ASTM C560-88(2005)e1

(Test Method)Standard Test Methods for Chemical Analysis of Graphite

Standard Test Methods for Chemical Analysis of Graphite

SIGNIFICANCE AND USE

These test methods provide a practical way to measure the concentration of certain trace elements in graphite. Many end uses of graphite require that it be free of elements which may be incompatible with certain nuclear applications. Other elemental contamination can affect the rate of oxidative degradation.

These test methods allow measurement of trace amounts of contaminants with a minimal amount of costly equipment. The colorimetric procedures used are accessible to most laboratories.

SCOPE

1.1 These test methods cover the chemical analysis of graphite.

1.2 The analytical procedures appear in the following order: Sections Silicon by the Molybdenum Blue (Colorimetric) Test Method8 to 14Iron by the o-Phenanthroline (Colorimetric) Test Method 15 to 21 Calcium by the Permanganate (Colorimetric) Test Method22 to 28 Aluminum by the 2-Quinizarin Sulfonic Acid Test Method29 to 35Titanium by the Peroxide (Colorimetric) Test Method 36 to 43 Vanadium by the 3,3`-Dimethylnaphthidine (Colorimetric) Test Method 44 to 51 Boron by the Curcumin-Oxalic Acid (Colorimetric) Test Method52 to 59

1.3 The preferred concentration of sought element in the final solution, the limits of sensitivity, and the precision of the results are given in Table 1.

1.4 The values stated in SI units are to be regarded as the standard.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. See 56.1 for specific caution statement.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information.

An American National Standard

´1

Designation:C560–88 (Reapproved 2005)

Standard Test Methods for

Chemical Analysis of Graphite

This standard is issued under the fixed designation C560; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

´ NOTE—Replaced the word “asbestos” in 25.7 editorially in August 2005.

