ASTM D291-86(1994)e1

(Test Method)Standard Test Method for Cubic Foot Weight of Crushed Bituminous Coal

Standard Test Method for Cubic Foot Weight of Crushed Bituminous Coal

SCOPE

1.1 This test method covers two procedures for determining the cubic foot weight of crushed coal less than 11/2 in. (37 mm) in size, such as is charged into coke ovens, as follows:

1.1.1 Procedure A -The cone procedure for determining an uncompacted weight per cubic foot (cubic metre).

1.1.2 Procedure B -The dropped-coal procedure for determining a compacted weight per cubic foot (cubic metre), comparable to actual bulk densities attained in coke ovens.

1.2 This method is not applicable to the testing of powdered coal as used in boiler plants, nor to the determination of weights per cubic foot of coal in storage piles.

1.3 The values stated in inch-pound units shall be regarded as the standard. Mass may be expressed in metric values.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

e1

Designation: D 291 – 86 (Reapproved 1994)

Standard Test Method for

Cubic Foot Weight of Crushed Bituminous Coal

This standard is issued under the fixed designation D 291; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

e NOTE—Section 12 was added editorially in November 1994.

1. Scope PROCEDURE A—CONE PROCEDURE FOR

UNCOMPACTED CUBIC FOOT (CUBIC METRE)

1.1 This test method covers two procedures for determining

1 WEIGHT

the cubic foot weight of crushed coal less than 1 ⁄2 in. (37 mm)

in size, such as is charged into coke ovens, as follows:

4. Apparatus

1.1.1 Procedure A—The cone procedure for determining an

4.1 Measuring Box, of rigid construction, having inside

uncompacted weight per cubic foot (cubic metre).

dimensions of 12.0 by 12.0 by 12.0 in. (305 by 305 by 305

1.1.2 Procedure B—The dropped-coal procedure for deter-

3 3 3

mm), and a volume of 1728 6 5 in. (0.0283 m 6 82 cm ). The

mining a compacted weight per cubic foot (cubic metre),

exact volume of the box shall be determined by water

comparable to actual bulk densities attained in coke ovens.

calibration.

