ASTM A746-09(2014)

(Specification)Standard Specification for Ductile Iron Gravity Sewer Pipe

Standard Specification for Ductile Iron Gravity Sewer Pipe

ABSTRACT

This specification covers ductile iron gravity sewer pipe centrifugally cast with push-on joints. This also covers trench load design procedures for both cement-lined pipe and flexible-lined pipe. Maximum depths of cover tables are included for both types of linings. Each pipe shall be subjected to a hydrostatic test and maybe performed either before or after the outside coating and inside coating have been applied, but shall be performed before the application of cement-mortar lining or of a special lining. The standard acceptance tests and additional control tests shall also be performed.

SCOPE

1.1 This specification covers 4 to 64-in. ductile iron gravity sewer pipe centrifugally cast with push-on joints. This specification may be used for pipe with other types of joints, as may be agreed upon at the time of purchase.

1.2 This specification covers trench load design procedures for both cement-lined pipe and flexible-lined pipe. Maximum depth of cover tables are included for both types of linings.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical conversions to SI units that are provided for information only and are not considered standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:A746 −09 (Reapproved 2014)

Standard Specification for

Ductile Iron Gravity Sewer Pipe

This standard is issued under the fixed designation A746; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.3 ASCE Standards:

Manuals and Reports on Engineering Practice, No.

1.1 This specification covers 4 to 64-in. ductile iron gravity

37,(WCPF Manual of Practice No. 9). “Design and

sewer pipe centrifugally cast with push-on joints. This speci-

Construction of Sanitary and Storm Sewers”

ficationmaybeusedforpipewithothertypesofjoints,asmay

2.4 AASHTO Standard:

be agreed upon at the time of purchase.

AASHTO T-99Standard Method of Test for the Moisture-

1.2 This specification covers trench load design procedures DensityRelationsofSoilsUsinga5.5lb(2.5kg)Rammer

for both cement-lined pipe and flexible-lined pipe. Maximum

and a 12 in. (305 mm) Drop

depth of cover tables are included for both types of linings.

3. Terminology

1.3 The values stated in inch-pound units are to be regarded

3.1 Symbols:

as standard. The values given in parentheses are mathematical

3.1.1 A—outside radius of pipe,

conversions to SI units that are provided for information only

D

and are not considered standard.

ft 5

2. Referenced Documents

D

inmetres 5

S D

2.1 ASTM Standards:

2 2

3.1.2 a—conversionfactor,lb/ft topsi=144(kN/m tokPa

D2487Practice for Classification of Soils for Engineering

Purposes (Unified Soil Classification System) =1)

D3282 Practice for Classification of Soils and Soil-

3.1.3 B—1.5 ft (0.457 m)

Aggregate Mixtures for Highway Construction Purposes

3.1.4 b—Effective pipe length: 36 in. (0.914 m)

E8Test Methods for Tension Testing of Metallic Materials

3.1.5 C—surface load factor, Table 1

E23Test Methods for Notched Bar Impact Testing of Me-

tallic Materials 3.1.6 D—outside diameter, in., Table 2

6 6

3.1.7 E—modulus of elasticity, 24 × 10 psi (165.5 × 10

2.2 ANSI/AWWA Standards:

kPa)

C104/A21.4 Cement Mortar Lining for Ductile-Iron Pipe

and Fittings for Water

3.1.8 E'—modulus of soil reaction, psi, Table 3

C111/A21.11Rubber-Gasket Joints for Ductile-Iron Pres-

3.1.9 F—impact factor, 1.5

sure Pipe and Fittings

3.1.10 f—designbendingstress,48 000psi(331×10 kPa)

C150/A21.50Thickness Design of Ductile-Iron Pipe

C600Installation of Ductile-Iron Water Mains and Their 3.1.11 H—depth of cover, ft (m)

Appurtenances

3.1.12 K — bending moment coefficient, Table 3

b

3.1.13 K — deflection coefficient, Table 3

x

3.1.14 P—wheel load, 16 000 lb (7257 kg)

This specification is under the jurisdiction of ASTM Committee A04 on Iron

3.1.15 P — earth load, psi (kPa)

Castings and is the direct responsibility of Subcommittee A04.12 on Pipes and

e

Tubes.

3.1.16 P— truck load, psi (kPa)

t

Current edition approved Oct. 1, 2014. Published October 2014. Originally

approved in 1977. Last previous edition approved in 2009 as A746–09. DOI: 3.1.17 P — trench load, psi (kPa) = P + P

v e t

10.1520/A0746-09R14.

3.1.18 R—reductionfactorwhichtakesintoaccountthefact

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

that the part of the pipe directly below the wheels is aided in

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website.

3 4

Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St., Available fromAmerican Society of Civil Engineers (ASCE), 1801Alexander

4th Floor, New York, NY 10036, http://www.ansi.org. Bell Dr., Reston, VA 20191, http://www.asce.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A746−09 (2014)

TABLE 1 Surface Load Factors for Single Truck on Unpaved Road

Pipe Size—in.

