ASTM F336-02

(Practice)Standard Practice for Design and Construction of Nonmetallic Enveloped Gaskets for Corrosive Service

Standard Practice for Design and Construction of Nonmetallic Enveloped Gaskets for Corrosive Service

SIGNIFICANCE AND USE

The gaskets covered by this practice can be used on, but are not limited to, equipment constructed of the following materials: (a) stoneware, (b) glass and glass-lined, (c) tantalum (solid and lined), (d) titanium (solid and lined or clad), (e) zirconium (solid and lined or clad), (f) silver (solid and lined), and (g) nickel and nickel alloys (solid and clad).

The gaskets provided for herein are for the following: (a) pipe flanges (flat or raised face), (b) vessel nozzles, (c) circular openings in vessels in excess of 12 in. (305 mm) diameter, and (d) oval openings in vessels.

SCOPE

1.1 This practice covers the designs, sizes, classifications, and construction of enveloped gaskets for severe corrosive applications. The envelope serves as the corrosion resistant member of the composite gasket and is a nonmetallic material such as polytetrafluoroethylene, PTFE, or related materials. The inserts are nonmetallic gasketing materials with or without metal reinforcement. Other types of composite gaskets are covered in Classification F 868.

1.2 This standard is based directly upon ANSI B16.21-1992; for that reason units are as ANSI stated in inches.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation:F336–02

Standard Practice for

Design and Construction of Nonmetallic Enveloped Gaskets

1

for Corrosive Service

This standard is issued under the fixed designation F 336; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope materials: (a) stoneware, (b) glass and glass-lined, (c) tantalum

(solid and lined), (d) titanium (solid and lined or clad), (e)

1.1 This practice covers the designs, sizes, classifications,

zirconium (solid and lined or clad), (f) silver (solid and lined),

and construction of enveloped gaskets for severe corrosive

and (g) nickel and nickel alloys (solid and clad).

applications. The envelope serves as the corrosion resistant

3.2 The gaskets provided for herein are for the following:

member of the composite gasket and is a nonmetallic material

(a) pipe flanges (flat or raised face), (b) vessel nozzles, (c)

such as polytetrafluoroethylene, PTFE, or related materials.

circular openings in vessels in excess of 12 in. (305 mm)

The inserts are nonmetallic gasketing materials with or without

diameter, and (d) oval openings in vessels.

metal reinforcement. Other types of composite gaskets are

covered in Classification F 868.

4. Sizes

1.2 This standard is based directly upon ANSI

4.1 The gasket nominal size listed in inches,Table 1, will be

B16.21–1992; for that reason units are as ANSI stated in

the same as used on the following pipe flanges in accordance

inches.

with ASME B16.21 – 1992:

1.3 This standard does not purport to address all of the

Pipe Size ASME

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

1

⁄2 to 24 in. B16.21 – 1992, Table 5 and 6

priate safety and health practices and determine the applica- Over 24 in. B16.21 – 1992, Table 1 and 2

bility of regulatory limitations prior to use.

4.2 Commercial dimensional tolerances apply, unless other-

wise agreed upon between the seller and the purchaser.

2. Referenced Documents

2.1 ASTM Standards:

5. Materials and Manufacture

D 3294 Specification for Polytetrafluoroethylene (PTFE)

5.1 The gaskets covered by this practice shall be made of

2

Resin Molded Sheet and Molded Basic Shapes

nonmetallic materials, except when a metal support is desired

2

D 3308 Specification for PTFE Resin Skived Tape

in the insert.

F 104 Classification System for Nonmetallic Gasket Mate-

5.2 Materials should be selected, both for inserts and

3

rials

envelopes, that will withstand the conditions under which they

3

F 112 Test Method for Sealability of Enveloped Gaskets

are to be subjected in service.

F 868 Classification for Laminated Composite Gasket Ma-

5.3 A list of reference literature for determining material

3

terials

suitability in corrosive environments is available from ASTM

2.2 Other Document:

Headquarters. It is entitled, “Materials of Construction ASTM

ASME B16.21 – 1992 Nonmetallic Flat Gaskets for Pipe

5

F-3.50.10 Corrosion Data Literature.”

4

Flanges

5.4 The design of the envelope classifies the enveloped

gasket as follows:

