ASTM F2589-06

(Specification)Standard Specification for Ornamental Fences Employing Steel Tubular Pickets

Standard Specification for Ornamental Fences Employing Steel Tubular Pickets

SCOPE

1.1 This specification establishes the minimum requirements for coated tubular picket ornamental fence systems fabricated from black (that is, not galvanized) steel components.

1.2 The requirements of this specification do not apply to vertical bar fence systems utilizing solid bar or wrought iron materials.

1.3 The values stated with inch-pound units are to be regarded as standard. The SI values in brackets are provided for information.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: F2589 – 06

Standard Specification for

Ornamental Fences Employing Steel Tubular Pickets

This standard is issued under the fixed designation F2589; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope E4 Practices for Force Verification of Testing Machines

1.1 This specification establishes the minimum require-

3. Terminology

ments for coated tubular picket ornamental fence systems

3.1 Definitions of Terms Specific to This Standard:

fabricated from black (that is, not galvanized) steel compo-

3.1.1 adhesion—the bonding integrity of an organic coating

nents.

to the base metal substrate.

1.2 The requirements of this specification do not apply to

3.1.2 corrosion resistance—the ability of an organically

vertical bar fence systems utilizing solid bar or wrought iron

coated metal product to resist attack due to the base metal

materials.

attempting to return to a more passive oxidized state.

1.3 The values stated with inch-pound units are to be

3.1.3 fence panel—fabricated unit consisting of rails and

regardedasstandard.TheSIvaluesinbracketsareprovidedfor

pickets. Also referred to as a fence section.

information.

3.1.4 impact resistance—the measure of an organically

2. Referenced Documents coated metal product to resist indention; the ability of a coating

toresistcrackingorlossofadhesionduetoreformingthemetal

2.1 ASTM Standards:

during bending or a shape change from abuse.

A500 Specification for Cold-Formed Welded and Seamless

3.1.5 ornamental accessory—any fitting that adds further

Carbon Steel Structural Tubing in Rounds and Shapes

decoration to an ornamental metal fence system including

A501 Specification for Hot-Formed Welded and Seamless

itemssuchasfinials,caps,picketcollars,rings,scrolls,orother

Carbon Steel Structural Tubing

ornamental panel inserts.

B117 Practice for Operating Salt Spray (Fog) Apparatus

3.1.6 post—vertical fence structural component that sup-

D714 Test Method for Evaluating Degree of Blistering of

ports the panel in the ornamental metal fence system.

Paints

3.1.7 rail—horizontal structural component of a fence

D523 Test Method for Specular Gloss

panel.

D822 Practice for Filtered Open-Flame Carbon-Arc Expo-

3.1.8 tubular picket—hollow vertical ornamental compo-

sures of Paint and Related Coatings

nent of a fence panel.

D1654 Test Method for Evaluation of Painted or Coated

3.1.9 tubular picket ornamental metal fence system—an

Specimens Subjected to Corrosive Environments

architectural metal fence system that combines ornamental

D2244 Practice for Calculation of Color Tolerances and

fence structural components (that is, tubular pickets, rails, and

Color Differences from Instrumentally Measured Color

posts) with ornamental accessories and fasteners, assembled

Coordinates

and evaluated as a complete installed structure.

D2794 Test Method for Resistance of Organic Coatings to

3.1.10 weathering resistance—the ability of an organically

the Effects of Rapid Deformation (Impact)

coated metal product to resist loss of coating gloss or color

D3359 Test Methods for Measuring Adhesion by Tape Test

change due to excessive humidity or ultra-violet (UV) sunlight

exposure.

This specification is under the jurisdiction of ASTM Committee F14 on

Fencing and is the direct responsibility of Subcommittee F14.35 on Architectural

4. Materials and Manufacture

Metal Fence Systems.

