ASTM F690-86(2003)e1

(Practice)Standard Practice for Underground Installation of Thermoplastic Pressure Piping Irrigation Systems

Standard Practice for Underground Installation of Thermoplastic Pressure Piping Irrigation Systems

SCOPE

1.1 This practice covers general and basic procedures related to the proper installation of thermoplastic, flexible, pressure piping, 36 in. nominal size and smaller, for underground irrigation systems. Because there is considerable variability in end-use requirements, soil conditions, and thermoplastic piping characteristics, it is the intent of this practice to outline general objectives and basics of proper installation and to provide pertinent references, rather than to prescribe detailed installation procedures.

1.2 This practice should not be used for installing thermoplastic underground sewer, drain, potable water, conduit or gas service piping.

1.3 The values stated in inch-pound units are to be regarded as the standard. Values in parentheses are given for information only.

1.4 This standard does not purport to address all of the safety problems, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

e1

Designation:F 690–86(Reapproved2003)

Standard Practice for

Underground Installation of Thermoplastic Pressure Piping

Irrigation Systems

This standard is issued under the fixed designation F 690; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Keywords editorially added in November 2003.

1. Scope internal restriction or obstruction, which could reduce line

capacity below design requirements.

1.1 This practice covers general and basic procedures re-

3.2 All joining materials shall be of composition that will

lated to the proper installation of thermoplastic, flexible,

not damage the pipe and shall be recommended for use at the

pressure piping, 36 in. nominal size and smaller, for under-

design pressure for the pipeline. Consult the manufacturer for

ground irrigation systems. Because there is considerable vari-

design and installation recommendations and refer to Practice

ability in end-use requirements, soil conditions, and thermo-

F 402.

plastic piping characteristics, it is the intent of this practice to

3.3 Whensteelorothermetallicjoiningmaterials,subjectto

outline general objectives and basics of proper installation and

corrosion, are used in the line, they shall be adequately

toprovidepertinentreferences,ratherthantoprescribedetailed

protected by wrapping or coating with high quality corrosion

installation procedures.

preventatives. Wrapping or coatings that are applied on metal-

1.2 This practice should not be used for installing thermo-

lic surfaces should not be applied on plastic pipes and fittings

plasticundergroundsewer,drain,potablewater,conduit,orgas

unless it is first established by consulting the piping manufac-

service piping.

turer that they have no detrimental effect on the plastic.

1.3 The values stated in inch-pound units are to be regarded

3.4 Joining specifications are listed under 2.1.3.

asthestandard.Valuesinparenthesesaregivenforinformation

3.5 Manufacturers of joining materials should be consulted

only.

for specific assembly instructions not covered by existing

1.4 This standard does not purport to address all of the

specifications. When requesting information, the intended ser-

safety problems, if any, associated with its use. It is the

vice application should be defined.

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

4. Trench Preparation

bility of regulatory limitations prior to use.

4.1 Trench Depth—Instablegranularsoils,whichtendtobe

2. Referenced Documents relatively smooth and free of all rocks and debris larger than ⁄2

in. (13 mm) in sizes, excavation may proceed directly to final

2.1 ASTM Standards:

grade.Where rocks of other protrusions are encountered which

D 2487 Test Method for Classification of Soils for Engi-

may cause point loading on the pipe, the trench bottom should

neering Purposes (Unified Soil Classification System)

be overexcavated to permit installation of proper bedding (see

D 2488 Practice for Description and Identification of Soils

Section 5).

(Visual-Manual Procedure)

4.2 Trench Width—The width of the trench at any point

F 402 Practice for Safe Handling of Solvent Cements,

below the top of the pipe should be established with attention

Primers,andCleanersUsedforJoiningThermoplasticPipe

given to these considerations:

and Fittings

4.2.1 The wider the trench at the top of the pipe, the greater

3. Joints and Connections

theearthloadimposedonthepipeuntiltheprismloadhasbeen

achieved.

