ASTM D6195-03e1

(Test Method)Standard Test Methods for Loop Tack

Standard Test Methods for Loop Tack

SIGNIFICANCE AND USE

These test methods provide a quantitative measure of the pressure-sensitive tack property of an adhesive.

These test methods are designed to measure the tack property of the adhesive mass. The tack of a given adhesive varies depending on the backing (generally, stiffer backings lead to higher values).

Theses test methods are suitable for quality control and research purposes.

Test Method A (using Tensile Tester) makes use of a specimen strip 7 in. (175 mm) in length. Both the FINAT FTM 9 “Quick Stick” Tack Measurement Test and the TLMI L-IB2 Tensile Tester Loop Tack Test also use a specimen strip of that length.

Test Method B (using Loop Tack Tester) makes use of a specimen strip five in. (125 mm) in length. That is the only length specimen strip that fits properly in the loop tack tester.

If the adhesive is not already otherwise coated, these test methods incorporate the use of a clear 2 mil (0.05 mm) polyester (PET) film backing for specimen preparation. Use of other backing materials changes performance of the specimen to be tested.

SCOPE

1.1 These test methods cover the determination of properties of a pressure-sensitive adhesive. These test methods are applicable to those adhesives that form a bond of measurable strength rapidly upon contact with another surface. Tack force may be measured as the force required to separate the adhesive from the adherend at the interface shortly after they have been brought into contact under a load equal only to the weight of the pressure-sensitive article (for example, tape, label, sticker, etc.) on a 1 in.2 contact area.

1.2 The following test methods are included:

1.2.1 Test Method A (using Tensile Tester), and

1.2.2 Test Method B (using Loop Tack Tester).

1.3 The values stated in inch-pound units are to be regarded as the standard because the industry standard width for pressure-sensitive tape is 1 inch. The values given in parentheses are for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

´1

Designation:D6195–03

Standard Test Methods for

1

Loop Tack

This standard is issued under the fixed designation D6195; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1

´ NOTE—Corrected research report reference in Section 16 editorially in March 2008.

1. Scope E177 Practice for Use of the Terms Precision and Bias in

ASTM Test Methods

1.1 These test methods cover the determination of proper-

E691 Practice for Conducting an Interlaboratory Study to

ties of a pressure-sensitive adhesive. These test methods are

Determine the Precision of a Test Method

applicable to those adhesives that form a bond of measurable

2.2 European Association for the Pre-Adhesed Labeling

strength rapidly upon contact with another surface. Tack force

3

Industry (FINAT) Standard:

may be measured as the force required to separate the adhesive

FTM 9 “Quick-Stick” Tack Measurement

from the adherend at the interface shortly after they have been

2.3 Tag and Label Manufacturers Institute, Inc. (TLMI)

brought into contact under a load equal only to the weight of

4

Standard:

the pressure-sensitive article (for example, tape, label, sticker,

2

L-IB1 TLMI Loop Tack Test

etc.) ona1in. contact area.

L-IB2 Tensile Tester Loop Tack Test

1.2 The following test methods are included:

1.2.1 Test Method A (using Tensile Tester), and

3. Terminology

1.2.2 Test Method B (using Loop Tack Tester).

3.1 Definitions:

1.3 The values stated in inch-pound units are to be regarded

3.1.1 Many of the terms found in these test methods are

as the standard because the industry standard width for

defined in Terminology D907.

pressure-sensitive tape is 1 inch. The values given in paren-

theses are for information purposes only.