4.1 Steel material for tubular picket ornamental fence sys-

Current edition approved June 1, 2006. Published June 2006. DOI: 10.1520/

F2589-06.

tem structural components (that is, tubular pickets, rails and

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

posts) shall conform to the requirements of Specifications

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

A500 or A501 and shall have a minimum yield strength of

Standards volume information, refer to the standard’s Document Summary page on

45 000 psi [310 MPa].

the ASTM website.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F2589 – 06

4.2 Organic Coating Materials 7. Testing – Structural

4.2.1 Powder coatings applied to the exterior surface of

7.1 Structural Test Method A – Application of Horizontal

fence components shall be polymer material: polyester or

Concentrated Load

epoxy and polyester combinations having a minimum thick-

7.1.1 Installation of Test Specimen—One line of fence with

ness of 3 mils; polyolefin elastomer having a minimum

a minimum of three panels of the fence system to be tested

thickness of 7 mils; or PVC having a minimum thickness of 10

shall be installed in accordance with the manufacturer’s speci-

mils.

fications and drawings. Selection of the test specimen should

4.2.2 Wet coating applied to the exterior surface of fence

consider the maximum range of styles and sizes to be certified

components shall be a two-coat paint application system (one

(see Section 10).

coat of epoxy, polyester, or polyurethane primer; one coat of

7.1.2 Apparatus

polyester, polyurethane, or acrylic liquid) with the total com-

7.1.2.1 Testing Machine—Any testing machine or loading

bined coating having a minimum thickness of 2 mils.

device, capable of imposing forces accurate to within 61%,

4.3 Fittings, fasteners, and decorative accessories for orna-

when calibrated in accordance with Practices E4, is suitable

mental steel fence systems shall be manufactured with a

andmaybeused,providedtherequirementsofspecifiedrateof

material and finish coating that meets the same protective

loading and unloading are met. The testing device shall be of

coating performance requirements as required for panels and

sufficient capacity to prevent yielding of its various compo-

posts.

nents and shall ensure that the applied load remains essentially

parallel to the relevant axis of the assembly during testing.

