ASTM D3223-02(2007)e1

(Test Method)Standard Test Method for Total Mercury in Water

Standard Test Method for Total Mercury in Water

SIGNIFICANCE AND USE

The presence of mercury in industrial discharge, domestic discharge, and potable water is of concern to the public because of its toxicity. Regulations and standards have been established that require the monitoring of mercury in water. This test method provides an analytical procedure to measure total mercury in water.

SCOPE

1.1 This test method covers the determination of total mercury in water in the range from 0.5 to 10.0 μg Hg/L (1). The test method is applicable to fresh waters, saline waters, and some industrial and sewage effluents. It is the user's responsibility to ensure the validity of this test method for waters of untested matrices.

1.1.1 The analyst should recognize that the precision and bias of this standard may be affected by the other constituents in all waters, as tap, industrial, river, and wastewaters. The cold vapor atomic absorption measurement portion of this method is applicable to the analysis of materials other than water (sediments, biological materials, tissues, etc.) if, and only if, an initial procedure for digesting and oxidizing the sample is carried out, ensuring that the mercury in the sample is converted to the mercuric ion, and is dissolved in aqueous media (2,3).

1.2 Both organic and inorganic mercury compounds may be analyzed by this procedure if they are first converted to mercuric ions. Using potassium persulfate and potassium permanganate as oxidants, and a digestion temperature of 95°C, approximately 100 % recovery of organomercury compounds can be obtained (2,4).

1.3 The range of the test method may be changed by instrument or recorder expansion or both, and by using a larger volume of sample.

1.4 A method for the disposal of mercury-containing wastes is also presented (Appendix X1) (5).

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see 7.8 and 10.8.2.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation: D3223 − 02(Reapproved 2007)

Standard Test Method for

Total Mercury in Water

This standard is issued under the fixed designation D3223; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the Department of Defense.

´ NOTE—Reference to Practice D2777 – 77 was editorially updated to D2777 – 06 in August 2007.

1. Scope 1.5 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

1.1 This test method covers the determination of total

responsibility of the user of this standard to establish appro-

mercury in water in the range from 0.5 to 10.0 µg Hg/L (1).

priate safety and health practices and determine the applica-

Thetestmethodisapplicabletofreshwaters,salinewaters,and

bility of regulatory limitations prior to use. For specific hazard

some industrial and sewage effluents. It is the user’s responsi-

statements, see 7.8 and 10.8.2.

bility to ensure the validity of this test method for waters of

untested matrices.

2. Referenced Documents

1.1.1 The analyst should recognize that the precision and

2.1 ASTM Standards:

bias of this standard may be affected by the other constituents

D512 Test Methods for Chloride Ion In Water

inallwaters,astap,industrial,river,andwastewaters.Thecold

D1129 Terminology Relating to Water

vaporatomicabsorptionmeasurementportionofthismethodis

D1193 Specification for Reagent Water

applicable to the analysis of materials other than water

D1245 Practice for Examination of Water-Formed Deposits

(sediments,biologicalmaterials,tissues,etc.)if,andonlyif,an

by Chemical Microscopy

initial procedure for digesting and oxidizing the sample is

D1252 Test Methods for Chemical Oxygen Demand (Di-

carried out, ensuring that the mercury in the sample is

chromate Oxygen Demand) of Water

converted to the mercuric ion, and is dissolved in aqueous

D1426 Test Methods for Ammonia Nitrogen In Water

media (2,3).

D2777 Practice for Determination of Precision and Bias of

1.2 Both organic and inorganic mercury compounds may be Applicable Test Methods of Committee D19 on Water

analyzed by this procedure if they are first converted to D3370 Practices for Sampling Water from Closed Conduits

mercuric ions. Using potassium persulfate and potassium D4691 Practice for Measuring Elements in Water by Flame

permanganate as oxidants, and a digestion temperature of Atomic Absorption Spectrophotometry

95°C, approximately 100 % recovery of organomercury com-

D4841 Practice for Estimation of Holding Time for Water

pounds can be obtained (2,4). Samples Containing Organic and Inorganic Constituents

D5810 Guide for Spiking into Aqueous Samples

1.3 The range of the test method may be changed by

D5847 Practice for Writing Quality Control Specifications

instrument or recorder expansion or both, and by using a larger

for Standard Test Methods for Water Analysis

volume of sample.

