ASTM E1190-95(2007)

(Test Method)Standard Test Methods for Strength of Power-Actuated Fasteners Installed in Structural Members

Standard Test Methods for Strength of Power-Actuated Fasteners Installed in Structural Members

SIGNIFICANCE AND USE

These test methods are intended to measure the anchoring capability and shear resistance of power-actuated fasteners to provide information from which applicable design values are to be derived for use in structural applications, such as in members of concrete, concrete masonry, and steel.

SCOPE

1.1 These test methods describe procedures for determining the static axial tensile and shear strengths of power-actuated fasteners installed in structural members made of concrete, concrete masonry, and steel.

1.2 These test methods are intended for use with fasteners that are installed perpendicular to a plane surface of the structural member.

1.3 Tests for combined tension and shear, fatigue, dynamic, and torsional load resistance are not covered.

1.4 The values stated in metric (SI) units are to be regarded as standard. The inch-pound units in parentheses are for information only.

1.5 This standard does not purport to address all of the safety concerns, if any, associated with its use. It is the responsibility of the user of this standard to establish appropriate safety and health practices and determine the applicability of regulatory limitations prior to use. Specific hazard statements are given in Section 6.

General Information

Relations

Standards Content (Sample)

NOTICE: This standard has either been superseded and replaced by a new version or withdrawn.

Contact ASTM International (www.astm.org) for the latest information

Designation: E1190 – 95 (Reapproved 2007)

Standard Test Methods for

Strength of Power-Actuated Fasteners Installed in Structural

Members

This standard is issued under the fixed designation E1190; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (´) indicates an editorial change since the last revision or reapproval.

1. Scope 2.2 ANSI Standard:

ANSI A10.3 Safety Requirements for Powder-Actuated

1.1 These test methods describe procedures for determining

Fastening Systems

the static axial tensile and shear strengths of power-actuated

fasteners installed in structural members made of concrete,

3. Terminology

concrete masonry, and steel.

3.1 Definitions of general terms may be found in Terminol-

1.2 These test methods are intended for use with fasteners

ogy E631.

that are installed perpendicular to a plane surface of the

3.2 Descriptions of Terms Specific to This Standard:

structural member.

3.2.1 powder-actuated fastening system—a system that uses

1.3 Tests for combined tension and shear, fatigue, dynamic,

explosive powder to embed the fastener in structural elements.

and torsional load resistance are not covered.

3.2.2 power-actuated fastening system—a system that uses

1.4 The values stated in metric (SI) units are to be regarded

explosive powder, gas combustion, or compressed air or other

as standard. The inch-pound units in parentheses are for

gas to embed the fastener in structural elements.

information only.

3.2.3 drive pin—a nail-like metal fastener designed to

1.5 This standard does not purport to address all of the

attach one material to another.

safety concerns, if any, associated with its use. It is the

3.2.4 threaded stud—a round metal-wire fastener, with a

responsibility of the user of this standard to establish appro-

pointed shank at one end and threads along the other end,

priate safety and health practices and determine the applica-

designed to be used as a removable fastening or in conjunction

bility of regulatory limitations prior to use. Specific hazard

with a threaded coupler.

statements are given in Section 6.

3.2.5 structural member—an element of a structural system

2. Referenced Documents such as a beam, column, or truss.

2 3.2.6 static load—a load or series of loads that are sup-

2.1 ASTM Standards:

ported by or are applied to a structure so gradually that forces

E4 Practices for Force Verification of Testing Machines

caused by change in momentum of the load and structural

E171 Specification for Atmospheres for Conditioning and

elements are negligible and all parts of the system at any

Testing Flexible Barrier Materials

instant are essentially in equilibrium.

E575 Practice for Reporting Data from Structural Tests of

3.2.7 tensile test—atestinwhichafastenerisloadedaxially

Building Constructions, Elements, Connections, and As-

in tension at a specified rate.

semblies

3.2.8 shear test—a test in which a force is applied perpen-

E631 Terminology of Building Constructions

dicularly to the axis of the fastener and parallel to the surface

of the structural member.