5. Physical Dimensions

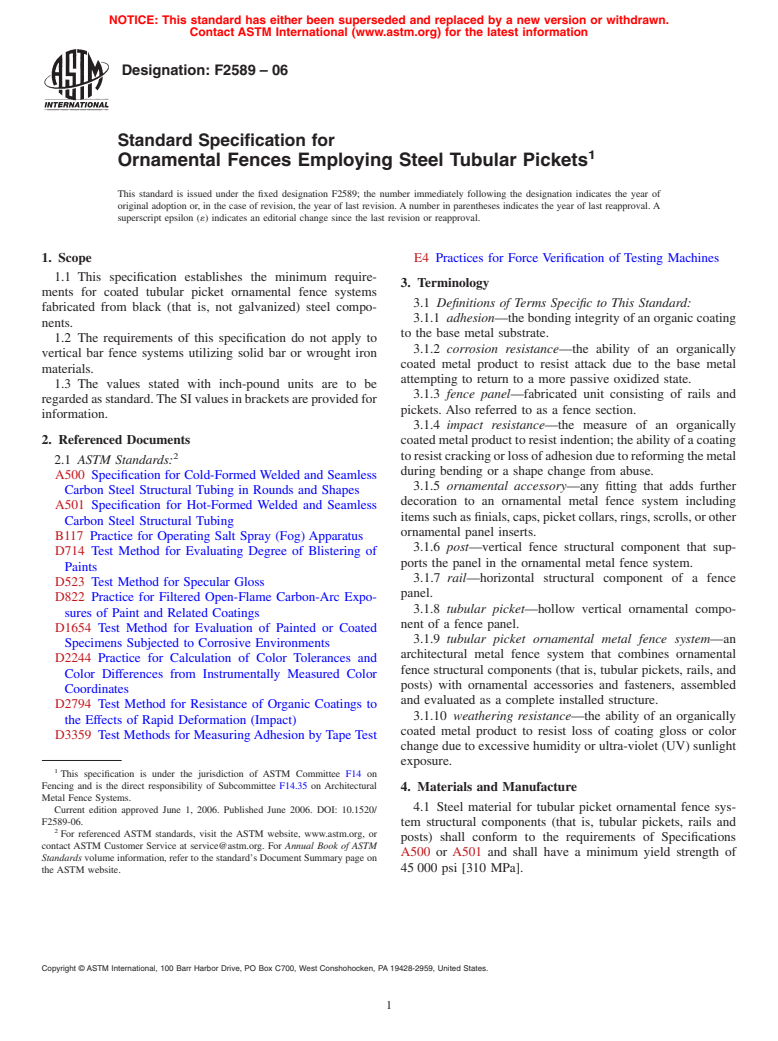

7.1.2.2 Test System—A diagrammatic test set-up for apply-

5.1 Cross-section and thickness dimensional requirements

ing horizontal tension forces to the assembly is shown in Fig.

for ornamental metal fence structural components shall be as

1.The bearing plate, normally 6-in. [150-mm] long, shall be of

specified by the manufacturer, provided that the performance

sufficient size to prevent local failure of the surrounding

criteria of Section 7 are met. Table 1 is provided as a guideline

structuralmembersorcomponents.Theloadingdeviceshallbe

to show nominal values typically used for residential, light

attached to the assembly by means of pins or a swivel

industrial (commercial), and industrial applications.

connector to prevent the direct transfer of any flexural forces

5.2 Fence height and space between rails may vary in

through the connection.

accordance with manufacturer’s standards, provided local or-

7.1.2.3 Deflection Measurements—Dial gauges, having a

dinances and building codes do not limit these dimensions for

smallest division of not more than 0.01 in. [0.25 mm], or any

a specific application, such as might be the case for pool safety,

suitable measurement devices or calibrated sensors of at least

gate safety, or structural wind load bearing capacity. No

comparable accuracy and sensitivity shall be used to measure

sharply pointed picket tops shall be used on fences less than 4

the horizontal displacements of the top rail relative to its

ft [1.22 m] in height.

originallocationateachloadingpointpriortoloadapplication.

NOTE 1—Fence height is a nominal value and is typically the distance

These devices shall have sufficient measurement capability to

from grade to the top of the fence.

indicate the displacement throughout the test range.

5.3 The spacing between pickets shall be 4 in. [101.6 mm] 7.1.3 Procedure

or less; however, if applicable local regulations (such as may

7.1.3.1 Positioning—Position the test stand in such a way

be applied to pool fencing, child care facility fencing, public that the load is applied, as shown in Fig. 1, to the structural

railing systems, or fencing adjacent to automated gates, etc.)

member perpendicular to the plane of the fence system without

have more restrictive spacing requirements, then those local causing any local failure at the point of load application.

regulations shall govern.

7.1.3.2 Mounting of Instruments—Mount the dial gauge,

measurement device, or sensor at the loading point as is shown

6. Workmanship

inFig.1.Placethesensingelementoftheinstrumentincontact

6.1 All ornamental metal fence system components shall be with and normal to the surface or an extension of the surface of

produced using materials and finishes specified in Section 4, the top rail of the fence system being tested in such a way as

and shall be free from defects in workmanship. to measure displacement in the direction of the applied load.

TABLE 1 Nominal Sizes for Ornamental Fence Structural Components

Application Component Typical Cross-Section Wall Thickness

5 5

Picket ⁄8 in. by ⁄8 in. [15.9 mm by 15.9 mm] 18 Ga.

Residential Rail 1 in. by 1 in. [25.4 mm by 25.4 mm] 18 Ga.

Post 2 in. by 2 in. [50.8 mm by 50.8 mm] 16 Ga.

3 3

Picket ⁄4 in. by ⁄4 in. [19.0 mm by 19.0 mm] 16 Ga.

Light Industrial

3 1 1 1

Rail 1 ⁄8 in. by 1 ⁄2 in. [44.4 mm by 38.1 mm] or 1 ⁄2 in. by 1 ⁄2 in. [38.1 mm by 38.1 mm] 14 Ga.

