ASTM D1252-06(2020)

(Test Method)Standard Test Methods for Chemical Oxygen Demand (Dichromate Oxygen Demand) of Water

Standard Test Methods for Chemical Oxygen Demand (Dichromate Oxygen Demand) of Water

SIGNIFICANCE AND USE

5.1 These test methods are used to chemically determine the maximum quantity of oxygen that could be consumed by biological or natural chemical processes due to impurities in water. Typically this measurement is used to monitor and control oxygen-consuming pollutants, both inorganic and organic, in domestic and industrial wastewaters.

5.2 The relationship of COD to other water quality parameters such as TOC and TOD is described in the literature.3

SCOPE

1.1 These test methods cover the determination of the quantity of oxygen that certain impurities in water will consume, based on the reduction of a dichromate solution under specified conditions. The following test methods are included:

Test Method A — Macro COD by Reflux Digestion and Titration

Test Method B — Micro COD by Sealed Digestion and Spectrometry

1.2 These test methods are limited by the reagents employed to a maximum chemical oxygen demand (COD) of 800 mg/L. Samples with higher COD concentrations may be processed by appropriate dilution of the sample. Modified procedures in each test method (Section 15 for Test Method A, and Section 24 for Test Method B) may be used for waters of low COD content (

1.3 As a general rule, COD results are not accurate if the sample contains more than 1000 mg/L Cl−. Consequently, these test methods should not be applied to samples such as seawaters and brines unless the samples are pretreated as described in Appendix X1.

1.4 This test method was used successfully on a standard made up in reagent water. It is the user’s responsibility to ensure the validity of these test methods for waters of untested matrices.

1.5 The values stated in SI units are to be regarded as standard. No other units of measurement are included in this standard.

1.6 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use. For specific hazard statements, see Section 8, 15.6, and 24.5.

1.7 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: D1252 − 06 (Reapproved 2020)

Standard Test Methods for

Chemical Oxygen Demand (Dichromate Oxygen Demand) of

Water

This standard is issued under the fixed designation D1252; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision.Anumber in parentheses indicates the year of last reapproval.A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope 1.7 This international standard was developed in accor-

dance with internationally recognized principles on standard-

1.1 These test methods cover the determination of the

ization established in the Decision on Principles for the

quantity of oxygen that certain impurities in water will

Development of International Standards, Guides and Recom-

consume, based on the reduction of a dichromate solution

mendations issued by the World Trade Organization Technical

under specified conditions. The following test methods are

Barriers to Trade (TBT) Committee.

included:

Test Method A — Macro COD by Reflux Digestion and Titration

2. Referenced Documents

Test MethodB—Micro COD by Sealed Digestion and Spectrometry

1.2 Thesetestmethodsarelimitedbythereagentsemployed

2.1 ASTM Standards:

to a maximum chemical oxygen demand (COD) of 800 mg/L. D1129Terminology Relating to Water

SampleswithhigherCODconcentrationsmaybeprocessedby

D1193Specification for Reagent Water

appropriate dilution of the sample. Modified procedures in D2777Practice for Determination of Precision and Bias of

each test method (Section 15 for Test Method A, and Section

Applicable Test Methods of Committee D19 on Water

24 for Test Method B) may be used for waters of low COD

D3223Test Method for Total Mercury in Water

content (<50 mg/L).

D3370Practices for Sampling Water from Flowing Process

Streams

1.3 As a general rule, COD results are not accurate if the

−

D5847Practice for Writing Quality Control Specifications

samplecontainsmorethan1000mg/LCl .Consequently,these

for Standard Test Methods for Water Analysis

test methods should not be applied to samples such as

D5905Practice for the Preparation of SubstituteWastewater

seawaters and brines unless the samples are pretreated as

E60Practice for Analysis of Metals, Ores, and Related

described in Appendix X1.

Materials by Spectrophotometry

1.4 This test method was used successfully on a standard

E275PracticeforDescribingandMeasuringPerformanceof

made up in reagent water. It is the user’s responsibility to

Ultraviolet and Visible Spectrophotometers

ensure the validity of these test methods for waters of untested

matrices.

3. Terminology

1.5 The values stated in SI units are to be regarded as

3.1 Definitions:

standard. No other units of measurement are included in this

3.1.1 For definitions of terms used in this standard, refer to

standard.

Terminology D1129.

1.6 This standard does not purport to address all of the

3.2 Definitions of Terms Specific to This Standard—The

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- term “oxygen demand” (COD) in these test methods is defined

in accordance with Terminology D1129 as follows:

priate safety, health, and environmental practices and deter-

mine the applicability of regulatory limitations prior to use.

3.2.1 oxygen demand, n—the amount of oxygen required

For specific hazard statements, see Section 8, 15.6, and 24.5.

underspecifiedtestconditionsfortheoxidationofwaterborne

organic and inorganic matter.