3.1 Joints and connections shall be assembled to withstand

4.2.2 Trench width should allow sufficient and safe working

the design working pressure for the pipeline without leakage,

room for proper alignment and assembly of the joints. Gener-

ally,atrenchwidthatthetopofthepipeofabout2ft(600mm)

This practice is under the jurisdiction of ASTM Committee F17 on Plastic

wider than the pipe diameter is adequate. However, for pipe

Piping Systems and is the direct responsibility of Subcommittee F17.61 on Water.

with an 18-in. (457-mm) diameter and larger in a vertical-

Current edition approved Aug. 10, 2003. Published September 2003. Originally

walled trench, a clearance of 3 ft (1 m) wider than the nominal

approved in 1980. Last previous edition approved in 1994 as F 690 – 84 (1994).

Annual Book of ASTM Standards, Vol 04.08. pipesizemaybeneeded.Forslopedtrenches,aminimumofan

Annual Book of ASTM Standards, Vol 08.04.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

e1

F 690–86 (2003)

18-in. (457-mm) greater trench bottom width than the pipe 5.2 If the pipe is to be assembled above ground, it should be

diameter allows sufficient width. If a wider trench becomes lowered into the trench, taking care not to drop it or damage it

necessary, the enlargement should be restricted as much as against the trench walls, nor to subject it or its joints to

possible to only that section above the top of the pipe. treatment, such as, dragging or excessive bending which could

4.2.3 Trench width should allow adequate room for snaking be injurious to the piping. With elastomeric seal joints, take

when recommended by the manufacturer or as may be required care to avoid joint displacement and pull out.Allow heat-fused

to accommodate thermal expansion or contraction. joints to cool or solvent-cemented joints to cure for the

4.2.4 Narrower trench widths may be utilized by joining the minimum prescribed time before moving the pipe. While

pipe above ground and lowering it into the trench, provided moving larger diameter pipe lines, care should be taken to

enough room is available in the trench for proper haunching. avoid excessive stressing of the joints.

Precautions outlined in 5.2 shall be followed.

5.3 Ensure that elastomeric seal joints are not installed so

4.3 Trench Depth—The trench depth shall be established they remain excessively deflected. Consult the pipe manufac-

with consideration given to requirements imposed by founda-

turer for maximum permissible joint deflection limits.

tion, bedding, pipe size, and cover.

5.4 Changes in the grade and line of direction of the pipe

4.4 Foundation—An adequate and stable foundation should

shallbelimitedandshallbegradualenoughsothatthebending

be present, or provided, for proper support at the total trench

of the pipe will develop neither excessive diametrical expan-

load.

sion nor excessive bending stresses.At no time should the pipe

4.4.1 Foundation preparation is not necessary when smooth

be blocked or braced to hold a bend. Excess curvature can

stable trench bottoms are encountered.

create stresses which could induce pipe failure under pressure.

4.4.2 Foundation preparation is necessary when unstable

Consult the pipe manufacturer for recommended minimum

trench bottom conditions are encountered.The designer should

pipe bending radius.

specify the stabilizing method and materials which will satis-

5.5 When installing pipe with elastomeric seal, flanged

factorily stabilize the encountered condition and provide ad-

joints, or with any connector which protrudes beyond the pipe

equate and permanent support.

diameter, bell holes should be excavated in the bedding

4.5 Bedding—The bedding material should consist of

material or trench bottom to permit the pipe to be continuously

gravel, sand, silty sand, silty gravel, or clayey sand in granular

supported. After pipe assembly and placement in the trench,

form and having a maximum particle size of ⁄4 in. (19 mm).

each bell hole should be filled with bedding material and

4.5.1 Bedding shall be provided whenever rock, hard pan,

compactedifnecessarytoattainthesamegeneraldensityasthe

boulders, or other materials that might damage the pipe are

rest of the bedding.

encountered in the trench bottom at the established pipe grade.