(Commercial)

1 1

Post 2 ⁄2 in. by 2 ⁄2 in. [63.5 mm by 63.5 mm] 14 Ga.

Picket 1 in. by 1 in. [25.4 mm by 25.4 mm] 16 Ga.

3 1 1 1

Industrial Rail 1 ⁄8 in. by 1 ⁄2 in. [44.4 mm by 38.1 mm] or 1 ⁄2 in. by 1 ⁄2 in. [38.1 mm by 38.1 mm] 14 Ga.

Post 3 in. by 3 in. [76.2 mm by 76.2 mm] 12 Ga.

F2589 – 06

FIG. 1 Test Set-Up for Application of Horizontal Concentrated Load

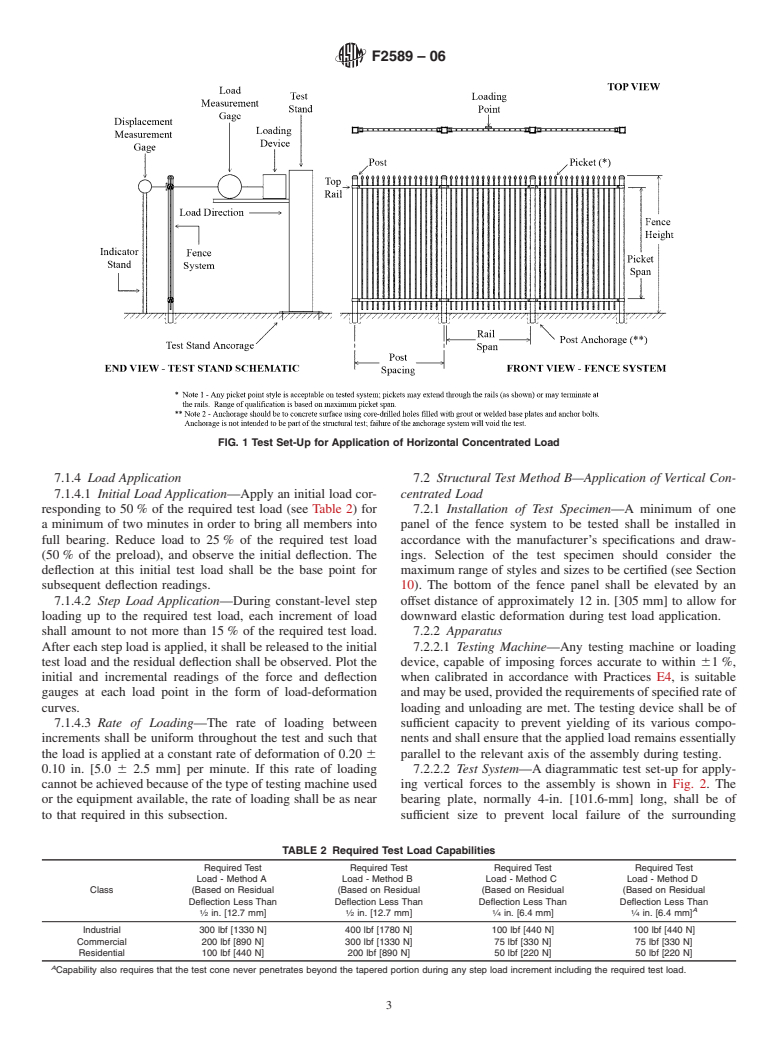

7.1.4 Load Application 7.2 Structural Test Method B—Application of Vertical Con-

7.1.4.1 Initial Load Application—Apply an initial load cor- centrated Load

responding to 50 % of the required test load (see Table 2) for 7.2.1 Installation of Test Specimen—A minimum of one

a minimum of two minutes in order to bring all members into panel of the fence system to be tested shall be installed in

full bearing. Reduce load to 25 % of the required test load accordance with the manufacturer’s specifications and draw-

