ASTM A471/A471M-19

(Specification)Standard Specification for Vacuum-Treated Alloy Steel Forgings for Turbine Rotor Disks and Wheels

Standard Specification for Vacuum-Treated Alloy Steel Forgings for Turbine Rotor Disks and Wheels

ABSTRACT

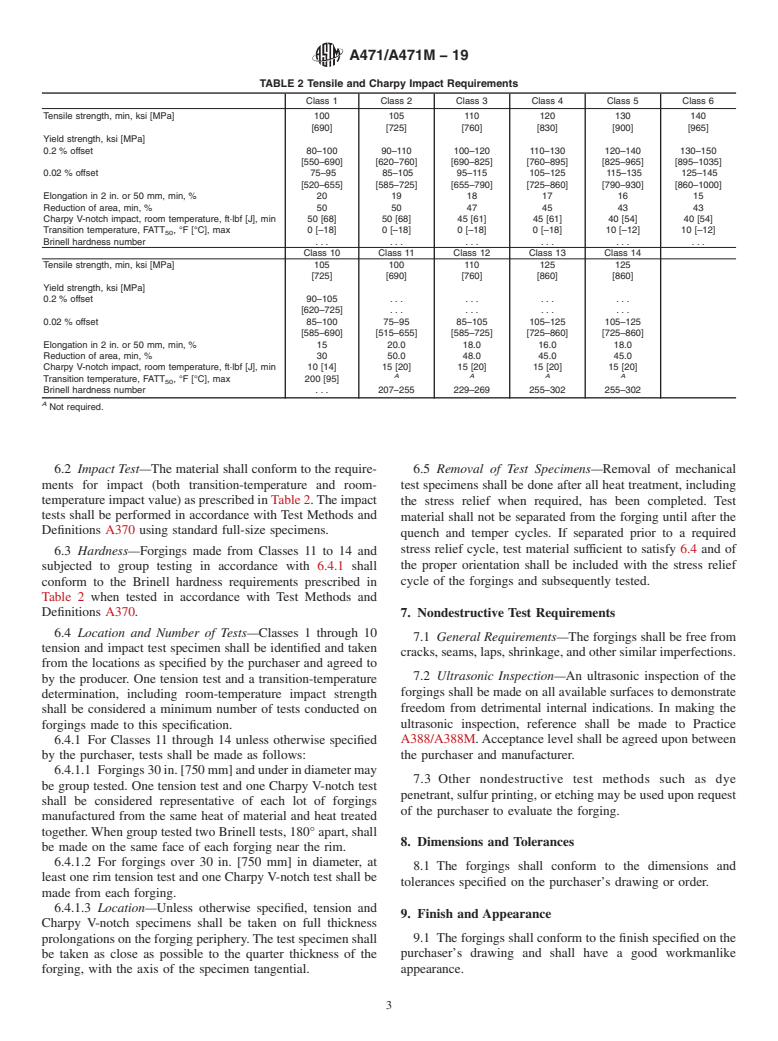

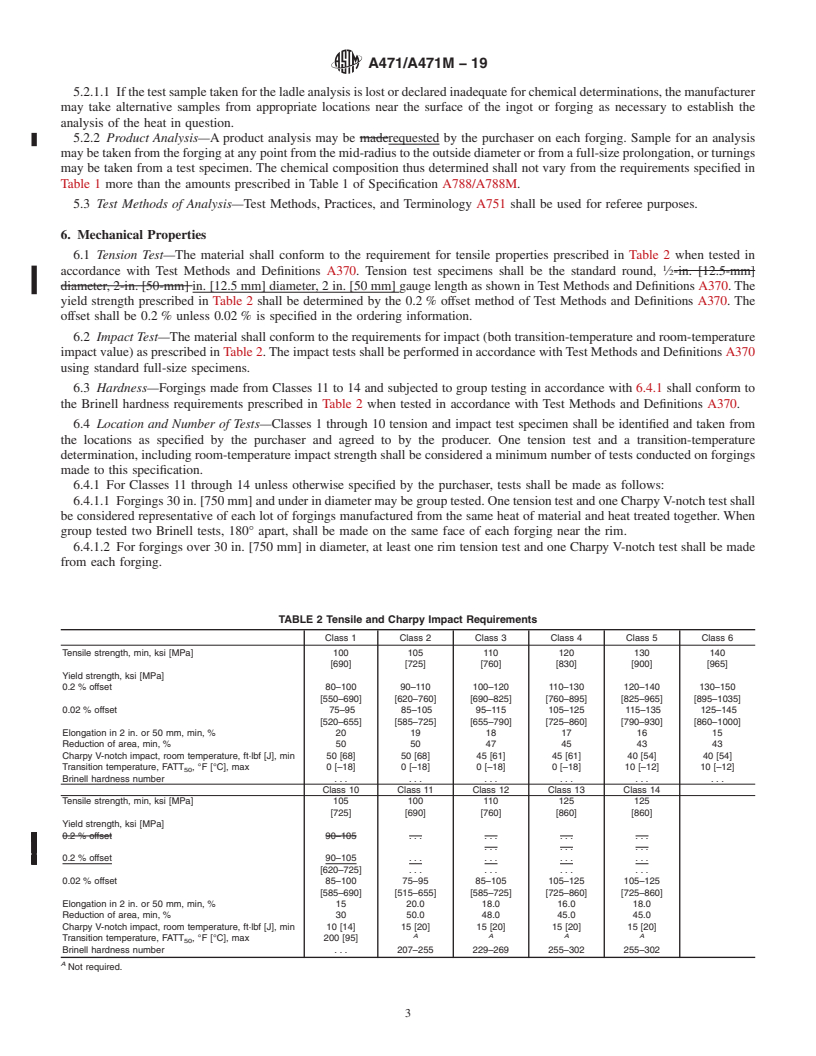

This specification covers vacuum-treated alloy steel forgings intended for use as turbine rotor disks and wheels. The steel shall be made by the basic electric-furnace process. The molten steel shall be vacuum treated using either the vacuum stream degassing process, vacuum-lift process or ladle degassing process prior to or during the pouring of the ingot in order to remove objectionable gases, particularly hydrogen. The forgings shall receive their hot mechanical work under a press, hammer, or mill of sufficient power to work the metal throughout its section. Before reheating for heat treatment, the forging shall be allowed to cool in a manner to prevent damage and to accomplish transformation. The forgings shall be heated to a suitable temperature for a sufficient length of time for complete austenitization and shall be tempered to develop the specified properties. The forgings shall be preliminarily machined on all surfaces prior to heat treatment and shall be stress relieved after machining. To measure some mechanical properties, the specimens shall be subjected to tension test, impact test, and hardness test. A non-destructive test like an ultrasonic inspection shall be made on all available surfaces to demonstrate freedom from detrimental internal indications.

SCOPE

1.1 This specification covers vacuum-treated alloy steel forgings intended for use as turbine rotor disks and wheels.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each system are not necessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used independently of the other, and values from the two systems shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety, health, and environmental practices and determine the applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

General Information

Relations

Buy Standard

Standards Content (Sample)

This international standard was developed in accordance with internationally recognized principles on standardization established in the Decision on Principles for the

Development of International Standards, Guides and Recommendations issued by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

