shape and remain stable, indicating it will not bubble or sag over time, when applied over a substrate, and its suitability for a specified use.

This test method is recommended for acceptance testing of commercial shipments however, caution is advised since information about between laboratory precision is incomplete. Comparative tests as directed in 5.2.1 are advisable.

5.2.1 If there are differences of practical significance between reported test results for two laboratories (or more), comparative test should be performed to determine if there is a statistical bias between them, using competent statistical assistance. At a minimum, use the samples for such a comparative test that are as homogeneous as possible, drawn from the same lot of material as the samples that resulted in disparate results during initial testing and randomly assigned in equal numbers to each laboratory. The test results from the laboratories involved should be compared using a statistical test for unpaired data, a probability level chosen prior to the testing series. If bias is found, either its cause must be found and corrected, or future test results for that material must be adjusted in consideration of the known bias.

This test method is used in industry to determine if a fabric grows, grows and then shrinks, shrinks and then grows, or remains the same when subjected to a specified range of humidity and temperature conditions.

SCOPE

1.1 This test method covers the determination of the dimensional stability of fabrics that are intended for use on panel and screen systems to cycled changes in humidity and temperature.

1.1.1 Panel and screen systems include acoustic panels, free standing screens, office partitions, and furniture systems.

1.2 The values stated in SI units are to be regarded as the standard. The values in parentheses are approximate inch-pound unit equivalents and are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:D6207–03 (Reapproved 2007)

Standard Test Method for

Dimensional Stability of Fabrics to Changes in Humidity and

Temperature

This standard is issued under the fixed designation D6207; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 4. Summary of Test Method

1.1 This test method covers the determination of the dimen- 4.1 Dimensional change (growth and shrinkage) data is

sional stability of fabrics that are intended for use on panel and collectedforaspecimenoffabricthatissubjectedtocontrolled

screen systems to cycled changes in humidity and temperature. cycles of specified relative humidity and temperature condi-

1.1.1 Panel and screen systems include acoustic panels, free tions.

standing screens, office partitions, and furniture systems.

5. Significance and Use

1.2 The values stated in SI units are to be regarded as the

standard. The values in parentheses are approximate inch- 5.1 The measured dimensional stability of a fabric deter-

mines whether a fabric has the potential to retain its original

pound unit equivalents and are for information only.

1.3 This standard does not purport to address all of the shape and remain stable, indicating it will not bubble or sag

over time, when applied over a substrate, and its suitability for

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- a specified use.

5.2 This test method is recommended for acceptance testing

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. of commercial shipments however, caution is advised since

information about between laboratory precision is incomplete.

2. Referenced Documents

Comparative tests as directed in 5.2.1 are advisable.

2.1 ASTM Standards: 5.2.1 If there are differences of practical significance be-

D123 Terminology Relating to Textiles tween reported test results for two laboratories (or more),

D4850 Terminology Relating to Fabrics and Fabric Test comparative test should be performed to determine if there is a

Methods statistical bias between them, using competent statistical assis-

D5034 Test Method for Breaking Strength and Elongation tance. At a minimum, use the samples for such a comparative

of Textile Fabrics (Grab Test) test that are as homogeneous as possible, drawn from the same

D5035 Test Method for Breaking Force and Elongation of lot of material as the samples that resulted in disparate results

Textile Fabrics (Strip Method) during initial testing and randomly assigned in equal numbers

to each laboratory. The test results from the laboratories

3. Terminology

involved should be compared using a statistical test for

3.1 Definitions:

unpaired data, a probability level chosen prior to the testing

3.1.1 For definitions of textile terms used in this test series. If bias is found, either its cause must be found and

method; bench mark; dimensional change; dimensional stabil-

corrected, or future test results for that material must be

ity; related to textiles, refer to Terminology D4850. adjusted in consideration of the known bias.

3.1.2 For definitions of other terms related to textiles, refer

5.3 This test method is used in industry to determine if a

to Terminology D123. fabric grows, grows and then shrinks, shrinks and then grows,

or remains the same when subjected to a specified range of

humidity and temperature conditions.

This test method is under the jurisdiction ofASTM Committee D13 onTextiles

and is the direct responsibility of Subcommittee D13.59 on Fabric Test Methods,

General. 6. Apparatus

Current edition approved July 1, 2007. Published August 2007. Originally

6.1 Environmental Test Chamber, meeting the following

approved in 1997. Last previous edition approved in 2003 as D6207 – 03. DOI:

criteria:

10.1520/D6207-03R07.