(50 % of the preload), and observe the initial deflection. The ings. Selection of the test specimen should consider the

deflection at this initial test load shall be the base point for maximum range of styles and sizes to be certified (see Section

subsequent deflection readings. 10). The bottom of the fence panel shall be elevated by an

7.1.4.2 Step Load Application—During constant-level step offset distance of approximately 12 in. [305 mm] to allow for

loading up to the required test load, each increment of load downward elastic deformation during test load application.

shall amount to not more than 15 % of the required test load. 7.2.2 Apparatus

After each step load is applied, it shall be released to the initial 7.2.2.1 Testing Machine—Any testing machine or loading

test load and the residual deflection shall be observed. Plot the device, capable of imposing forces accurate to within 61%,

initial and incremental readings of the force and deflection when calibrated in accordance with Practices E4, is suitable

gauges at each load point in the form of load-deformation andmaybeused,providedtherequirementsofspecifiedrateof

curves. loading and unloading are met. The testing device shall be of

7.1.4.3 Rate of Loading—The rate of loading between sufficient capacity to prevent yielding of its various compo-

increments shall be uniform throughout the test and such that nents and shall ensure that the applied load remains essentially

the load is applied at a constant rate of deformation of 0.20 6 parallel to the relevant axis of the assembly during testing.

0.10 in. [5.0 6 2.5 mm] per minute. If this rate of loading 7.2.2.2 Test System—A diagrammatic test set-up for apply-

cannot be achieved because of the type of testing machine used ing vertical forces to the assembly is shown in Fig. 2. The

or the equipment available, the rate of loading shall be as near bearing plate, normally 4-in. [101.6-mm] long, shall be of

to that required in this subsection. sufficient size to prevent local failure of the surrounding

TABLE 2 Required Test Load Capabilities

Required Test Required Test Required Test Required Test

Load - Method A Load - Method B Load - Method C Load - Method D

Class (Based on Residual (Based on Residual (Based on Residual (Based on Residual

Deflection Less Than Deflection Less Than Deflection Less Than Deflection Less Than

A

1 1 1 1

⁄2 in. [12.7 mm] ⁄2 in. [12.7 mm] ⁄4 in. [6.4 mm] ⁄4 in. [6.4 mm]

Industrial 300 lbf [1330 N] 400 lbf [1780 N] 100 lbf [440 N] 100 lbf [440 N]

Commercial 200 lbf [890 N] 300 lbf [1330 N] 75 lbf [330 N] 75 lbf [330 N]

Residential 100 lbf [440 N] 200 lbf [890 N] 50 lbf [220 N] 50 lbf [220 N]

A

Capability also requires that the test cone never penetrates beyond the tapered portion during any step load increment including the required test load.

F2589 – 06

FIG. 2 Test Set-Up for Application of Vertical Concentrated Load

structural members or components. The bearing plate shall be accordance with the manufacturer’s specifications and draw-

positionedflushtothetoprailandshallhaveaholeatitscenter ings. Selection of the test specimen should consider the

sufficiently sized to fit over a picket if the style being tested has maximum range of styles and sizes to be certified (see Section

pickets that extend above the top rail. The loading device shall 10). Test specimens used for Test MethodsAor B may be used

be attached to the assembly by means of pins or a swivel again to perform Test Method C, provided the pickets have not

connector to prevent the direct transfer of any flexural forces been damaged during previous testing.

through the connection. 7.3.2 Apparatus

7.2.2.3 Deflection Measurements—Onedialgauge,havinga 7.3.2.1 Testing Machine—Any testing machine or loading

smallest division of not more than 0.01 in. [0.25 mm], or any device, capable of imposing forces accurate to within 61%,

suitable measurement device or calibrated sensor of at least when calibrated in accordance with Practices E4, is suitable

comparable accuracy and sensitivity shall be used to measure andmaybeused,providedtherequirementsofspecifiedrateof

the vertical displacements of the top rail relative to the original loading and unloading are met. The testing device shall be of

location at the loading point after release of the preload. sufficient

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.