These test methods are under the jurisdiction of ASTM Committee D19 on

Water and are the direct responsibility of Subcommittee D19.06 on Methods for

Analysis for Organic Substances in Water. For referenced ASTM standards, visit the ASTM website, www.astm.org, or

Current edition approved Jan. 1, 2020. Published January 2020. Originally contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

ɛ1

approved in 1953. Last previous edition approved in 2012 as D1252–06 (2012) . Standards volume information, refer to the standard’s Document Summary page on

DOI: 10.1520/D1252-06R20. the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

D1252 − 06 (2020)

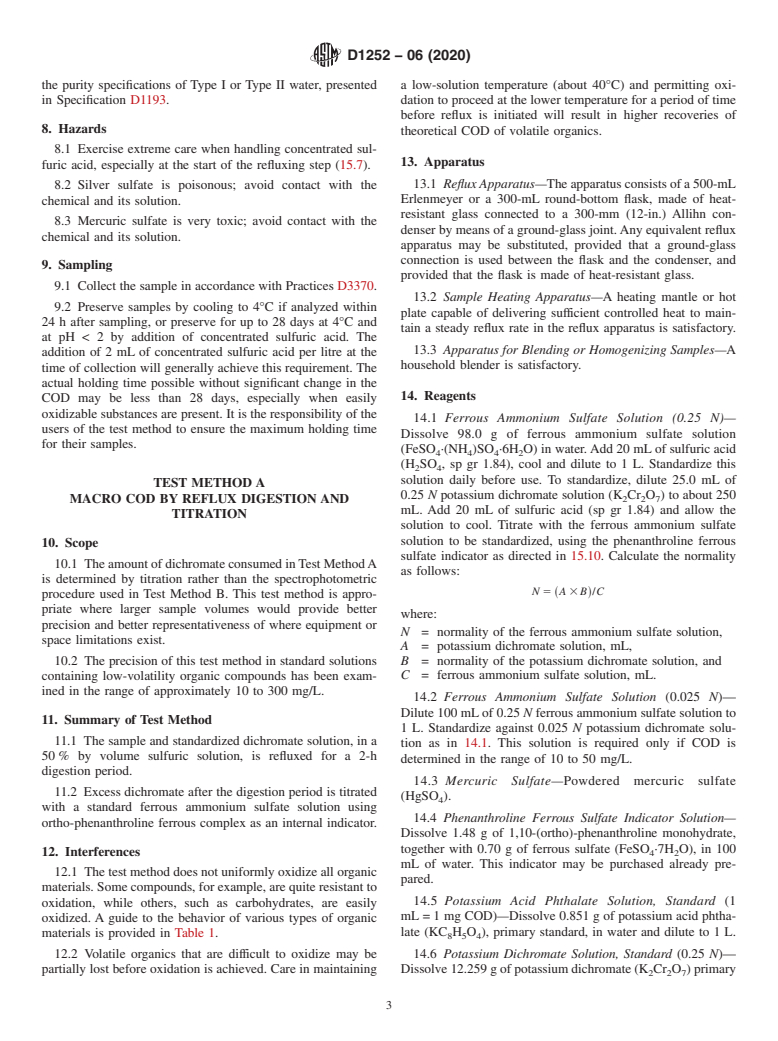

TABLE 1 Test Method A, Recovery of Theoretical COD for

4. Summary of Test Methods

Various Organic Material

4.1 Most organic and oxidizable inorganic substances pres-

Reactivity, Percent of Theoretical

ent in water are oxidized by a standard potassium dichromate Component

A B C D E

1 2 3 4 5

solution in 50% sulfuric acid (vol/vol). The dichromate

Aliphatic Compounds

consumed (Test Method A) or tri-valent chromium produced

Acetone 98 . 96 94 .

(Test Method B) is determined for calculation of the COD Acetic acid 92 92 98 . .

Acrolein 62 . . . .

value.

Butyric acid 89 93 . . .

Dextrose 95 . . . .

4.2 The oxidation of many otherwise refractory organics is

Diethylene glycol 93 . . 70 .

facilitated by the use of silver sulfate that acts as a catalyst in

Ethyl acetate 95 . . 85 .

the reaction.

Methyl ethyl ketone 98 . . 90 .

4.3 These test methods provide for combining the reagents

Aromatic Compounds

and sample in a manner that minimizes the loss of volatile Acetophenone 89 . . . .

Benzaldehyde . . . 80 .

organic materials, if present.

Benzene 60–98 . 41 . .

Benzoic acid 98 . . 100 .

4.4 The oxidation of up to 1000 mg/L of chloride ion is

Dioctyl phthalate 83 . . . .

inhibited by the addition of mercuric sulfate to form stable and

Diphenyl 81 . . . .

soluble mercuric sulfate complex.Atechnique to remove up to

o-cresol 95 . . 95 .