For referencedASTM standards, visist theASTM Web Site, www.astm.org, or

6.1.1 Capable of testing two specimens at one time, each

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

150 by 1000, 6 6 mm (6.0 by 39.0, 6 0.25 in.) mounted

Standardsvolume information, refer to the standard’s Document Summary page on

vertically in a single frame.

the ASTM web site.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

D6207–03 (2007)

6.1.2 Capable of a relative humidity range of 15 to 95%, 8.2 Calibrate the test chamber instrumentation as recom-

controllable to 6 5%. mended by the manufacturer, to maintain relative humidity and

6.1.3 Capable of a temperature range of 15 to 35 °C (59 to temperature accuracy.

95 °F) with a tolerance of 62°C(6 4 °F).

6.1.4 Provision for automatic cycling of humidity and 9. Preparation of Test Specimens

temperature conditions.

9.1 Position and clamp length and width test specimens in

6.1.5 Having visible humidity and temperature indicators

the specimen frame. (See Fig. 2).

and a continuous recording device (digital readout or plotter).

9.2 Attach a weighted spring clamp to the lower end of each

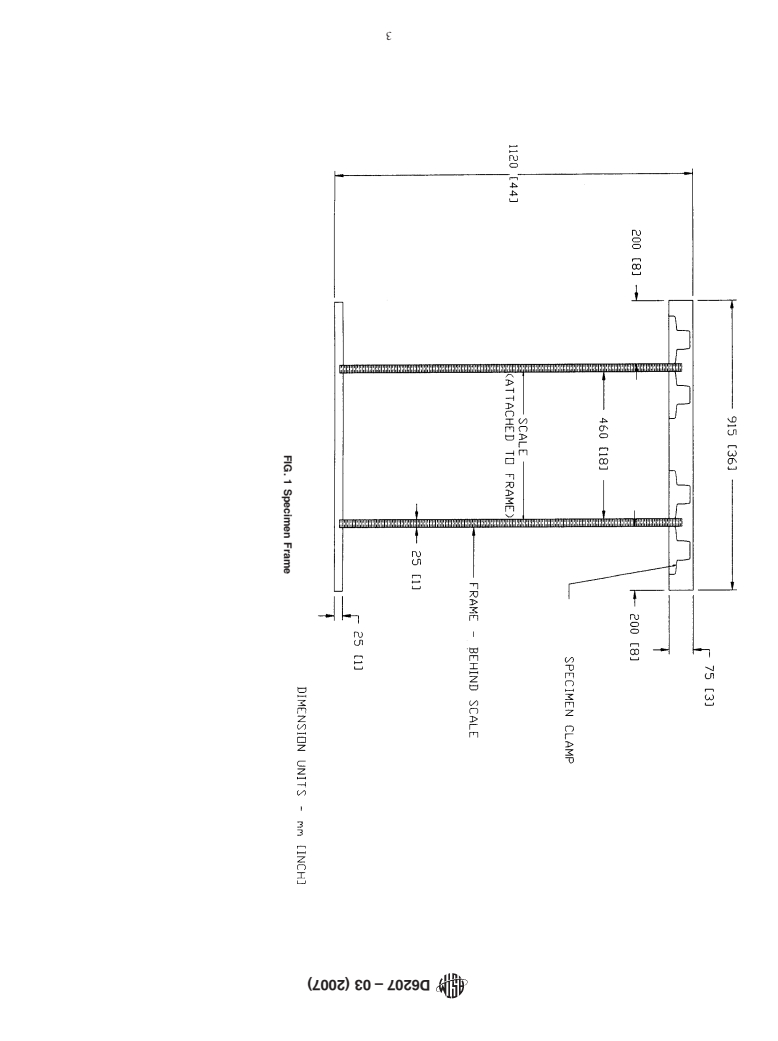

6.2 Specimen Frame, meeting the following criteria:

specimen (see 6.4). Do not remove the weighted springs

6.2.1 Of a size that will fit in the test chamber and hold two

clamps until the test has been completed.

specimens, see Fig. 1.

9.3 Precondition the specimens (see 9.2)for24hat15+/-

6.2.2 With a means for measuring specimen length of at

5 % relative humidity (RH) and 32 +/- 2° C (90 +/- 4 °F).

least 1000 mm (36 in.) in increments of 1 mm (0.05 or ⁄16 in.).

9.3.1 The specimens may be preconditioned in a separate

6.2.3 With a means for holding and suspending the speci-

controlled drying oven, a preconditioning oven, or the envi-

men vertically.

ronmental test chamber.

6.3 Pointers, T-shaped or common straight

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.