3. Terminology

1.4 Amethod for the disposal of mercury-containing wastes

is also presented (Appendix X1) (5).

3.1 Definitions: For definitions of terms used in this test

method, refer to Terminology D1129.

4. Summary of Test Method

This test method is under the jurisdiction of ASTM Committee D19 on Water

and is the direct responsibility of Subcommittee D19.05 on Inorganic Constituents

4.1 The test method consists of a wet chemical oxidation

in Water.

which converts all mercury to the mercuric ion; reduction of

Current edition approved Aug. 1, 2007. Published August 2007. Originally

mercuric ions to metallic mercury, followed by a cold vapor

approved in 1979. Last previous edition approved in 2002 as D3223 – 02. DOI:

10.1520/D3223-02R07E01.

Adapted from research investigations by the U. S. Environmental Protection

Agency’s Analytical Quality Control Laboratory, Cincinnati, OH, and Region IV For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Surveillance and Analysis Division, Chemical Services Branch, Athens, GA. contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

The boldface numbers in parentheses refer to the references at the end of this Standards volume information, refer to the standard’s Document Summary page on

test method. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

´1

D3223 − 02 (2007)

atomic absorption analysis (1,2).Ageneral guide for flame and

vapor generation atomic absorption applications is given in

Practice D4691.

4.2 Cold vapor atomic absorption analysis is a physical

method based on the absorption of ultraviolet radiation at a

wavelength of 253.7 nm by mercury vapor. The mercury is

reduced to the elemental state and aerated from solution in

either a closed recirculating system or an open one-pass

system. The mercury vapor passes through a cell positioned in

the light path of an atomic absorption spectrophotometer.

Absorbance is measured as a function of mercury concentra-

tion.

5. Significance and Use

5.1 The presence of mercury in industrial discharge, domes-

tic discharge, and potable water is of concern to the public

because of its toxicity. Regulations and standards have been

established that require the monitoring of mercury in water.

This test method provides an analytical procedure to measure

total mercury in water.