These test methods are under the jurisdiction of ASTM Committee E06 on

3.2.9 fastener spacing, s—the distance between the longi-

Performance of Buildings and are the direct responsibility of Subcommittee E06.13

tudinal axes of two fasteners in the same plane. Also, distance

on Structural Performance of Connections in Building Construction.

between longitudinal axis of fastener and nearest edge of

Current edition approved April 1, 2007. Published April 2007. Originally

´1

approved in 1987. Last previous edition approved in 2000 as E1190 – 95 (2000)

test-system supports (see s in Fig. 1).

. DOI: 10.1520/E1190-95R07.

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standard’s Document Summary page on Available fromAmerican National Standards Institute (ANSI), 25 W. 43rd St.,

the ASTM website. 4th Floor, New York, NY 10036, http://www.ansi.org.

Copyright ©ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

E1190 – 95 (2007)

FIG. 1 Typical Static Tension Test Arrangement

3.2.10 edge distance, c—the distance from the longitudinal shall be used for laboratory testing. If pressure gages are used

axis (center) of a fastener to the nearest edge of the structural for field testing, they shall be calibrated immediately prior to

member in which it is installed. use.

5.1.1 Tensile Test—A system suitable for applying tensile

3.2.11 embedment depth, h —the distance from the surface

ef

forces is shown in Fig. 1 for a single fastener specimen. The

of the structural member to the installed end of the fastener

test system supports shall be of sufficient size to prevent failure

including its point, if any.

of the surrounding structural member. The loading rod shall be

3.2.12 displacement—movement of a fastener relative to

of a size to develop the ultimate strength of the fastener

the structural member. In tensile tests, displacement is mea-

hardware with minimal elongation and shall be attached to the

suredalongtheaxisofthefastener;insheartestsitismeasured

fastener by means of a connector that will minimize the direct

in the direction of the applied load perpendicular to the axis of

transfer of bending forces through the connection. When

the fastener.

displacements are measured, dial gages or a linear variable

differential transformer (LVDT) shall be mounted in a manner

4. Significance and Use

so as to ensure accurate displacement measurement.

