ASTM D3483-83(2005)

(Test Method)Standard Test Methods for Accumulated Deposition in a Steam Generator Tube

Standard Test Methods for Accumulated Deposition in a Steam Generator Tube

SCOPE

1.1 These test methods cover determination of the weight per unit area of waterside deposits on heat-transfer surfaces of steam generator tubes. Two test methods are given as follows: Sections Test Method A---Mechanical Removal 6 to 11 Test Method B---Solvent Removal 12 to 18

1.2 Neither test method is normally applicable to fire-tube boilers.

1.3 A comparison of the results obtainable with the two test methods is shown in Fig. 1.

1.4 A scope section is provided in each test method. It is the responsibility of the analyst to determine the acceptability of these test methods for each situation.

1.5 This standard does not purport to address the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

AnAmerican National Standard

Designation:D 3483–83 (Reapproved 2005)

Standard Test Methods for

Accumulated Deposition in a Steam Generator Tube

This standard is issued under the fixed designation D 3483; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 These test methods cover determination of the weight

per unit area of waterside deposits on heat-transfer surfaces of

steam generator tubes. Two test methods are given as follows:

Sections

Test MethodA—Mechanical Removal 6 to 11

Test Method B—Solvent Removal 12 to 18

1.2 Neither test method is normally applicable to fire-tube

boilers.

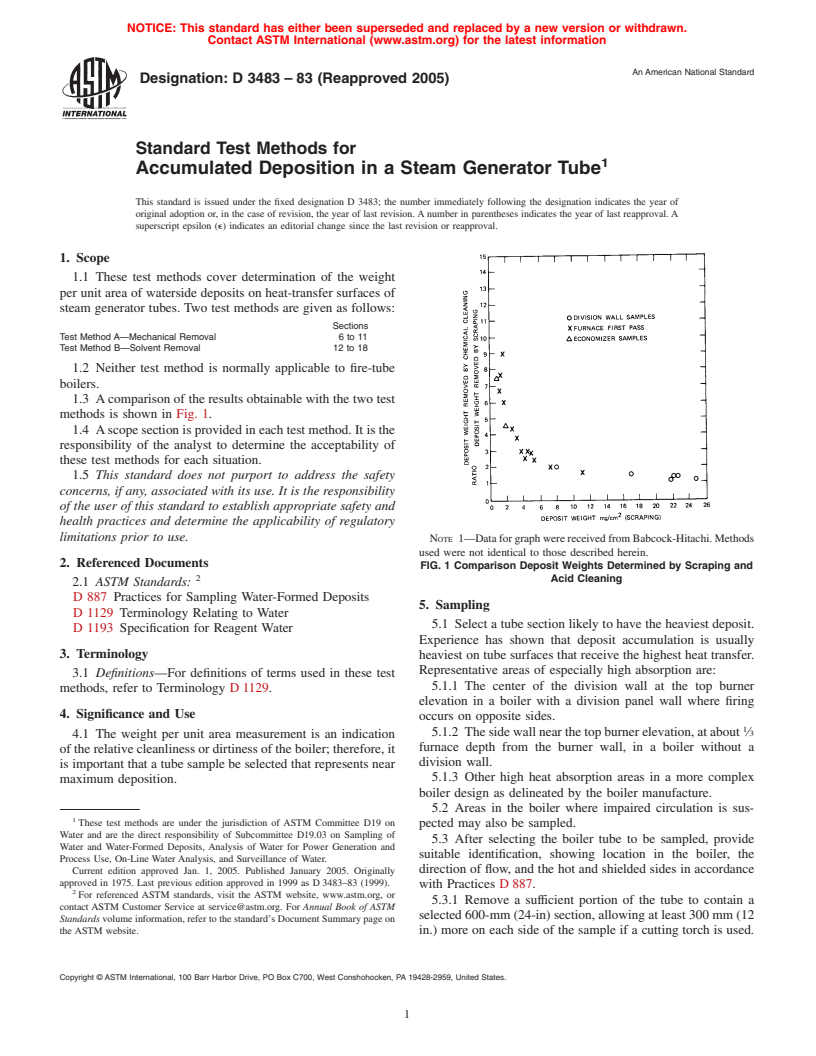

1.3 Acomparison of the results obtainable with the two test

methods is shown in Fig. 1.

1.4 Ascope section is provided in each test method. It is the

responsibility of the analyst to determine the acceptability of

these test methods for each situation.

1.5 This standard does not purport to address the safety

concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and

health practices and determine the applicability of regulatory

limitations prior to use.

NOTE 1—DataforgraphwerereceivedfromBabcock-Hitachi.Methods

used were not identical to those described herein.

2. Referenced Documents

FIG. 1 Comparison Deposit Weights Determined by Scraping and

Acid Cleaning

2.1 ASTM Standards:

D 887 Practices for Sampling Water-Formed Deposits

5. Sampling

D 1129 Terminology Relating to Water

5.1 Select a tube section likely to have the heaviest deposit.

D 1193 Specification for Reagent Water

Experience has shown that deposit accumulation is usually

3. Terminology

heaviest on tube surfaces that receive the highest heat transfer.

