ASTM B790/B790M-00

(Practice)Standard Practice for Structural Design of Corrugated Aluminum Pipe, Pipe-Arches, and Arches for Culverts, Storm Sewers, and Other Buried Conduits

Standard Practice for Structural Design of Corrugated Aluminum Pipe, Pipe-Arches, and Arches for Culverts, Storm Sewers, and Other Buried Conduits

SCOPE

1.1 This practice is intended for the structural design of corrugated aluminum pipe and pipe-arches, and aluminum structural plate pipe, pipe-arches, and arches for use as culverts and storm sewers and other buried conduits. This practice is for pipe installed in a trench or embankment and subjected to highway, railroad, and aircraft loadings. It must be recognized that a buried corrugated aluminum pipe is a composite structure made up of the aluminum ring and the soil envelope, and both elements play a vital part in the structural design of this type of structure.

1.2 Corrugated aluminum pipe and pipe-arches shall be of annular fabrication using riveted seams, or of helical fabrication having a continuous lockseam.

1.3 Structural plate pipe, pipe-arches, and arches are fabricated in separate plates that when assembled at the job site by bolting form the required shape.

1.4 This specification is applicable to design in inch-pound units as Specification B790M. SI units are shown in brackets in the text for clarity, but they are the applicable values when the design is done in accordance with Specification B790M.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B 790/B 790M – 00

Standard Practice for

Structural Design of Corrugated Aluminum Pipe, Pipe-

Arches, and Arches for Culverts, Storm Sewers, and Other

Buried Conduits

This standard is issued under the fixed designation B 790/B 790M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope * Pipe for Sewers and Drains

B 746/B 746M Specification for Corrugated Aluminum

1.1 This practice is intended for the structural design of

Alloy Structural Plate for Field-Bolted Pipe, Pipe-Arches,

corrugated aluminum pipe and pipe-arches, and aluminum

and Arches

structural plate pipe, pipe-arches, and arches for use as culverts

B 788/B 788M Practice for Installing Factory-Made Cor-

andstormsewersandotherburiedconduits.Thispracticeisfor

rugated Aluminum Culverts and Storm Sewer Pipe

pipe installed in a trench or embankment and subjected to

B 789/B 789M Practice for Installing Corrugated Alumi-

highway, railroad, and aircraft loadings. It must be recognized

num Structural Plate Pipe for Culverts and Sewers

that a buried corrugated aluminum pipe is a composite struc-

D 698 Test Method for Laboratory Compaction Character-

ture made up of the aluminum ring and the soil envelope, and

istics of Soil Using Standard Effort (12 400 ft-lbf/ft [600

both elements play a vital part in the structural design of this

kN-m/m ])

type of structure.

D 1556 Test Method for Density and Unit Weight of Soil In

1.2 Corrugated aluminum pipe and pipe-arches shall be of

Place by the Sand-Cone Method

annular fabrication using riveted seams, or of helical fabrica-

D 2167 Test Method for Density and Unit Weight of Soil In

tion having a continuous lockseam.

Place by the Rubber Balloon Method

1.3 Structural plate pipe, pipe-arches, and arches are fabri-

D 2487 Classification of Soils for Engineering Purposes

cated in separate plates that when assembled at the job site by

(Unified Soil Classification Systems)

bolting form the required shape.

D 2922 Test Methods for Density of Soil and Soil-

1.4 This specification is applicable to design in inch-pound

Aggregate In Place by Nuclear Methods (Shallow Depth)

units as Specification B 790 or in SI units as Specification

D 2937 Test Methods for Density of Soil In Place by the

B 790M. Inch-pound units and SI units are not necessarily

Drive-Cylinder Method

equivalent. SI units are shown in brackets in the text for clarity,

2.2 FAA Standards:

but they are the applicable values when the design is done in

AC No. 150/5320-5B, Advisory Circular, “Airport Drain-

accordance with Specification B 790M.

age,” Department of Transportation, Federal Aviation

1.5 This standard does not purport to address all of the

Administration, Publication No. SN-050-007-00149-5,

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

2.3 AASHTO Standards:

priate safety and health practices and determine the applica-

Specifications for Highway Bridges

bility of regulatory limitations prior to use.