Designation:A471/A471M −19

Standard Specification for

Vacuum-Treated Alloy Steel Forgings for Turbine Rotor

1

Disks and Wheels

This standard is issued under the fixed designationA471/A471M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E139 Test Methods for Conducting Creep, Creep-Rupture,

and Stress-Rupture Tests of Metallic Materials

1.1 This specification covers vacuum-treated alloy steel

forgings intended for use as turbine rotor disks and wheels.

3. Ordering Information

1.2 The values stated in either SI units or inch-pound units

3.1 Material supplied to this specification shall conform to

are to be regarded separately as standard. The values stated in

the requirements of Specification A788/A788M, which out-

each system are not necessarily exact equivalents; therefore, to

lines additional ordering information, manufacturing methods

ensure conformance with the standard, each system shall be

and procedures, marking, certification, production analysis

used independently of the other, and values from the two

variations, and additional supplementary requirements.

systems shall not be combined.

3.2 The purchaser shall specify in the inquiry and order the

1.3 This standard does not purport to address all of the

class of steel desired and test and purchase options (see 4.5.5,

safety concerns, if any, associated with its use. It is the

5.2.2, 6.1, 6.3, 6.4, and Section 7).

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.3 Forging Drawing—Each forging shall be manufactured

mine the applicability of regulatory limitations prior to use.

in accordance with a purchaser-supplied drawing showing the

1.4 This international standard was developed in accor-

finished dimensions and the locations of mechanical test

dance with internationally recognized principles on standard-

specimens.

ization established in the Decision on Principles for the

3.4 Supplementary requirements are provided and shall

Development of International Standards, Guides and Recom-

apply only when specified in the purchaser’s order.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Materials and Manufacture

2. Referenced Documents

4.1 Melting Process:

2

2.1 ASTM Standards: 4.1.1 The steel shall be made by the basic electric-furnace

A275/A275M Practice for Magnetic Particle Examination of process, with additional ladle refining being optional.