4. Summary of Test Method

1.4 This standard does not purport to address all of the

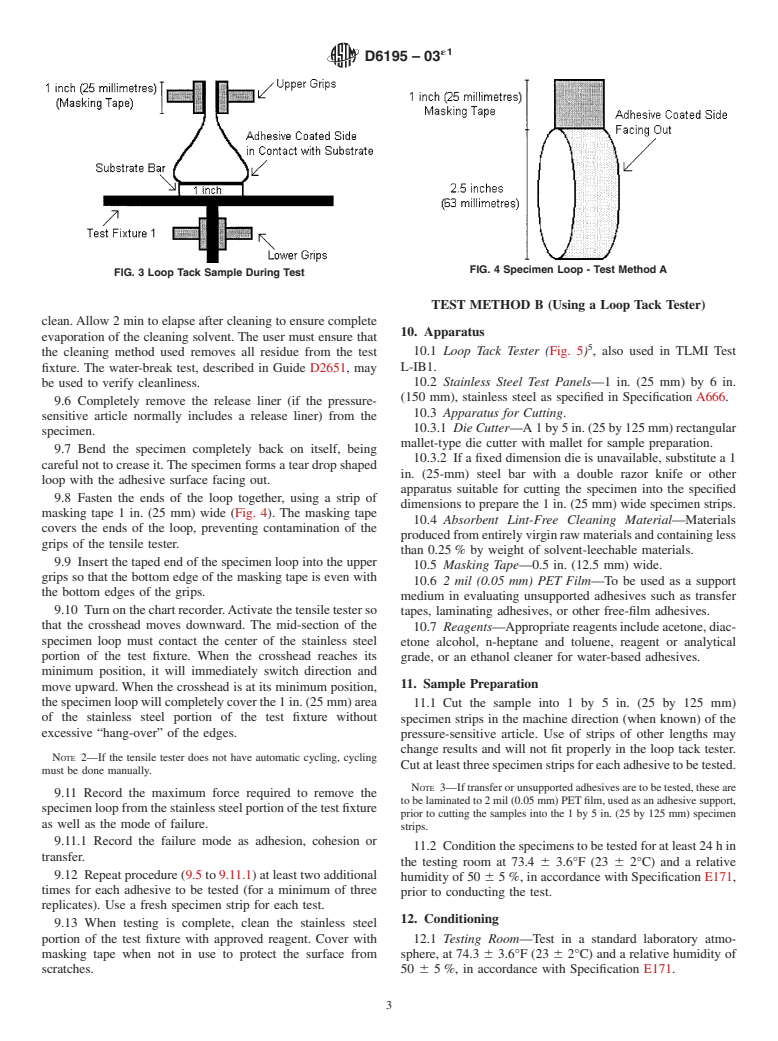

4.1 These test methods involve allowing a loop of pressure-

safety concerns, if any, associated with its use. It is the

sensitive adhesive with its backing to be brought into con-

responsibility of the user of this standard to establish appro-

2

trolled contact witha1in. (25 by 25 mm) surface of stainless

priate safety and health practices and determine the applica-

steel, with the only force applied being the weight of the

bility of regulatory limitations prior to use.

pressure-sensitivearticleitself.Thepressure-sensitivearticleis

2. Referenced Documents then removed from the substrate, with the force to remove the

2 pressure-sensitive article from the adherend measured by a

2.1 ASTM Standards:

recording instrument.

A666 Specification for Annealed or Cold-Worked Auste-

4.2 Test Method A (using a Tensile Tester) applies when a

nitic Stainless Steel Sheet, Strip, Plate, and Flat Bar

TensileTesterisusedtomeasurelooptackandinvolvestheuse

D907 Terminology of Adhesives

of a loop prepared from an 7 in. (175 mm) specimen strip.

D2651 Guide for Preparation of Metal Surfaces for Adhe-

4.3 Test Method B (using a LoopTackTester) applies when

sive Bonding

a Loop Tack Tester is used to measure loop tack and involves

E4 Practices for Force Verification of Testing Machines

the use of a loop prepared from a 5 in. (125 mm) specimen

E171 Specification for Atmospheres for Conditioning and

strip.

Testing Flexible Barrier Materials

5. Significance and Use

1

5.1 These test methods provide a quantitative measure of

These test methods are under the jurisdiction of ASTM Committee D14 on

Adhesives and are the direct responsibility of Subcommittee D14.50 on Hot Melt

the pressure-sensitive tack property of an adhesive.

Pressure Sensitive Archive Adhesives.

5.2 These test methods are designed to measure the tack

Current edition approved April 10, 2003. Published May 2003. Originally

property of the adhesive mass. The tack of a given adhesive

approved in 1997. Last previous edition approved in 1997 as D6195 - 97. DOI:

10.1520/D6195-03E01.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

3

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Available from FINAT, Laan CopesVan Cattenburch 79, 2585 EW,The Hague,

Standards volume information, refer to the standard’s Document Summary page on Holland.

4

the ASTM website. Available from TLMI, 40 Shuman Blvd., Ste. 295, Naperville, IL 60563.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