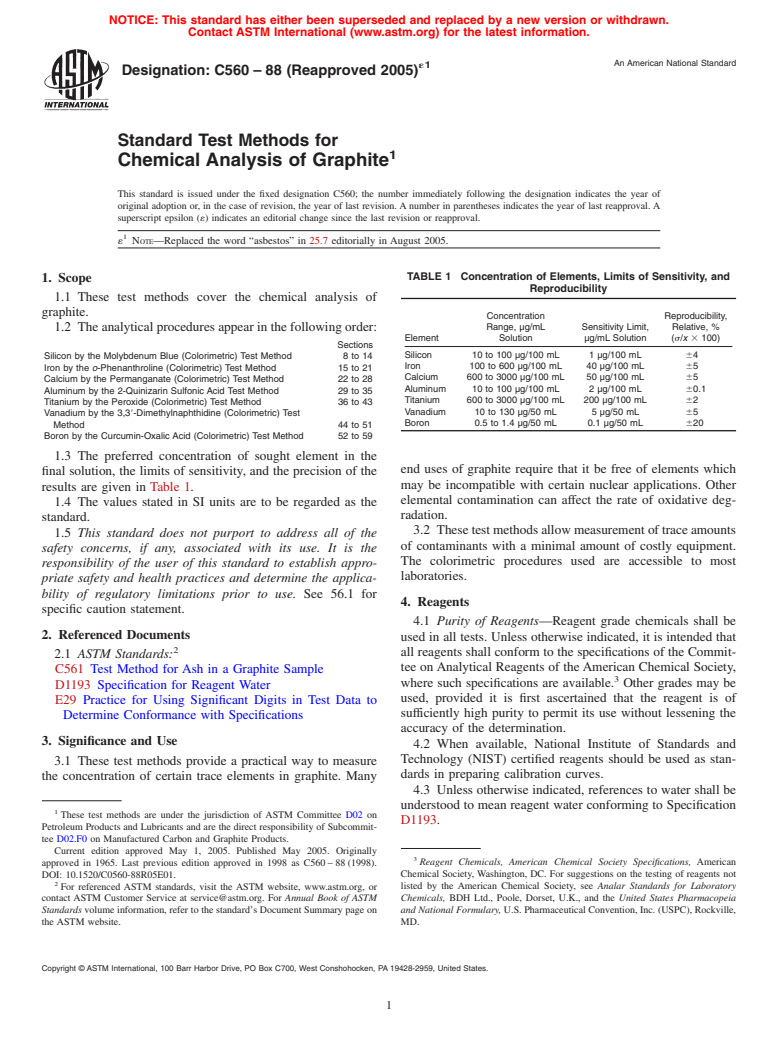

TABLE 1 Concentration of Elements, Limits of Sensitivity, and

1. Scope

Reproducibility

1.1 These test methods cover the chemical analysis of

graphite.

Concentration Reproducibility,

Range, µg/mL Sensitivity Limit, Relative, %

1.2 The analytical procedures appear in the following order:

Element Solution µg/mL Solution (s/x 3 100)

Sections

Silicon 10 to 100 µg/100 mL 1 µg/100 mL 64

Silicon by the Molybdenum Blue (Colorimetric) Test Method 8 to 14

Iron 100 to 600 µg/100 mL 40 µg/100 mL 65

Ironbythe o-Phenanthroline (Colorimetric) Test Method 15 to 21

Calcium 600 to 3000 µg/100 mL 50 µg/100 mL 65

Calcium by the Permanganate (Colorimetric) Test Method 22 to 28

Aluminum 10 to 100 µg/100 mL 2 µg/100 mL 60.1

Aluminum by the 2-Quinizarin Sulfonic Acid Test Method 29 to 35

Titanium 600 to 3000 µg/100 mL 200 µg/100 mL 62

Titanium by the Peroxide (Colorimetric) Test Method 36 to 43

Vanadium 10 to 130 µg/50 mL 5 µg/50 mL 65

Vanadium by the 3,38-Dimethylnaphthidine (Colorimetric) Test

Boron 0.5 to 1.4 µg/50 mL 0.1 µg/50 mL 620

Method 44 to 51

Boron by the Curcumin-Oxalic Acid (Colorimetric) Test Method 52 to 59

1.3 The preferred concentration of sought element in the

end uses of graphite require that it be free of elements which

final solution, the limits of sensitivity, and the precision of the

may be incompatible with certain nuclear applications. Other

results are given in Table 1.

elemental contamination can affect the rate of oxidative deg-

1.4 The values stated in SI units are to be regarded as the

radation.

standard.

3.2 Thesetestmethodsallowmeasurementoftraceamounts

1.5 This standard does not purport to address all of the

of contaminants with a minimal amount of costly equipment.

safety concerns, if any, associated with its use. It is the

The colorimetric procedures used are accessible to most

responsibility of the user of this standard to establish appro-

laboratories.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use. See 56.1 for

4. Reagents

specific caution statement.

4.1 Purity of Reagents—Reagent grade chemicals shall be

2. Referenced Documents

used in all tests. Unless otherwise indicated, it is intended that

all reagents shall conform to the specifications of the Commit-

2.1 ASTM Standards:

tee onAnalytical Reagents of theAmerican Chemical Society,

C561 Test Method for Ash in a Graphite Sample

where such specifications are available. Other grades may be

D1193 Specification for Reagent Water

used, provided it is first ascertained that the reagent is of

E29 Practice for Using Significant Digits in Test Data to

sufficiently high purity to permit its use without lessening the

Determine Conformance with Specifications

accuracy of the determination.

3. Significance and Use

4.2 When available, National Institute of Standards and

Technology (NIST) certified reagents should be used as stan-

3.1 These test methods provide a practical way to measure

dards in preparing calibration curves.

the concentration of certain trace elements in graphite. Many

4.3 Unless otherwise indicated, references to water shall be

understood to mean reagent water conforming to Specification

These test methods are under the jurisdiction of ASTM Committee D02 on

D1193.

Petroleum Products and Lubricants and are the direct responsibility of Subcommit-

tee D02.F0 on Manufactured Carbon and Graphite Products.