1.2 This method is not applicable to the testing of powdered

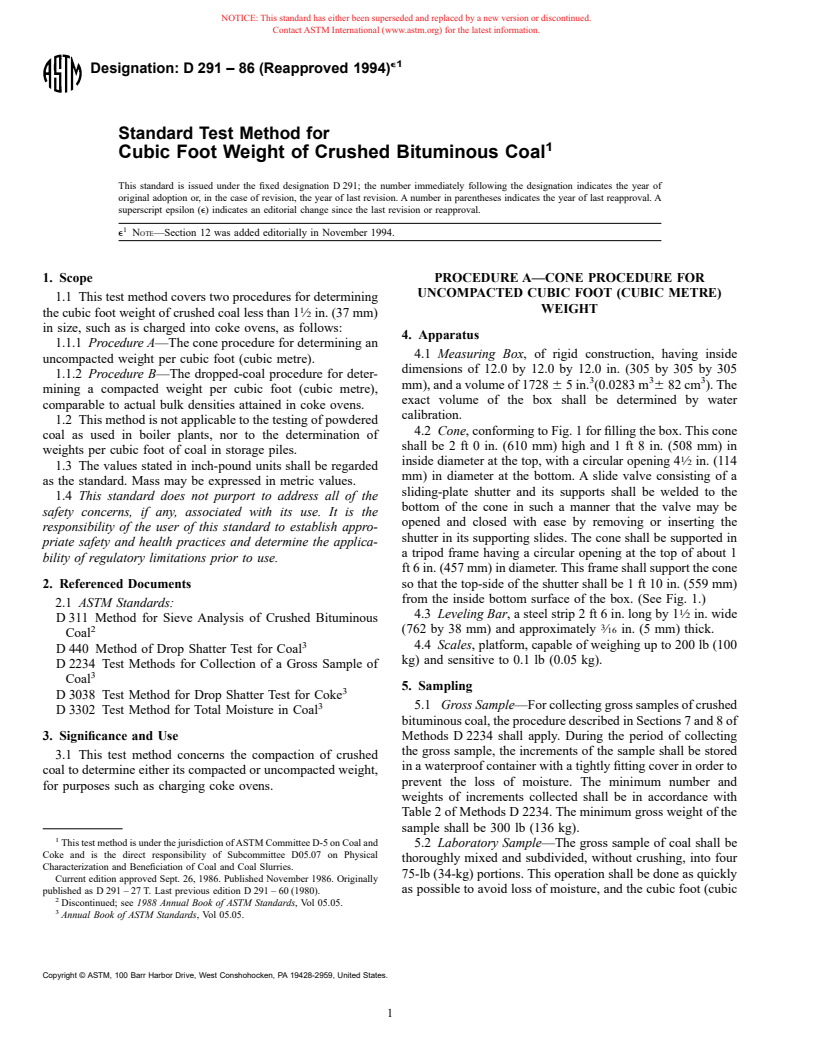

4.2 Cone, conforming to Fig. 1 for filling the box. This cone

coal as used in boiler plants, nor to the determination of

shall be 2 ft 0 in. (610 mm) high and 1 ft 8 in. (508 mm) in

weights per cubic foot of coal in storage piles.

inside diameter at the top, with a circular opening 4 ⁄2 in. (114

1.3 The values stated in inch-pound units shall be regarded

mm) in diameter at the bottom. A slide valve consisting of a

as the standard. Mass may be expressed in metric values.

sliding-plate shutter and its supports shall be welded to the

1.4 This standard does not purport to address all of the

bottom of the cone in such a manner that the valve may be

safety concerns, if any, associated with its use. It is the

opened and closed with ease by removing or inserting the

responsibility of the user of this standard to establish appro-

shutter in its supporting slides. The cone shall be supported in

priate safety and health practices and determine the applica-

a tripod frame having a circular opening at the top of about 1

bility of regulatory limitations prior to use.

ft 6 in. (457 mm) in diameter. This frame shall support the cone

2. Referenced Documents so that the top-side of the shutter shall be 1 ft 10 in. (559 mm)

from the inside bottom surface of the box. (See Fig. 1.)

2.1 ASTM Standards:

4.3 Leveling Bar, a steel strip 2 ft 6 in. long by 1 ⁄2 in. wide

D 311 Method for Sieve Analysis of Crushed Bituminous

(762 by 38 mm) and approximately ⁄16 in. (5 mm) thick.

Coal

4.4 Scales, platform, capable of weighing up to 200 lb (100

D 440 Method of Drop Shatter Test for Coal

kg) and sensitive to 0.1 lb (0.05 kg).

D 2234 Test Methods for Collection of a Gross Sample of

Coal

5. Sampling

D 3038 Test Method for Drop Shatter Test for Coke

3 5.1 Gross Sample—For collecting gross samples of crushed

D 3302 Test Method for Total Moisture in Coal

bituminous coal, the procedure described in Sections 7 and 8 of

3. Significance and Use Methods D 2234 shall apply. During the period of collecting

the gross sample, the increments of the sample shall be stored

3.1 This test method concerns the compaction of crushed

in a waterproof container with a tightly fitting cover in order to

coal to determine either its compacted or uncompacted weight,

prevent the loss of moisture. The minimum number and

for purposes such as charging coke ovens.

weights of increments collected shall be in accordance with

Table 2 of Methods D 2234. The minimum gross weight of the

sample shall be 300 lb (136 kg).

This test method is under the jurisdiction of ASTM Committee D-5 on Coal and

5.2 Laboratory Sample—The gross sample of coal shall be

Coke and is the direct responsibility of Subcommittee D05.07 on Physical

thoroughly mixed and subdivided, without crushing, into four

Characterization and Beneficiation of Coal and Coal Slurries.

75-lb (34-kg) portions. This operation shall be done as quickly

Current edition approved Sept. 26, 1986. Published November 1986. Originally

as possible to avoid loss of moisture, and the cubic foot (cubic

published as D 291 – 27 T. Last previous edition D 291 – 60 (1980).

Discontinued; see 1988 Annual Book of ASTM Standards, Vol 05.05.

Annual Book of ASTM Standards, Vol 05.05.

