ASTM B398/B398M-14

(Specification)Standard Specification for Aluminum-Alloy 6201-T81 and 6201-T83 Wire for Electrical Purposes

Standard Specification for Aluminum-Alloy 6201-T81 and 6201-T83 Wire for Electrical Purposes

ABSTRACT

This specification covers aluminum-alloy 6201-T81 round wire which are solution heat-treated, cold worked, and artificially aged for electrical purposes. The material shall conform to the chemical composition requirements. Tensile properties such as tensile strength and elongation and bending properties shall be determined via a tension test and bending test, respectively. The electrical resistivity and density of the wires shall be measured as well.

SCOPE

1.1 This specification covers aluminum-alloy 6201-T81 (hard, solution heat-treated, cold worked, and artificially aged) and 6201-T83 (hard, higher conductivity, solution heat-treated, cold worked, and artificially aged) round wire for electrical purposes.Note 1—The alloy and temper designations conform to ANSI H35.1 and H35.1M. Aluminum-alloy 6201 corresponds to unified numbering system alloy A96201 in accordance with Practice E527.

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. The values in each system are not exact equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result in nonconformance with the specification.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

General Information

Relations

Buy Standard

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: B398/B398M −14

StandardSpecification for

Aluminum-Alloy 6201-T81 and 6201-T83 Wire for Electrical

1

Purposes

This standard is issued under the fixed designation B398/B398M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

3

1. Scope 2.3 ANSI Standard:

ANSI H35.1 American National Standard for Alloy and

1.1 This specification covers aluminum-alloy 6201-T81

Temper Designation Systems for Aluminum

(hard, solution heat-treated, cold worked, and artificially aged)

ANSI H35.1M American National StandardAlloy and Tem-

and 6201-T83 (hard, higher conductivity, solution heat-treated,

per Designation Systems for Aluminum [Metric]

cold worked, and artificially aged) round wire for electrical

4

purposes. 2.4 NIST Standard:

NBS Handbook 100 —Copper Wire Tables

NOTE 1—The alloy and temper designations conform to ANSI H35.1

and H35.1M. Aluminum-alloy 6201 corresponds to unified numbering

3. Terminology

system alloy A96201 in accordance with Practice E527.

1.2 The values stated in inch-pound or SI units are to be

3.1 Definitions of Terms Specific to This Standard:

regarded separately as standard. The values in each system are 3.1.1 lot—A group of production units, up to 30 000 lb [15

not exact equivalents; therefore, each system shall be used

metric tons] of mass, of one type and size of wire, which was

independently of the other. Combining values from the two produced during the same time period, under similar produc-

systems may result in nonconformance with the specification.

tion conditions, and is presented for acceptance at the same

1.2.1 For density, resistivity and temperature, the values time (Explanatory Notes 1 and 2).

stated in SI units are to be regarded as standard.

3.1.2 production unit—A coil, reel, spool, or other package

of wire that represents a single usable length.

2. Referenced Documents

3.1.3 sample—The production unit or units from which a

2.1 The following documents of this issue in effect on date

test specimen or specimens has been removed, and which is

of material purchase form a part of this specification to the

considered to have properties representative of the lot.

extent referenced herein.

3.1.4 specimen—A length of wire removed for test pur-

2

2.2 ASTM Standards:

poses.

B193 Test Method for Resistivity of Electrical Conductor

Materials

4. Ordering Information

B557 Test Methods for Tension Testing Wrought and Cast

4.1 Orders for material under this specification shall include

Aluminum- and Magnesium-Alloy Products

the following information:

B557M Test Methods for Tension Testing Wrought and Cast

4.1.1 Quantity of each size,

Aluminum- and Magnesium-Alloy Products (Metric)

4.1.2 Wire size: diameter in inches or in millimetres (see

B830 Specification for Uniform Test Methods and Fre-

11.1),

quency

4.1.3 Special tension test, if required (see 7.2 and 7.3),

E527 Practice for Numbering Metals and Alloys in the

4.1.4 Frequency of bending test (see 8.2),

Unified Numbering System (UNS)

4.1.5 Special jointing procedures, if permitted (see 12.2),

4.1.6 Place of inspection (see 15.2),

1

This specification is under the jurisdiction of ASTM Committee B01 on

4.1.7 Package size and type (see 16.1), and

Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on

4.1.8 Special package marking, if required (see 16.4).

Conductors of Light Metals.

Current edition approved April 1, 2014. Published April 2014. Originally

approved in 1963. Last previous edition approved in 2013 as B398 – 02 (2013).

DOI: 10.1520/B0398_B0398M-14.