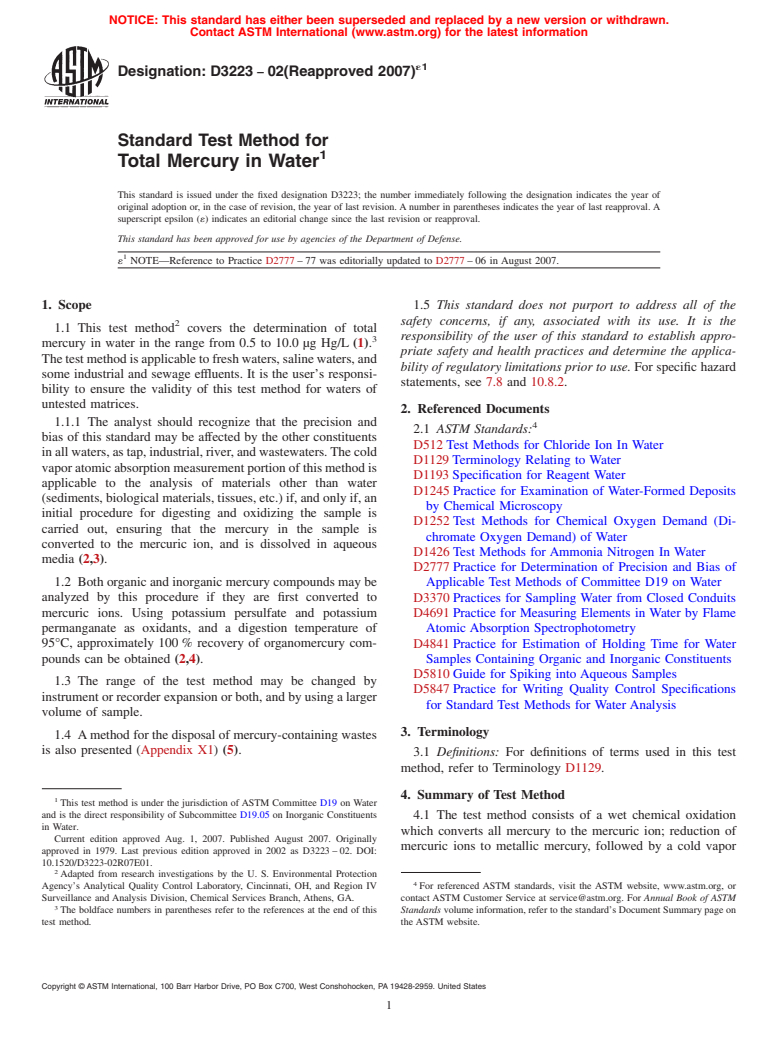

A—Reaction flask G—Hollow cathode mercury lamp

B—60-W light bulb H—Atomic absorption detector

C—Rotameter, 1 L of air per minute J— Gas washing bottle containing

6. Interference

0.25 % iodine in a 3 % potassium io-

dide solution

6.1 Possible interference from sulfide is eliminated by the

D— Absorption cell with quartz windows K—Recorder, any compatible model

additionofpotassiumpermanganate.Concentrationsashighas

E— Air pump, 1 L of air per minute

20 mg/L of sulfide as sodium sulfide do not interfere with the

F—Glass tube with fritted end

recovery of added inorganic mercury from distilled water (2).

FIG. 1 Schematic Arrangement of Equipment for Mercury Mea-

6.2 Copper has also been reported to interfere; however,

surement by Cold Vapor Atomic Absorption Technique Closed

copper concentrations as high as 10 mg/Lhave no effect on the

Recirculating System

recovery of mercury from spiked samples (2).

6.3 Seawaters, brines, and industrial effluents high in chlo-

mercury using the cold vapor technique in the working range

rides require additional permanganate (as much as 25 mL). specified may be used.

During the oxidation step chlorides are converted to free

7.2.1 Mercury Hollow Cathode Lamp.

chlorine which will also absorb radiation at 253.7 nm. Care 7.2.2 Simultaneous Background Correction—Background

must be taken to assure that free chlorine is absent before

correction may be necessary to compensate for molecular

mercury is reduced and swept into the cell. This may be absorption that can occur at this mercury wavelength. It is the

accomplished by using an excess of hydroxylamine sulfate

analyst’s responsibility to determine the applicable use.

reagent (25 mL). The dead air space in the reaction flask must

7.3 Recorder—Any multirange variable speed recorder that

also be purged before the addition of stannous sulfate. Both

is compatible with the ultraviolet (UV) detection system is

inorganic and organic mercury spikes have been quantitatively

suitable.

recovered from sea water using this technique (2).

