ASTM F824-93(1999)

(Specification)Standard Specification for Tables, Mess, Marine, Steel

Standard Specification for Tables, Mess, Marine, Steel

SCOPE

1.1 This specification covers the construction of round, square, and rectangular marine mess tables with or without adjustable lee rails for use in crew, officer, and passenger dining areas aboard ship.

1.2 The values stated in inch-pound units are to be regarded as the standard. The metric equivalents, given in parentheses, are provided for information only.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

An American National Standard

Designation: F 824 – 93 (Reapproved 1999)

Standard Specification for

Tables, Mess, Marine, Steel

This standard is issued under the fixed designation F 824; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 National Electrical Manufacturer’s Association:

NEMA LD-3 High Pressure Decorative Laminates

1.1 This specification covers the construction of round,

2.3 American Institute of Steel Construction Manual:

square, and rectangular marine mess tables with or without

AISC Wire and Sheet Metal Gages— Equivalent Thickness

adjustable lee rails for use in crew, officer, and passenger

in Decimals of an Inch, U.S. Standard Gage (USSG) for

dining areas aboard ship.

Uncoated Hot and Cold Rolled Sheets

1.2 The values stated in inch-pound units are to be regarded

as the standard. The metric equivalents, given in parentheses,

3. Terminology

are provided for information only.

3.1 Definitions of Terms Specific to This Standard:

2. Referenced Documents 3.1.1 mess table—a dining table for use in crew, officer, or

passenger dining areas, consisting of a horizontal top assembly

2.1 ASTM Standards:

and one or more supporting pedestals.

A 53/A 53M Specification for Pipe, Steel, Black and Hot-

2 3.1.2 table top—the assembled horizontal surface of the

Dipped, Zinc-Coated Welded and Seamless

mess table including the substrate, top covering, lee rails, and

A 167 Specification for Stainless and Heat-Resisting

edge binder, or all of the preceding.

Chromium-Nickel Steel Plate, Sheet, and Strip

3.1.2.1 substrate—the structural core of the top assembly.

A 240/A 240M Specification for Heat-Resisting Chromium

3.1.2.2 top covering—the decorative melamine laminate

and Chromium-Nickel Stainless Steel Plate, Sheet, and

attached to the top surface of the substratae.

Strip for Pressure Vessels

3.1.2.3 Lee Rails:

A 366/A366M Specification for Commercial Steel (CS)

(a) fixed lee rail—a trim piece at the edge of the table top

Sheet, Carbon, (0.15 Maximum Percent) Cold-Rolled

that projects above the upper surface of the table top to retain

A 500 Specification for Cold-Formed Welded and Seamless

tableware and act as an edge binder.

Carbon Steel Structural Tubing in Rounds and Shapes

(b) adjustable lee rail—a trim piece at the edge of the table

A 501 Specification for Hot-Formed Welded and Seamless

2 top that can be raised above the upper surface of the table top

Carbon Steel Structural Tubing

to retain tableware and can be retracted when not needed.

A 567/A567M Specification for Castings, Iron, Cobalt, and

3.1.2.4 edge binder—the finishing strips of metal applied to

Nickel-Base Alloy, for High Strength at Elevated Tempera-

the edge of the table top.

tures

3.1.2.5 cleanout—an interruption in the raised portion of the

A 569/A569M Specification for Steel, Carbon (0.15 Maxi-

lee rail to facilitate cleaning of table top.

mum, Percent), Hot-Rolled Sheet and Strip Commercial

3.1.2.6 pedestal—a round or square tubular column, or

A 582/A 582M Specification for Free-Machining Stainless

stanchion, that supports the table top. Each pedestal has a

Steel Bars

table-support plate at its upper end and provisions at the bottom

B 221 Specification for Aluminum and Aluminum-Alloy

for attaching to the structural deck.

Extruded Bars, Rods, Wire, Profiles, and Tubes

7 (a) table support platea flanged, dished plate or flat plate

D 907 Terminology of Adhesives

with gussets welded to top of pedestal for supporting and

attaching to the table top.

3.1.2.7 deck socket—a metal sleeve or adaptor welded to the

This specification is under the jurisdiction of ASTM Committee F-25 on Ships

and Marine Technology and is the direct responsibility of Subcommittee F25.03 on

structural deck, over which the table pedestal is installed and

Outfitting.

attached.

Current edition approved August 15, 1993. Published October 1993. Originally

published as F 824 – 83. Last previous edition F 824 – 88.

Annual Book of ASTM Standards, Vol 01.01.

Annual Book of ASTM Standards, Vol 01.03.

4 8

Discontinued, see 1986 Annual Book of ASTM Standards, Vol 01.02. Available from the National Electrical Manufacturers Association, 1300 N.

Annual Book of ASTM Standards, Vol 01.05. 17th St., Suite 1847, Rosslyn, VA 22209.

6 9

Annual Book of ASTM Standards, Vol 02.02. Available from the American Institute of Steel Construction, One E. Wacker

Annual Book of ASTM Standards, Vol 15.06. Dr., Suite 3100, Chicago, IL 60601–2001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