Steel Forgings 4.1.2 Provisions for subsequent secondary melting of the

A370 Test Methods and Definitions for Mechanical Testing steel by the consumable electrode-electroslag or vacuum-arc

of Steel Products remelting processes are included in Supplementary Require-

A388/A388M Practice for Ultrasonic Examination of Steel ment S4.

Forgings

4.2 The vacuum degassing requirements of Specification

A751 Test Methods, Practices, and Terminology for Chemi-

A788/A788M are mandatory.

cal Analysis of Steel Products

4.3 Discard—Sufficient discard shall be taken from each

A788/A788M Specification for Steel Forgings, General Re-

ingot to secure freedom from pipe and undue segregation in the

quirements

finished forging.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel,

4.4 Forging Process—The forgings shall receive their hot

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

mechanical work under a press, hammer, or mill of sufficient

A01.06 on Steel Forgings and Billets.

power to work the metal throughout its section. The forgings

Current edition approved May 1, 2019. Published May 2019. Originally

shall be upset by forming from a block having an axial length

approved in 1962. Last previous edition approved in 2014 as A471/A471M–09

(2014). DOI: 10.1520/A0471_A0471M–19.

before upsetting of at least two times the thickness of the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

forging after upsetting.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.4.1 The as-forged dimensions of each forging shall be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. planned so the metal is shaped by forging as close as is

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United Sta

...

This document is not an ASTM standard and is intended only to provide the user of an ASTM standard an indication of what changes have been made to the previous version. Because

it may not be technically possible to adequately depict all changes accurately, ASTM recommends that users consult prior editions as appropriate. In all cases only the current version

of the standard as published by ASTM is to be considered the official document.

Designation: A471/A471M − 09 (Reapproved 2014) A471/A471M − 19

Standard Specification for

Vacuum-Treated Alloy Steel Forgings for Turbine Rotor

1

Disks and Wheels

This standard is issued under the fixed designation A471/A471M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope Scope*

1.1 This specification covers vacuum-treated alloy steel forgings intended for use as turbine rotor disks and wheels.

1.2 The values stated in either SI units or inch-pound units are to be regarded separately as standard. The values stated in each

system mayare not benecessarily exact equivalents; therefore, to ensure conformance with the standard, each system shall be used

independently of the other. Combiningother, and values from the two systems may result in non-conformance with the

standard.shall not be combined.

1.3 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility

of the user of this standard to establish appropriate safety safety, health, and healthenvironmental practices and determine the

applicability of regulatory limitations prior to use.

1.4 This international standard was developed in accordance with internationally recognized principles on standardization

established in the Decision on Principles for the Development of International Standards, Guides and Recommendations issued

by the World Trade Organization Technical Barriers to Trade (TBT) Committee.

2. Referenced Documents

2

2.1 ASTM Standards:

A275/A275M Practice for Magnetic Particle Examination of Steel Forgings

A370 Test Methods and Definitions for Mechanical Testing of Steel Products

A388/A388M Practice for Ultrasonic Examination of Steel Forgings

A751 Test Methods, Practices, and Terminology for Chemical Analysis of Steel Products

A788/A788M Specification for Steel Forgings, General Requirements

E139 Test Methods for Conducting Creep, Creep-Rupture, and Stress-Rupture Tests of Metallic Materials

3. Ordering Information

3.1 Material supplied to this specification shall conform to the requirements of Specification A788/A788M, which outlines

additional ordering information, manufacturing methods and procedures, marking, certification, production analysis variations, and

additional supplementary requirements.

3.2 The purchaser shall specify in the inquiry and order the class of steel desired and test and purchase options (see 4.5.5, 5.2.2,

6.1, 6.3, Section 76.4, and Section 15.17).

3.3 Forging Drawing—Each forging shall be manufactured in accordance with a purchaser-supplied drawing showing the

finished dimensions and the locations of mechanical test specimens.

3.4 Supplementary requirements are provided and shall apply only when specified in the purchaser’spurchaser’s order.

4. Materials and Manufacture

4.1 Melting Process:

4.1.1 The steel shall be made by the basic electric-furnace process, with additional ladle refining being optional.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee A01.06

on Steel Forgings and Billets.

Current edition approved Oct. 1, 2014May 1, 2019. Published October 2014May 2019. Originally approved in 1962. Last previous edition approved in 20092014 as

A471/A471M – 09.A471/A471M–09 (2014). DOI: 10.1520/A0471_A0471M-09R14.10.1520/A0471_A0471M–19.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM Standards

volume information, refer to the standard’sstandard’s Document Summary page on the ASTM website.

