ASTM B788/B788M-09(2020)

(Practice)Standard Practice for Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer Pipe

Standard Practice for Installing Factory-Made Corrugated Aluminum Culverts and Storm Sewer Pipe

SIGNIFICANCE AND USE

4.1 Corrugated aluminum pipe functions structurally as a flexible ring which is supported by and interacts with the compacted surrounding soil. The soil constructed around the pipe is thus an integral part of the structural system. It is therefore important to ensure that the soil structure or backfill is made up of acceptable material and is well-constructed. Field verification of soil structure acceptability using Test Methods D1556/D1556M, D2167, D2937, or D6938 as applicable, and comparing the results with Test Method D698 in accordance with the specifications for each project, is the most reliable basis for installation of an acceptable structure. The required density and method of measurement are not specified by this practice, but they must be established in the specifications for each project.

SCOPE

1.1 This practice describes procedures, soils, and soil placement for the proper installation of corrugated aluminum culverts and storm sewers in either trench or projection installations. A typical trench installation is shown in Fig. 1, and a typical embankment (projection) installation is shown in Fig. 2. The pipes described in this practice are manufactured in a factory and furnished to the job in lengths ordinarily from 10 to 30 ft [3 to 9 m], with 20 ft [6 m] being common, for field joining. This practice applies to structures designed in accordance with Practice B790/B790M.

FIG. 1 Typical Trench Installation

FIG. 2 Typical Embankment (Projection) Installation

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation: B788/B788M − 09 (Reapproved 2020)

Standard Practice for

Installing Factory-Made Corrugated Aluminum Culverts and

Storm Sewer Pipe

This standard is issued under the fixed designation B788/B788M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

This standard has been approved for use by agencies of the U.S. Department of Defense.

1. Scope B745/B745M Specification for Corrugated Aluminum Pipe

for Sewers and Drains

1.1 This practice describes procedures, soils, and soil place-

B790/B790M Practice for Structural Design of Corrugated

ment for the proper installation of corrugated aluminum

Aluminum Pipe, Pipe-Arches, and Arches for Culverts,

culverts and storm sewers in either trench or projection

Storm Sewers, and Other Buried Conduits

installations. A typical trench installation is shown in Fig. 1,

D698 Test Methods for Laboratory Compaction Character-

and a typical embankment (projection) installation is shown in

istics of Soil Using Standard Effort (12,400 ft-lbf/ft (600

Fig. 2. The pipes described in this practice are manufactured in

kN-m/m ))

a factory and furnished to the job in lengths ordinarily from 10

D1556/D1556M Test Method for Density and Unit Weight

to 30 ft [3 to 9 m], with 20 ft [6 m] being common, for field

of Soil in Place by Sand-Cone Method

joining. This practice applies to structures designed in accor-

D2167 Test Method for Density and Unit Weight of Soil in

dance with Practice B790/B790M.

Place by the Rubber Balloon Method

1.2 The values stated in either SI units or inch-pound units

D2487 Practice for Classification of Soils for Engineering

are to be regarded separately as standard. The values stated in

Purposes (Unified Soil Classification System)

each system are not necessarily exact equivalents; therefore, to

D2937 Test Method for Density of Soil in Place by the

ensure conformance with the standard, each system shall be

Drive-Cylinder Method

used independently of the other, and values from the two

D6938 TestMethodsforIn-PlaceDensityandWaterContent

systems shall not be combined.

of Soil and Soil-Aggregate by Nuclear Methods (Shallow

1.3 This standard does not purport to address all of the

Depth)

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro- 3. Terminology

priate safety, health, and environmental practices and deter-

3.1 Definitions of Terms Specific to This Standard:

mine the applicability of regulatory limitations prior to use.

3.1.1 bedding, n—the earth or other material on which a

1.4 This international standard was developed in accor-

pipe is supported.

dance with internationally recognized principles on standard-

3.1.2 haunch, n—the portion of the pipe cross section

ization established in the Decision on Principles for the

between the maximum horizontal dimension and the top of the

Development of International Standards, Guides and Recom-

bedding.

mendations issued by the World Trade Organization Technical

3.1.3 invert, n—the lowest point on the pipe cross section;

Barriers to Trade (TBT) Committee.

also, the bottom portion of a pipe.

2. Referenced Documents

3.1.4 pipe, n—a conduit having full circular shape; also, in

2.1 ASTM Standards: a general context, all structure shapes covered by this practice.

3.1.5 pipe-arch, n—a pipe with an approximate semicircular

crown, small-radius corners, and large-radius invert.

This practice is under the jurisdiction of ASTM Committee B07 on Light

Metals and Alloys and is the direct responsibility of Subcommittee B07.08 on

Corrugated Aluminum Pipe and Corrugated Aluminum Structural Plate.