F 824

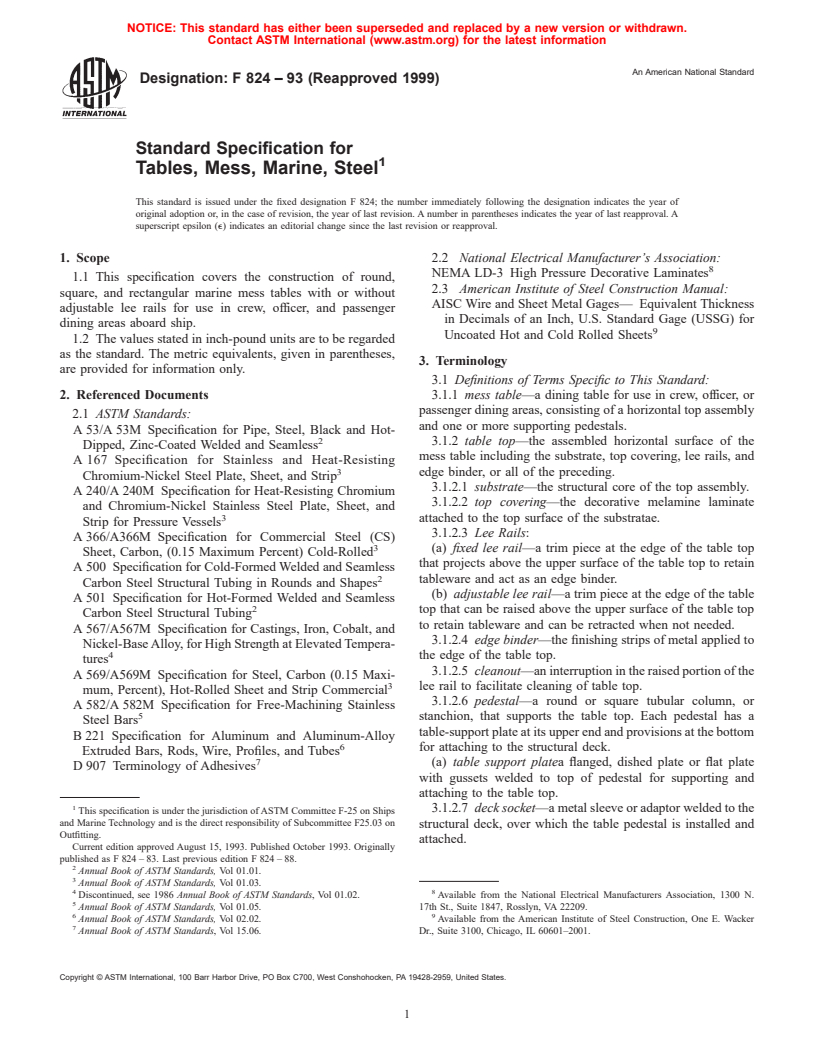

4. Classification A 501 shall apply to all pedestal dimensions. Pedestals shall be

of either welded or seamless construction. The choice of round

4.1 Types:

or square pedestal shall be at the option of the table manufac-

4.1.1 Type I—Round mess table with single pedestal.

turer. Round pedestals shall be black steel pipe in accordance

4.1.2 Type II—Square mess table with single pedestal.

with Specification A 53/A 53M. Square pedestals shall be

4.1.3 Type III—Rectangular mess table.

structural-steel tubing in accordance with Specifications A 500

4.1.3.1 Grade 1—Rectangular table with single pedestal.

or A 501.

4.1.3.2 Grade 2—Rectangular table with two pedestals.

6.3.2 Table Support Plate, may be either a flanged dished

4.2 Classes:

plate or a flat plate with gussets. If a flat plate and gussets, it

4.2.1 Class A—Table with fixed lee rails.

shall be of hot-rolled, commercial-quality steel pickled and

4.2.2 Class B—Table with adjustable lee rails.

oiled in accordance with Specification A 567/A 567M and with

a minimum thickness of 7 USSG (0.1793 in. or 5 mm). For

5. Ordering Information

dished plate, it shall be cold-rolled steel sheet of commercial

5.1 Orders for materials under this specification shall in-

quality in accordance with Specification A 366/A 366M and

clude the following:

with a minimum thickness of 14 USSG (0.0747 in. or 2 mm).

5.1.1 Quantity and size of each type, grade, and class.

6.3.3 Pedestals may be attached to the deck by welding or

5.1.2 Paint:

by attaching to deck socket. Unless specified in the ordering

5.1.2.1 Color—The purchaser shall pick from manufactur-

document, the method used is at the option of the table

er’s samples or submit a sample chip of color desired.

manufacturer. If round pedestals and sleeves are used, provi-

5.1.2.2 Manufacturer’s standard baked enamel will be fur-

sions must be made to ensure that the table will not turn.

nished unless otherwise required and indicated by the pur-

6.4 Joining:

chaser.

6.4.1 Metal Components, shall be joined by welding or

5.1.3 Color or pattern of melamine laminate top covering.

gluing with a structural adhesive as defined in Terminology

5.1.4 If pedestal deck sockets are required, they shall be

D 907.

specified in the ordering document; otherwise, the table manu-

6.4.2 Joining shall be adequate to prevent racking during

facturer shall have the option of supplying pedestals without

manufacture or service.

sockets but with 2 in. (51 mm) of scribing for trimming and

6.4.3 Spotwelds, shall be spaced approximately 3 in. (76

welding to the deck on the ship.

mm) on centers.

5.1.5 If the total weight of the table assembly is required, it

6.4.4 Visible Spotwelds, higher than the general surface of

shall be requested by the purchaser.

the adjacent metal, shall be ground smooth.

6.4.5 Visible Spotweld Depressions, shall be spot filled and

6. Materials and Manufacture

ground flush.

6.1 For typical design, see Fig. 1, Fig. 2, and Fig. 3.

6.2 Tops:

6.2.1 Tops shall be steel construction with a decorative

7. Performance Requirements

melamine laminate top cover. The minimum thickness for the

top plate, stiffener, and edge channels shall be 16 USSG 7.1 Tops for mess tables shall be capable of supporting a

(0.0598 in. or 1.50 mm) and made from cold-rolled steel sheet load of 400 lb (181 kg) uniformly distributed over an area of 2

2 2

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.