´1

D6195–03

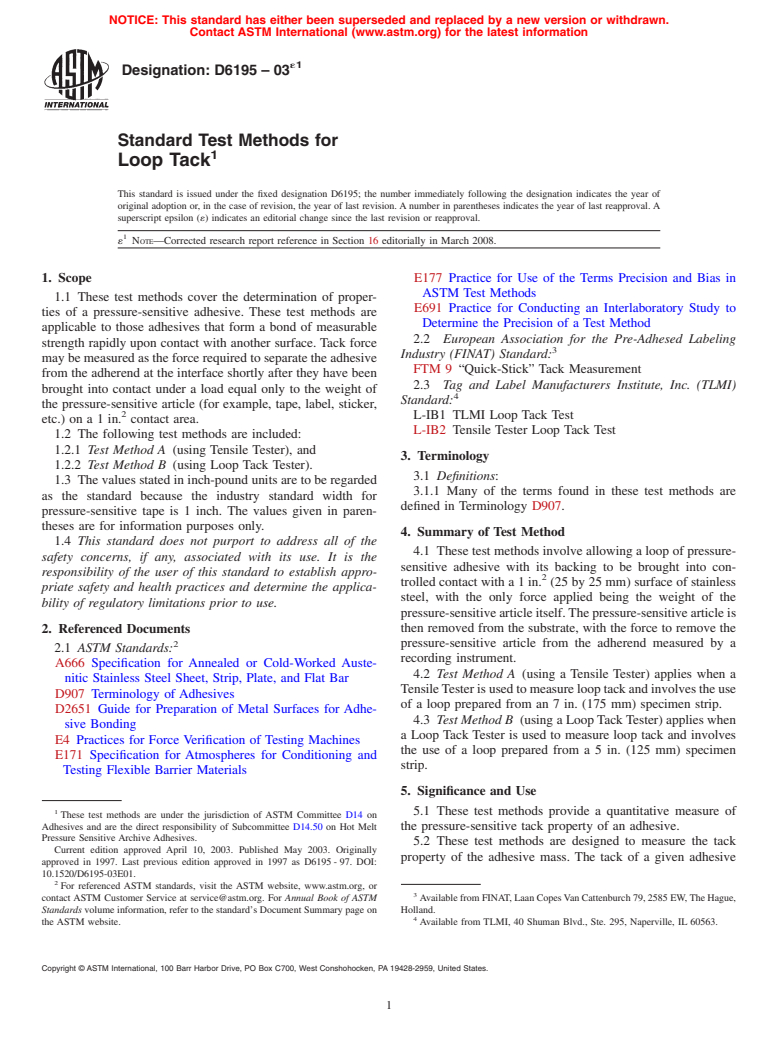

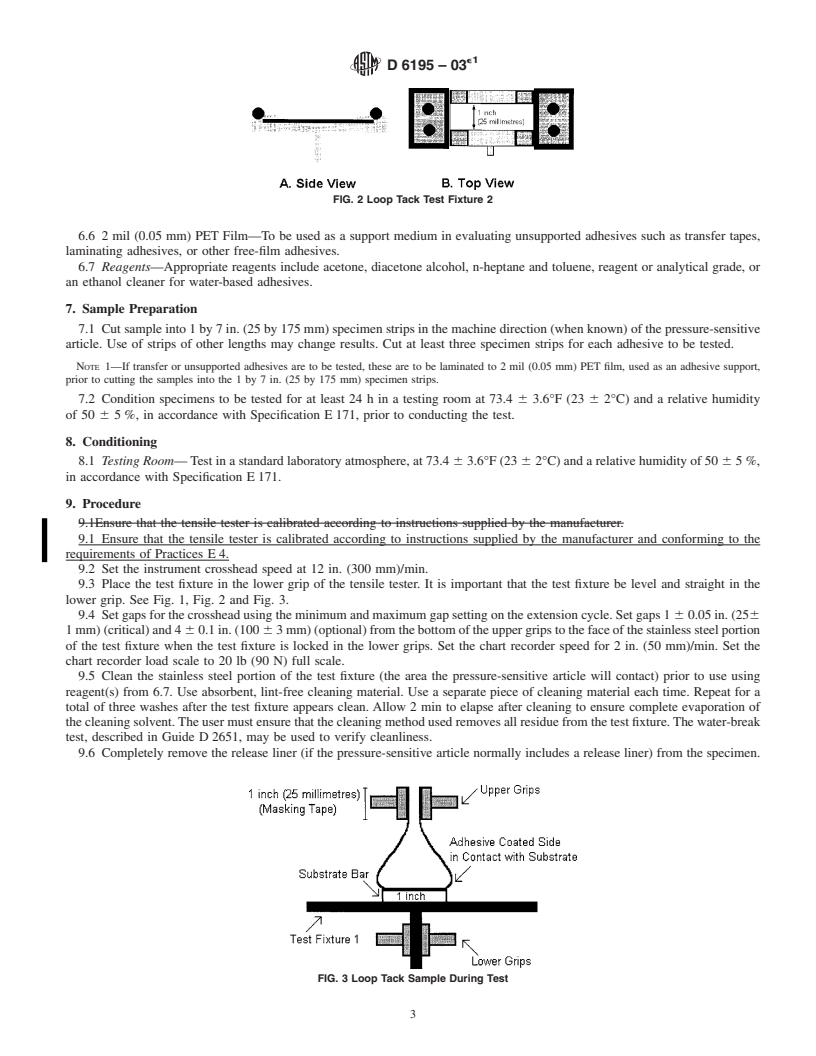

FIG. 2 Loop Tack Test Fixture 2

6.6 2 mil (0.05 mm) PET Film—To be used as a support

FIG. 1 Loop Tack Test Fixture 1

medium in evaluating unsupported adhesives such as transfer

ta

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

e1

Designation:D6195–97 Designation: D 6195 – 03

Standard Test Methods for

1

Loop Tack

This standard is issued under the fixed designation D 6195; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1

e NOTE—Corrected research report reference in Section 16 editorially in March 2008.

1. Scope

1.1 These test methods cover the determination of properties of a pressure-sensitive adhesive.ThisThese test method ismethods

are applicable to those adhesives that form a bond of measurable strength rapidly upon contact with another surface. Tack force

may be measured as the force required to separate the adhesive from the adherend at the interface shortly after they have been

brought into contact under a load equal only to the weight of the pressure-sensitive article (for example, tape, label, sticker, etc.)

2

on a 1 in. contact area.

1.2 The following test methods are included:

1.2.1 Test Method A (using Tensile Tester), and

1.2.2 Test Method B (using Loop Tack Tester).

1.3The values stated in inch-pound units are to be regarded as the standard. The values given in parentheses are for information

purposes only.

1.3 The values stated in inch-pound units are to be regarded as the standard because the industry standard width for

pressure-sensitive tape is 1 inch. The values given in parentheses are for information purposes only.

1.4 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory

limitations prior to use.

2. Referenced Documents

2.1 ASTM Standards:

2

A 666 Specification for Annealed or Cold-Worked Austenitic Stainless Steel, Sheet, Strip, Plate, and Flat Bar

3

D 907 Terminology of Adhesives

3

D 2651 Guide for Preparation of Metal Surfaces for Adhesive Bonding

4

E 4 Practices for Force Verification of Testing Machines

5

E 171 Specification for Standard Atmospheres for Conditioning and Testing Flexible Barrier Materials