Depth

of Cover 3 4 6 8 10 12 14 16 18

ft

Surface Load Factor—C

2.5 0.0589 0.0713 0.1020 0.1328 0.1615 0.1901 0.2178 0.2443 0.2698

3 0.0437 0.0530 0.0759 0.0990 0.1207 0.1424 0.1637 0.1843 0.2044

4 0.0265 0.0321 0.0460 0.0602 0.0736 0.0871 0.1005 0.1136 0.1265

5 0.0176 0.0213 0.0306 0.0401 0.0490 0.0581 0.0672 0.0761 0.0849

6 0.0125 0.0151 0.0217 0.0284 0.0348 0.0413 0.0478 0.0542 0.0606

7 0.0093 0.0113 0.0162 0.0212 0.0260 0.0308 0.0357 0.0405 0.0453

8 0.0072 0.0087 0.0125 0.0164 0.0201 0.0238 0.0276 0.0313 0.0350

9 0.0057 0.0069 0.0099 0.0130 0.0160 0.0190 0.0219 0.0249 0.0279

10 0.0046 0.0056 0.0081 0.0106 0.0130 0.0154 0.0179 0.0203 0.0227

12 0.0032 0.0039 0.0056 0.0074 0.0091 0.0108 0.0125 0.0142 0.0159

14 0.0024 0.0029 0.0042 0.0055 0.0067 0.0080 0.0092 0.0105 0.0117

16 0.0018 0.0022 0.0032 0.0042 0.0051 0.0061 0.0071 0.0080 0.0090

20 0.0012 0.0014 0.0020 0.0027 0.0033 0.0039 0.0045 0.0052 0.0058

24 0.0008 0.0010 0.0014 0.0019 0.0023 0.0027 0.0032 0.0036 0.0040

28 0.0006 0.0007 0.0010 0.0014 0.0017 0.0020 0.0023 0.0026 0.0030

32 0.0005 0.0006 0.0008 0.0011 0.0013 0.0015 0.0018 0.0020 0.0023

Depth Pipe Size—in.