Representative areas of especially high absorption are:

3.1 Definitions—For definitions of terms used in these test

5.1.1 The center of the division wall at the top burner

methods, refer to Terminology D 1129.

elevation in a boiler with a division panel wall where firing

4. Significance and Use

occurs on opposite sides.

5.1.2 Thesidewallnearthetopburnerelevation,atabout ⁄3

4.1 The weight per unit area measurement is an indication

furnace depth from the burner wall, in a boiler without a

of the relative cleanliness or dirtiness of the boiler; therefore, it

division wall.

is important that a tube sample be selected that represents near

5.1.3 Other high heat absorption areas in a more complex

maximum deposition.

boiler design as delineated by the boiler manufacture.

5.2 Areas in the boiler where impaired circulation is sus-

These test methods are under the jurisdiction of ASTM Committee D19 on

pected may also be sampled.

Water and are the direct responsibility of Subcommittee D19.03 on Sampling of

5.3 After selecting the boiler tube to be sampled, provide

Water and Water-Formed Deposits, Analysis of Water for Power Generation and

suitable identification, showing location in the boiler, the

Process Use, On-Line Water Analysis, and Surveillance of Water.

direction of flow, and the hot and shielded sides in accordance

Current edition approved Jan. 1, 2005. Published January 2005. Originally

approved in 1975. Last previous edition approved in 1999 as D 3483–83 (1999).

with Practices D 887.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

5.3.1 Remove a sufficient portion of the tube to contain a

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

selected 600-mm (24-in) section, allowing at least 300 mm (12

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. in.) more on each side of the sample if a cutting torch is used.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

D 3483–83 (2005)

NOTE 1—No oil or water is to be used in any mechanical cutting

9.4 Carefullyscrapethesurfacetodislodgeandindividually

operation.

collect the more easily removable deposits from between the

boundaries of each sample. Complete the deposit removal by

5.3.2 Separateaselected600-mm(24-in.)sectionbycareful

brushing or applying an electric vibrating tool, or both. Dry the

application of an anchored pipe vise and a tube cutter.

removed material in an oven at 105°C for 1 h. Grind suffi-

TEST METHOD A—MECHANICAL REMOVAL

ciently to pass through a No. 325 (45-µm) stainless steel sieve

andweighthescreenedportionofeachhalf;recordtheweights

6. Scope

in milligrams.

6.1 The mechanical removal test method is preferred when

NOTE 3—Drying the sample may affect subsequent analysis by X-ray

deposition is comparatively heavy and the deposits are rela-

diffraction.

tively easy to dislodge. The deposit, so removed, may serve as

NOTE 4—The purpose of the grinding and screening operation is to

the sample for determining the composition of the material.

prevent a weighing error from chips of steel that may have been lodged in

the deposit during the sample-cutting operation.

7. Summary of Test Method

9.5 Determine the areas from which the two deposits were

7.1 A section of the most heavily fouled portion of the

removed, measuring each dimension to the nearest 1 mm.Trim

sampled tube is selected on a visual basis. After dividing the

sheetsofpapertomakepatternsoftheactualsurfacesthatwere

tube, the water-formed deposit is removed mechanically from

stripped. If the pattern is regular in shape, determine the area

a measured area. The weight of the dry material is reported as

by direct measurement. If the pattern is irregular, determine the

milligrams of deposit per square millimetre of boiler tube

area by comparing the weight of the pattern to the weight of a

surface.

sheet of paper of known area.

8. Apparatus

10. Calculation

8.1 Cutting Tool or Torch, removing a suitable portion of

10.1 Determine the weight of accumulated deposits per unit

boiler tube and a vise for crimping.

area, in milligrams per square millimetre, directly by dividing

NOTE 2—Lightly crimping the sample tube in a vise may be effective in the weight of deposit in milligrams by the area in square

removal of very brittle deposits. However, any physical change that the

millimetres.

tube specimen is subjected to may effect any subsequent metallographic

examination. 11. Precision and Bias

8.2 Tube Cutter. 11.1 See 18.1.

8.3 Tube End Sealers, to protect the sample if the determi-

TEST METHOD B—SOLVENT REMOVAL

nation is to be made elsewhere than on the site.

8.4 Milling Machine (Preferred) or Band Saw, to separate

12. Scope

the fireside half of the tube from the shielded half by

12.1 The solvent removal test method is preferable where

longitudinal sectioning (dry cut).

deposition is relatively light and the deposit is adherent to the

8.5 Magnet, to remove metal chips from the deposited

base metal.

material, especially if a band saw is used.

13. Summary of Test Method

8.6 Scraping Tool, for removing the less adherent deposits

(like a scalpel or a heavy screwdriver, the end of which has

13.1 The deposit that has accumulated in the selected boiler

been thinned).

tube specimen is determined by measuring the weight loss of

8.7 Vise, for removal of brittle deposits.

the tube sample after deposit removal with inhibited hydro-

8.8 Vibrating Tool, to remove more adherent deposits (a

chloric acid. In the event copper plates out on the tube sample

small head should be available for use within pits).

during the cleaning operation, an ammonium persulfate solu-

8.9 Oven, for drying the deposits.

tion is used to remove the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.