4. Significance and Use

Current edition approved Sept. 1, 2020. Published September 2020. Originally

4.1 Corrugated aluminum pipe functions structurally as a

approved in 1988. Last previous edition approved in 2014 as B788/

B788M – 09 (2014). DOI: 10.1520/B0788_B0788M-09R20.

flexible ring which is supported by and interacts with the

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

compacted surrounding soil. The soil constructed around the

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

pipe is thus an integral part of the structural system. It is

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. therefore important to ensure that the soil structure or backfill

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

B788/B788M − 09 (2020)

continuous rock foundation, it is necessary to provide a

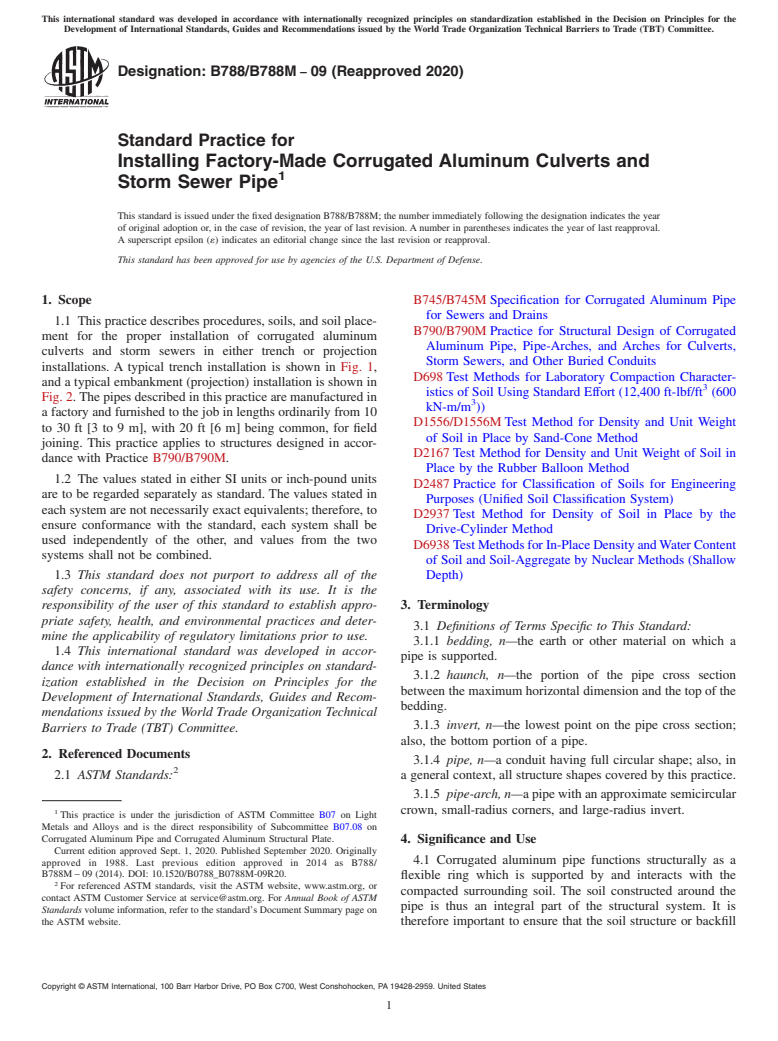

suitable soil bedding under the pipe. See Fig. 3.

6.2 Lateral changes in foundation should never be such that

the pipe is firmly supported while the backfill alongside is not.

When soft material is encountered during construction and

must be removed in order to provide an adequate foundation,

remove the soft material for a distance of three pipe widths,

unless the engineer has set another limit. See Fig. 4.

6.3 Performance of buried pipe is enhanced by allowing the

pipe to settle slightly under load compared to the columns of

soil alongside. Thus, for larger pipes it can be beneficial to

purposely create a foundation under the pipe itself which will

yield under load more than will the foundation under the

columns of soil to each side. It can usually be obtained by

placing a layer of compressible soil of a suitable thickness, less

FIG. 1 Typical Trench Installation

densely compacted than the soil alongside, beneath the struc-

ture. This creates favorable relative movement between pipe

and the soil on each side. It is of particular importance on

pipe-arches.