of Cover 20 24 30 36 42 48 54 60 64

ft Surface Load Factor—C

2.5 0.2941 0.3390 0.3962 0.4437 0.4813 0.5115 0.5366 0.5488 0.5592

3 0.2237 0.2602 0.3085 0.3507 0.3857 0.4153 0.4412 0.4543 0.4657

4 0.1391 0.1635 0.1972 0.2284 0.2559 0.2808 0.3040 0.3164 0.3277

5 0.0936 0.1106 0.1347 0.1576 0.1786 0.1982 0.2173 0.2278 0.2377

6 0.0669 0.0793 0.0970 0.1143 0.1304 0.1458 0.1612 0.1698 0.1781

7 0.0500 0.0594 0.0730 0.0863 0.0988 0.1111 0.1235 0.1306 0.1374

8 0.0387 0.0461 0.0567 0.0672 0.0773 0.0871 0.0973 0.1031 0.1088

9 0.0309 0.0367 0.0453 0.0538 0.0620 0.0700 0.0784 0.0833 0.0880

10 0.0251 0.0299 0.0370 0.0440 0.0507 0.0574 0.0644 0.0685 0.0725

12 0.0176 0.0210 0.0259 0.0309 0.0357 0.0405 0.0456 0.0486 0.0515

14 0.0130 0.0155 0.0192 0.0229 0.0265 0.0301 0.0339 0.0362 0.0384

16 0.0100 0.0119 0.0147 0.0176 0.0204 0.0232 0.0262 0.0279 0.0297

20 0.0064 0.0076 0.0095 0.0113 0.0131 0.0149 0.0169 0.0181 0.0192

24 0.0045 0.0053 0.0066 0.0079 0.0091 0.0104 0.0118 0.0126 0.0134

28 0.0033 0.0039 0.0049 0.0058 0.0067 0.0077 0.0087 0.0093 0.0099

32 0.0025 0.0030 0.0037 0.0044 0.0052 0.0059 0.0067 0.0071 0.0076

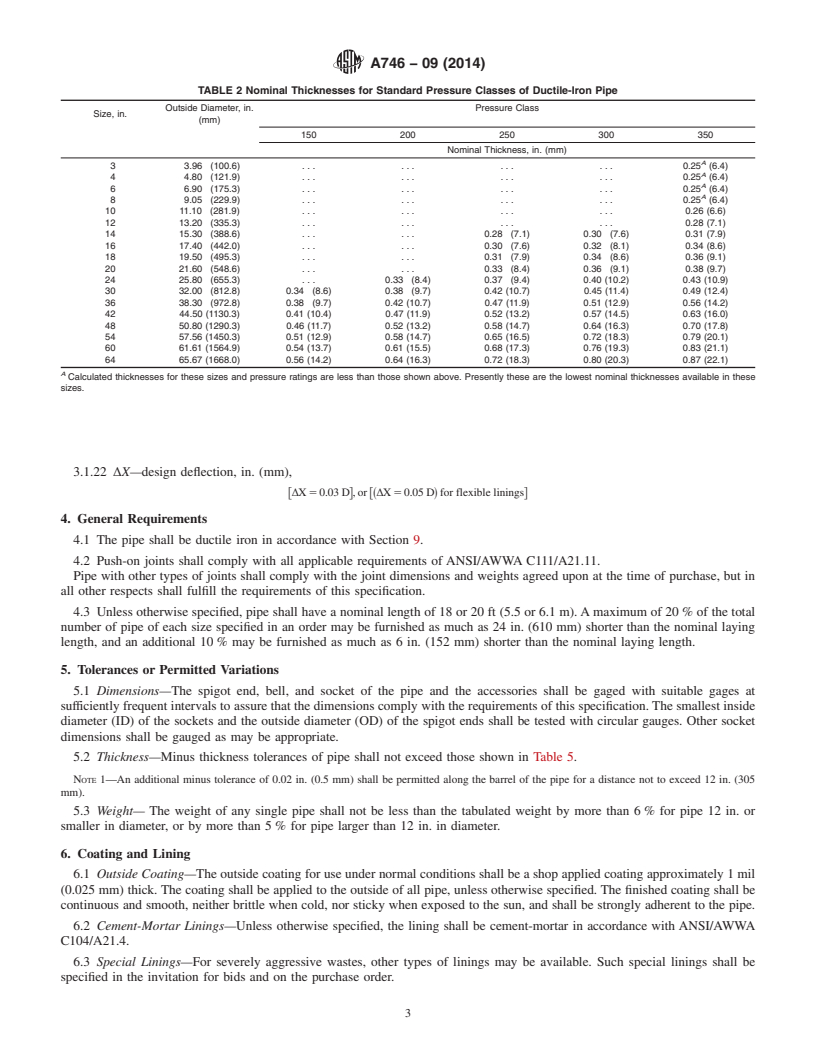

TABLE 2 Nominal Thicknesses for Standard Pressure Classes of Ductile-Iron Pipe

Outside Diameter, in. Pressure Class

Size, in.

(mm)

150 200 250 300 350

Nominal Thickness, in. (mm)

A

3 3.96 (100.6) . . . . . . . . . . . . 0.25 (6.4)

A

4 4.80 (121.9) . . . . . . . . . . . . 0.25 (6.4)

A

6 6.90 (175.3) . . . . . . . . . . . . 0.25 (6.4)

A

8 9.05 (229.9) . . . . . . . . . . . . 0.25 (6.4)

10 11.10 (281.9) . . . . . . . . . . . . 0.26 (6.6)

12 13.20 (335.3) . . . . . . . . . . . . 0.28 (7.1)

14 15.30 (388.6) . . . . . . 0.28 (7.1) 0.30 (7.6) 0.31 (7.9)

16 17.40 (442.0) . . . . . . 0.30 (7.6) 0.32 (8.1) 0.34 (8.6)

18 19.50 (495.3) . . . . . . 0.31 (7.9) 0.34 (8.6) 0.36 (9.1)

20 21.60 (548.6) . . . . . . 0.33 (8.4) 0.36 (9.1) 0.38 (9.7)

24 25.80 (655.3) . . . 0.33 (8.4) 0.37 (9.4) 0.40 (10.2) 0.43 (10.9)

30 32.00 (812.8) 0.34 (8.6) 0.38 (9.7) 0.42 (10.7) 0.45 (11.4) 0.49 (12.4)

36 38.30 (972.8) 0.38 (9.7) 0.42 (10.7) 0.47 (11.9) 0.51 (12.9) 0.56 (14.2)

42 44.50 (1130.3) 0.41 (10.4) 0.47 (11.9) 0.52 (13.2) 0.57 (14.5) 0.63 (16.0)

48 50.80 (1290.3) 0.46 (11.7) 0.52 (13.2) 0.58 (14.7) 0.64 (16.3) 0.70 (17.8)

54 57.56 (1450.3) 0.51 (12.9) 0.58 (14.7) 0.65 (16.5) 0.72 (18.3) 0.79 (20.1)

60 61.61 (1564.9) 0.54 (13.7) 0.61 (15.5) 0.68 (17.3) 0.76 (19.3) 0.83 (21.1)

64 65.67 (1668.0) 0.56 (14.2) 0.64 (16.3) 0.72 (18.3) 0.80 (20.3) 0.87 (22.1)

A

Calculated thicknesses for these sizes and pressure ratings are less than those shown above. Presently these are the lowest nominal thicknesses available in these

sizes.

A746−09 (2014)