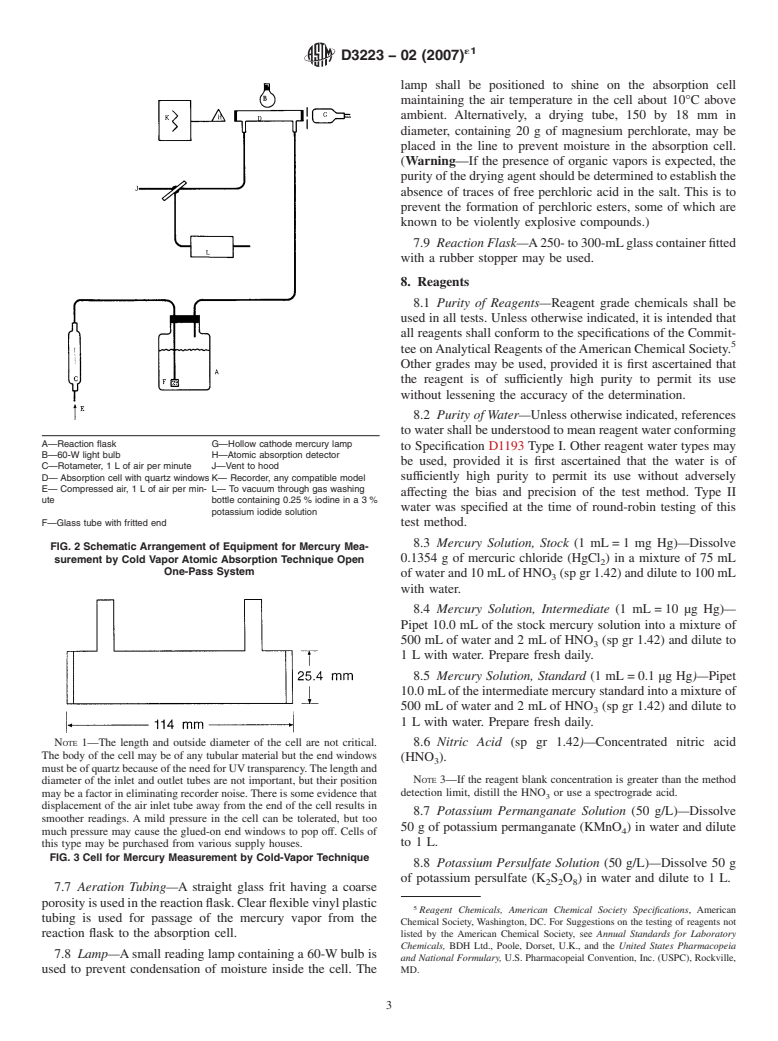

7.4 Absorption Cell—The cell (Fig. 3) is constructed from

6.4 Volatile organic materials that could interfere will be

glass 25.4-mm outside diameter by 114 mm (Note 2).The ends

removed with sample digestion as described in 11.2 through

are ground perpendicular to the longitudinal axis and quartz

11.4.

windows (25.4-mm diameter by 1.6 mm thickness) are ce-

mented in place. Gas inlet and outlet ports (6.4-mm diameter)

7. Apparatus

are attached approximately 12 mm from each end. The cell is

NOTE 1—Take care to avoid contamination of the apparatus with

strapped to a support and aligned in the light beam to give

mercury. Soak all glass apparatus, pipets, beakers, aeration tubes, and

maximum transmittance.

reaction flasks in nitric acid (HNO ) (1 + 1), and rinse with mercury-free

water before use.

NOTE 2—An all-glass absorption cell, 18 mm in outside diameter by

7.1 The schematic arrangement of the closed recirculating

200 mm, with inlet 12 mm from the end, 18-mm outside diameter outlet

in the center, and with quartz windows has been found suitable. Methyl

systemisshowninFig.1andtheschematicarrangementofthe

methacrylate tubing may also be used.

open one-pass system is shown in Fig. 2.

7.5 Air Pump—A peristaltic pump, with electronic speed

7.2 Atomic Absorption Spectrophotometer—A commercial

control, capable of delivering 1 L of air per minute may be

atomic absorption instrument is suitable if it has an open-

used. Regulated compressed air can be used in the open

burner head area in which to mount an absorption cell, and if

one-pass system.

it provides the sensitivity and stability for the analyses. Also

instruments designed specifically for the measurement of 7.6 Flowmeter, capable of measuring an air flow of 1 L/min.

´1

D3223 − 02 (2007)

lamp shall be positioned to shine on the absorption cell

maintaining the air temperature in the cell about 10°C above

ambient. Alternatively, a drying tube, 150 by 18 mm in

diameter, containing 20 g of magnesium perchlorate, may be

placed in the line to prevent moisture in the absorption cell.

(Warning—If the presence of organic vapors is expected, the

purityofthedryingagentshouldbedeterminedtoestablishthe

absence of traces of free perchloric acid in the salt. This is to

prevent the formation of perchloric esters, some of which are

known to be violently explosive compounds.)

7.9 ReactionFlask—A250-to300-mLglasscontainerfitted

with a rubber stopper may be used.

8. Reagents

8.1 Purity of Reagents—Reagent grade chemicals shall be

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

tee onAnalytical Reagents of theAmerican Chemical Society.

Other grades may be used, provided it is first ascertained that

the reagent is of sufficiently high purity to permit its use

without lessening the accuracy of the determination.