Copyright © ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

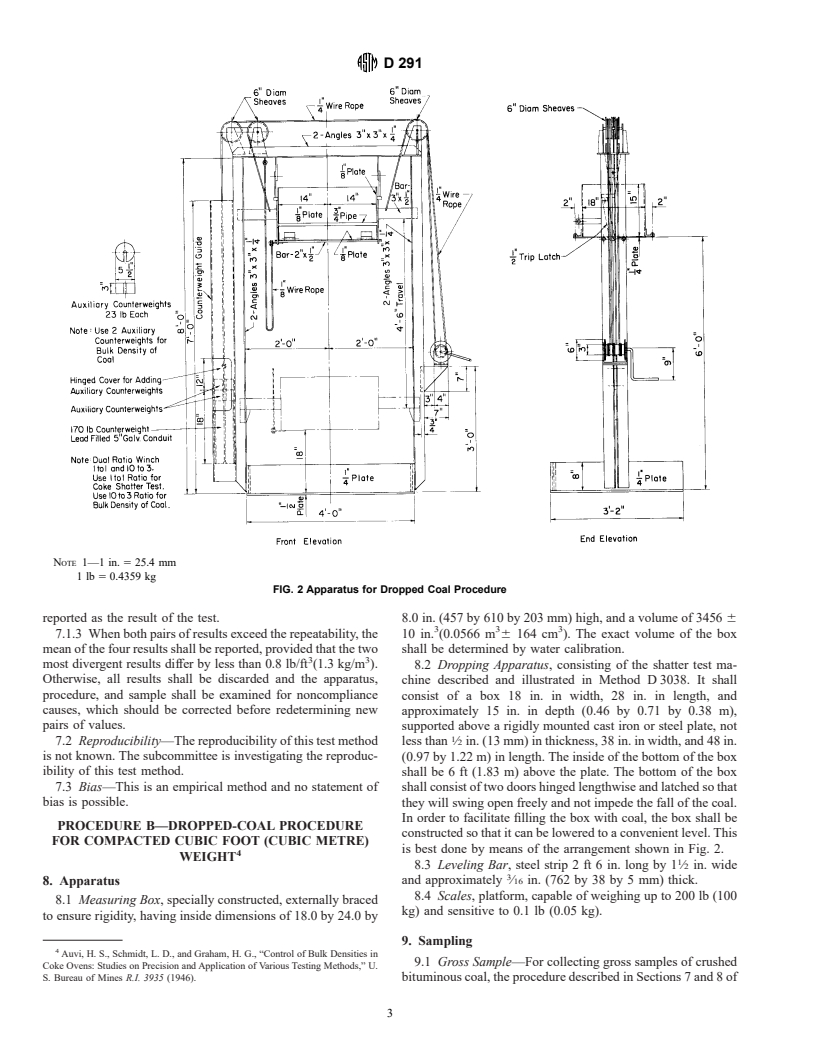

D 291

NOTE 1—1 in. 5 25.4 mm

FIG. 1 Apparatus for Cone Procedure

metre) weight shall be determined immediately. If this deter- box on the platform scale and weigh it to the nearest 0.1 lb

mination cannot be made immediately, the samples shall be (0.05 kg). Avoid jarring or shifting of the filled box until all

kept in waterproof containers with tightly fitting covers until excess coal is leveled off. Record the difference in weight

the time for making the determination. between the filled and empty box to the nearest 0.1 lb (0.05 kg)

as the uncompacted cubic foot weight.

6. Procedure

NOTE 1—Aside from the character of the coal itself, moisture content

6.1 Before filling the cone hopper, level it in its tripod on a

and size distribution of the coal are the two main factors which affect the

solid floor. Pour the prepared sample into a pile on the floor and

cubic foot weight. A moisture determination and sieve analysis of the coal

should be reported along with the cubic foot weight for proper interpre-

carefully flatten it to about 4 in. (100 mm) in thickness. Avoid

tation of the cubic foot weight. For directions for making these determi-

pounding of the pile with the back of the shovel. Take

nations, see the following:

successive shovelfuls from uniformly distributed points in the

Moisture—Test Method D 3302.

pile, and allow them to slide gently from the shovel into the

Sieve Analysis—Method D 311.

hopper at different peripheral points. This will prevent segre-

7. Precision and Bias

gation and packing while the hopper is being filled. Place about

75 lb (34 kg) of coal in the hopper. 7.1 Repeatability:

6.2 Center the previously weighed cubic foot (cubic metre) 7.1.1 Duplicate results by the same operator in a given

box under the valve of the cone. Then remove the valve shutter laboratory on consecutive tests determined within a minimum

completely, allowing all of the coal to flow into the box and interval of time shall be considered suspect if they differ by

3 3

overflow the edges. Loosen wet coal, not flowing freely from more than 0.6 lb/ft (9.6 kg/m ).

the hopper, by gently thrusting downward through the coal to 7.1.2 When two results are obtained that differ by more than

the valve with the leveling bar. this value, two additional tests shall be made. If the second pair

6.3 After filling the box, carefully level off the excess coal of results differs by less than the repeatability, the first pair

above the box edge by means of the leveling bar, and place the shall be discarded and the mean of the second pair shall be

D 291

NOTE 1—1 in. 5 25.4 mm

1lb 5 0.4359 kg

FIG. 2 Apparatus for Dropped Coal Procedure

reported as the

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.