A

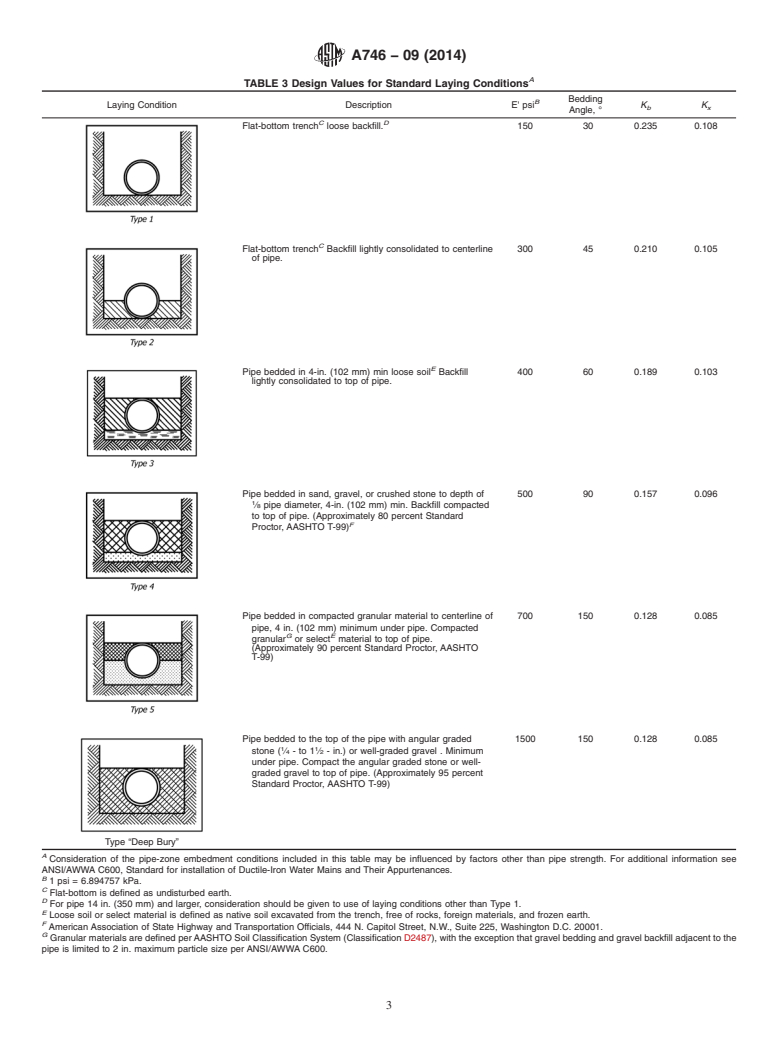

TABLE 3 Design Values for Standard Laying Conditions

Bedding

B

Laying Condition Description E' psi K K

b x

Angle, °

C D

Flat-bottom trench loose backfill. 150 30 0.235 0.108

C

Flat-bottom trench Backfill lightly consolidated to centerline 300 45 0.210 0.105

of pipe.

E

Pipe bedded in 4-in. (102 mm) min loose soil Backfill 400 60 0.189 0.103

lightly consolidated to top of pipe.

Pipe bedded in sand, gravel, or crushed stone to depth of 500 90 0.157 0.096

⁄8 pipe diameter, 4-in. (102 mm) min. Backfill compacted

to top of pipe. (Approximately 80 percent Standard

F

Proctor, AASHTO T-99)

Pipe bedded in compacted granular material to centerline of 700 150 0.128 0.085

pipe, 4 in. (102 mm) minimum under pipe. Compacted

G E

granular or select material to top of pipe.

(Approximately 90 percent Standard Proctor, AASHTO

T-99)

Pipe bedded to the top of the pipe with angular graded 1500 150 0.128 0.085

1 1

stone ( ⁄4 -to1 ⁄2 - in.) or well-graded gravel . Minimum

under pipe. Compact the angular graded stone or well-

graded gravel to top of pipe. (Approximately 95 percent

Standard Proctor, AASHTO T-99)

Type “Deep Bury”

A

Consideration of the pipe-zone embedment conditions included in this table may be influenced by factors other than pipe strength. For additional information see

ANSI/AWWA C600, Standard for installation of Ductile-Iron Water Mains and Their Appurtenances.

B

1 psi = 6.894757 kPa.

C

Flat-bottom is defined as undisturbed earth.

D

For pipe 14 in. (350 mm) and larger, consideration should be given to use of laying conditions other than Type 1.

E

Loose soil or select material is defined as native soil excavated from the trench, free of rocks, foreign materials, and frozen earth.

F

American Association of State Highway and Transportation Officials, 444 N. Capitol Street, N.W., Suite 225, Washington D.C. 20001.

G

Granular materials are defined per AASHTO Soil Classification System (Classification D2487), with the exception that gravel bedding and gravel backfill adjacent to the

pipe is limited to 2 in. maximum particle size per ANSI/AWWA C600.

A746−09 (2014)

TABLE 5 Allowances for Casting Tolerance

carryingthetruckloadbyadjacentpartsofthepipethatreceive

little or no load from the wheels, Table 4 Size, in. Casting Tolerance, in. (mm)

3–8 0.05 (1.3)

3.1.19 t—net thickness, in. (mm)

10–12 0.06 (1.5)

14–42 0.07 (1.8)

3.1.20 t —minimum manufacturing thickness, in., t + 0.08,

48 0.08 (2.0)

(in mm, t + 2.0)

54–64 0.09 (2.3)

3 3

3.1.21 w—soil weight, 120 lb/ft (18.85 kN/m )

3.1.22 ∆X—design deflection, in. (mm),

∆X 5 0.03D ,or ∆X 5 0.05D forflexiblelinings 6. Coating and Lining

@ # @~ ! #

6.1 Outside Coating—The outside coating for use under

4. General Requirements

normal conditions shall be a shop applied coating approxi-

4.1 ThepipeshallbeductileironinaccordancewithSection

mately 1 mil (0.025 mm) thick.The coating shall be applied to

9.

the outside of all pipe, unless otherwise specified.The finished

coating shall be continuous and smooth, neither brittle when

4.2 Push-on joints shall comply with all applicable require-

ments of ANSI/AWWA C111/A21.11. cold, nor sticky when exposed to the sun, and shall be strongly

adherent to the pipe.

Pipe with other types of joints shall comply with the joint

dimensions and weights agreed upon at the time of purchase,

6.2 Cement-Mortar Linings—Unless otherwise specified,

but in all other respects shall fulfill the requirements of this

the lining shall be cement-mortar in accordance with ANSI/

specification.

AWWA C104/A21.4.

4.3 Unless otherwise specified, pipe shall have a nominal

6.3 Special Linings—For severely aggressive wastes, other

lengthof18or20ft(5.5or6.1m).Amaximumof20%ofthe

types of linings may be available. Such special linings shall be

total number of pipe of each size specified in an order may be

specified in the invitation for bids and on the purchase order.

furnishedasmuchas24in.(610mm)shorterthanthenominal

laying length, and an additional 10% may be furnished as 7. Pipe Design

muchas6in.(152mm)shorterthanthenominallayinglength.