4.1 These test methods are intended to measure the anchor-

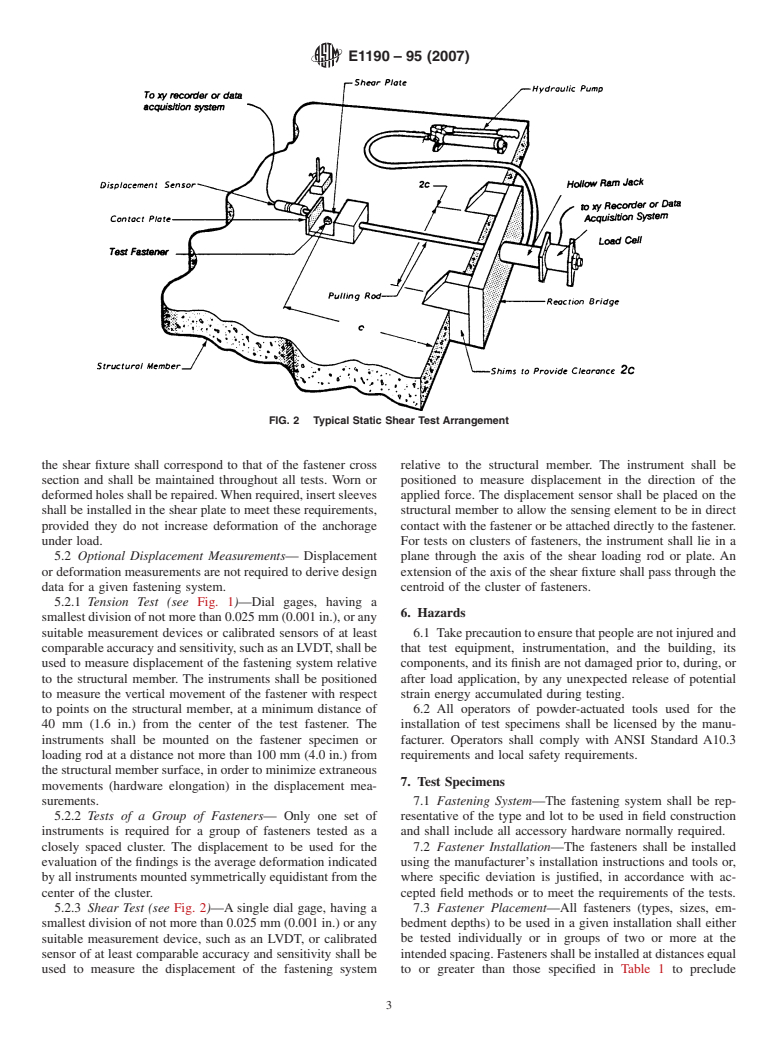

5.1.2 Shear Test:

ing capability and shear resistance of power-actuated fasteners

5.1.2.1 Asystem suitable for applying shear forces is shown

toprovideinformationfromwhichapplicabledesignvaluesare

inFig.2.forasinglefastenerspecimen.Thecomponentsofthe

to be derived for use in structural applications, such as in

test fixture shall be of sufficient size and strength to prevent

members of concrete, concrete masonry, and steel.

yielding during application of the ultimate test load. The test

systemsupportshallbeofsufficientsizetopreventlocalfailure

5. Apparatus

of the structural member in the bearing contact area. When

displacements are measured, dial gages or a linear variable

5.1 Equipment—Any system suitable for applying tensile

and shear forces shall be used, provided the requirements for differential transformer (LVDT) shall be mounted in a manner

so as to ensure accurate displacement measurement.

rate of loading in 9.4 are met, and the instrumentation is

capable of measuring the forces to an accuracy within 62% 5.1.2.2 The thickness of the shear fixture in the immediate

of the applied force, when calibrated in accordance with vicinity of the test fastener shall be approximately equal to the

Practices E4. The device shall be of sufficient capacity to fastener diameter at the point of intersection of the fastener and

prevent yielding of its various components and shall ensure the base material unless otherwise specified. The hole in the

that the applied tensile forces remain parallel to the axes of the shear fixture designed to accommodate the fastener shall have

fastenersandthattheappliedshearforcesremainparalleltothe a diameter that is 0.5 6 0.1 mm (0.020 6 0.004 in.) greater

surface of the structural member during testing. Load cells than that of the fastener tested. The initial shape of the hole in

E1190 – 95 (2007)

FIG. 2 Typical Static Shear Test Arrangement

the shear fixture shall correspond to that of the fastener cross relative to the structural member. The instrument shall be

section and shall be maintained throughout all tests. Worn or positioned to measure displacement in the direction of the

deformedholesshallberepaired.Whenrequired,insertsleeves applied force. The displacement sensor shall be placed on the

shall be installed in the shear plate to meet these requirements, structural member to allow the sensing element to be in direct

provided they do not increase deformation of the anchorage contact with the fastener or be attached directly to the fastener.

under load. For tests on clusters of fasteners, the instrument shall lie in a

5.2 Optional Displacement Measurements— Displacement plane through the axis of the shear loading rod or plate. An

or deformation measurements are not required to derive design extension of the axis of the shear fixture shall pass through the

data for a given fastening system. centroid of the cluster of fasteners.

5.2.1 Tension Test (see Fig. 1)—Dial gages, having a

6. Hazards

smallestdivisionofnotmorethan0.025mm(0.001in.),orany

suitable measurement devices or calibrated sensors of at least 6.1 Takeprecautiontoensurethatpeoplearenotinjuredand

comparableaccuracyandsensitivity,suchasanLVDT,shallbe that test equipment, instrumentation, and the building, its

used to measure displacement of the fastening system relative components, and its finish are not damaged prior to, during, or

to the structural member. The instruments shall be positioned after load application, by any unexpected release of potential

to measure the vertical movement of the fastener with respect strain energy accumulated during testing.

to points on the structural member, at a minimum distance of 6.2 All operators of powder-actuated tools used for the

40 mm (1.6 in.) from the center of the test fastener. The installation of test specimens shall be licensed by the manu-

instruments shall be mounted on the fastener specimen or facturer. Operators shall comply with ANSI Standard A10.3

loading rod at a distance not more than 100 mm (4.0 in.) from requirements and local safety requirements.

the structural member surface, in order to minimize extraneous

7. Test Specimens

movements (hardware elongation) in the displacement mea-

surements. 7.1 Fastening System—The fastening system shall be rep-

5.2.2 Tests of a Group of Fasteners— Only one set of resentative of the type and lot to be used in field construction

instruments is required for a group of fasteners tested as a and shall include all accessory hardware normally required.

closely spaced cluster. The displacement to be used for the 7.2 Fastener Installation—The fasteners shall be installed

evaluation of the findings is the average deformation indicated using the manufacturer’s installation instructions and tools or,

by all instruments mounted symmetrically equidistant from the where specific deviation is justified, in accordance with ac-

center of the cluster. cepted field methods or to meet the requirements of the tests.