Current edition approved May 1, 2005. Published May 2005. Originally

approved in 1965. Last previous edition approved in 1998 as C560 – 88 (1998). Reagent Chemicals, American Chemical Society Specifications, American

DOI: 10.1520/C0560-88R05E01. Chemical Society, Washington, DC. For suggestions on the testing of reagents not

For referenced ASTM standards, visit the ASTM website, www.astm.org, or listed by the American Chemical Society, see Analar Standards for Laboratory

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Chemicals, BDH Ltd., Poole, Dorset, U.K., and the United States Pharmacopeia

Standards volume information, refer to the standard’s Document Summary page on and National Formulary, U.S. Pharmaceutical Convention, Inc. (USPC), Rockville,

the ASTM website. MD.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

´1

C560–88 (2005)

4.4 National Institute of Standards and Technology certified 11.4 Silicon, Working Solution (1 mL= 0.01 mg Si)—Dilute

reagents specified in certain steps of this procedure may no 10 mL of standard silicon solution (1 mL = mg Si) to 1 L in a

longerbeavailable.IfNISTreagentsarenotavailable,thenthe volumetric flask. Transfer to a polyethylene bottle.

highest purity reagent grade shall be substituted.

11.5 Sodium Carbonate Solution (100 g/L)—Dissolve100g

ofsodiumcarbonate(Na CO )inwateranddiluteto1L.Store

2 3

5. Sampling

in a polyethylene bottle.

5.1 The entire sample of graphite should be crushed and 11.6 Stannous Chloride Solution—Dissolve 2.5 g of stan-

ground to pass a No. 60 (250-µm) sieve in a roll crusher. The

nous chloride (SnCl ·2H O) in 5 mL of hot concentrated HCl

2 2

sample may have been reduced in size initially by drilling the (sp gr 1.19) and dilute to 250 mL with water. Prepare a fresh

test bar with silicon carbide-tipped drills.

solution every 2 weeks.

11.7 Sulfuric Acid (H SO ) (1+3)—Carefully mix 1 volume

2 4

6. Rounding Calculated Values

of concentrated H SO , sp gr 1.84 with 3 volumes of water.

2 4

6.1 Calculated values shall be rounded to the desired num-

ber of places in accordance with Practice E29. 12. Preparation of Calibration Curve

12.1 Calibration Solutions—Transfer 0, 1.0, 3.0, 5.0, 7.0,

7. Precision and Bias

and 10 mL of silicon working solution (1 mL = 0.01 mg Si) to

7.1 No statement is being made about either the precision or

100-mL volumetric flasks. Add 5 drops of H SO (1+3) and

2 4

bias of these test methods. At this time Committee C05 is

dilute to approximately 10 mL.

investigating new standard methods of chemical analysis of

12.2 Color Development—Add 2.5 mL of (NH ) Mo O

4 6 7 24

graphite that will eventually replace these test methods. For

solution to each flask and let stand 5 min. Then add 5.0 mL of

this reason, no statistical study of these test methods has been

H SO (1+3), mix well, and add 5 drops of SnCl solution.

2 4 2

planned.

Dilute to volume and let stand 5 min.

7.2 The relative reproducibility data in Table 1 has no

12.3 Photometry—Transfer a suitable portion of the reagent

supportive research report on file and does not conform to

blank solution to a 1-cm absorption cell and adjust the

ASTM precision and bias standards.

photometertotheinitialsetting,usingawavelengthof765nm.

While maintaining this photometer adjustment, take the pho-

SILICON BY THE MOLYBDENUM BLUE TEST

tometric readings of the calibration solutions.

METHOD

12.4 Calibration Curve—Plot the photometric readings (ab-

sorbance) of the calibration solution against micrograms of

8. Summary of Test Method

silicon per 100 mL of solution.