7.1 Step 1—Design for trench load.

7.1.1 Determine the trench load, P . Table 6 gives the

v

5. Tolerances or Permitted Variations

trenchload,includingtheearthload,P ,plusthetruckload,P,

e t

5.1 Dimensions—The spigot end, bell, and socket of the

for 2.5 to 32 ft (0.76 to 9.75 m) of cover.

pipe and the accessories shall be gaged with suitable gages at

7.1.2 Determine the standard laying condition from the

sufficiently frequent intervals to assure that the dimensions

descriptions in Table 3 and select the appropriate table for

comply with the requirements of this specification. The small-

diameter-thickness ratios from Tables 7-12. Each table lists

estinsidediameter(ID)ofthesocketsandtheoutsidediameter

diameter-thickness ratios calculated for both bending and

(OD) of the spigot ends shall be tested with circular gauges.

deflection over a range of trench loads.

Other socket dimensions shall be gauged as may be appropri-

7.1.3 Refer to the column headed “ Bending-Stress Design”

ate.

intheappropriatetableofTables7-12,andlocatethetabulated

5.2 Thickness—Minus thickness tolerances of pipe shall not trench load P from Sec. 7.1.1. If the calculated P is halfway

v v

exceed those shown in Table 5. between two tabulated values, use the larger P value. Select

v

the corresponding D/t value for this P . Divide the pipe’s

v

NOTE 1—An additional minus tolerance of 0.02 in. (0.5 mm) shall be

outside diameter D (Table 2)bythe D/t value to obtain the net

permitted along the barrel of the pipe for a distance not to exceed 12 in.

thickness t required for bending stress design.

(305 mm).

5.3 Weight—The weight of any single pipe shall not be less 7.2 Step 2—Addition of service allowance.

than the tabulated weight by more than 6% for pipe 12 in. or 7.2.1 Add the service allowance of 0.08 in. (2.0 mm) to the

smaller in diameter, or by more than 5% for pipe larger than net thickness t. The resulting thickness is the minimum

12 in. in diameter. thickness t .

TABLE 4 Reduction Factors (R) for Truck Load Calculations

Depth of Cover, ft (m)

<4 (1.2) 4 to 7 >7 to 10 >10 (3.0)

Size, in. (1.2 to 2.1) (2.4 to 3.0)

Reduction Factor

3 to 12 1.00 1.00 1.00 1.00

14 0.92 1.00 1.00 1.00

16 0.88 0.95 1.00 1.00

18 0.85 0.90 1.00 1.00

20 0.83 0.90 0.95 1.00

24 to 30 0.81 0.85 0.95 1.00

36 to 64 0.80 0.85 0.90 1.00

A746−09 (2014)

A

TABLE 6 Earth Loads (P ) Truck Loads (P) and Trench Loads (P ), psi

e t v

Depth of 3-in. Pipe 4-in. Pipe 6-in. Pipe 8-in. Pipe 10-in. Pipe 12-in. Pipe 14-in. Pipe 16-in. Pipe 18-in. Pipe 20-in. Pipe

P

e

Cover, ft (m) P P P P P P P P P P P P P P P P P P P P

t v t v t v t v t v t v t v t v t v t v

2.5 (0.8) 2.1 9.9 12.0 9.9 12.0 9.9 12.0 9.8 11.9 9.7 11.8 9.6 11.7 8.7 10.8 8.2 10.3 7.8 9.9 7.5 9.6

3 (0.9) 2.5 7.4 9.9 7.4 9.9 7.3 9.8 7.3 9.8 7.2 9.7 7.2 9.7

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A746 − 09 A746 − 09 (Reapproved 2014)

Standard Specification for

Ductile Iron Gravity Sewer Pipe

This standard is issued under the fixed designation A746; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers 4 to 64-in. ductile iron gravity sewer pipe centrifugally cast with push-on joints. This specification

may be used for pipe with other types of joints, as may be agreed upon at the time of purchase.

1.2 This specification covers trench load design procedures for both cement-lined pipe and flexible-lined pipe. Maximum depth

of cover tables are included for both types of linings.

1.3 The values stated in inch-pound units are to be regarded as standard. The values given in parentheses are mathematical

conversions to SI units that are provided for information only and are not considered standard.

2. Referenced Documents

2.1 ASTM Standards:

D2487 Practice for Classification of Soils for Engineering Purposes (Unified Soil Classification System)

D3282 Practice for Classification of Soils and Soil-Aggregate Mixtures for Highway Construction Purposes

E8 Test Methods for Tension Testing of Metallic Materials

E23 Test Methods for Notched Bar Impact Testing of Metallic Materials

2.2 ANSI/AWWA Standards:

C104/A21.4 Cement Mortar Lining for Ductile-Iron Pipe and Fittings for Water

C111/A21.11 Rubber-Gasket Joints for Ductile-Iron Pressure Pipe and Fittings

C150/A21.50 Thickness Design of Ductile-Iron Pipe

C600 Installation of Ductile-Iron Water Mains and Their Appurtenances

2.3 ASCE Standards:

Manuals and Reports on Engineering Practice, No. 37, (WCPF Manual of Practice No. 9). “Design and Construction of Sanitary

and Storm Sewers”

2.4 AASHTO Standard:

AASHTO T-99 Standard Method of Test for the Moisture-Density Relations of Soils Using a 5.5 lb (2.5 kg) Rammer and a 12

in. (305 mm) Drop

3. Terminology

3.1 Symbols:

3.1.1 A—outside radius of pipe,

D

ft 5

D

in metres 5

S D

2 2

3.1.2 a—conversion factor, lb/ft to psi = 144 (kN/m to kPa = 1)

3.1.3 B—1.5 ft (0.457 m)

This specification is under the jurisdiction of ASTM Committee A04 on Iron Castings and is the direct responsibility of Subcommittee A04.12 on Pipes and Tubes.