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A471/A471M − 19

4.1.2 Provisions for subsequent secondary melting of the steel by the consumable electrode-electroslag or vacuum-arc remelting

processes are included in Supplementary Requirement S4.

4.2 The vacuum degassing requirements of Specification A788/A788M are mandatory.

4.3 Discard—Sufficient discard shall be taken from each ingot to secure freedom from pipe and undue segregation in the

finished forging.

4.4 Forging Process—The f

...

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: A471/A471M − 19

Standard Specification for

Vacuum-Treated Alloy Steel Forgings for Turbine Rotor

1

Disks and Wheels

This standard is issued under the fixed designation A471/A471M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope* E139 Test Methods for Conducting Creep, Creep-Rupture,

and Stress-Rupture Tests of Metallic Materials

1.1 This specification covers vacuum-treated alloy steel

forgings intended for use as turbine rotor disks and wheels.

3. Ordering Information

1.2 The values stated in either SI units or inch-pound units

3.1 Material supplied to this specification shall conform to

are to be regarded separately as standard. The values stated in

the requirements of Specification A788/A788M, which out-

each system are not necessarily exact equivalents; therefore, to

lines additional ordering information, manufacturing methods

ensure conformance with the standard, each system shall be

and procedures, marking, certification, production analysis

used independently of the other, and values from the two

variations, and additional supplementary requirements.

systems shall not be combined.

3.2 The purchaser shall specify in the inquiry and order the

1.3 This standard does not purport to address all of the

class of steel desired and test and purchase options (see 4.5.5,

safety concerns, if any, associated with its use. It is the

5.2.2, 6.1, 6.3, 6.4, and Section 7).

responsibility of the user of this standard to establish appro-

priate safety, health, and environmental practices and deter-

3.3 Forging Drawing—Each forging shall be manufactured

mine the applicability of regulatory limitations prior to use.

in accordance with a purchaser-supplied drawing showing the

1.4 This international standard was developed in accor-

finished dimensions and the locations of mechanical test

dance with internationally recognized principles on standard-

specimens.

ization established in the Decision on Principles for the

3.4 Supplementary requirements are provided and shall

Development of International Standards, Guides and Recom-

apply only when specified in the purchaser’s order.

mendations issued by the World Trade Organization Technical

Barriers to Trade (TBT) Committee.

4. Materials and Manufacture

2. Referenced Documents

4.1 Melting Process:

2

2.1 ASTM Standards: 4.1.1 The steel shall be made by the basic electric-furnace

A275/A275M Practice for Magnetic Particle Examination of process, with additional ladle refining being optional.

Steel Forgings 4.1.2 Provisions for subsequent secondary melting of the

A370 Test Methods and Definitions for Mechanical Testing steel by the consumable electrode-electroslag or vacuum-arc

of Steel Products remelting processes are included in Supplementary Require-

A388/A388M Practice for Ultrasonic Examination of Steel ment S4.

Forgings

4.2 The vacuum degassing requirements of Specification

A751 Test Methods, Practices, and Terminology for Chemi-

A788/A788M are mandatory.

cal Analysis of Steel Products

4.3 Discard—Sufficient discard shall be taken from each

A788/A788M Specification for Steel Forgings, General Re-

ingot to secure freedom from pipe and undue segregation in the

quirements

finished forging.

1

This specification is under the jurisdiction of ASTM Committee A01 on Steel, 4.4 Forging Process—The forgings shall receive their hot

Stainless Steel and Related Alloys and is the direct responsibility of Subcommittee

mechanical work under a press, hammer, or mill of sufficient

A01.06 on Steel Forgings and Billets.

power to work the metal throughout its section. The forgings

Current edition approved May 1, 2019. Published May 2019. Originally

shall be upset by forming from a block having an axial length

approved in 1962. Last previous edition approved in 2014 as A471/A471M–09

(2014). DOI: 10.1520/A0471_A0471M–19.

before upsetting of at least two times the thickness of the

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

forging after upsetting.

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

4.4.1 The as-forged dimensions of each forging shall be

Standards volume information, refer to the standard’s Document Summary page on

the ASTM website. planned so the metal is shaped by forging as close as is

*A Summary of Changes section appears at the end of this standard

Copyright © ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959. United States

1

---------------------- Page: 1 ----------------------

A471/A471M − 19

practical to the dimensions shown on the purchaser’s drawing

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.