3. Significance and Use

5.4.1 Split, knife cut (Fig. 1 and Fig. 2).

3.1 The gaskets covered by this practice can be used on, but

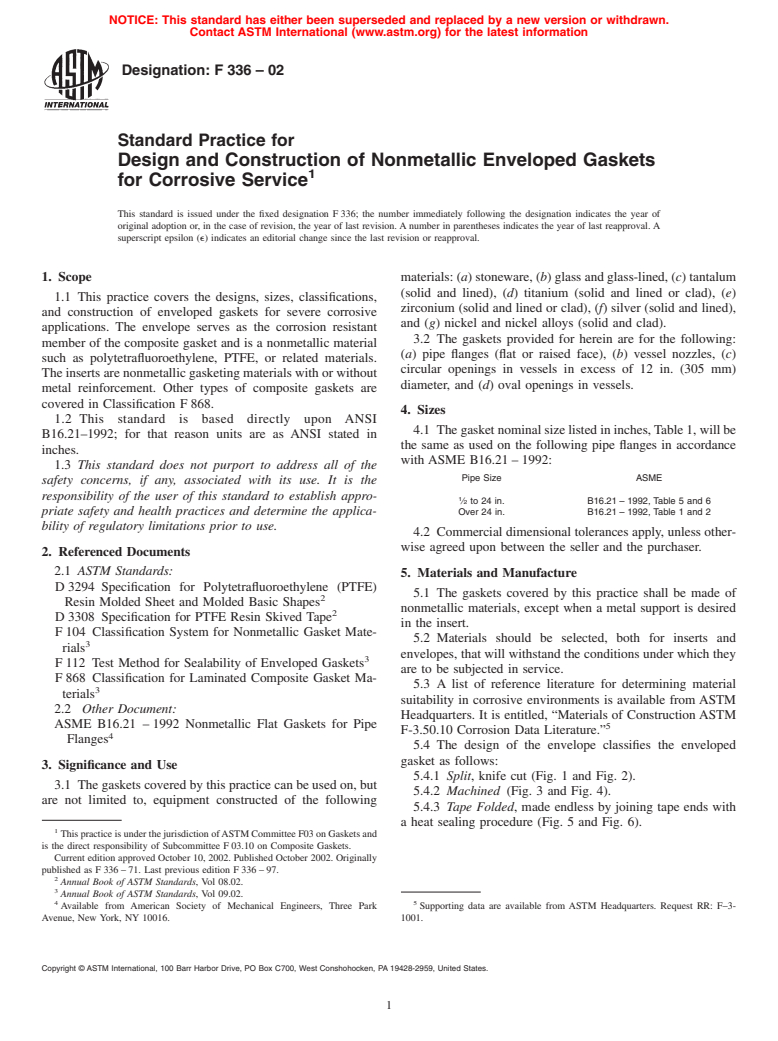

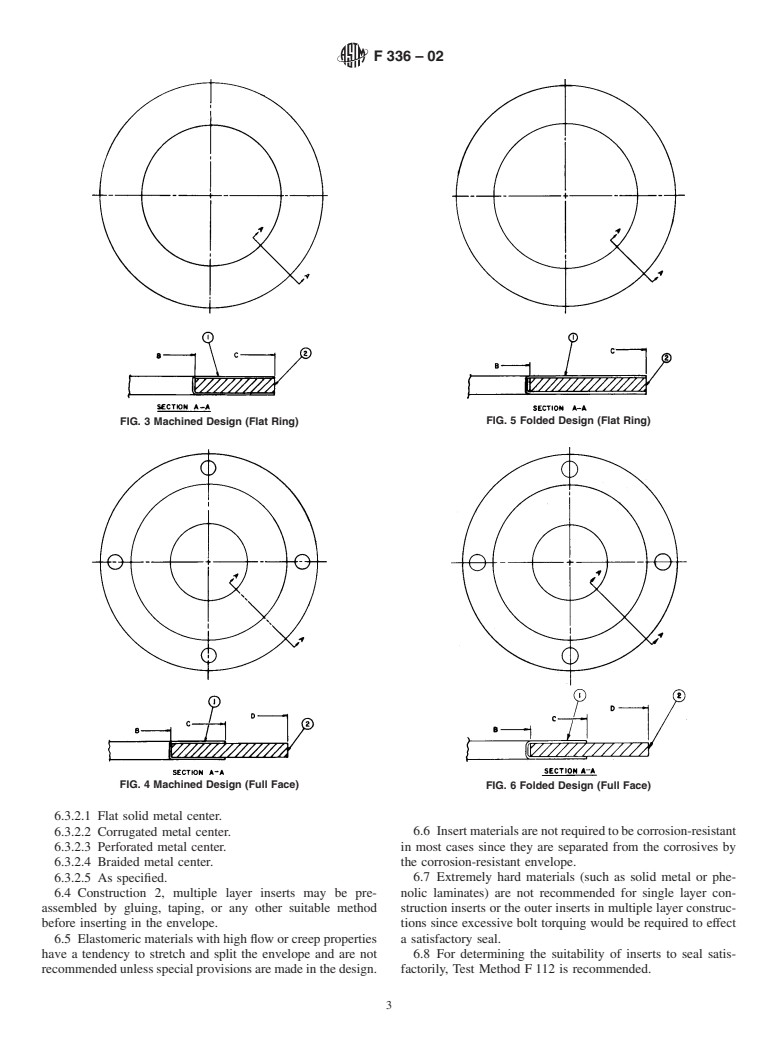

5.4.2 Machined (Fig. 3 and Fig. 4).

are not limited to, equipment constructed of the following

5.4.3 Tape Folded, made endless by joining tape ends with

a heat sealing procedure (Fig. 5 and Fig. 6).

1

This practice is under the jurisdiction ofASTM Committee F03 on Gaskets and

is the direct responsibility of Subcommittee F 03.10 on Composite Gaskets.

Current edition approved October 10, 2002. Published October 2002. Originally

published as F 336 – 71. Last previous edition F 336 – 97.

2

Annual Book of ASTM Standards, Vol 08.02.

3

Annual Book of ASTM Standards, Vol 09.02.

4 5

Available from American Society of Mechanical Engineers, Three Park Supporting data are available from ASTM Headquarters. Request RR: F–3-

Avenue, New York, NY 10016. 1001.

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

1

---------------------- Page: 1 ----------------------

F336–02

A

TABLE 1 Nominal Gasket Sizes

NOTE 1—Refer to Fig. 1 through Fig. 6 for explanation of gasket

component details.

NOTE 2—Split design inserts not to be smaller than nominal pipe size.

NOTE 3—Insidediameteroffoldedandmachineddesignenvelopeswill

adjoin the insert inside diameter assuring noninterference with flow

through pipe.

NOTE 4—Full face gaskets shall have envelope outside diameter same

as ring gasket outside diameter.

NOTE 5—Sizes 14 in. (356 mm) and larger may be made from

machined envelopes depend

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.