Current edition approved May 1, 2009Oct. 1, 2014. Published June 2009October 2014. Originally approved in 1977. Last previous edition approved in 20032009 as

A746 – 03.A746 – 09. DOI: 10.1520/A0746-09.10.1520/A0746-09R14.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

Available from American Society of Civil Engineers (ASCE), 1801 Alexander Bell Dr., Reston, VA 20191, http://www.asce.org.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

A746 − 09 (2014)

3.1.4 b—Effective pipe length: 36 in. (0.914 m)

3.1.5 C—surface load factor, Table 1

3.1.6 D—outside diameter, in., Table 2

6 6

3.1.7 E—modulus of elasticity, 24 × 10 psi (165.5 × 10 kPa)

3.1.8 E'—modulus of soil reaction, psi, Table 3

3.1.9 F—impact factor, 1.5

3.1.10 f—design bending stress, 48 000 psi (331 × 10 kPa)

3.1.11 H—depth of cover, ft (m)

3.1.12 K — bending moment coefficient, Table 3

b

3.1.13 K — deflection coefficient, Table 3

x

3.1.14 P—wheel load, 16 000 lb (7257 kg)

3.1.15 P — earth load, psi (kPa)

e

3.1.16 P — truck load, psi (kPa)

t

3.1.17 P — trench load, psi (kPa) = P + P

v e t

3.1.18 R—reduction factor which takes into account the fact that the part of the pipe directly below the wheels is aided in

carrying the truck load by adjacent parts of the pipe that receive little or no load from the wheels, Table 4

3.1.19 t—net thickness, in. (mm)

3.1.20 t —minimum manufacturing thickness, in., t + 0.08, (in mm, t + 2.0)

3 3

3.1.21 w—soil weight, 120 lb/ft (18.85 kN/m )

TABLE 1 Surface Load Factors for Single Truck on Unpaved Road

Pipe Size—in.

Depth

of Cover 3 4 6 8 10 12 14 16 18

ft

Surface Load Factor—C

2.5 0.0589 0.0713 0.1020 0.1328 0.1615 0.1901 0.2178 0.2443 0.2698

3 0.0437 0.0530 0.0759 0.0990 0.1207 0.1424 0.1637 0.1843 0.2044

4 0.0265 0.0321 0.0460 0.0602 0.0736 0.0871 0.1005 0.1136 0.1265

5 0.0176 0.0213 0.0306 0.0401 0.0490 0.0581 0.0672 0.0761 0.0849

6 0.0125 0.0151 0.0217 0.0284 0.0348 0.0413 0.0478 0.0542 0.0606

7 0.0093 0.0113 0.0162 0.0212 0.0260 0.0308 0.0357 0.0405 0.0453

8 0.0072 0.0087 0.0125 0.0164 0.0201 0.0238 0.0276 0.0313 0.0350

9 0.0057 0.0069 0.0099 0.0130 0.0160 0.0190 0.0219 0.0249 0.0279

10 0.0046 0.0056 0.0081 0.0106 0.0130 0.0154 0.0179 0.0203 0.0227

12 0.0032 0.0039 0.0056 0.0074 0.0091 0.0108 0.0125 0.0142 0.0159

14 0.0024 0.0029 0.0042 0.0055 0.0067 0.0080 0.0092 0.0105 0.0117

16 0.0018 0.0022 0.0032 0.0042 0.0051 0.0061 0.0071 0.0080 0.0090

20 0.0012 0.0014 0.0020 0.0027 0.0033 0.0039 0.0045 0.0052 0.0058

24 0.0008 0.0010 0.0014 0.0019 0.0023 0.0027 0.0032 0.0036 0.0040

28 0.0006 0.0007 0.0010 0.0014 0.0017 0.0020 0.0023 0.0026 0.0030

32 0.0005 0.0006 0.0008 0.0011 0.0013 0.0015 0.0018 0.0020 0.0023

Depth Pipe Size—in.

of Cover 20 24 30 36 42 48 54 60 64

ft Surface Load Factor—C

2.5 0.2941 0.3390 0.3962 0.4437 0.4813 0.5115 0.5366 0.5488 0.5592

3 0.2237 0.2602 0.3085 0.3507 0.3857 0.4153 0.4412 0.4543 0.4657

4 0.1391 0.1635 0.1972 0.2284 0.2559 0.2808 0.3040 0.3164 0.3277

5 0.0936 0.1106 0.1347 0.1576 0.1786 0.1982 0.2173 0.2278 0.2377

6 0.0669 0.0793 0.0970 0.1143 0.1304 0.1458 0.1612 0.1698 0.1781

7 0.0500 0.0594 0.0730 0.0863 0.0988 0.1111 0.1235 0.1306 0.1374

8 0.0387 0.0461 0.0567 0.0672 0.0773 0.0871 0.0973 0.1031 0.1088

9 0.0309 0.0367 0.0453 0.0538 0.0620 0.0700 0.0784 0.0833 0.0880

10 0.0251 0.0299 0.0370 0.0440 0.0507 0.0574 0.0644 0.0685 0.0725

12 0.0176 0.0210 0.0259 0.0309 0.0357 0.0405 0.0456 0.0486 0.0515

14 0.0130 0.0155 0.0192 0.0229 0.0265 0.0301 0.0339 0.0362 0.0384

16 0.0100 0.0119 0.0147 0.0176 0.0204 0.0232 0.0262 0.0279 0.0297

20 0.0064 0.0076 0.0095 0.0113 0.0131 0.0149 0.0169 0.0181 0.0192

24 0.0045 0.0053 0.0066 0.0079 0.0091 0.0104 0.0118 0.0126 0.0134

28 0.0033 0.0039 0.0049 0.0058 0.0067 0.0077 0.0087 0.0093 0.0099

32 0.0025 0.0030 0.0037 0.0044 0.0052 0.0059 0.0067 0.0071 0.0076

A746 − 09 (2014)

TABLE 2 Nominal Thicknesses for Standard Pressure Classes of Ductile-Iron Pipe

Outside Diameter, in. Pressure Class

Size, in.