6

E 177 Practice for Use of the Terms Precision and Bias in ASTM Test Methods

6

E 691 Practice for Conducting an Interlaboratory Study to Determine the Precision of a Test Method

7

2.2 European Association for the Pre-Adhesed Labeling Industry (FINAT) Standard:

FTM 9 “Quick-Stick” Tack Measurement

8

2.3 Tag and Label Manufacturers Institute, Inc. (TLMI) Standard:

L-IB1 TLMI Loop Tack Test

1

This test method is under the jurisdiction of ASTM Committee D-14 on Adhesives and is the direct responsibility of Subcommittee D14.50 on Hot Melt and Pressure

Sensitive Adhesives.

Current edition approved November 10, 1997. Published May 1998.

1

These test methods are under the jurisdiction of ASTM Committee D14 on Adhesives and are the direct responsibility of Subcommittee D14.50 on Hot Melt Pressure

Sensitive Archive Adhesives.

Current edition approved April 10, 2003. Published May 2003. Originally approved in 1997. Last previous edition approved in 1997 as D 6195 - 97.

2

Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 15.06.

4

Annual Book of ASTM Standards, Vol 15.09., Vol 03.01.

5

Annual Book of ASTM Standards, Vol 14.02., Vol 15.09.

6

Available from FINAT, Laan Copes Van Cattenburch 79, 2585 EW, The Hague, Holland.

6

Annual Book of ASTM Standards, Vol 14.02.

7

Available from TLMI, 40 Shuman Blvd., Ste. 295, Naperville, IL 60563.

7

Available from FINAT, Laan Copes Van Cattenburch 79, 2585 EW, The Hague, Holland.

8

Available from Chem Instruments, 510 Commercial Drive, Fairfield, OH 45014-7593.

8

Available from TLMI, 40 Shuman Blvd., Ste. 295, Naperville, IL 60563.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

e1

D6195–03

L-IB2 Tensile Tester Loop Tack Test

3. Terminology

3.1 Definitions:

3.1.1 Many of the terms found in thisthese test methods are defined in Terminology D 907.

4. Summary of Test Method

4.1 These test methods involve allowing a loop of pressure-sensitive adhesive with its backing to be brought into controlled

2

contactwitha1in. (25by25mm)surfaceofstainlesssteel,withtheonlyforceappliedbeingtheweightofthepressure-sensitive

article itself. The pressure-sensitive arti

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.