ASTM C949-80(2012)

(Test Method)Standard Test Method for Porosity in Vitreous Whitewares by Dye Penetration

Standard Test Method for Porosity  in  Vitreous  Whitewares  by  Dye  Penetration

SIGNIFICANCE AND USE

This test method provides a means for readily determining if a ceramic is properly fired (matured). Penetration of any extent may negate the usefulness of the ceramic, or, arbitrarily, some degree of penetration may be acceptable for the use or commercial quality of the item being tested.

SCOPE

1.1 This test method covers procedures for detecting pores, cracks, or other voids that may be present in otherwise impermeable whiteware ceramics, or as porosity in underfired ware.

Note 1—This test method was partially derived from ANSI C29.1.

1.2 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: C949 − 80(Reapproved 2012)

Standard Test Method for

Porosity in Vitreous Whitewares by Dye Penetration

This standard is issued under the fixed designation C949; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 5. Significance and Use

1.1 This test method covers procedures for detecting pores, 5.1 This test method provides a means for readily determin-

cracks, or other voids that may be present in otherwise ing if a ceramic is properly fired (matured). Penetration of any

impermeable whiteware ceramics, or as porosity in underfired extent may negate the usefulness of the ceramic, or, arbitrarily,

ware. some degree of penetration may be acceptable for the use or

commercial quality of the item being tested.

NOTE 1—This test method was partially derived from ANSI C29.1.

1.2 This standard does not purport to address all of the

6. Apparatus

safety concerns, if any, associated with its use. It is the

6.1 Vessel, capable of applying and holding a pressure of

responsibility of the user of this standard to establish appro-

10 000 psi (68.9 MPa).

priate safety and health practices and determine the applica-

6.1.1 Fig. 1 illustrates a satisfactory device.

bility of regulatory limitations prior to use

NOTE 2—Fig. 1 does not represent the only possible design or

2. Referenced Documents configuration. It is representative of a device that has been successfully

used.

2.1 ASTM Standards:

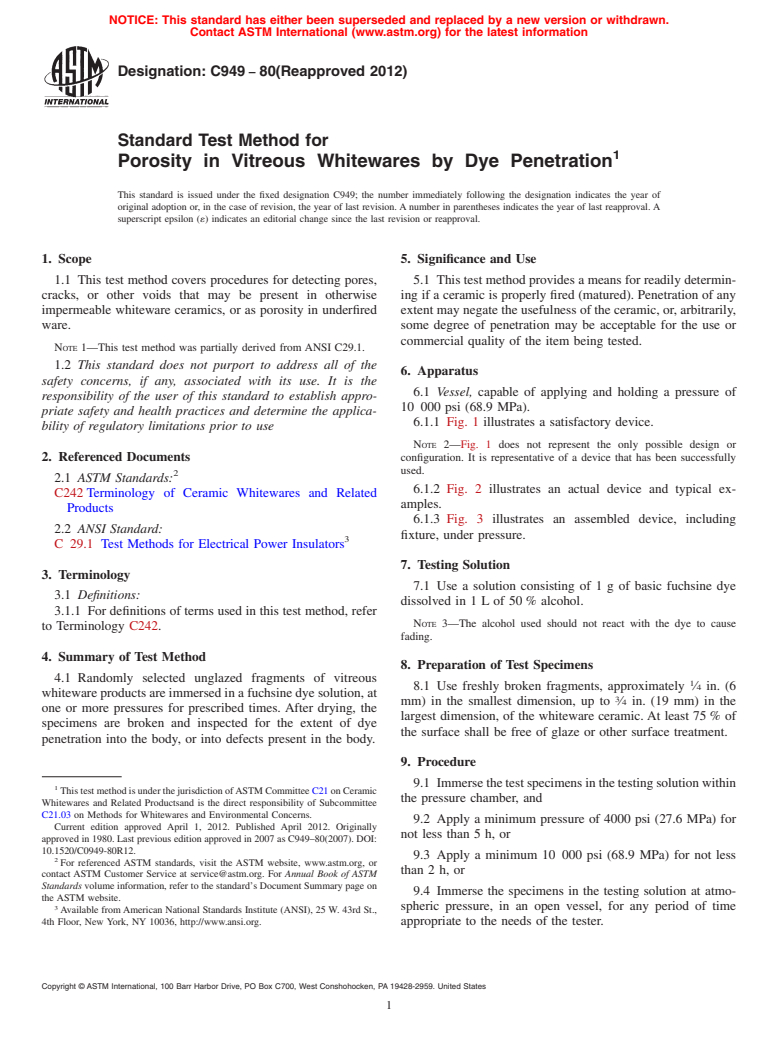

6.1.2 Fig. 2 illustrates an actual device and typical ex-

C242 Terminology of Ceramic Whitewares and Related

amples.

Products

6.1.3 Fig. 3 illustrates an assembled device, including

2.2 ANSI Standard:

fixture, under pressure.

C 29.1 Test Methods for Electrical Power Insulators

7. Testing Solution

3. Terminology

7.1 Use a solution consisting of1gof basic fuchsine dye

3.1 Definitions:

dissolved in 1 L of 50 % alcohol.

3.1.1 For definitions of terms used in this test method, refer

NOTE 3—The alcohol used should not react with the dye to cause

to Terminology C242.

fading.

4. Summary of Test Method

8. Preparation of Test Specimens

4.1 Randomly selected unglazed fragments of vitreous

8.1 Use freshly broken fragments, approximately ⁄4 in. (6

whiteware products are immersed in a fuchsine dye solution, at

mm) in the smallest dimension, up to ⁄4 in. (19 mm) in the

one or more pressures for prescribed times. After drying, the

largest dimension, of the whiteware ceramic. At least 75 % of

specimens are broken and inspected for the extent of dye

the surface shall be free of glaze or other surface treatment.

penetration into the body, or into defects present in the body.

9. Procedure

9.1 Immersethetestspecimensinthetestingsolutionwithin

This test method is under the jurisdiction ofASTM Committee C21 on Ceramic

the pressure chamber, and

Whitewares and Related Productsand is the direct responsibility of Subcommittee

C21.03 on Methods for Whitewares and Environmental Concerns.

9.2 Apply a minimum pressure of 4000 psi (27.6 MPa) for

Current edition approved April 1, 2012. Published April 2012. Originally

not less than 5 h, or

approved in 1980. Last previous edition a

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.