(mm)

150 200 250 300 350

Nominal Thickness, in. (mm)

A

3 3.96 (100.6) . . . . . . . . . . . . 0.25 (6.4)

A

4 4.80 (121.9) . . . . . . . . . . . . 0.25 (6.4)

A

6 6.90 (175.3) . . . . . . . . . . . . 0.25 (6.4)

A

8 9.05 (229.9) . . . . . . . . . . . . 0.25 (6.4)

10 11.10 (281.9) . . . . . . . . . . . . 0.26 (6.6)

12 13.20 (335.3) . . . . . . . . . . . . 0.28 (7.1)

14 15.30 (388.6) . . . . . . 0.28 (7.1) 0.30 (7.6) 0.31 (7.9)

16 17.40 (442.0) . . . . . . 0.30 (7.6) 0.32 (8.1) 0.34 (8.6)

18 19.50 (495.3) . . . . . . 0.31 (7.9) 0.34 (8.6) 0.36 (9.1)

20 21.60 (548.6) . . . . . . 0.33 (8.4) 0.36 (9.1) 0.38 (9.7)

24 25.80 (655.3) . . . 0.33 (8.4) 0.37 (9.4) 0.40 (10.2) 0.43 (10.9)

30 32.00 (812.8) 0.34 (8.6) 0.38 (9.7) 0.42 (10.7) 0.45 (11.4) 0.49 (12.4)

36 38.30 (972.8) 0.38 (9.7) 0.42 (10.7) 0.47 (11.9) 0.51 (12.9) 0.56 (14.2)

42 44.50 (1130.3) 0.41 (10.4) 0.47 (11.9) 0.52 (13.2) 0.57 (14.5) 0.63 (16.0)

48 50.80 (1290.3) 0.46 (11.7) 0.52 (13.2) 0.58 (14.7) 0.64 (16.3) 0.70 (17.8)

54 57.56 (1450.3) 0.51 (12.9) 0.58 (14.7) 0.65 (16.5) 0.72 (18.3) 0.79 (20.1)

60 61.61 (1564.9) 0.54 (13.7) 0.61 (15.5) 0.68 (17.3) 0.76 (19.3) 0.83 (21.1)

64 65.67 (1668.0) 0.56 (14.2) 0.64 (16.3) 0.72 (18.3) 0.80 (20.3) 0.87 (22.1)

A

Calculated thicknesses for these sizes and pressure ratings are less than those shown above. Presently these are the lowest nominal thicknesses available in these

sizes.

3.1.22 ΔX—design deflection, in. (mm),

@ΔX5 0.03 D#, or @~ΔX5 0.05 D! for flexible linings#

4. General Requirements

4.1 The pipe shall be ductile iron in accordance with Section 9.

4.2 Push-on joints shall comply with all applicable requirements of ANSI/AWWA C111/A21.11.

Pipe with other types of joints shall comply with the joint dimensions and weights agreed upon at the time of purchase, but in

all other respects shall fulfill the requirements of this specification.

4.3 Unless otherwise specified, pipe shall have a nominal length of 18 or 20 ft (5.5 or 6.1 m). A maximum of 20 % of the total

number of pipe of each size specified in an order may be furnished as much as 24 in. (610 mm) shorter than the nominal laying

length, and an additional 10 % may be furnished as much as 6 in. (152 mm) shorter than the nominal laying length.

5. Tolerances or Permitted Variations

5.1 Dimensions—The spigot end, bell, and socket of the pipe and the accessories shall be gaged with suitable gages at

sufficiently frequent intervals to assure that the dimensions comply with the requirements of this specification. The smallest inside

diameter (ID) of the sockets and the outside diameter (OD) of the spigot ends shall be tested with circular gauges. Other socket

dimensions shall be gauged as may be appropriate.

5.2 Thickness—Minus thickness tolerances of pipe shall not exceed those shown in Table 5.

NOTE 1—An additional minus tolerance of 0.02 in. (0.5 mm) shall be permitted along the barrel of the pipe for a distance not to exceed 12 in. (305

mm).

5.3 Weight— The weight of any single pipe shall not be less than the tabulated weight by more than 6 % for pipe 12 in. or

smaller in diameter, or by more than 5 % for pipe larger than 12 in. in diameter.

6. Coating and Lining

6.1 Outside Coating—The outside coating for use under normal conditions shall be a shop applied coating approximately 1 mil

(0.025 mm) thick. The coating shall be applied to the outside of all pipe, unless otherwise specified. The finished coating shall be

continuous and smooth, neither brittle when cold, nor sticky when exposed to the sun, and shall be strongly adherent to the pipe.

6.2 Cement-Mortar Linings—Unless otherwise specified, the lining shall be cement-mortar in accordance with ANSI/AWWA

C104/A21.4.