Toluene 83 . . 45 .

40 000 mg/L chloride is shown in Appendix X1 for Test

Potassium acid 100 . . . .

Method B. The maximum chloride concentration that may be

phthalate

tolerated with the procedure for low COD, Test Method A

Nitrogen Compounds

(15.10), has not been established.

Acrylonitrile 48 . . 44 .

4.5 Thechemicalreactioninvolvedinoxidationofmaterials Adenine . . . . 59

Aniline 80 . . 74 .

by dichromate is illustrated by the following reaction with

Butyl amine 57 . . . .

potassium acid phthalate (KC H O ):

8 5 4 Pyridine 0 . 1 . 2

Quinoline . . . . 87

41H SO 110K Cr O 12KC H O

2 4 2 2 7 8 5 4

Trimethylamine 1 . . . .

→10Cr ~SO ! 111K SO 116CO 146H O

2 4 3 2 4 2 2 Tryptophane . . . . 87

Uric acid . . . . 61

Since 10 mol of potassium dichromate has the same oxida-

A

Hamilton, C. E., unpublished data.

tion power as 15 mol of oxygen, the equivalent reaction is:

B

Moore, W. A., and Walker, W. W., Analytical Chemistry, Vol 28, 1956, p. 164.

C

Dobbs, R. A., and Williams, R. T., ibid., Vol 35, 1963 p. 1064.

2KC H O 115O 1H SO →16CO 16H O1K SO

8 5 4 2 2 4 2 2 2 4 D

Buzzell, J. C., Young, R. H. F., and Ryckman, D. W., “Behaviors of Organic

Chemicals in the Aquatic Environment; Part II, Dilute Systems,” Manufacturing

Thus,2molofpotassiumacidphthalateconsumes15molof

Chemists Association, April 1968, p. 34.

oxygen. The theoretical COD of potassium acid phthalate is E

Chudoba, J., and Dalesicky, J., Water Research, Vol 7, No. 5, 1973, p. 663.

1.175gofoxygenpergramofpotassiumacidphthalate(Table

1).

5. Significance and Use

described in Appendix X1 when using Test Method B. Since

this pretreatment was not evaluated during the interlaboratory

5.1 Thesetestmethodsareusedtochemicallydeterminethe

study,theuserofthetestmethodisresponsibletoestablishthe

maximum quantity of oxygen that could be consumed by

precision and bias of each sample matrix.

biological or natural chemical processes due to impurities in

water. Typically this measurement is used to monitor and

6.2 Oxidizable inorganic ions, such as ferrous, nitrite,

control oxygen-consuming pollutants, both inorganic and

sulfite, and sulfides are oxidized and measured as well as

organic, in domestic and industrial wastewaters.

organic constituents.

5.2 The relationship of COD to other water quality param-

7. Reagents

eters such as TOC and TOD is described in the literature.

7.1 Purity of Reagents—Reagent grade chemicals shall be

6. Interference and Reactivity usedinalltests.Allreagentsshallconformtothespecifications

of the Committee on Analytical Reagents of the American

6.1 Chloride ion is quantitatively oxidized by dichromate in

Chemical Society, where such specifications are available.

acidsolution.(1.0mg/Lofchlorideisequivalentto0.226mg/L

of COD.) As the COD test is not intended to measure this

7.2 Purity of Water—Unless otherwise indicated, reference

demand, concern for chloride oxidation is eliminated up to to water shall be understood to mean reagent water that meets

1000 mg/L of chloride by complexing with mercuric sulfate.

6.1.1 Up to 40 000 mg/L chloride ion can be removed with

ACS Reagent Chemicals, Specifications and Procedures for Reagents and

a cation based ion exchange resin in the silver form as

Standard-Grade Reference Materials, American Chemical Society, Washington,

DC. For suggestions on the testing of reagents not listed by theAmerican Chemical

Society, see Analar Standards for Laboratory Chemicals, BDH Ltd., Poole, Dorset,

Handbook for Monitoring Industrial Wastewater, U.S. Environmental Protec- U.K., and the United States Pharmacopeia and National Formulary, U.S. Pharma-

tion Agency, Aug. 1973, pp. 5-10 to 5-12. copeial Convention, Inc. (USPC), Rockville, MD.

D1252 − 06 (2020)

the purity specifications of Type I or Type II water, presented a low-solution temperature (about 40°C) and permitting oxi-

in Specification D1193. dation to proceed at the lower temperature for a period of time

before reflux is initiated will result in higher recoveries of

8. Hazards

theoretical COD of volatile organics.

8.1 Exercise extreme care when handling concentrated sul-

13. Apparatus

furic acid, especially at the start of the refluxing step (15.7).