8.2 Purity of Water—Unless otherwise indicated, references

towatershallbeunderstoodtomeanreagentwaterconforming

A—Reaction flask G—Hollow cathode mercury lamp

to Specification D1193 Type I. Other reagent water types may

B—60-W light bulb H—Atomic absorption detector

be used, provided it is first ascertained that the water is of

C—Rotameter, 1 L of air per minute J—Vent to hood

sufficiently high purity to permit its use without adversely

D— Absorption cell with quartz windows K— Recorder, any compatible model

E— Compressed air, 1 L of air per min- L— To vacuum through gas washing

affecting the bias and precision of the test method. Type II

ute bottle containing 0.25 % iodine in a 3 %

water was specified at the time of round-robin testing of this

potassium iodide solution

F—Glass tube with fritted end test method.

8.3 Mercury Solution, Stock (1 mL = 1 mg Hg)—Dissolve

FIG. 2 Schematic Arrangement of Equipment for Mercury Mea-

surement by Cold Vapor Atomic Absorption Technique Open 0.1354 g of mercuric chloride (HgCl ) in a mixture of 75 mL

One-Pass System

of water and 10 mLof HNO (sp gr 1.42) and dilute to 100 mL

with water.

8.4 Mercury Solution, Intermediate (1 mL = 10 µg Hg)—

Pipet 10.0 mL of the stock mercury solution into a mixture of

500 mL of water and 2 mL of HNO (sp gr 1.42) and dilute to

1 L with water. Prepare fresh daily.

8.5 Mercury Solution, Standard (1 mL = 0.1 µg Hg)—Pipet

10.0mLoftheintermediatemercurystandardintoamixtureof

500 mL of water and 2 mL of HNO (sp gr 1.42) and dilute to

1 L with water. Prepare fresh daily.

NOTE 1—The length and outside diameter of the cell are not critical. 8.6 Nitric Acid (sp gr 1.42)—Concentrated nitric acid

The body of the cell may be of any tubular material but the end windows

(HNO ).

mustbeofquartzbecauseoftheneedforUVtransparency.Thelengthand

diameter of the inlet and outlet tubes are not important, but their position NOTE 3—If the reagent blank concentration is greater than the method

detection limit, distill the HNO or use a spectrograde acid.

may be a factor in eliminating recorder noise.There is some evidence that

displacement of the air inlet tube away from the end of the cell results in

8.7 Potassium Permanganate Solution (50 g/L)—Dissolve

smoother readings. A mild pressure in the cell can be tolerated, but too

50 g of potassium permanganate (KMnO ) in water and dilute

much pressure may cause the glued-on end windows to pop off. Cells of

to1L.

this type may be purchased from various supply houses.

FIG. 3 Cell for Mercury Measurement by Cold-Vapor Technique

8.8 Potassium Persulfate Solution (50 g/L)—Dissolve 50 g

of potassium persulfate (K S O ) in water and dilute to 1 L.

2 2 8

7.7 Aeration Tubing—A straight glass frit having a coarse

porosityisusedinthereactionflask.Clearflexiblevinylplastic

Reagent Chemicals, American Chemical Society Specifications, American

tubing is used for passage of the mercury vapor from the

Chemical Society, Washington, DC. For Suggestions on the testing of reagents not

reaction flask to the absorption cell. listed by the American Chemical Society, see Annual Standards for Laboratory

Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

7.8 Lamp—Asmall reading lamp containing a 60-W bulb is

and National Formulary, U.S. Pharmacopeial Convention, Inc. (USPC), Rockville,

used to prevent condensation of moisture inside the cell. The MD.

´1

D3223 − 02 (2007)

8.9 Sodium Chloride-Hydroxylamine Sulfate Solution (120 10.7 After waiting 30 s treat each flask individually by

g/L)—Dissolve 120 g of sodium chloride (NaCl) and 120 g of adding 5 mLof the SnSO solution and immediately attach the

hydroxylamine sulfate [(NH OH) H SO ] in water and dilute bottle to the aeration apparatus forming a closed system. Refer

2 2 2 4

to1L. to Note 5.

10.8 After the absorbance has reached a maximum and the

NOTE 4—The analyst may wish to use hydroxylamine hydrochloride

instead of hydroxylamine sulfate. The analyst should dissolve 12 g of recorder pen has leveled off, prepare the system for the next

hydroxylamine hydrochloride in 100 mL of Type I water.

standard by one of the following procedures:

10.8.1 Close

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.