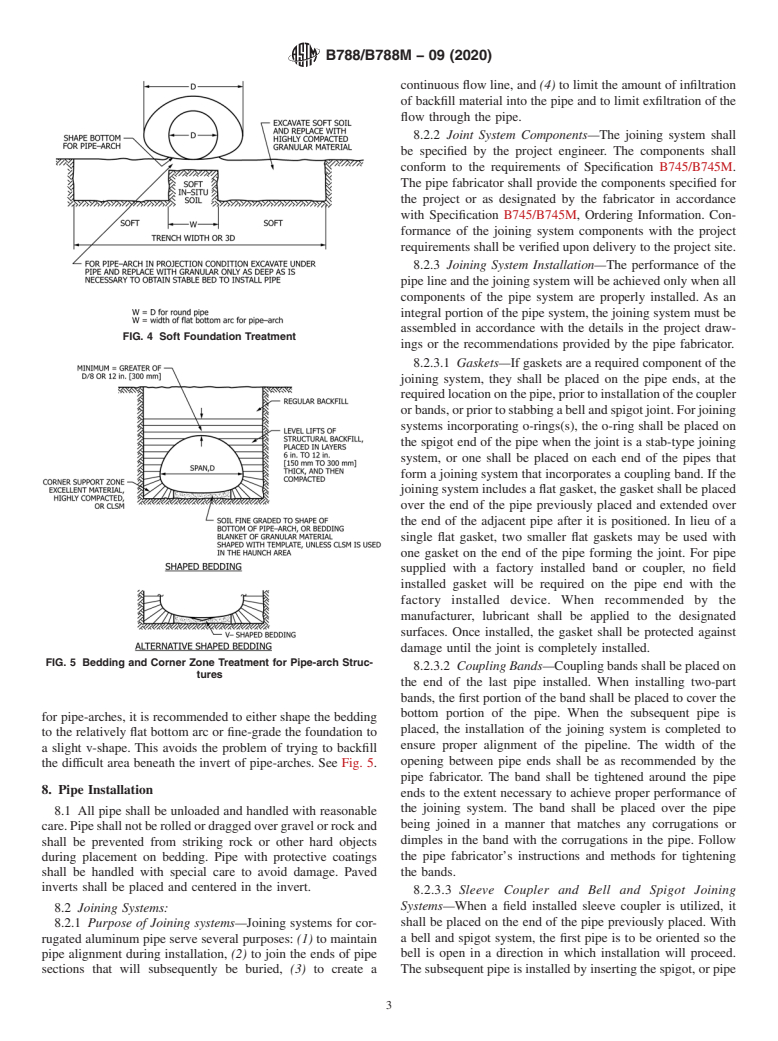

6.4 Pipe-arches—All pipe-arch structures must have excel-

lent soil support at their corners by both the in-situ foundation

and the structural backfill. See Figs. 4 and 5. They do not

require the same degree of support under their large-radius

inverts.

6.5 Theengineerisencouragedtodevelopdetailsspecificto

the site based on the general principles for foundation condi-

tions given in 6.1 – 6.4.

FIG. 2 Typical Embankment (Projection) Installation

7. Bedding

7.1 Material used for bedding beneath the pipe shall meet

is made up of acceptable material and is well-constructed. the requirements of this section. Material in contact with the

Field verification of soil structure acceptability using Test

pipe shall not contain rock retained on a 3-in. [75 mm] ring,

Methods D1556/D1556M, D2167, D2937,or D6938 as

frozen lumps, chunks of highly plastic clay, organic matter,

applicable, and comparing the results with Test Method D698

corrosive material, or other deleterious material. It is not

in accordance with the specifications for each project, is the

required to shape the bedding to the pipe geometry. However,

most reliable basis for installation of an acceptable structure.

The required density and method of measurement are not

specified by this practice, but they must be established in the

specifications for each project.

5. Trench Excavation

5.1 To obtain anticipated structural performance of corru-

gated aluminum pipe it is not necessary to control trench width

beyond the minimum required for proper installation of pipe

and backfill. However, the soil on each side beyond the

excavated trench must be able to support anticipated loads.

Whenaconstructionsituationcallsforarelativelywidetrench,

it shall be made as wide as required, for its full depth if so

desired. However, trench excavation must be in compliance

with any local, state, and federal codes and safety regulations.

6. Foundation

6.1 The supporting soil beneath the pipe must provide a

reasonably uniform resistance to the imposed load, both

longitudinally and laterally. Sharp variations in the foundation

must be avoided. When rock is encountered, it must be

excavated and replaced with soil. If the pipe runs along a FIG. 3 Foundation Transition Zones and Rock Foundations

B788/B788M − 09 (2020)

continuous flow line, and (4) to limit the amount of infiltration

of backfill material into the pipe and to limit exfiltration of the

flow through the pipe.

8.2.2 Joint System Components—The joining system shall

be specified by the project engineer. The components shall

conform to the requirements of Specification B745/B745M.

The pipe fabricator shall provide the components specified for

the project or as designated by the fabricator in accordance

with Specification B745/B745M, Ordering Information. Con-

formance of the joining system components with the project

requirements shall be verified upon delivery to the project site.

8.2.3 Joining System Installation—The performance of the

pipe line and the joining system will be achieved only when all

components of the pipe system are properly installed. As an

integral portion of the pipe system, the joining system must be

assembled in accordance with the details in the project draw-

FIG. 4 Soft Foundation Treatment

ings or the recommendations provided by the pipe fabricator.