8.1 Silicomolybdic acid is formed by adding ammonium

molybdate to soluble silicates in acid solution. The heteropoly

13. Procedure for Carbonate Fusion

acid is reduced with stannous chloride to form a deep blue

colloidal solution. Photometric measurement is made at 765 13.1 Sample Solution—Rinse the ash (from a 50 to 75-g ash

nm. Regular classical gravimetric methods for silica using sample)fromtheplatinumdishintoamullitemortarwiththree

sodium carbonate fusion followed by hydrofluoric acid vola- 0.5-g portions of Na CO passing a No. 100 (150-µm) sieve

2 3

tilization may be suitable for use. (see Test Method C561). Grind the resulting mixture to pass a

No. 200 (75-µm) sieve to ensure intimate contact of the ash

9. Stability of Color

with the flux. Then transfer the mixture to a platinum crucible

(containing 0.5 g of Na CO ) with three 0.5-g rinses of

9.1 The blue colored solution should be disposed of and the

2 3

Na CO . Add sufficient Na CO to bring the total Na CO

determination repeated if a period of 12 h has elapsed between 2 3 2 3 2 3

content to 6 g. Cover the crucible, and fuse gently over a

color development and measurements.

bunsen burner.

10. Interferences

13.1.1 When fusion is complete (usually 30 min to 1 h),

removethecruciblefromtheburner,swirltodistributethemelt

10.1 There is no interference from the ions usually present

on the sides of the crucible, and allow to cool. Then place the

in graphite.

crucible and contents in a 200-mL high-form beaker and add

11. Reagents 25 mL of water. Cover the beaker with a watch glass, and

cautiously add HCl (1+1) to decompose the melt. When

11.1 Ammonium Molybdate (50 g/L)—Dissolve 50 g of

solution of the melt is complete, boil for several minutes on a

ammonium molybdate ((NH ) -Mo O ·4H O) in water and

4 6 7 24 2

hot plate and cool.

dilute to 1 L.

13.1.2 Transfer to a 100-mL volumetric flask, dilute to

11.2 Hydrochloric Acid (HCl) (1+1)—Mix equal volumes

volume, and mix. Transfer a suitable aliquot of this solution to

of concentrated HCl, sp gr 1.19 and water.

a 100-mL volumetric flask.

11.3 Silicon, Standard Solution (1 mL= 1 mg Si)—Dissolve

13.2 Color Development—Adjust the pH of the aliquot to 6

10.1 g of sodium silicate (Na SiO ·9H O) in water and dilute

2 3 2

to 8 with Na CO solution, then proceed in accordance with

to 1 L in a volumetric flask. Store in a polyethylene bottle.

2 3

13.2.

Determine exact concentration by the standard gravimetric

procedure. 13.3 Photometry—Proceed in accordance with 12.3.

´1

C560–88 (2005)

13.4 Calibration—Convert the photometric reading of the volumetric flasks. Add NH OH (1+1) until the brown hydrous

sample solution to micrograms of silicon by means of the precipitate of ferric hydroxide (Fe(OH) ) is just visible. Then

calibration curve. add HCl (1+1) drop-wise, while stirring, until the precipitate

just dissolves. Bring the pH of the solution to 3.0 by adding 2

14. Calculation

additional drops of HCl (1+1). Then add 2 mLof NH OH·HCl

14.1 Calculate the parts per million (ppm) of silicon in the solution.

19.2 Color Development—Heat the solutions in the flasks

original sample as follows:

almost to boiling. Add 1 mL of o-phenanthroline solution and

Silicon, ppm A 3 B /W

~ !

allow the solutions to cool. Then dilute to the mark with water.

where:

19.3 Photometry—Transfer a suitable portion of the reagent

A = silicon per 100 mL of solution found in the aliquot

blank solution to a 1-cm absorption cell, and adjust the

used, µg,

spectrophotometer to the initial setting using a wavelength of

B = aliquot factor = original volume divided by aliquot

490 nm. While maintaining this photometer adjustment, take

taken for analysis, and

the photometric readings of the calibration solutions.

W = original sample weight, g.