13.1 RefluxApparatus—Theapparatusconsistsofa500-mL

8.2 Silver sulfate is poisonous; avoid contact with the

Erlenmeyer or a 300-mL round-bottom flask, made of heat-

chemical and its solution.

resistant glass connected to a 300-mm (12-in.) Allihn con-

8.3 Mercuric sulfate is very toxic; avoid contact with the

denser by means of a ground-glass joint.Any equivalent reflux

chemical and its solution.

apparatus may be substituted, provided that a ground-glass

connection is used between the flask and the condenser, and

9. Sampling

provided that the flask is made of heat-resistant glass.

9.1 Collect the sample in accordance with Practices D3370.

13.2 Sample Heating Apparatus—A heating mantle or hot

9.2 Preserve samples by cooling to 4°C if analyzed within

plate capable of delivering sufficient controlled heat to main-

24 h after sampling, or preserve for up to 28 days at 4°C and

tain a steady reflux rate in the reflux apparatus is satisfactory.

at pH<2by addition of concentrated sulfuric acid. The

13.3 Apparatus for Blending or Homogenizing Samples—A

addition of 2 mL of concentrated sulfuric acid per litre at the

household blender is satisfactory.

time of collection will generally achieve this requirement. The

actual holding time possible without significant change in the

14. Reagents

COD may be less than 28 days, especially when easily

oxidizable substances are present. It is the responsibility of the

14.1 Ferrous Ammonium Sulfate Solution (0.25 N)—

users of the test method to ensure the maximum holding time

Dissolve 98.0 g of ferrous ammonium sulfate solution

for their samples.

(FeSO ·(NH )SO ·6H O) in water.Add 20 mLof sulfuric acid

4 4 4 2

(H SO , sp gr 1.84), cool and dilute to 1 L. Standardize this

2 4

solution daily before use. To standardize, dilute 25.0 mL of

TEST METHOD A

0.25 N potassium dichromate solution (K Cr O ) to about 250

2 2 7

MACRO COD BY REFLUX DIGESTION AND

mL. Add 20 mL of sulfuric acid (sp gr 1.84) and allow the

TITRATION

solution to cool. Titrate with the ferrous ammonium sulfate

solution to be standardized, using the phenanthroline ferrous

10. Scope

sulfate indicator as directed in 15.10. Calculate the normality

10.1 TheamountofdichromateconsumedinTestMethodA

as follows:

is determined by titration rather than the spectrophotometric

N 5 ~A 3B!/C

procedure used in Test Method B. This test method is appro-

priate where larger sample volumes would provide better

where:

precision and better representativeness of where equipment or

N = normality of the ferrous ammonium sulfate solution,

space limitations exist.

A = potassium dichromate solution, mL,

10.2 The precision of this test method in standard solutions B = normality of the potassium dichromate solution, and

C = ferrous ammonium sulfate solution, mL.

containing low-volatility organic compounds has been exam-

ined in the range of approximately 10 to 300 mg/L.

14.2 Ferrous Ammonium Sulfate Solution (0.025 N)—

Dilute100mLof0.25 Nferrousammoniumsulfatesolutionto

11. Summary of Test Method

1 L. Standardize against 0.025 N potassium dichromate solu-

11.1 The sample and standardized dichromate solution, in a

tion as in 14.1. This solution is required only if COD is

50% by volume sulfuric solution, is refluxed for a 2-h

determined in the range of 10 to 50 mg/L.

digestion period.

14.3 Mercuric Sulfate—Powdered mercuric sulfate

11.2 Excess dichromate after the digestion period is titrated

(HgSO ).

with a standard ferrous ammonium sulfate solution using

14.4 Phenanthroline Ferrous Sulfate Indicator Solution—

ortho-phenanthroline ferrous complex as an internal indicator.

Dissolve 1.48 g of 1,10-(ortho)-phenanthroline monohydrate,

together with 0.70 g of ferrous sulfate (FeSO ·7H O), in 100

12. Interferences 4 2

mL of water. This indicator may be purchased already pre-

12.1 Thetestmethoddoesnotuniformlyoxidizeallorganic

pared.

materials.Somecompounds,forexample,arequiteresistantto

14.5 Potassium Acid Phthalate Solution, Standard (1

oxidation, while others, such as carbohydrates, are easily

mL=1 mg COD)—Dissolve 0.851 g of potassium acid phtha-

oxidized. A guide to the behavior of various types of organic

late (KC H O ), primary standard, in water and dilute to 1 L.

materials is provided in Table 1.

8 5 4

12.2 Volatile organics that are difficult to oxidize may be 14.6 Potassium Dichromate Solution, Standard (0.25 N)—

partially lost before oxidation is achieved. Care in maintaining Dissolve12.259gofpotassiumdichromate(K Cr O )primary

2 2 7

----------

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.