2 3

For referenced ASTM standards, visit the ASTM website, www.astm.org, or Available from American National Standards Institute (ANSI), 25 W. 43rd St.,

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Standards volume information, refer to the standard’s Document Summary page on Available from National Technical Information Service (NTIS), 5285 Port

the ASTM website. Royal Rd., Springfield, VA 22161, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B398/B398M − 14

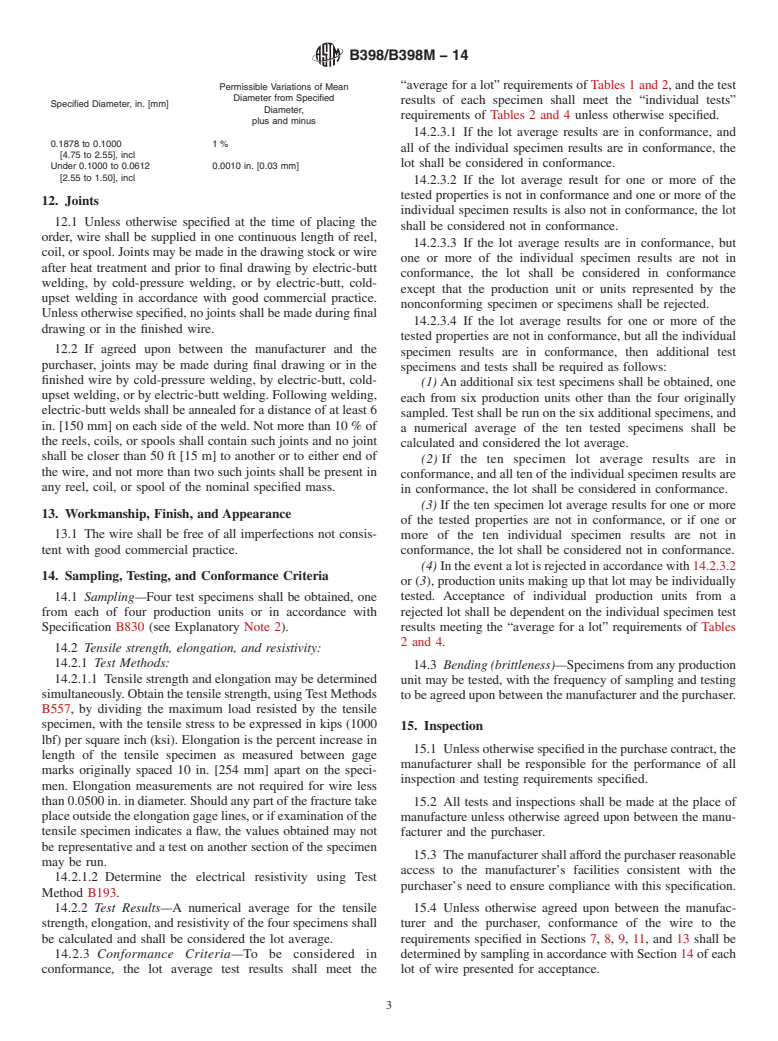

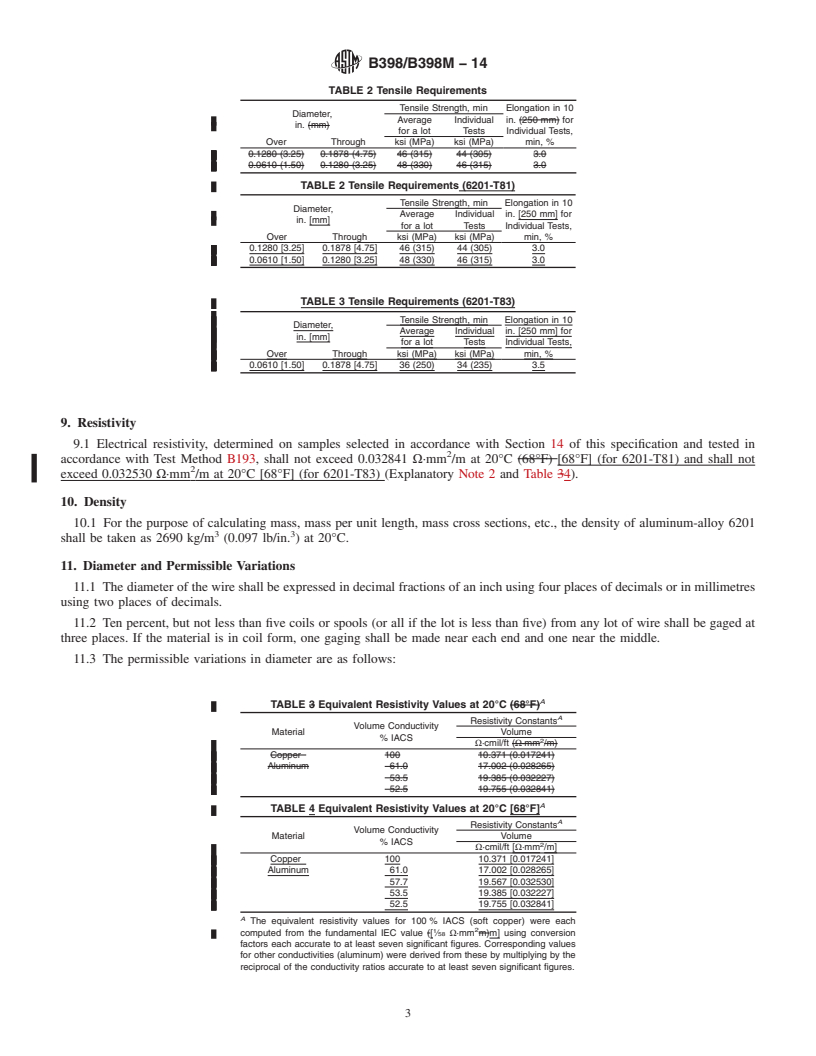

TABLE 2 Tensile Requirements (6201-T81)

5. Material and Manufacture

Tensile Strength, min Elongation in 10

5.1 The aluminum alloy used shall be of such quality that Diameter,

Average Individual in. [250 mm] for

in. [mm]

wire produced from it can comply with the requirements as to

for a lot Tests Individual Tests,

Over Through ksi (MPa) ksi (MPa) min, %

chemical composition, tensil

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: B398/B398M − 02 (Reapproved 2013) B398/B398M − 14

Standard Specification for

Aluminum-Alloy 6201-T81 and 6201-T83 Wire for Electrical

1

Purposes

This standard is issued under the fixed designation B398/B398M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specification covers aluminum-alloy 6201-T81 (hard:(hard, solution heat-treated, cold worked, and artificially aged)

and 6201-T83 (hard, higher conductivity, solution heat-treated, cold worked, and artificially aged) round wire for electrical

purposes.

NOTE 1—The alloy and temper designations conform to ANSI H35.1 and H35.1M. Aluminum-alloy 6201 corresponds to unified numbering system

alloy A96201 in accordance with Practice E527.

1.2 The values stated in inch-pound or SI units are to be regarded separately as standard. The values in each system are not exact

equivalents; therefore, each system shall be used independently of the other. Combining values from the two systems may result

in nonconformance with the specification.

1.2.1 For density, resistivity and temperature, the values stated in SI units are to be regarded as standard.

2. Referenced Documents

2.1 The following documents of this issue in effect on date of material purchase form a part of this specification to the extent

referenced herein.

2

2.2 ASTM Standards:

B193 Test Method for Resistivity of Electrical Conductor Materials

B557 Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products

B557M Test Methods for Tension Testing Wrought and Cast Aluminum- and Magnesium-Alloy Products (Metric)