5.6 It is advisable to permit newly installed pipe to cool to

4.5.2 When bedding is used, it shall be kept as nearly

approximately ground temperature prior to backfilling. This

uniform in depth as possible to minimize differential settle-

will minimize the development of contraction stresses on the

ment.

joints and, in the case of solvent-cemented connections, it will

4.6 Minimum Earth Cover—Protection from traffic loading

prevent the possibility of joint separation due to contraction

or frost penetration, or both should be considered when

forces acting on an incompletely cured bond. Typically, pipe

establishing minimum earth cover requirements.

willcooladequatelysoonafterbeingplacedonashaded-trench

4.6.1 For installations exposed to normal farm vehicle

bottom.

traffic, the minimum total cover should not be less than:

5.7 Where differential settlement could create concentrated

Pipe1to2 ⁄2 in. in diameter: 18 in. (450 mm)

loading on a pipe or joint, for example, at a point of connection

Pipe 3 to 4 in. in diameter: 24 in. (600 mm)

of a buried pipe to a rigid structure, such as a manhole,

Pipe 5 in. and larger in diameter: 30 in. (750 mm)

Pipe 5 to 18 in. in diameter: 30 in. (750 mm) manufacturer’s recommendations should be followed to pre-

Pipe 18 in. and larger in diameter: 36 in. (900 mm)

vent, or to properly relieve, damaging andshearingforces. One

technique is to use extra care when compacting the foundation

4.6.2 The pipe line should be installed at sufficient depths to

and bedding under a rigid structure. Other techniques might

provide protection from traffic crossing, farming operations,

include construction of a supporting structure underneath the

and soil cracking. Load-bearing capabilities of installed pipe

joint and the pipe of about three diameters in cross section or

vary with type of pipe, type of backfill, soil conditions, and

the utilization of a flexible joint.

installation procedures. Consult the manufacturer for informa-

5.8 Special Installation—With certain pipes and in some

tion on product response to expected maximum earth loading.

soil conditions it is possible to install long lengths of pipe by

4.6.3 The trench depth shall be sufficient to ensure place-

the plowing-in technique. Consult the manufacturer for recom-

ment of the top of the pipe at least 10 in. (250 mm) below the

mendations.

known frost line. When conditions and design requirements

prevent satisfaction of this requirement, system design and

installation must ensure proper drainage in the low portions of 6. Thrust Blocking

the line.

6.1 When installing piping systems that include joints that

are not self restraining (for example, elastomeric seal type)

5. Pipe Assembly and Installation

thrust blocking may be necessary at certain points in the

5.1 Preparation of Joints—Joint assembly shall be done in system, such as changes in direction, in order to prevent

accordance with specifications listed under 2.1.3. possible disengagement of the fitting from the pipe.

e1

F 690–86 (2003)