19.4 Calibration Curve—Plot the absorbance of the calibra-

tion solution against micrograms of iron per 100 mL of

IRON BY THE ORTHO-PHENANTHROLINE

solution.

(PHOTOMETRIC) TEST METHOD

20. Procedure

15. Summary of Test Method

20.1 Sample Solution—Proceed in accordance with 13.1.

15.1 After suitable dilution of an aliquot from the carbonate

20.2 ColorDevelopment—Proceedinaccordancewith19.2.

fusion is adjusted to a pH of 3.0, the iron is reduced with

20.3 Photometry—Proceed in accordance with 19.2.

hydroxylamine hydrochloride. The ferrous ortho-

20.4 Calibration—Convert the photometric reading of the

phenanthroline complex is formed, and its absorption is mea-

sample solution to micrograms of iron by means of the

sured at a wavelength of 490 nm.

calibration curve.

16. Stability of Color

21. Calculation

16.1 The color becomes stable within 15 min and does not

21.1 Calculate the ppm of iron in the original sample as

change for at least 48 h.

follows:

Fe, ppm A 3 B!/W

~

17. Interferences

17.1 No interfering elements are normally present in graph-

where:

ite.

A = iron per 100 mL of solution in the aliquot used, µg,

B = aliquot factor = original volume divided by aliquot

18. Reagents

taken for analysis, and

18.1 Ammonium Hydroxide (NH OH) (1+1)—Mix equal W = original sample weight, g.

volumes of concentrated NH OH, sp gr 0.90 and water.

CALCIUM BY THE PERMANGANATE

18.2 Bromine Water—Add 10 mL of bromine to 1 L of

(COLORIMETRIC) TEST METHOD

water. Allow to stand for 24 h.

18.3 Hydrochloric Acid (HCl) (1+1)—Mix equal volumes

22. Summary of Test Method

of concentrated HCl, sp gr 1.19 and water.

22.1 Calcium is precipitated as the oxalate, filtered off, and

18.4 Hydroxylamine Hydrochloride Solution—Dissolve 10

dissolved in sulfuric acid.The acid solution is added to a dilute

g of hydroxylamine hydrochloride (NH OH·HCl) in water and

potassium permanganate solution, and the decrease in absorp-

dilute to 100 mL. Discard the solution if color develops on

tion is measured at a wavelength of 528 nm.

standing for long periods of time.

18.5 Iron, Standard Solution (1 mL = 0.1 mg Fe)—Into a

23. Stability of Color

100-mLbeaker, weigh 0.1000 g of iron wire. Dissolve the wire

in 50 mLof HCl (1+1).Add 1 mLof bromine water to oxidize 23.1 Potassium permanganate solution is decomposed rap-

idly by exposure to air or light. Photometric readings should be

the iron to the ferric state. Boil the solution to expel the excess

bromine and dilute to 1 L in a volumetric flask. made at once.

18.6 Iron Wire, primary standard, over 99.9 % pure.

24. Interferences

18.7 o-Phenanthroline—Dissolve2gof 1,10-

phenanthrolineinethylalcoholanddiluteto250mLwithethyl 24.1 Ashedgraphitesamplesarenormallyfreeofsignificant

alcohol in a volumetric flask. Discard this solution if color concentrations of possible interfering ions.

develops upon long standing.

25. Reagents

19. Preparation of Calibration Curve

25.1 Ammonium Hydroxide (NH OH ) (1+6)—Mix 1 vol-

4 2

19.1 Calibration Solutions—Transfer 0.0, 1.0, 2.0, 3.0, 4.0, ume of concentrated NH OH , sp gr 0.90 with 6 volumes of

4 2

5.0, and 6.0 mLof iron solution (1 mL= 0.1 mg Fe) to 100-mL water.

´1

C560–88 (2005)

25.2 Ammonium Oxalate Solution—Prepare a saturated so- and mixed, proceed as follows: pipet a suitable aliquot (usually

lution of ammonium oxalate ((NH )

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.