B830 Specification for Uniform Test Methods and Frequency

E527 Practice for Numbering Metals and Alloys in the Unified Numbering System (UNS)

3

2.3 ANSI Standard:

ANSI H35.1 American National Standard for Alloy and Temper Designation Systems for Aluminum

ANSI H35.1M American National Standard Alloy and Temper Designation Systems for Aluminum [Metric]

4

2.4 NIST Standard:

NBS Handbook 100 Copper—Copper Wire Tables

3. Terminology

3.1 Definitions of Terms Specific to This Standard:

3.1.1 lot—A group of production units, up to 30 000 lb [15 metric tons] of mass, of one type and size of wire, which was

produced during the same time period, under similar production conditions, and is presented for acceptance at the same time

(Explanatory Notes 1 and 2).

3.1.2 production unit—A coil, reel, spool, or other package of wire that represents a single usable length.

3.1.3 sample—The production unit or units from which a test specimen or specimens has been removed, and which is considered

to have properties representative of the lot.

1

This specification is under the jurisdiction of ASTM Committee B01 on Electrical Conductors and is the direct responsibility of Subcommittee B01.07 on Conductors

of Light Metals.

Current edition approved April 1, 2013April 1, 2014. Published April 2013April 2014. Originally approved in 1963. Last previous edition approved in 20072013 as

B398 – 02 (2007).(2013). DOI: 10.1520/B0398_B0398M-02R13.10.1520/B0398_B0398M-14.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’s Document Summary page on the ASTM website.

3

Available from American National Standards Institute (ANSI), 25 W. 43rd St., 4th Floor, New York, NY 10036, http://www.ansi.org.

4

Available from National Technical Information Service (NTIS), 5285 Port Royal Rd., Springfield, VA 22161, http://www.ntis.gov.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

B398/B398M − 14

3.1.4 specimen—A length of wire removed for test purposes.

4. Ordering Information

4.1 Orders for material under this specification shall include the following information:

4.1.1 Quantity of each size,

4.1.2 Wire size: diameter in inches or in millimetres (see 11.1),

4.1.3 Special tension test, if required (see 7.2 and 7.3),

4.1.4 Frequency of bending test (see 8.2),

4.1.5 Special jointing procedures, if permitted (see 12.2),

4.1.6 Place of inspection (see 15.2),

4.1.7 Package size and type (see 16.1), and

4.1.8 Special package marking, if required (see 16.4).

5.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.