5.2.3 Shear Test (see Fig. 2)—A single dial gage, having a 7.3 Fastener Placement—All fasteners (types, sizes, em-

smallest division of not more than 0.025 mm (0.001 in.) or any bedment depths) to be used in a given installation shall either

suitable measurement device, such as an LVDT, or calibrated be tested individually or in groups of two or more at the

sensor of at least comparable accuracy and sensitivity shall be intended spacing. Fasteners shall be installed at distances equal

used to measure the displacement of the fastening system to or greater than those specified in Table 1 to preclude

E1190 – 95 (2007)

TABLE 1 Fastener Spacing, s, and Edge Distance, c, to Preclude

on the purpose of the test, the number of tests shall be

Influences on Fastener Performance

increased. These tests shall be repeated for each variation in

Minimum Fastener

fastener type, size, embedment depth, location, and for each

Minimum Edge Distance,

Shank Diameter, Spacing,

mm (in.)

variation in the type or strength of structural member. Alter-

mm (in.) mm (in.)

natively,ifthesamplesizeistenandthecoefficientofvariation

Steel Concrete Steel Concrete

2.5to4.0 25 (1.0) 100 (4.0) 12 (0.5) 80 (3.2)†

is 15 % or greater, the fastener capacity shall be based on the

(0.100 to 0.156)

lowest test value for the original ten tests instead of increasing

4.1to5.0 25 (1.0) 130 (5.1) 12 (0.5) 90 (3.5)

(0.157 to 0.199) the sample size.

5.1to6.5 40 (1.6) 150 (5.9) 25 (1.0) 100 (4.0)

8.2 All installed fasteners shall be tested regardless of

(0.200 to 0.250)

fastener embedment, angle of installation, damage to the

† The value in parenthesis was corrected editorially

structural member, or damage to the fastener. Fasteners that

cannot be tested, because they did not set at all, that is were not

installed properly, shall be reported as invalid data points.

influences from adjacent fasteners or edges during testing.

Invalid data points shall not be included when determining the

These distances are not to be considered minimum distances.

average ultimate test values.

Tests shall be performed to determine minimum spacing and

8.3 For developing minimum edge distances and fastener

edge distances.

spacings, the number of fasteners for each condition shall be at

7.4 Structural Member—The structural member in which

least ten.

the fastener is to be installed shall be representative of the

materials and configuration intended for field use. Concrete or

9. Procedure

masonry structural members do not have to be reinforced with

steel (Note 1).

9.1 Positioning of Loading System:

9.1.1 Tension Test—Position the loading system over the

NOTE 1—The location and orientation of reinforcement embedded in

fastener, such as shown in Fig. 1, in such a way that the test

concrete and masonry members may influence fastener capacity. Their

system supports are equidistant from the test fastener and

influence shall be evaluated if reinforcement is used.

spaced sufficiently apart as not to influence the test findings.

7.5 The concrete or masonry structural member thickness,

The failure plane of the fastening system shall not interact with

T, shall be sufficient to ensure that the installation and testing

the test system supports. Provide uniform contact between the

of the fastener will not crack or cause any other failure of the

surface of the structural member and the test system supports.

base material.

Position and attach the loading rod so that the load is applied

7.6 The length, L, and width, W, of concrete structural

through the center of a single fastener, as shown in Fig. 1,or

members shall ensure that no shear breakout or tension failure

through the centroid of a cluster of fasteners. Whenever a

spall intersects either the outside edges of the structural

loading plate is required in the testing of a cluster of fasteners,

member or the bearing contact points of the test frame.

...

Questions, Comments and Discussion

Ask us and Technical Secretary will try to provide an answer. You can facilitate discussion about the standard in here.