6.3 Special Linings—For severely aggressive wastes, other types of linings may be available. Such special linings shall be

specified in the invitation for bids and on the purchase order.

A746 − 09 (2014)

A

TABLE 3 Design Values for Standard Laying Conditions

Bedding

B

Laying Condition Description E' psi K K

b x

Angle, °

C D

Flat-bottom trench loose backfill. 150 30 0.235 0.108

C

Flat-bottom trench Backfill lightly consolidated to centerline 300 45 0.210 0.105

of pipe.

E

Pipe bedded in 4-in. (102 mm) min loose soil Backfill 400 60 0.189 0.103

lightly consolidated to top of pipe.

Pipe bedded in sand, gravel, or crushed stone to depth of 500 90 0.157 0.096

⁄8 pipe diameter, 4-in. (102 mm) min. Backfill compacted

to top of pipe. (Approximately 80 percent Standard

F

Proctor, AASHTO T-99)

Pipe bedded in compacted granular material to centerline of 700 150 0.128 0.085

pipe, 4 in. (102 mm) minimum under pipe. Compacted

G E

granular or select material to top of pipe.

(Approximately 90 percent Standard Proctor, AASHTO

T-99)

Pipe bedded to the top of the pipe with angular graded 1500 150 0.128 0.085

1 1

stone ( ⁄4 - to 1 ⁄2 - in.) or well-graded gravel . Minimum

under pipe. Compact the angular graded stone or well-

graded gravel to top of pipe. (Approximately 95 percent

Standard Proctor, AASHTO T-99)

Type “Deep Bury”

A

Consideration of the pipe-zone embedment conditions included in this table may be influenced by factors other than pipe strength. For additional information see

ANSI/AWWA C600, Standard for installation of Ductile-Iron Water Mains and Their Appurtenances.

B

1 psi = 6.894757 kPa.

C

Flat-bottom is defined as undisturbed earth.

D

For pipe 14 in. (350 mm) and larger, consideration should be given to use of laying conditions other than Type 1.

E

Loose soil or select material is defined as native soil excavated from the trench, free of rocks, foreign materials, and frozen earth.

F

American Association of State Highway and Transportation Officials, 444 N. Capitol Street, N.W., Suite 225, Washington D.C. 20001.

G

Granular materials are defined per AASHTO Soil Classification System (Classification D2487), with the exception that gravel bedding and gravel backfill adjacent to the

pipe is limited to 2 in. maximum particle size per ANSI/AWWA C600.

A746 − 09 (2014)

TABLE 4 Reduction Factors (R) for Truck Load Calculations

Depth of Cover, ft (m)

<4 (1.2) 4 to 7 >7 to 10 >10 (3.0)

Size, in. (1.2 to 2.1) (2.4 to 3.0)

Reduction Factor

3 to 12 1.00 1.00 1.00 1.00

14 0.92 1.00 1.00 1.00

16 0.88 0.95 1.00 1.00

18 0.85 0.90 1.00 1.00

20 0.83 0.90 0.95 1.00

24 to 30 0.81 0.85 0.95 1.00

36 to 64 0.80 0.85 0.90 1.00

TABLE 5 Allowances for Casting Tolerance

Size, in. Casting Tolerance, in. (mm)

3–8 0.05 (1.3)

10–12 0.06 (1.5)

14–42 0.07 (1.8)

48 0.08 (2.0)

54–64 0.09 (2.3)

7. Pipe Design

7.1 Step 1—Design for trench load.

7.1.1 Determine the trench load, P . Table 6 gives the trench load, including the earth load, P , plus the truck load, P , for 2.5

v e t

to 32 ft (0.76 to 9.75 m) of cover.

A

TABLE 6 Earth Loads (P ) Truck Loads (P ) and Trench Loads (P ), psi

e t v

Depth of 3-in. Pipe 4-in. Pipe 6-in. Pipe 8-in. Pipe 10-in. Pipe 12-in. Pipe 14-in. Pipe 16-in. Pipe 18-in. Pipe 20-in. Pipe

P

e

Cover, ft (m) P P P P P P P P P P P P P P P P P P P P

t v t v t v t v t v t v t v t v t v t v

2.5 (0.8) 2.1 9.9 12.0 9.9 12.0 9.9 12.0 9.8 11.9 9.7 11.8 9.6 11.7 8.7 10.8 8.2 10.3 7.8 9.9 7.5 9.6

3 (0.9) 2.5 7.4 9.9 7.4 9.9 7.3 9.8 7.3 9.8 7.2 9.7 7.2 9.7 6.6 9.1 6.2 8.7 5.9 8.4 5.7 8.2

4 (1.2) 3.3 4.4 7.7 4.5 7.8 4.4 7.7 4.4 7.7 4.4 7.7 4.4 7.7 4.4 7.7 4.1 7.4 3.9 7.2 3.9 7.2

5 (1.5) 4.2 3.0 7.2 3.0 7.2 3.0 7.2 3.0 7.2 2.9 7.1 2.9 7.1 2.9 7.1 2.8 7.0 2.6 6.8 2.6 6.8

6 (1.8) 5.0 2.1 7.1 2.1 7.1 2.1 7.1 2.1 7.1 2.1 7.1 2.1 7.1 2.1 7.1 2.0 7.0 1.9 6.9 1.9 6.9

7 (2.1) 5.8 1.6 7.4 1.6 7.4 1.6 7.4 1.6 7.4 1.6 7.4 1.6 7.4 1.6 7.4 1.5 7

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.