3. Terminology

2. Referenced Documents

3.1 Definitions of Terms Specific to This Standard:

2.1 ASTM Standards:

3.1.1 arch, n—a pipe shape that is supported on footings

B 745/B 745M Specification for Corrugated Aluminum

and does not have a full metal invert.

Annual Book of ASTM Standards, Vol 02.02.

1 3

This practice is under the jurisdiction of ASTM Committee B07 on Light Annual Book of ASTM Standards, Vol 04.08.

Metals and Alloys and is the direct responsibility of Subcommittee B07.08 on AvailablefromStandardizationDocumentsOrderDesk,Bldg.4SectionD,700

Aluminum Culvert. Robbins Ave., Philadelphia, PA 19111-5094, Attn: NPODS.

Current edition approved July 10, 2000. Published September 2000. Originally Available from American Association of State Highway and Transportation

published as B 790–90. Last previous edition B 790–99. Officials, 444 N. Capitol Street NW, Suite 225, Washington, DC 20001.

*A Summary of Changes section appears at the end of this standard.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

B 790/B 790M

3.1.2 bedding, n—the earth or other material on which the

r = radius of gyration of corrugation, in. [mm], see

pipe is laid consist of a thin layer of important material on top

Tables 1-7,

of the in-situ foundation.

r = corner radius of pipe-arch, ft [mm],

c

R = Factored resistance for each limit state, lbf/ft

3.1.3 haunch, n—the portion of the pipe cross section

f

[kN/m],

between the maximum horizontal dimension and the top of the

R = Nominal resistance for each limit state, lbf/ft

bedding.

n

[kN/m],

3.1.4 invert, n—the lowest portion of the pipe cross section;

s = pipe diameter or span, in. [mm],

also, the bottom portion of the pipe.

S = pipe diameter or span, ft [m],

3.1.5 pipe, n—a conduit having a full circular shape or, in a

SF = safety factor,

general contex, all structure shapes covered by this practice.

SS = required seam strength, lbf/ft [kN/m],

3.1.6 pipe-arch, n—a pipe shape consisting of an approxi-

T = thrust in pipe wall, lbf/ft [kN/m], and

mate semicircular top portion, small radius corners, and large

T = Factored thrust in pipe wall, lbf/ft [kN/m],

f

3 3

radius invert.

W = the unit force derived from 1 ft [m]offill

3 3

material above the pipe, lbf/ft [kN/m ].When the

4. Symbols actual fill material is not known, use 120 lbf/ft

[19 kN/m ],

4.1 The symbols used in this practice have the following

f = Resistance factor.

significance:

NOTE 1—For pipes meeting B 745/B 745M, both minimum yield and

2 2

A = required wall area, in. /ft [mm /mm],

minimum tensile strengths are based on the H-32 temper material.

AL = maximum highway design axle load, lbf [N],

d = depth of corrugation, in. [mm], 5. Basis of Design

6 2

E = modulus of elasticity, 10 3 10 lbf/in.

3 5.1 The recommendations presented herein, represent gen-

[69 3 10 MPa],

erally accepted design practice. The design engineer shall,

EL = earth load, lbf/ft [kPa],

however, determine that these recommendations meet particu-

fc = critical buckling stress, lbf/in. [MPa],

lar project needs.

FF = flexibility factor, in./lbf [mm/N],

fu = specified minimum tensile strength,

6. Loads

= 31 000 lbf/in. [215 MPa] for corrugated alu-

6.1 The design load or pressure on a pipe is comprised of

minumpipeperB745/B745MusingAlcladAlloy

earth load (EL), live load (LL), and impact load (IL). These

3004–H34,

loads are applied as a fluid pressure acting on the pipe

= 27 000 lbf/in. [185 MPa] for corrugated alu-

periphery.

minumpipeperB745/B745MusingAlcladAlloy

6.2 For aluminum pipe buried in a trench or in an embank-

3004–H32,

ment on a yielding foundation, loads are defined as follows:

= 35 000 lbf/in. [245 MPa] for 0.100 through

6.2.1 Earth Load—The earth load EL is the weight of the

0.150 inch [2.52 through 3.81 mm] thick alumi-

column of soil directly above the pipe calculated as:

num structural plate per B 746/B 746M,

= 34 000 lbf/in. [235 MPa] for 0.175 through

0.250 inch [4.44 through 6.35 mm] thick alumi-

TABLE 1 Sectional Properties of Corrugated Aluminum Sheets

1 1

num structural plate per B 746/B 746M, for Corrugation: 1 ⁄2 by ⁄4 in. [38 by 6.5 mm] (Helical)

fy = specified minimum yield strength,

= 20 000 lbf/in. [140 MPa] for corrugated alu-

minumpipeperB745/B745MusingAlcladAlloy

3004–H32,

= 24 000 lbf/in. [165 MPa] for all other corru-

gated aluminum pipe and structural plate per B

745/B 745M and B 746/B 746M,

H = depth of fill above top of pipe, ft [m],

H = maximum depth of fill, ft [m],

max

H = minimum depth of fill, ft [m],

min

4 4

I = moment of inertia of corrugation, in. /in. [mm /

mm], see Tables 1-7),

NOTE—Inch-pound dimensions shown in this figure are exact values

IL = impact load, lbf/ft [kPa],

used in calculating the section properties. Nominal values for some of

k = soil stiffness factor—0.22 for good sidefill mate-

these dimensions are used in other places in this practice.

rial compacted to 90 % of standard density based

Moment of Inertia, Radius of

Specified Thick- Area of Section A,

on Test Method D 698, −3 4

I 3 10 in. /in. Gyration,

2 2

ness, in. [mm] in. /ft [mm /mm]

LL = live load, lbf/ft [kPa], [mm /mm] r, in. [mm]

0.048 [1.22] 0.608 [1.287] 0.344 [5.64] 0.0824 [2.093]

P = total design load or pressure, lbf/ft [kPa],

2 0.060 [1.52] 0.761 [1.611] 0.439 [7.19] 0.0832 [2.113]

