ASTM D5426-07a

(Practice)Standard Practices for Visual Inspection and Grading of Fabrics Used for Inflatable Restraints

Standard Practices for Visual Inspection and Grading of Fabrics Used for Inflatable Restraints

SIGNIFICANCE AND USE

These practices are suitable for incorporation in a specification. Any reference to material or cushion specification in these practices shall mean any similar agreement between the purchaser and supplier relating to the inspection and acceptance of fabric intended for inflatable restraint use.

These practices constitute the terminology, conditions, equipment, and procedures by which rolls of inflatable restraint fabrics or cut parts are inspected and graded.

A specification incorporating these practices may deviate from them to account for considerations of fabric property, material handling equipment, or inflatable restraint cushion design, or a combination thereof. Whenever such deviations from standard occur, they are recorded in the report.

These practices acknowledge that, in the normal course of production, acceptable rolls of fabric will be produced containing imperfections; subsequently, pieces will be cut from the rolls and those pieces that contain major imperfections restricted in Tables 1-5 will be culled at that time.

The accuracy in the results from visually inspecting fabric using these practices is affected by the ability of the inspector to detect, identify, and evaluate the severity of an imperfection in a moving fabric or in a cut part. Such ability can be affected by visual acuity, viewing distance, fabric traverse speed, lighting conditions, inspector discipline and training, and the availability and accuracy of suitable visual aids.

Systematic bias may result from using these practices whenever the precision or scale of the visual aids used to identify and quantify major imperfections differs between the purchaser and supplier.

SCOPE

1.1 These practices cover procedures for the inspection and grading of coated and uncoated woven fabrics, and for the inspection and culling of cut parts made of such fabrics, all of which are used in the manufacture of inflatable restraint cushions.

1.2 For ease of reference, the scope, summary of practice, significance and use, apparatus, sampling, procedure, and report sections are listed separately for each inspection practice.Inspection PracticeSectionFabric RollsCut Pieces

1.3 These practices can be used to distinguish those fabric imperfections that may adversely affect inflatable restraint cushion fabrication or performance from those imperfections that will not.

1.4 Only major imperfections are considered in the grading systems of these practices.

1.5 Procedures and apparatus other than those stated in these practices may be used by agreement of the purchaser and supplier with the specific deviations from these practices acknowledged in the report.

1.6 The values stated in SI units are to be regarded as the standard. The values given in parentheses are for information only.

This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: D 5426 – 07a

Standard Practices for

Visual Inspection and Grading of Fabrics Used for Inflatable

1

Restraints

This standard is issued under the fixed designation D 5426; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2. Referenced Documents

2

1.1 These practices cover procedures for the inspection and 2.1 ASTM Standards:

grading of coated and uncoated woven fabrics, and for the D 123 Terminology Relating to Textiles

inspection and culling of cut parts made of such fabrics, all of D 3990 Terminology Relating to Fabric Defects

3

which are used in the manufacture of inflatable restraint 2.2 ASTM Adjuncts:

cushions. Reference Photographs of Imperfections

1.2 For ease of reference, the scope, summary of practice,

3. Terminology

significance and use, apparatus, sampling, procedure, and

3.1 Definitions—For definitions of textile terms used in

report sections are listed separately for each inspection prac-

tice. these practices, refer to Terminologies D 123 and D 3990.