8.2.3.1 Gaskets—If gaskets are a required component of the

joining system, they shall be placed on the pipe ends, at the

requiredlocationonthepipe,priortoinstallationofthecoupler

orbands,orpriortostabbingabellandspigotjoint.Forjoining

systems incorporating o-rings(s), the o-ring shall be placed on

the spigot end of the pipe when the joint is a stab-type joining

system, or one shall be placed on each end of the pipes that

form a joining system that incorporates a coupling band. If the

joining system includes a flat gasket, the gasket shall be placed

over the end of the pipe previously placed and extended over

the end of the adjacent pipe after it is positioned. In lieu of a

single flat gasket, two smaller flat gaskets may be used with

one gasket on the end of the pipe forming the joint. For pipe

supplied with a factory installed band or coupler, no field

installed gasket will be required on the pipe end with the

factory installed device. When recommended by the

manufacturer, lubricant shall be applied to the designated

surfaces. Once installed, the gasket shall be protected against

damage until the joint is completely installed.

FIG. 5 Bedding and Corner Zone Treatment for Pipe-arch Struc-

8.2.3.2 Coupling Bands—Coupling bands shall be placed on

tures

the end of the last pipe installed. When installing two-part

bands, the first portion of the band shall be placed to cover the

bottom portion of the pipe. When the subsequent pipe is

for pipe-arches, it is recommended to either shape the bedding

placed, the installation of the joining system is completed to

to the relatively flat bottom arc or fine-grade the foundation to

ensure proper alignment of the pipeline. The width of the

a slight v-shape. This avoids the problem of trying to backfill

opening between pipe ends shall be as recommended by the

the difficult area beneath the invert of pipe-arches. See Fig. 5.

pipe fabricator. The band shall be tightened around the pipe

8. Pipe Installation

ends to the extent necessary to achieve proper performance of

the joining system. The band shall be placed over the pipe

8.1 All pipe shall be unloaded and handled with reasonable

being joined in a manner that matches any corrugations or

care.Pipeshallnotberolledordraggedovergravelorrockand

dimples in the band with the corrugations in the pipe. Follow

shall be prevented from striking rock or other hard objects

the pipe fabricator’s instructions and methods for tightening

during placement on bedding. Pipe with protective coatings

shall be handled with special care to avoid damage. Paved the bands.

inverts shall be placed and centered in the invert.

8.2.3.3 Sleeve Coupler and Bell and Spigot Joining

Systems—When a field installed sleeve coupler is utilized, it

8.2 Joining Systems:

shall be placed on the end of the pipe previously placed. With

8.2.1 Purpose of Joining systems—Joining systems for cor-

a bell and spigot system, the first pipe is to be oriented so the

rugated aluminum pipe serve several purposes: (1) to maintain

bell is open in a direction in which installation will proceed.

pipe alignment during installation, (2) to join the ends of pipe

sections that will subsequently be buried, (3) to create a The subsequent pipe is installed by inserting the spigot, or pipe

B788/B788M − 09 (2020)

end without the sleeve coupler, to the maximum depth permit- D2167, D2937, and D6938 shall be used to determine the

ted by the joining system. Follow the pipe fabricator’s instruc- in-place density of the soil. Soil types SM and SC are

tions for the method of assembly and use of insertion force. acceptable, but they will require closer control to obtain the

8.2.4 Joint Backfill—The joining system was selected based specified density. Soil Groups ML and CL are not preferred

on the expected site conditions, specifically the type and materials, while soil Groups OL, MH, CH, OH, and PT are not

gradation of backfill material. The structural backfill material acceptable.

used around the pipe shall be in accordance with the project

9.3 Special materials other than soil are acceptable when

specifications. Backfill material shall conform to that specified

used as described in 10.1.

inSection9,andshallbeplacedinaccordancewithSection10.

Care shall be exercised during backfill placement not to

10. Structural Backfill Placement

damage or dislodge the joining system.

10.1 Structural backfill shall be placed in non-compacted

layers from 6 to 12 in. [150 to 300 mm] in depth depending on

9. Structural Backfill Material

the type of material and compaction equipment or method.

9.1 Structural backfill is that material that surrounds the

Each layer or lift shall be compacted before adding the next

pipe, extending laterally to the walls of the trench, or to the fill

lift. On flat bedding, care must be taken to place material under

material for embankment construction, and extending verti-

the pipe haunches and compact it firmly. Structural backfill on

cally from the invert to an elevation of 1 ft [300 mm] or ⁄8 the

each side of the pipe shall be kept in balance. Generally, no

diameter or span, whichever is greater, over the pipe. The

more than one lift difference will be permitted. Construction

necessary width of structural backfill depends on the quality of

equipment shall not be used over or alongside the pipe without

the trench wall

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.