P = Factored crown pressure, lbf/ft [kPa],

f

B 790/B 790M

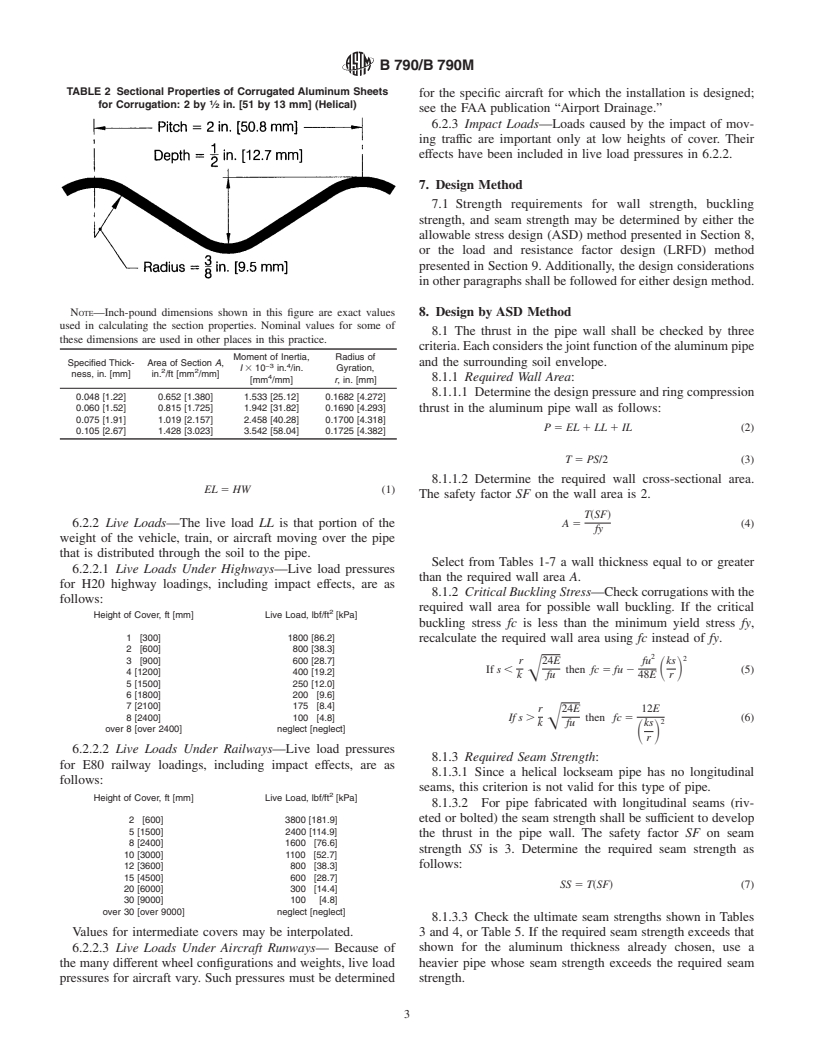

TABLE 2 Sectional Properties of Corrugated Aluminum Sheets

for the specific aircraft for which the installation is designed;

for Corrugation: 2 by ⁄2 in. [51 by 13 mm] (Helical)

see the FAA publication “Airport Drainage.”

6.2.3 Impact Loads—Loads caused by the impact of mov-

ing traffic are important only at low heights of cover. Their

effects have been included in live load pressures in 6.2.2.

7. Design Method

7.1 Strength requirements for wall strength, buckling

strength, and seam strength may be determined by either the

allowable stress design (ASD) method presented in Section 8,

or the load and resistance factor design (LRFD) method

presented in Section 9. Additionally, the design considerations

in other paragraphs shall be followed for either design method.

8. Design by ASD Method

NOTE—Inch-pound dimensions shown in this figure are exact values

used in calculating the section properties. Nominal values for some of

8.1 The thrust in the pipe wall shall be checked by three

these dimensions are used in other places in this practice.

criteria. Each considers the joint function of the aluminum pipe

Moment of Inertia, Radius of

Specified Thick- Area of Section A, and the surrounding soil envelope.

−3 4

I 3 10 in. /in. Gyration,

2 2

ness, in. [mm] in. /ft [mm /mm]

8.1.1 Required Wall Area:

[mm /mm] r, in. [mm]

8.1.1.1 Determine the design pressure and ring compression

0.048 [1.22] 0.652 [1.380] 1.533 [25.12] 0.1682 [4.272]

0.060 [1.52] 0.815 [1.725] 1.942 [31.82] 0.1690 [4.293] thrust in the aluminum pipe wall as follows:

0.075 [1.91] 1.019 [2.157] 2.458 [40.28] 0.1700 [4.318]

P 5 EL 1 LL 1 IL (2)

0.105 [2.67] 1.428 [3.023] 3.542 [58.04] 0.1725 [4.382]

T 5 PS/2 (3)

8.1.1.2 Determine the required wall cross-sectional area.

EL 5 HW (1)

The safety factor SF on the wall area is 2.

T~SF!

A 5 (4)

6.2.2 Live Loads—The live load LL is that portion of the

fy

weight of the vehicle, train, or aircraft moving over the pipe

that is distributed through the soil to the pipe.

Select from Tables 1-7 a wall thickness equal to or greater

6.2.2.1 Live Loads Under Highways—Live load pressures

than the required wall area A.

for H20 highway loadings, including impact effects, are as

8.1.2 Critical Buckling Stress—Check corrugations with the

follows:

required wall area for possible wall buckling. If the critical

Height of Cover, ft [mm] Live Load, lbf/ft [kPa]

buckling stress fc is less than the minimum yield stress fy,

1 [300] 1800 [86.2]

recalculate the required wall area using fc instead of fy.