3.2 For definitions of imperfections in inflatable restraints,

Inspection Practice Section

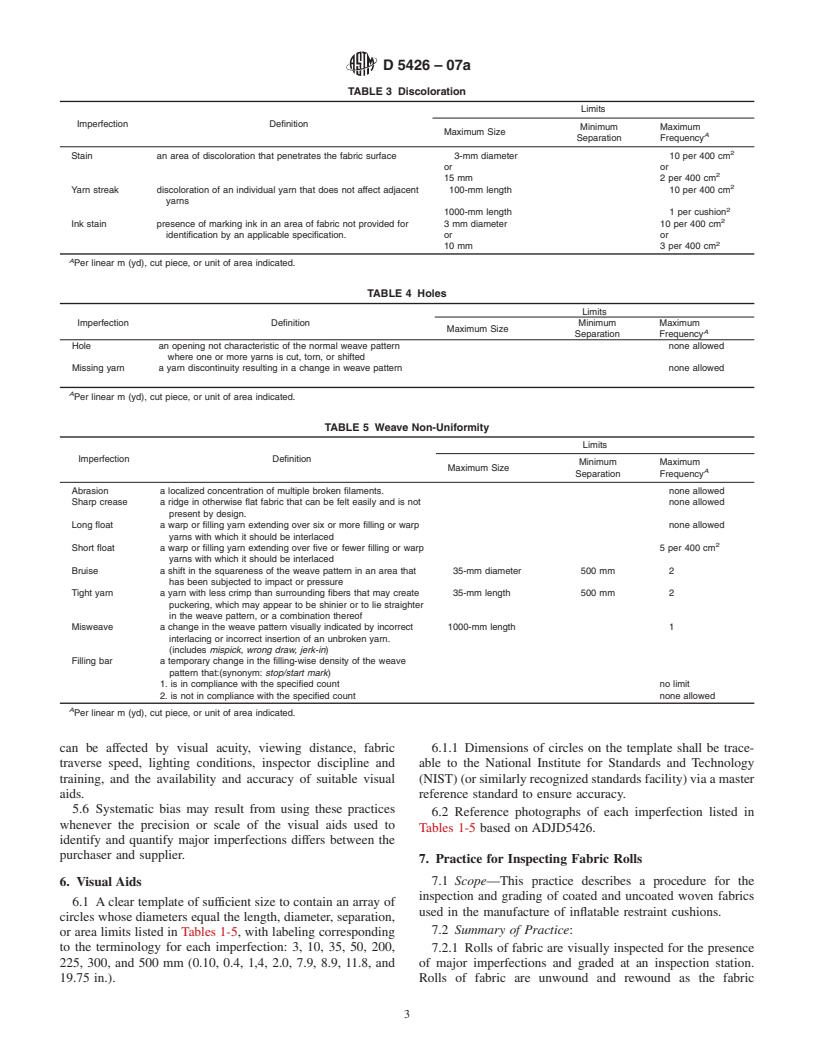

additionally refer to Tables 1-5 of these practices.

Fabric Rolls 7

Cut Pieces 8

4. Summary of Practices

1.3 These practices can be used to distinguish those fabric

4.1 Rollsoffinishedorcoatedfabricareexaminedformajor

imperfections that may adversely affect inflatable restraint

imperfections as the fabric traverses an inspection station.

cushion fabrication or performance from those imperfections

They are graded on the basis of a unit area.

that will not.

4.2 Cut pieces are inspected individually for major imper-

1.4 Only major imperfections are considered in the grading

fections. Cut pieces containing major imperfections are culled

systems of these practices.

from use for later review.

1.5 Procedures and apparatus other than those stated in

5. Significance and Use

these practices may be used by agreement of the purchaser and

supplier with the specific deviations from these practices

5.1 These practices are suitable for incorporation in a

acknowledged in the report.

specification. Any reference to material or cushion specifica-

1.6 The values stated in SI units are to be regarded as the

tion in these practices shall mean any similar agreement

standard. The values given in parentheses are for information

between the purchaser and supplier relating to the inspection

only.

and acceptance of fabric intended for inflatable restraint use.

1.7 This standard does not purport to address all of the

5.2 These practices constitute the terminology, conditions,

safety concerns, if any, associated with its use. It is the

equipment,andproceduresbywhichrollsofinflatablerestraint

responsibility of the user of this standard to establish appro-

fabrics or cut parts are inspected and graded.

priate safety and health practices and determine the applica-

bility of regulatory limitations prior to use.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service ast service@astm.org. For Annual Book of ASTM

1

These practices are under the jurisdiction ofASTM Committee D13 onTextiles Standardsvolume information, refer to the standrd’s Document Summary page on

and are the direct responsibility of Subcommittee D13.20 on Inflatable Restraints. the ASTM website.

3

Current edition approved July 1, 2007. Published July 2007. Originally approved Available from: ASTM International Headquarters. Order Adjunct No.

in 1993. Last previous edition approved in 2007 as D 5426 – 07. ADJD5426. Original adjunct produced in 1996.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

D 5426 – 07a

TABLE 1 Coating Non-Uniformity

Limits

Imperfection Definition

Minimum Maximum

Maximum Size

A

Separation Frequency

Soft the presence of non-coating material within or on the coating 15 mm 2

contamination layer, such material visibly appearing to be of small size, diameter none within the line

smooth in surface texture, and of a thickness that does not where two OPW

protrude significantly above the surface of the coating layer. inflatable layers

Examples are dirt, smudge, lint, human hair, yarn filaments, interface

and flies and similarly small insects.

Hard the presence of non-coating material within or on the coating none

contamination layer, such material visibly appearing to be of small size,

smooth in surface texture, and of a thickness that protrudes

significantly above the surface of the coating layer.

Examples are metal filings, glass,

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.