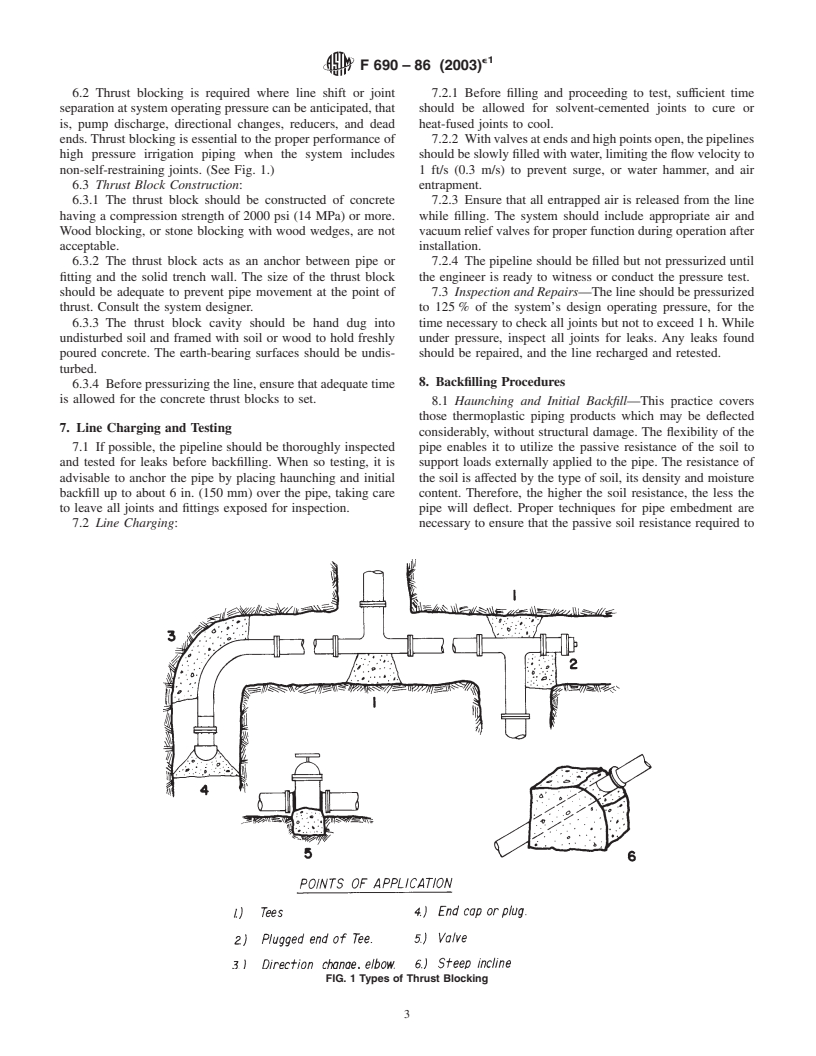

6.2 Thrust blocking is required where line shift or joint 7.2.1 Before filling and proceeding to test, sufficient time

separation at system operating pressure can be anticipated, that should be allowed for solvent-cemented joints to cure or

is, pump discharge, directional changes, reducers, and dead heat-fused joints to cool.

ends. Thrust blocking is essential to the proper performance of 7.2.2 Withvalvesatendsandhighpointsopen,thepipelines

high pressure irrigation piping when the system includes should be slowly filled with water, limiting the flow velocity to

non-self-restraining joints. (See Fig. 1.) 1 ft/s (0.3 m/s) to prevent surge, or water hammer, and air

6.3 Thrust Block Construction: entrapment.

6.3.1 The thrust block should be constructed of concrete 7.2.3 Ensure that all entrapped air is released from the line

having a compression strength of 2000 psi (14 MPa) or more. while filling. The system should include appropriate air and

Wood blocking, or stone blocking with wood wedges, are not vacuum relief valves for proper function during operation after

acceptable. installation.

6.3.2 The thrust block acts as an anchor between pipe or 7.2.4 The pipeline should be filled but not pressurized until

fitting and the solid trench wall. The size of the thrust block the engineer is ready to witness or conduct the pressure test.

should be adequate to prevent pipe movement at the point of 7.3 Inspection and Repairs—The line should be pressurized

thrust. Consult the system designer. to 125 % of the system’s design operating pressure, for the

6.3.3 The thrust block cavity should be hand dug into time necessary to check all joints but not to exceed 1 h. While

undisturbed soil and framed with soil or wood to hold freshly under pressure, inspect all joints for leaks. Any leaks found

poured concrete. The earth-bearing surfaces should be undis- should be repaired, and the line recharged and retested.

turbed.

8. Backfilling Procedures

6.3.4 Before pressurizing the line, ensure that adequate time

is allowed for the concrete thrust blocks to set.

8.1 Haunching and Initial Backfill—This practice covers

those thermoplastic piping products which may be deflected

7. Line Charging and Testing

considerably, without structural damage. The flexibility of the

7.1 If possible, the pipeline should be thoroughly inspected pipe enables it to utilize the passive resistance of the soil to

and tested for leaks before backfilling. When so testing, it is support loads externally applied to the pipe. The resistance of

advisable to anchor the pipe by placing haunching and initial the soil is affected by the type of soil, its density and moisture

backfill up to about 6 in. (150 mm) over the pipe, taking care content. Therefore, the higher the soil resistance, the less the

to leave all joints and fittings exposed for inspection. pipe will deflect. Proper techniques for pipe embedment are

7.2 Line Charging: necessary to ensure that the passive soil resistance required to

FIG. 1 Types of Thrust Blocking

e1

F 690–86 (2003)

prevent excessive pipe deflection will be developed and 8.2 Compaction Methods:

maintained.Thedesignerwilldeterminetheminimummaterial

8.2.1 When using mechanical tamping to achieve desired

requirements and extent of compaction depending on pipe

backfill soil densities, care must be taken to ensure that the

selected and the end-use conditions.The following embedment

tamping or vibratory equipment does not come in contact with

materials are recommended (see Classification D 2487 and

the pipe. Care should be taken to avoid defo

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.