2 [600] 800 [38.3]

3 [900] 600 [28.7] r 24E fu ks

If s , then fc 5 fu 2 (5)

ΠS D

4 [1200] 400 [19.2]

k fu 48E r

5 [1500] 250 [12.0]

6 [1800] 200 [9.6]

7 [2100] 175 [8.4]

r 24E 12E

8 [2400] 100 [4.8] If s . then fc 5 (6)

Œ

k fu ks

over 8 [over 2400] neglect [neglect]

S D

r

6.2.2.2 Live Loads Under Railways—Live load pressures

8.1.3 Required Seam Strength:

for E80 railway loadings, including impact effects, are as

8.1.3.1 Since a helical lockseam pipe has no longitudinal

follows:

seams, this criterion is not valid for this type of pipe.

Height of Cover, ft [mm] Live Load, lbf/ft [kPa]

8.1.3.2 For pipe fabricated with longitudinal seams (riv-

eted or bolted) the seam strength shall be sufficient to develop

2 [600] 3800 [181.9]

5 [1500] 2400 [114.9]

the thrust in the pipe wall. The safety factor SF on seam

8 [2400] 1600 [76.6]

strength SS is 3. Determine the required seam strength as

10 [3000] 1100 [52.7]

follows:

12 [3600] 800 [38.3]

15 [4500] 600 [28.7]

SS 5 T~SF! (7)

20 [6000] 300 [14.4]

30 [9000] 100 [4.8]

over 30 [over 9000] neglect [neglect]

8.1.3.3 Check the ultimate seam strengths shown in Tables

Values for intermediate covers may be interpolated.

3 and 4, or Table 5. If the required seam strength exceeds that

6.2.2.3 Live Loads Under Aircraft Runways— Because of shown for the aluminum thickness already chosen, use a

the many different wheel configurations and weights, live load heavier pipe whose seam strength exceeds the required seam

pressures for aircraft vary. Such pressures must be determined strength.

B 790/B 790M

2 1

TABLE 3 Sectional Properties of Corrugated Aluminum Sheets for Corrugation: 2 ⁄3 by ⁄2 in. [68 by 13 mm] (Helical or Annular)

NOTE—Inch-pound dimensions shown in this figure are exact values used in calculating the section properties. Nominal values for some of these

dimensions are used in other places in this practice.

Ultimate Longitudinal Seam

Strength of Riveted

Area of Moment

Specified Radius of

Sec- of Inertia, Corrugated Aluminum Pipe,

Thick- Gyration,

−3

Pounds [kN] per Foot [metre] of Seam

tion A, l 3 10

ness, in. r,in.

2 4

in. /ft in. /in.

5 3

[mm] [mm] ⁄16-in. [7.94 mm] Rivets ⁄8-in. [9.53 mm] Rivets

2 4

[mm /mm] [mm /mm]

A B A B

Single Double Single Double

0.060 [1.52] 0.775 [1.640] 1.892 [31.00] 0.1712 [4.348] 9000 [131] 14 000 [204] . .

0.075 [1.91] 0.968 [2.049] 2.392 [39.20] 0.1721 [4.371] 9000 [131] 18 000 [263] . .

0.105 [2.67] 1.356 [2.870] 3.425 [56.13] 0.1741 [4.422] . . 15 600 [228] 31 500 [460]

0.135 [3.43] 1.745 [3.694] 4.533 [74.28] 0.1766 [4.486] . . 16 200 [237] 33 000 [482]

0.164 [4.17] 2.130 [4.509] 5.725 [93.82] 0.1795 [4.559] . . 16 800 [245] 34 000 [496]

A

Single means one row of rivets, one rivet per corrugation.

B

Double means two rows of rivets, one rivet per corrugation per row.

9. Design by LRFD Method wall, shall be taken as the ultimate seam strength shown in

Tables 3 and 4, or Table 5.

9.1 Factored Loads—The pipe shall be designed to resist

the following combination of factored earth load (EL) and live

10. Handling and Installation

load plus impact (LL+IL):

P 5 1.95EL 1 1.75~LL 1 IL! (8)

10.1 The pipe shall have enough rigidity to withstand the

f

forces that are normally applied during shipment and placing.

9.2 FactoredThrust—Thefactoredthrust,T,perunitlength

f

Both shop- and field-assembled pipe shall have strength

ofwallshallbedeterminedfromthefactoredcrownpressureP

f

adequate to withstand compaction of the s

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.